MS24015电主轴的机械设计【全套CAD9张+3D+说明书等】

收藏

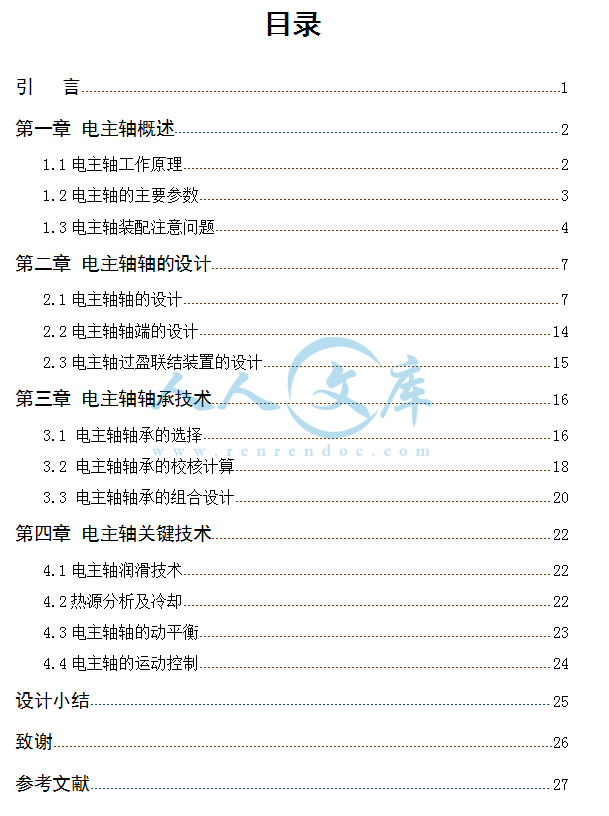

资源目录

压缩包内文档预览:

编号:456907

类型:共享资源

大小:1.76MB

格式:RAR

上传时间:2015-07-15

上传人:小****

认证信息

个人认证

崔**(实名认证)

辽宁

IP属地:辽宁

50

积分

- 关 键 词:

-

ms24015

电主轴

机械设计

机床电主轴

- 资源描述:

-

- 内容简介:

