液压伺服千斤顶系统设计【机械毕业设计word+CAD图纸】【答辩通过】

收藏

资源目录

压缩包内文档预览:

编号:458563

类型:共享资源

大小:5.80MB

格式:RAR

上传时间:2015-07-20

上传人:小***

认证信息

个人认证

林**(实名认证)

福建

IP属地:福建

40

积分

- 关 键 词:

-

液压

伺服

千斤顶

系统

设计

机械

毕业设计

word

cad

图纸

答辩

通过

- 资源描述:

-

目录

1. 引言2

1.1 选题的依据及课题的意义2

1.2 国内外的研究概况3

1.3 单片机控制系统的发展概况4

1.4 PID控制算法的发展概况5

1.5 设计要求及工作内容6

1.6 目标、主要特色及工作进度7

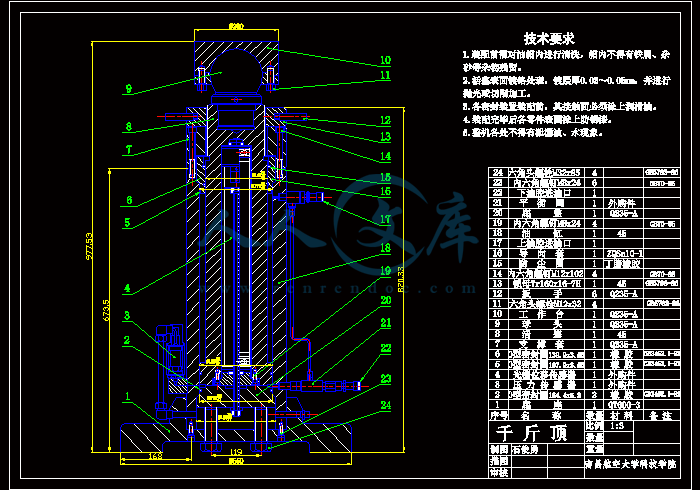

2. 机械结构与液压传动系统设计7

2.1系统结构分析7

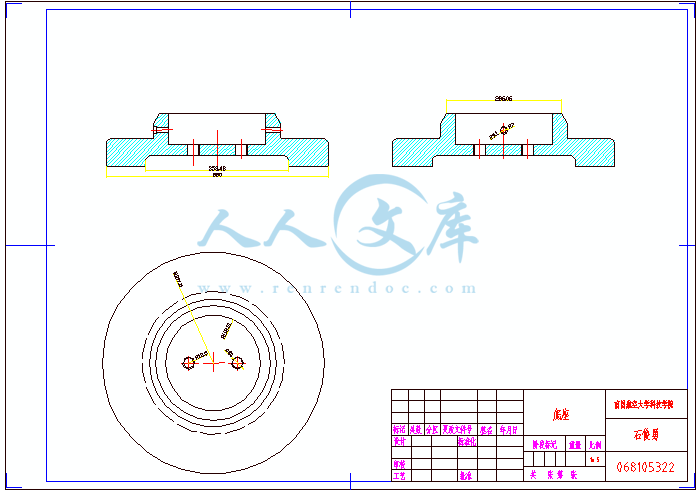

2.2 千斤顶零部件分析9

2.3 油缸与螺纹的校验12

2.3.1油缸的壁厚校验12

2.3.2 锁母螺纹牙剪切强度校验13

2.3.3锁母螺纹牙的弯曲强度校验14

2.4 液压系统分析14

2.5 液压泵与电动机的选择15

2.6 超高压泵站简介16

3 . 单片机控制系统设计17

3.1 单片机的选用及功能介绍17

3.2 片外存储器功能简介18

3.3 显示部分设计21

3.4 键盘部分设计25

3.5 交流异步电动机变频调速系统27

3.5.1 交流异步电动机变频调速原理28

3.5.2主电路和逆变电路工作原理28

3.5.3 变频与变压32

3.6 位移检测部分的设计38

3.6.1 位移检测传感器的选用38

3.6.2 光栅位移传感器与单片机的接口设计40

3.7 位移传感器部分的设计43

3.7.1 A/D转换器的选择43

3.7.2 压力传感器与单片机的接口设计47

