!【详情如下】CAD图纸+word设计说明书.doc[10000字,35页]【需要咨询购买全套设计请加QQ97666224】.bat

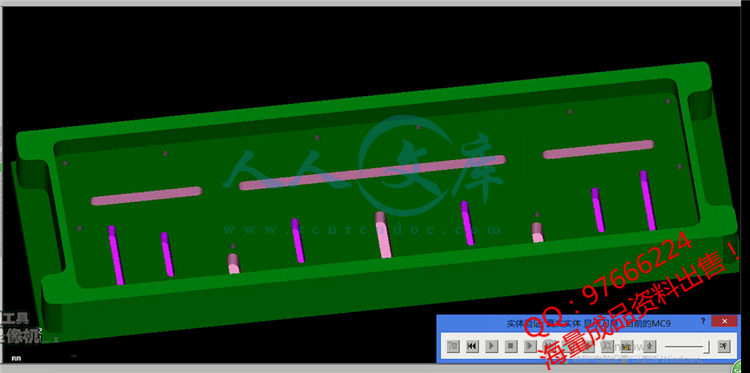

后视图A_仿真.MC9

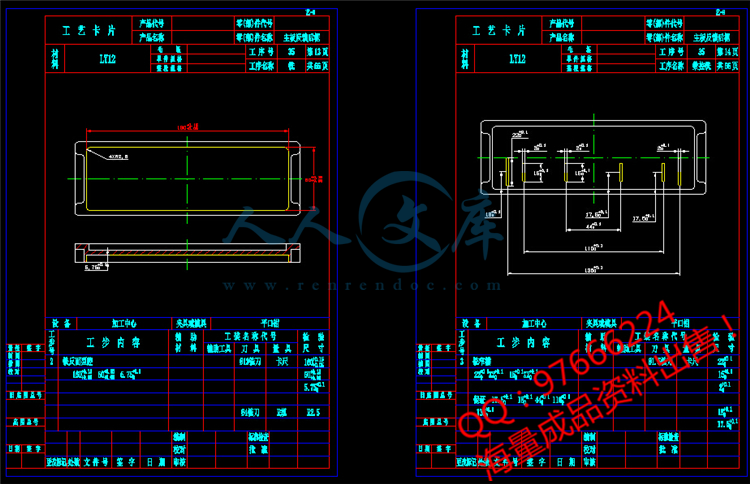

工艺卡片及零件图.dwg

nc程序.doc

设计说明书.doc[10000字,35页]

仿真视频.avi

数控机床毕业外文翻译.doc

答辩.ppt

摘 要

近年来,随着数控技术与仿真技术的发展,在现代制造工业中,性能良好的加工中心设备和数控仿真技术使许多零件的加工更为方便,使得产品质量和加工效率都有所提高。利用这些设备如何能高效地加工出更为优质的零件,已成为企业关心的问题。

本文以主板反馈后框为例,基于近年应用起来的高速加工制造,利用工厂现有的数控设备,在结合资料,实际加工经验及主板反馈后框的要求的基础上,对主板反馈后框的加工工艺进行了深入的研究,对主板反馈后框加工的工艺路线进行了拟定,介绍了工艺规程的设计,如何选择每道工序的定位基准,重点论述了如何制定出先进的工艺卡片和工序卡片,积极探索出加工该类零件的较好的工艺方案,数控加工过程,并在对零件进行工艺分析的基础上,对零件的造型,CNC程序的生成,仿真加工等方面进行了阐述。

通过对主板反馈后框工工艺编制和加工仿真的研究,可以缩短产品开发周期,降低生产成本,提高产品质量和生产效率,对提高我国制造水平,迈入世界先进技术了、行列有重要意义。

关键词:主板反馈后框,工艺规程,数控仿真

ABSTRACT

In recent years,with the development of computer technology and simulation technology, in the modern manufacturing industry, good performance of the machining center and CNC simulation technology to make it more convenient in many parts of the processing,It makes the product quality and processing efficiency has increased in.How to use these devices to make more efficient processing of the high-quality parts, has become a business concern.

In this paper,we take the motherboard box for an example, based on recent high-speed processing manufacturing application up, using factory existing numerical control equipment, in combination with material, the actual processing experience, on the basis of the requirements of the motherboard box,thoroughly analysing the main motherboard box processing status,planing the motherboard box of the processing route, introducing the design procedure, introducing how to select the locating datum of each procedure,focuses on how to develop advanced process card, actively explore out the good of such parts processing process scheme, nc machining process of spare parts, and based on the analysis of the technology of parts, the modelling CNC program generated, simulation processing were expounded.

Thoroughly analysing the motherboard box processing status and computer simulation of machining, the period of blade manufacturing can be shortened, manufacturing cast can be decreased,and the quality of blades and machining efficiency can be improved. It is of great significance in improving the manufacture technology of hydraulic turbine in our country and making our hydraulic turbine manufacturer's technology up to international advanced technology level.

Key words: the motherboard box,processing status,nc machining simulation

目录

摘 要I

ABSTRACTII

第一章 概述1

1.1. 课题名称及意义1

第二章 工艺分析3

2.1 生产类型3

2.1.1 生产纲领3

2.2 工艺分析3

2.2.1 分析零件图3

2.2.2 工艺分析4

第三章 工艺设计6

3.1 毛坯的选择6

3.2 刀具的选择6

3.3 夹具的选择7

3.4 拟订工艺路线8

第四章 加工仿真14

4.1 仿真软件简介14

4.2 加工仿真14

4.2.1 档案读取14

4.2.2 图形平移至原点15

4.2.3 刀具路径15

4.2.4 实体仿真22

4.2.5后置处理23

第五章 全文总结27

参考文献28

致 谢29

毕业设计小结30

参考献文

[1] 闫光明.《现代制造工艺基础》.西北工业大学出版社,2009

[2] 顾崇衔.《机械制造工艺学》.陕西科学出版社,2011

[3] 王凡.《实用机械制造工艺师手册》.机械工业出版社,2007

[4] 刘朝儒.《机械制图》.高等教育出版社,2006

[5] 张代东.《机械工程材料应用基础》.机械工业出版社,2010

川公网安备: 51019002004831号

川公网安备: 51019002004831号