-

毕 业 设 计(论 文)任 务 书 机械工程 系(院) 20 08 届 题 目 电 主 轴 的 设 计 学生姓名 专业班级 指导教师 职 称 填写日期: 2008 年 3 月 12 日 设计(论文)依据 nts 国内电主轴的研究始于 2 0 世纪 6 0 年代 ,主要用于零件内表 面磨削 ,这种电主轴的功率低 ,刚度小。并且它采用无内圈式向心推力球轴承 ,限制了高速电主轴的生产社会化和商品化。 2 0 世纪 70 年代后期至 80 年代 ,随着高速主轴轴承的开发 ,研制了高刚度、高速电主轴 ,它被广泛应用于各种内圆磨床和各个机械制造领域。在 2 0世纪 80年代末以后 ,由磨用电主轴转向铣用电主轴 ,它不仅能加工各种形体复杂的模具 ,而且开发了用于木工机械用的风冷式高速铣用电主轴 ,推动了高速电主轴在铣削中的应用。目前国内研究高速电主轴的科研机构有我国河南省洛阳轴承研究所 ,他们能自行研究 开发电主轴 ,其 DmN 值达到了很高的水平 ;广州钜联高速电主轴有限公司研发的大功率静压轴承电主轴曾获得日内瓦国际专利技术博览会金奖 ;广东工业大学高速加工和机床研究所也开发了数控铣床高速电主轴。在我国的安阳市 ,有一家中外合资的电主轴生产厂家 安阳莱必泰机械有限公司 ,它拥有先进的电主轴、机床主轴设计和制造技术。该公司研制生产的加工中心电主轴 ,采用先进技术 ,配有矢量闭环控制系统 ,能对主轴实行恒功率调速 ,准停制动。 国外高速电主轴技术的研究现状国外高速电主轴技术由于研究较早 ,技术水平也处于领先 地位 ,电主轴已越来越多地应用到工业制造业中。著名的有瑞士的 Fisher 公司、 Ibag 公司、德 国的 GMN 公司、 Hofer 公司、 Siemens 公司、意大利 Faemat 公司、Gamfior 公司及美国 Ingersoll 公司、日本 Okuma 公司和 Fanuc 公司等 ,它们的技术水平代表了这个领域的世界先进水平。并在此基础之上 ,这些外国厂家已生产了多种商品化高速机床。如瑞士米克朗公司 ,就是世界上著名的精密机床制造商。它生产的机床配备最高达 6 0 0 0 0r/min 的高速电主轴 ,可以满足不同的切削要求 。 随着机床技术、高速切削技术的发展和实际应用的需要,人们对机床电主轴的性能也提出了越来越高的要求,电主轴技术的发展趋势主要表现在以下几个方面:向高速大功率和低速大转矩方向发展,向高精度、高刚度方向发展,向精确定向(准停)方向发展,向快速起、停方向发展,向超高速方向发展,向标准化方向发展 任务要求 nts 根据设计课题所要完成的设计任务要求,确定具体的任务要求如下: 1、熟悉设计内容,对所要设计的课题进行分析,确定方案; 2、根据设计课题任务,要求对高速电主轴机械部分进行设计; 3、根据初步 设计完成电主轴结构草图,在此基础上完成零件图设计; 4、要求对所要设计的电主轴轴身进行校核,使机身结构合理具有一定的稳定性; 5、轴身部分设计要体现良好的工艺性和经济性; 6、论文必须符合要求,不少于 10000 字。 进度计划 nts 3 月 23 日 3 月 30 日 熟悉设计内容及设计要求; 3 月 31 日 4 月 13 日 查阅各类相关资料,进行初步设计,结构分析,确定总体方案; 4 月 14 日 5 月 4 日 进行各类设计工作并完成,同时完成论文草稿; 5 月 5 日 5 月 14 日 完成设计论文,最终完成设计任务 书所要求的内容; 5 月 15 日 5 月 17 日 进行最后审核,准备毕业答辩工作。 任务下达人(指导教师)签字: 年 月 日 任务接受人(学生)签字: 年 月 日 教研室主任签字: 年 月 日 说明:该任务书每生一式两份,签字有效,一份系(院 )存档,一份学生留存。 nts1 毕业设计(论文)外文参考文献翻译 机械工程 系(院) 20 08 届 题 目 (中文) 电主轴的机械设计 (英文) the mechanic designs of electric spindles 学生姓名 专业班 完成日期: 2008 年 3 月 23 日 目 录 nts2 1.电主轴技术水平分析 ( 8) 2. 高速电主轴单元( 14) The electrical technical level of main shaft is analysed nts3 Abstract: Electrical main shaft is the processing machine tool of numerical control heart parts , this paper has introduced typical structure and the working principle of electrical main shaft , has elaborated the crucial technology of electrical main shaft , has summarized it to develop tendency. Keyword: The electrical porcelain ball of main shaft mix the bearing lubrication of oil gas 1, it is general to state the processing quality that can not only raise processing efficiency substantially because of high speed processing and can still raise workpiece apparently, so, its application field is very extensive , is especially in aerospace , the manufacturing industries such as automobile and mould in. It is spoilt recently that so, the machine tool of numerical control that has high speed process capability has become market. Now, the domestic and international each famous manufacturer of machine tool adopts the electrical structure of main shaft extensively in the machine tool of numerical control , is especially being compound to process machine tool and much axle to unite to move , polyhedron processing machine tool and the machine tool of parallel connection in. Electrical main shaft is the processing machine tool of numerical control heart parts , its performance index direct decision the level of machine tool, it is that machine tool realizes basic condition and the prerequisite of high speed processing. 2 the working principle electrical main shaft of the working principle, typical structure and 2.1 advantage electrical main shafts of electrical main shaft is the direct motor rotor of be hollow pack in main shaft on, stator knows super-cooling but cover fixes , form a complete unit of main shaft in the casing hole of main shaft, after starting eclectricity rotor directly drive the operation of main shaft. The typical structural layout way of the typical structural electrical unit of main shaft of 2.2 electrical main shafts is that generator sets up before main shaft , rear axle Cheng