4.系统的PID控制算法48

4.1 PID控制原理48

4.2 数字PID控制算法50

4.2.1 位置式PID控制算法50

4.2.2 增量式PID控制算法51

4.3 智能自适应PID控制器52

5. 系统模拟仿真57

5.1 SIMULINK概述58

5.2 SIMULINK的窗口和菜单58

5.3 用SIMUINK创建模型60

5.4 用SIMULINK进行系统仿真与分析61

5.4.1 建立控制系统模型61

5.4.2 系统模块参数设置与仿真参数设置62

5.4.3 系统仿真与分析64

6.结论67

7.致谢68

8. 参考文献68

1. 引言

1.1 选题的依据及课题的意义

随着现代社会的不断发展,工业化程度的不断深入,大尺寸、大重量、不规则表面的工件越来越多的成为工厂加工的对象。而在加工过程中如何将这些工件准确的提升至预定位置则成为最难解决的问题,这时传统的千斤顶和起重机等设备就显示出先天不足的缺陷来。也正是在这种环境下,同步顶升系统应运而生,并在建筑、机械加工、造船等行业扮演着越来越重要的角色。同步顶升系统是由控制系统协调控制多个千斤顶,使其具备顶升大重量、大体积、复杂工作表面的工件的能力,并具有同步升降、点动升降、连续升降、侧翻仰俯等功能的机电一体化设备。其控制系统可以是微机、单片机、可编程控制器等;其动力系统有液压式、气电式、汽液两用式等;吨位从几百公斤到几千吨不等,主要由动力方式和千斤顶的个数来决定 。由于其体积小、承载重、精度高、结构简单、控制方便、使用灵活等优点被广泛的用于电力、建筑、机械制造、矿山、铁路桥梁、造船等多种行业中,在设备安装、起顶拆卸、静力压桩、设备校调、基础沉降等工作岗位发挥了重要的作用。基于单片机控制、液压传动的四顶顶升系统是较常见的,控制算法较简单的一种。由于其控制简便、吨位适中、价格也很低廉的优点使得其在中小企业、民营单位甚至轻工业领域都有很高的使用度。其重要性不言而喻,对其进行研究和开发具有很大的市场空间和实用价值。

- 内容简介:

-

Servo hydraulic jacks Student Name: Shi Junyong Class: 068105322 Supervisor : Gao Yanfeng Abstract: Digg this liter four-designed system, the main parameter is the high per jack about 1000mm, the maximum stroke is 400mm, the maximum load of 20t. Jack load due to a larger location with high precision, thus lifting speed should not be too large, the maximum lifting speed should be controlled within the 60mm/min. Works, the two four-way solenoid valve of the solenoid working state is controlled by the microcontroller, when the solenoid valve energized, the valve Left access system, oil by the solenoid valve and balancing valve into the cylinder under the cavity, so jack up, and from fuel tanks on the cavity flow, flow through solenoid valve and filter tank back in, then the role of balancing valve is equivalent to a one-way valve; the other hand, When the solenoid valve power, the valve access system the right position, oil flows through valve cylinder on the cavity, when the chamber pressure reaches a certain value, the upper balance valve access system, when a balance acts as a throttle valve, the oil flow from the fuel tank under the cavity, by balancing valve, solenoid valve and filter flow back to tank. In order to achieve a lifting jack for the function, and have overload protection and power protection. In order to adapt to the complex work piece surface, jack the table should be used with the piston rod connected to rotate connections made at work when lifting systems, hydraulic jack table with the surface shape can be adjusted freely rotate, so when the piston rod at the top of the design Insert the ball, and form a rotating table vice As the size of a long grating, the piston and piston rod to place the grating made of hollow shape. Work light emitting devices with photosensitive elements for synchronous movement with the piston, the bottom grating fixed to the bottom cover fixed, light source and grating by reading the relative displacement of the first into a digital signal is passed to the microcontroller. Keywords: 4 Synchronous Lift SCM Grating Signature of supervisor: nts 伺服液压千斤顶 学生姓名:石俊勇 班级: 068105322 指导老师:高延峰 摘要 :所设计的四顶顶升系统的主要参数是每只千斤顶高约 1000mm,最大行程为 400mm,最大载荷为 20t。因千斤顶载荷较大,位置精度要求较高,故顶升速度不宜过大,最大顶升速度应控制在 60mm/min 以内。 工作原理是,二位四通电磁换向阀的电磁铁的工作状态是由单片机控制的,当换向阀电磁铁通电时,换向阀左位接入系统,油液经电磁换向阀和平衡阀进入油缸下腔,使得千斤顶上升,再从油缸上腔流出,经电磁换向阀和滤油 器流回到油箱内,这时平衡阀的作用相当于一个单向阀;反之,当换向阀电磁铁断电时,换向阀右位接入系统,油液经换向阀流入油缸上腔,当上腔压力达到一定值时,平衡阀上位接入系统,这时平衡阀的作用相当于一个节流阀,油液从油缸下腔流出,经平衡阀、电磁换向阀和滤油器流回到油箱。从而实现了千斤顶升降换向功能,并具有过载保护和断电保护的功能。 为了适应复杂工作表面的工件,千斤顶的工作台与活塞杆应采用转动连接副相连 当顶升系统工作时,液压千斤顶工作台可随工件表面形状进行自由转动调节,所以设计时将活塞杆顶部插入球头,与工作台形成转动副。 由于光栅尺的尺寸较长,将活塞和活塞杆做成中空状来放置光栅。工作时发光元件与光敏元件随活塞作同步运动,光栅尺下端固定在底盖上不动,光源与光栅尺的相对位移量通过读数头转化为数字信号传递给单片机。 关键词: 四顶同步顶升 单片机 光栅 指导老师:高延峰 ntsIEEE TRANSACTIONS ON ROBOTICS, VOL. 24, NO. 5, OCTOBER 2008 1199Real-Time Adaptive Motion Planning (RAMP)of Mobile Manipulators in Dynamic EnvironmentsWith Unforeseen ChangesJohn Vannoy and Jing Xiao, Senior Member, IEEEAbstractThis paper introduces a novel and general real-timeadaptive motion planning (RAMP) approach suitable for plan-ning trajectories of high-DOF or redundant robots, such as mobilemanipulators, in dynamic environments with moving obstacles ofunknown trajectories. The RAMP approach enables simultaneouspath and trajectory planning and simultaneous planning and exe-cution of motion in real time. It facilitates real-time optimizationof trajectories under various optimization criteria, such as min-imizing energy and time and maximizing manipulability. It alsoaccommodates partially specified task goals of robots easily. Theapproach exploits redundancy in redundant robots (such as lo-comotion versus manipulation in a mobile manipulator) throughloose coupling of robot configuration variables to best achieve ob-stacle avoidance and optimization objectives. The RAMP approachhas been implemented and tested in simulation over a diverse set oftask environments, including environments with multiple mobilemanipulators. The results (and also the accompanying video) showthat the RAMP planner, with its high efficiency and flexibility, notonly handles a single mobile manipulator well in dynamic environ-ments with various obstacles of unknown motions in addition tostatic obstacles, but can also readily and effectively plan motionsfor each mobile manipulator in an environment shared by multiplemobile manipulators and other moving obstacles.IndexTermsAdaptive, dynamic obstacles of unknown motion,loose coupling, mobile manipulators, partially specified goal, realtime, redundant robots, trajectory optimization.I. INTRODUCTIONMOTION PLANNING is a fundamental problem inrobotics1,2concernedwithdevisingadesirablemo-tion for a robot to reach a goal. Motion planning for high-DOFarticulated manipulators or mobile manipulators is more chal-lenging than for mobile robots because the high-dimensionalconfiguration space of a robot has little or no resemblance tothe physical space that the robot works in, and how to constructManuscript received May 16, 2007; revised December 13, 2007 and March 5,2008. First