between ( as picture show ), its advantage is that the axial size of the unit of main shaft is the big, medium-sized machine tool of numerical control short comparatively, the rigidity of main shaft big, power suits comparatively; It is insufficient to be the naturally scattered hot condition in the generator in the casing of main shaft that encloses to differ from , has higher temperature rise. The 1 casings of main shaft the 2 cooling sets of 3 4 5 import stator rotors of cooling water the 6 sets of 7 8 9 10 former 11 can export feedback installation bearing rear axles of cooling water of runner shaft of main shaft of main shaft Cheng the advantage electrical province of main shaft of 2.3 electrical main shafts have gone to take ship or positive drive, the 0 transmissions that have realized machine tool have raised transmission efficiency. The rigidity of nts4 electrical main shaft good, rotary precision is sex high respond fast good, can realize very high rotational speed and add and slow down degree and decide angle stop fast definitely ( C axle control ), the scope of speed adjustment is wide. 3, the crucial technical concept of electrical main shaft of electrical main shaft should not be simple to understand for the merely a sleeve of main shaft , and should be a set of assembly, include: Stator, rotor, bearing, the high speed installation of frequency conversion and lubrication install and cool installation. Therefore electrical main shaft is the with high speed bearing technical, lubrication technical, cooling technical technical, precise production of dynamic balancing with the technologies such as assembly technology as well as generator high speed drive synthesize to utilize. The with high speed bearing technology of 3.1 electrical main shafts realizes the electrical high speed of main shaft to melt, is precise and crucial to be the application of high speed precise bearing. Now the bearing that applied in high speed precise electrical main shaft have precise roll bearing and liquid movement press bearing and gas press bearing and magnetic suspension bearing quietly, but it is precise angle contact porcelain ball bearing and precise cylinder roller bearing mainly. It is high that liquid movement press the standardization level of bearing; Gas presses bearing quietly to be improper for in the rate occasion of great merit; Magnetic suspension bearing because of control system complex, price is expensive , its practicality gets restriction. Angle contact ball bearing can not only at the same time bear radial and axial load, and rigidity high, high speed performance good, structural simple compact, kind specifications numerous repair easily to change, thus in electrical main shaft, get extensive application. Now along with the development of porcelain bearing technology, the electrical bearing of main shaft of the most application is to mix porcelain ball bearing, roll body use Si3N4 porcelain ball, with the structure of little pearl dense pearl , bearing ferrule encloses for GCr15 steel. Is this kind of to mix bearing to pass to reduce little centrifugal force and top moment , reduce the friction between little ball and raceway groove , so get lower temperature rise and better high speed performance. Porcelain ball mix bearing and steel ball bearing compare , advantage is as follows: ( 1 ) the porcelain ball bearing friction performance of porcelain and steel composition very good, can reduce the stress of material and lubricant. ( 2 ) because of porcelain density low , can reduce the centrifugal force in operation. ( 3 ) the heat with lower porcelain coefficient of expansion have reduced bearing efficiently add the change of load in advance. ( 4 ) the flexible mould of porcelain quantity higher, can raise the rigidity of bearing. Above-mentioned factor have prolonged the life of bearing substantially with have promoted the operation limit speed of bearing. nts5 The lubrication technical with high speed electrical main shaft of 3.2 electrical main shafts the temperature rise that must control bearing with reasonable, controallable bearing lubrication way , in order to guarantee stability and the precision of the machining complex of numerical control of machine tool. Adopt to roll the lubrication way of the electrical main shaft of bearing now have the waies such as fat lubrication, oil fog lubrication and the lubrication of oil gas mainly. Fat lubrication in the electricity with relatively lower rotational speed main shaft in is more common lubrication way. The lubrication system of fat lubrication type electrical main shaft is simple , uses convenience and free from contamination , has strong versatility. Oil fog lubrication has lubrication and cooling double role, it is taking compressed air as power , mixes oil liquid atomization into air through oil fog ware to flow , then transports it to need the location of lubrication. The equipment needed by oil fog lubrication is simple , maintenance convenience has more cheap price , is a kind of with high speed electrical lubrication way of main shaft that used generally. But it has pollutive environment, oil consume more higher shortcoming. Along with the raising that people ask for environmental protection, oil fog lubrication way must be superseded gradually. The lubrication technology of oil gas is use compressed air the lubricating oil of be trace difference succession continuously land provide each set of bearing of main shaft accurately, small oil drop in roll with , outside raceway between form the flexible oil membrane of dynamic pressure, and reduce air can take the partial heats produced by bearing operation. Practice shows that the fuel delivery in lubrication is been harmful for too much less , and former two lubrication waies can not control the amount of fuel delivery accurately , disadvantage in the raising of the bearing rotational speed and life of main shaft. And develop the lubrication way of oil gas of geting up recently the lubricating oil that can control the point of every friction accurately quantity, reliability is very high. Practice proof and the lubrication of oil gas are the most ideal method of lubrication of great merit of the rate electrical bearing of main shaft, but the equipment needed by it is complex , cost is high. Because of the lubrication way lubrication effect ideal of oil gas, now have become international the last most popular lubrication way. Its cooling electrical main shaft and the analysis of thermal source of 3.3 electrical main shafts have two major internal thermal sources: Built-in motor give out heat with the bearing of main shaft give out heat. If not control , from the heat that this arouses warp can the serious processing precision and bearing service life that reduces machine tool , so, the service life that causes electrical main shaft shortens. Electrical main shaft because of the depository type configuration of main shaft in adopting, locate in the generator in the unit of main shaft can not break up with fan heat, therefore naturally, scattered hot condition is lacked nts6 comparatively. Generator is realizing energy transition , is internal to produce power loss , so makes generator give out heat. Study to show , is under generator with high speed operation condition , have near 1/3 generator give out heat quantity from generator rotor produce , and the absolutely most of heats that rotor produces are passed through the air gap between rotor and stator in stator; Others 2/3 the stator that heat produces in generator. So produce the major solution method of giving out heat for generator is the cycle for that generator stator adopts cooling fluid