published October 10, 2008; current version published October 31,2008. This paper was recommended for publication by Associate EditorK. Yamane and Editor L. Parker upon evaluation of the reviewers comments.A preliminary part of this paper was presented at the IEEE International Con-ference on Intelligent Robots and Systems, Sendai, Japan, 2004.The authors are with the Intelligent, Multimedia and Interactive Systems(IMI) Laboratory, Department of Computer Science, University of NorthCarolina at Charlotte, Charlotte, NC 28223 USA (e-mail: jmvannoy; xiao).This paper has supplementary downloadable material available at, provided by the authors: a video showing the real-time planning and execution of mobile manipulator motion by our RAMPalgorithm. This video is 14 MB in size.Color versions of one or more of the figures in this paper are available onlineat .Digital Object Identifier 10.1109/TRO.2008.2003277a configuration space higher than three dimensions efficientlyremains a largely unsolved problem.A. Related Research on Motion PlanningRandomized algorithms, such as the popular probabilisticroadmap (PRM) method 3 and rapidly exploring random tree(RRT) method 4, are found to be very effective in findinga collision-free path for a robot with high DOFs offline be-cause such algorithms avoid building the robots configurationspace explicitly by sampling the configuration space. The PRMmethod has inspired considerable work on improving samplingand roadmap construction 2, including a recent paper 5 onproducing compact roadmaps to better capture the different ho-motopic path groups. By building a tree rather than a graph, theRRTmethodismoresuitableforgeneratingapathinoneshotorgeneratingatrajectorydirectlyandthusmoresuitableforonlineoperation 6. Both methods have seen many variants 2.There are also methods for path planning based on ge-netic algorithms (GAs), or more broadly, evolutionary com-putation 7, 8, which are general frameworks of randomizedsearch subject to user-defined optimization criteria. Such op-timization techniques have been used widely and successfullyin many application domains 8, 9 to tackle NP-hard opti-mization problems. There are two major ways of applications.One straightforward way is to map a problem into the formsuitable for a standard, off-the-shelf GA, solve it by runningthe GA, and then, map the results back to the application do-main. This one-size-fit-all approach is often not effective be-cause it forces artificial transformation of a problem into some-thing else that is confined in the format of a standard GA butmay losecertain important nature of the original problem. SomeGA-based path planning methods 10, 11 adopt such an ap-proach, where C-space is discretized into a grid, and a path is interms of a fixed-length sequence of grid points. As the standardGA operates on fixed-length bit strings, search is often veryslow.A more effective approach is to adopt the general idea ofevolutionary computation to solve a problem in a more naturalandsuitablerepresentation.Thepathplanningmethodsreportedin 1214 belong to such a customized approach. A real-timepathplanningmethodisreportedin12for2DOFpointmobilerobots, which is extended in 13 for 3 DOF point flying robotswith specific constraints. A multiresolution path representationis proposed in 14 for path planning. However, all evolution-ary algorithms have a number of parameters that must be setappropriately, which is often not a trivial task.1552-3098/$25.00 2008 IEEEnts1200 IEEE TRANSACTIONS ON ROBOTICS, VOL. 24, NO. 5, OCTOBER 2008Unlike path planning, motion planning has to produce anexecutable trajectory for a robot in configurationtime space,or CT-space, and not merely a geometrical path. A commonapproach is to conduct trajectory planning on the basis of a pathgenerated by a path planner. A notable framework is the elasticstrip method 15, which can deform a trajectory for a robotlocallytoavoidmovingobstaclesinsideacollision-free“tunnel”that connects the initial and goal locations of the robot in a 3-Dworkspace. Such a “tunnel” is generated from a decomposition-based path planning strategy 16. The other approach is toconduct path and trajectory planning simultaneously. However,most effort in this category is focused on offline algorithmsassumingthattheenvironmentiscompletelyknownbeforehand,i.e., static objects are known, and moving objects are knownwithknowntrajectories1720.Asfordealingwithunknownmoving obstacles, only recently some methods were introducedfor mobile robots 21, 22.The combination of mobility and manipulation capabilitymakes a mobile manipulator applicable to a much wider rangeof tasks than a fixed-base manipulator or a mobile robot. For amobile manipulator, a task goal state is often partially specifiedas either a configuration of the end-effector, which we call aplace-to-place task, or a desired path (or trajectory) of the end-effector, which we call a contour-following task, and the targetlocation/path of the base is often unspecified.Here, a major issue of motion planning is the coordination ofthe mobile base and the manipulator. This issue, as it involvesredundancy resolution, presents both challenges and opportu-nities. There exists a rich literature addressing this issue frommany aspects. Some researchers treat the manipulator and themobile base together as a redundant robot in planning its pathfor place-to-place tasks 2325. Some focused on planning asequence of “commutation configurations” for the mobile basewhen the robot was to perform a sequence of tasks 26, 27subject to various constraints and optimization criteria. Othersfocused on coordinating the control of the mobile base and themanipulator in a contour-following task 28, 29 by tryingto position the mobile base to maximize manipulability. Manyconsidered nonholonomic constraints.While most of the existing work assumes known environ-ments with known obstacles for a mobile manipulator, a fewresearchers considered local collision avoidance of unknown,moving obstacles online. One method 30 used RRT as a localplanner to update a roadmap originally generated by PRM todeal with moving obstacles. For contour-following tasks, an ef-ficient method 31 allows the base to adjust its path to avoid amoving obstacle if possible while keeping the end-effector fol-lowing a contour, such as a straight line. Another method 29allowed the base to pause in order to let an unexpected obsta-cle pass while the arm continued its contour-following motionunder an event-based control scheme. Other methods includeone based on potential field 32 to avoid unknown obstaclesand one based on a neuro-fuzzy controller 33 to modify thebase motion locally to avoid a moving obstacle stably. Thereis also an online planner for the special purpose of planningthe motions of two robot arms getting parts from a conveyerbelt 34.However, we are not aware of any existing work that can planmotions of high-DOF robots globally among many unknowndynamic obstacles.B. Our Problem and ApproachPlanning high-DOF robot motion in such an environmentof many unknown dynamic obstacles poses special challenges.First, planning has to be done in real time, cannot be done of-fline, and cannot be based on a certain prebuilt map because theenvironment is constantly changing in unforeseen ways, i.e.,the configuration space obstacles are unknown and changing.Examples of such environments include a large public squarefull of people moving in different ways, a warehouse full ofbusy-moving robots and human workers, and so on. Such anenvironment is very different from static or largely static envi-ronments or known dynamic environments (i.e., with other ob-ject trajectories known), where motion planning can reasonablyrely on exploring C-space (for known static environments) orCT-space(forknowndynamicenvironments)offline(suchasbyPRM). The elastic strip method provides the flexibility to makesmall adjustments of a robot motion to avoid unknown motionsof obstacles, if the underlying topology of the C-space does notchange. For an environment with changing C-space topologyin unknown ways, a planned path/trajectory can be invalidatedcompletelyatanytime,andthus,real-timeadaptiveglobalplan-ning capability is required for making drastic changes of robotmotion. Planning and execution of motion should be simulta-neous and based on sensing so that planning has to be very fastand always able to adapt to changes of the environment.By nature, to tackle motion planning in an unknown dynamicenvironment cannot result in a complete planning algorithm.That is, no algorithm can guarantee success in such an unknownenvironment. We can only strive for a rational algorithm thatserves as the “best driver of a high-DOF robot, but even thebest driver cannot guarantee to be accident-free if other thingsin the environment are not under his/her control.This paper addresses the problem of real-time simultaneouspath and trajectory planning of high-DOF robots, such asmobile manipulators, performing general place-to-place tasksin a dynamic environment with obstacle motions unknown.The obstacle motions can obstruct either the base or the armor both of a mobile manipulator. We introduce a unique andgeneral real-time adaptive motion planning (RAMP) approach.Our RAMP approach is built upon both the idea of randomizedplanning and that of the anytime, parallel, and optimizedplanning of evolutionary computation, while avoiding thedrawbacks. The result is a unique and original approacheffective for the concerned problem.The RAMP approach has the following characteristics.1) Whole trajectories are represented at once in CT-spaceand constantly improved during simultaneous plan-ning and execution, unlike algorithms that build apath/trajectory sequentially (or incrementally) so that awholepath/trajectorycanbecomeavailableonlyattheendof the planning process. Our anytime planner can providea valid trajectory quickly and continue to produce betterntsVANNOY AND XIAO: REAL-TIME ADAPTIVE MOTION PLANNING (RAMP) OF MOBILE MANIPULATORS IN DYNAMIC ENVIRONMENTS 1201trajectories at any later time to suit the need of real-timeglobal planning.2) Different optimization criteria (such as minimizing