flow to carry out force to cool. Typical cooling system is to cool generator stator with the water type cooling installation of outer circulation , goes to the heat tape of generator. What angle contact ball bearing give out heat , is roller mainly under high speed and the rolling friction between raceway, the etc. that receive the top sliding friction that moment produces as well as the viscous friction of lubricating oil produce. Reduce little bearing to give out heat the major measure of quantity: ( 1 ) reduce the diameter of little ball properly reduce little ball diameter can reduce little centrifugal force and top moment, so, reduce little friction, quantity decreases to give out heat. ( 2 ) adopt new material for example adopt porcelain material do ball, porcelain ball bearing and steel quality angle contact ball bearing are compared with , when high speed turns around ball and raceway between roll with sliding friction reduce little, give out heat to measure reduction. ( 3 ) the lubrication way oil gas of reasonable adopting and the lubrication waies such as oil fog for bearing not only have lubrication role, still have certain cooling role. Service life and the performance of 3.4 electrical main shafts that design and assembly electrical main shaft will get must carry out elaborate design and production for the electrical every part of main shaft. The stator of electrical main shaft from have is high Dao the high quality flat of silicon steel of magnetic rate press repeatedly, in stator cavity have to rush system inlay line groove. Rotor from rotor core, squirrel cage and runner shaft 3 partial groups become. Location precision and the size precision of the case of main shaft will also directly affect the comprehensive precision of main shaft. Usually directly design bearing hole in the case of main shaft on, to add to pack generator stator must open at least one end. When the high speed of main shaft spins , any unbalanced quality of Xiao De arouses the vibration of high frequency of big electrical main shaft. Therefore the precision requirement of dynamic balancing of precise electrical main shaft reach G1 G0. 4 levels. For the dynamic balancing of this kind of grade, with conventional method, it is the insufficient dynamic balancing that need to still carry out whole after assembling to carry out dynamic balancing only respectively before assembling for every element on main shaft, even still design special voluntarily balanced system to realize the online dynamic balancing of main shaft. Additionally, when designing electrical main shaft must comply with structural symmetrical principle, key coupling and thread coupling strictly in electrical nts7 main shaft on have been prohibited use, and have adopted profit coupling generally, realize torque with this transmit. After profit coupling and thread coupling or key coupling compare have: Will not produce curved and torsion stress on main shaft, as the revolving precision of main shaft does not affect; the sport control of 3.5 little electrical main shafts in the machine tool of numerical control in, electrical main shaft usually adopts the method of frequency control. Now, there are the ordinary drive and control of frequency conversion mainly , direct torque and control as well as the drive of vector control actuator control 3 kinds of control way. Ordinary frequency conversion is scalar drive and control, it drives to control property, export power and rotational speed for permanent torque drives into direct ratio. It is thought of that the development performance of the ordinary control of frequency conversion is not enough to manage , in low speed, control performance is not good, export power is not enough to stabilize , also does not have C axle function. But price is cheap , has simple structure , is used in grinding