en-ergy and time and optimizing manipulability) can beaccommodated flexibly and easily in a seamless fash-ion. Optimization is done directly in the original, con-tinuous CT-space rather than being confined to a certainlimited graph or roadmap. Trajectories are planned andoptimized directly rather than conditional to the results ofpath planning.3) Our planner is intrinsically parallel with multiple diversetrajectories present all the time to allow instant, and ifnecessary, drastic adjustment of robot motion to adapt tonewly sensed changes in the environment. This is differ-ent from planners capable of only local trajectory adjust-ment based on a known set of homotopic paths. It is alsodifferent from sequential planners, such as anytime A*search 35, which also requires building a discrete statespace for searcha limitation that our planner does nothave.4) Trajectory search and evaluation (of its optimality) areconstantly adaptive to changes but built upon the resultsof previous search (i.e., knowledge accumulated) to beefficient for real-time processing.5) As planning and execution (i.e., robot motion followingthe planned result so far) are simultaneous, partially feasi-ble trajectories are allowed, and the robot may follow thefeasible part of such a trajectory (if it is the current best)and switch to a better trajectory to avoid the infeasiblepart.6) With multiple trajectories from our planner, each trajec-tory can end at a different goal location in a goal region,i.e., partially specified goals, rather than a single goal con-figuration.7) Our planner represents a trajectory for a redundant robot,such as a mobile manipulator, as loosely coupled trajec-tories of redundant variables to take advantage of the re-dundancy in order to best achieve obstacle avoidance andvarious optimization objectives.The rest of the paper is organized as follows. Section II pro-vides an overview of our RAMP approach; Sections III and IVdescribe problem representation and initialization; Section Voutlines our optimization criteria for trajectory evaluation anddescribes the strategies for evaluation. Sections VI and VII de-scribe the strategies to alter trajectories to produce better ones.Section VIII describes how the RAMP planner can create andpreserve a diverse set of trajectories. Section IX provides im-plementation and experimentation results and discusses perfor-mance of the planner. Section X concludes the paper.II. OVERVIEW OF THE RAMP APPROACHOnebasicpremiseofourapproachisthattheplanningprocessand the execution of motion are interweaving to enable simul-taneous robot motion planning and execution. This is achievedthrough our anytime planning algorithm that always maintainsa set of complete trajectories in the CT-space of the robot calleda population. The feasibility and optimality of each trajectory,called fitness, is evaluated through an evaluation function cod-ing the optimization criteria. Feasibility refers to collision-freeandsingularity-free.Bothinfeasibleandfeasibletrajectoriesareallowed in a population. Feasible trajectories are considered fit-ter than infeasible trajectories. Within each type, trajectories arecompared for optimality in fitness.Theinitialpopulationisacombinationofrandomlygeneratedand deliberately seeded trajectories. Deliberately seeded trajec-tories include ones constructed to represent distinct subpopula-tionsinordertoachievecertaindiversityinthepopulation.Iftheenvironment contains known static obstacles, trajectories basedon preplanned feasible paths with respect to the known staticobstacles can also be included. See Section IV for more details.Once the initial population is formed, it is then improved to afitterpopulationthroughiterationsofimprovements,calledgen-erations. In each generation, a trajectory is randomly selectedandalteredbyarandomlyselectedmodificationoperatoramonga number of different modification operators, and the resultingtrajectory may be used to replace a trajectory that is not thefittest to form a new generation. The fittest trajectory is alwayskept in the population and can only improve from generation togeneration. Each generation is also called a planning cycle.To improve the fitness of the initial population, a number ofinitial planning cycles may be run based on the initial sensinginformation of the environment before the robot begins execut-ing the fittest trajectory. The robot need not wait for a feasibletrajectory to emerge; if no feasible trajectory is available, therobot will begin moving along the fittest in feasible trajectorywhile continuing the search for a fitter, and hopefully will locatea feasible trajectory before it comes within a distance thresholdD of the first predicted collision or singularity of the executedtrajectory. This strategy makes sense because: 1) the presentlypredicted infeasible trajectory may become feasible later andvice versa; 2) as to be described later, our planner makes therobot switch to a better trajectory if one is available, and thus,before the infeasible part of the curr

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号