machine and ordinary with high speed milling machine etc. normally. Vector control technology imitate the control of the motivation of direct current, with rotor magnetic field it is directional , use vector the method of alternating come to realize drive and control, have good development performance. Vector control actuator has great torque value when just starting , besides, electrical main shaft has simple structure and very little inertia, so, it is big to start acceleration, can realize to start after instant reach promise limit speed. It is two that this kind of actuator also have open loop and closed circuit, the latter can realize the feedback of location and speed , not only has better development performance , can still realize C axle function; And the development performance of the former is lacked , also does not have C axle function , but has relatively cheap price. Directly torque control develops after being then vector control technology, is another as geting up to grow the new high performance alternating technology of speed adjustment, its control thought is novel , construction of system is succinct and clear , more suits the drive of high speed electrical main shaft , can more satisfy the with high speed electrical high rotational speed of main shaft, the wide scope of speed adjustment and high speed instant to allow the requirement of development property and the property of static quiet that stops , has become a hot technology of alternating transmission field. 4 electrical main shaft develop tendency along with the high speed and technology of machine tool cut the needs of actual application and the development of technology, people have also put forward more and more high requirement for the performance of the electrical main shaft of machine tool, the technology of electrical main shaft develop tendency major expression in some following aspects: ( 1 ) to the at low speed big torque direction development and rate of great merit ( 2 ) to high accuracy and high rigidity direction development ( 3 ) to accurately directional( stop definitely) direction development ( 4 ) to fast nts8 from , stop direction development ( 5 ) to exceed with high speed direction development ( 6 ) to standardization direction development 。 电主轴技术水平分析 摘要: 电主轴是高速数控加工机床的 “心脏部件 ”,本文介绍了电主轴的工作原理、典型结构,阐述了电主轴的关键技术,总结了其发展趋势。 关键词: 电主轴 陶瓷球混合轴承 油气润滑 1、概述 由于高速加工不但可以大幅度提高加工效率,而且还可以显著提高工件的加工质量,所以其应用领域非常广泛,特别是在航空航天、汽车和模具等制造业中。于是,具有高速加工能力的数控机床已成为市场新宠。目前,国内外各著名机床制造商在高 速数控机床中广泛采用电主轴结构,特别是在复合加工机床、多轴联动、多面体加工机床和并联机床中。电主轴是高速数控加工机床的 “心脏部件 ”,其性能指标直接决定机床的水平,它是机床实现高速加工的前提和基本条件。 2、电主轴的工作原理、典型结构及优点 nts9 2.1 电主轴的工作原理 电主轴就是直接将空心的电动机转子装在主轴上,定子通过冷却套固定在主轴箱体孔内,形成一个完整的主轴单元,通电后转子直接带动主轴运转。 2.2电主轴的典型结构 电主轴单元典型的结构布局方式是电机置于主轴前、后轴承之间,其优点是主轴单元的轴 向尺寸较短,主轴刚度大,功率大,较适合于大、中型高速数控机床;其不足是在封闭的主轴箱体内电机的自然散热条件差,温升比较高 。 2.3电主轴的优点 电主轴省去了带轮或齿轮传动,实现了机床的 “零传动 ”,提高了传动效率。电主轴的刚性好、回转精度高、快速响应性好,能够实现极高的转速和加、减速度及定角度的快速准停( C轴控制),调速范围宽。 3、电主轴的关键技术 “电主轴 ”的概念不应简单理解为只是一根主轴套筒,而应该是一套组件,包括:定子、转子、轴承、高速变频装置、润滑装置、冷却装置等。因此电主轴是高速轴承技术、润滑技术、冷却技术、动平衡技术、精密制造与装配技术以及电机高速驱动等技术的综合运用。 3.1电主轴的高速轴承技术 实现电主轴高速化精密化的关键是高速精密轴承的应用。目前在高速精密电主轴中应用的轴承有精密滚动轴承、液体动静压轴承、气体静压轴承和磁悬浮轴承等,但主要是精密角接触陶瓷球轴承和精密圆柱滚子轴承。液体动静压轴承的标准化程度不高;气体静压轴承不适合于大功率场合;磁悬浮轴承由于控制系统复杂,价格昂贵,其实用性受到限制。 角接触球轴承不但可同时承受径向和轴向载荷,而且刚度高、高速性能好、结构简单紧凑、品种规格繁多 、便于维修更换,因而在电主轴中得到广泛的应用。目前随着陶瓷轴承技术的发展,应用最多的电主轴轴承是混合陶瓷球轴承,即滚动体使用 Si3N4陶瓷球,采用 “小珠密珠 ”结构,轴承套圈为 GCr15钢圈。这种混合轴承通过减小离心力和陀螺力矩,来减小滚珠与沟道间的摩擦,从而获得较低的温升及较好的高速性能。 陶瓷球混合轴承与钢球轴承相比,优点如下: ( 1) 陶瓷与钢组成的陶瓷球轴承摩擦性能非常好,能降低材料与润滑剂的应力。 ( 2)因陶瓷密度低,可降低运转时的离心力。 ( 3)陶瓷较低的热膨胀系数有效降低了轴承预加负荷的变化。 ( 4)陶瓷的弹性模量较高,可以提高轴承的刚性。 上述因素大幅度地延长了轴承的寿命和提升了轴承的运转极限速度。 3.2电主轴的润滑技术 nts10 高速电主轴必须采用合理的、可控制的轴承润滑方式来控制轴承的温升,以保证数控机床工艺系统的精度和稳定性。采用滚动轴承的电主轴的润滑方式目前主要有脂润滑、油雾润滑和油气润滑等方式。 脂润滑在转速相对较低的电主轴中是较常见的润滑方式。脂润滑型电主轴的润滑系统简单、使用方便、无污染、通用性强。 油雾润滑具有润滑和冷却双重作用,它以压缩空气为动力,通过油雾器将油液雾化并混入空气流中 ,然后把其输送

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号