抓物机器车机构设计及运动仿真

基于Solidworks的抓物机器车机构设计及运动仿真 【优秀含20张CAD图纸+SW三维建模+仿真+机械设备全套课程毕业设计】

【带任务书+中期检查表+开题报告+进度计划表+答辩ppt+外文翻译】【47页@正文14800字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

任务书基于Solidworks的抓物机器车机构设计及运动仿真.doc

中期检查表.doc

开题报告.doc

毕设进度表.doc

答辩.pptx

设计论文.docx

A0总装图.dwg

A33.dwg

a33333.dwg

SW三维建模

上车身.DWG

下车身.DWG

丝杆.DWG

丝杆螺母.DWG

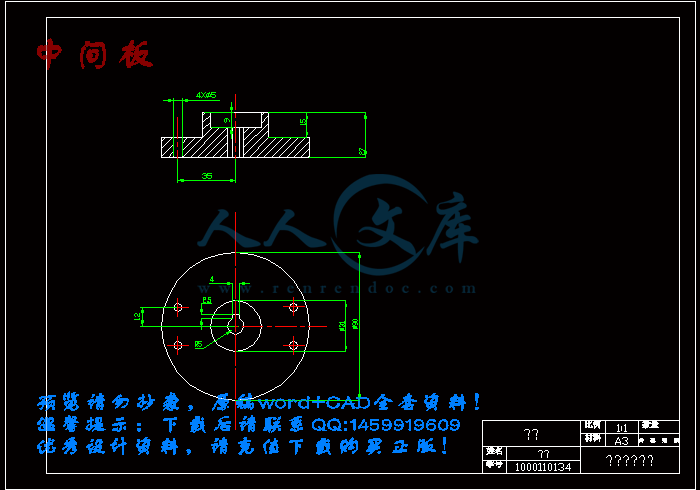

中间板.DWG

仿真视频

其他的零件图.dxf

固定架.DWG

外文翻译

大齿轮.DWG

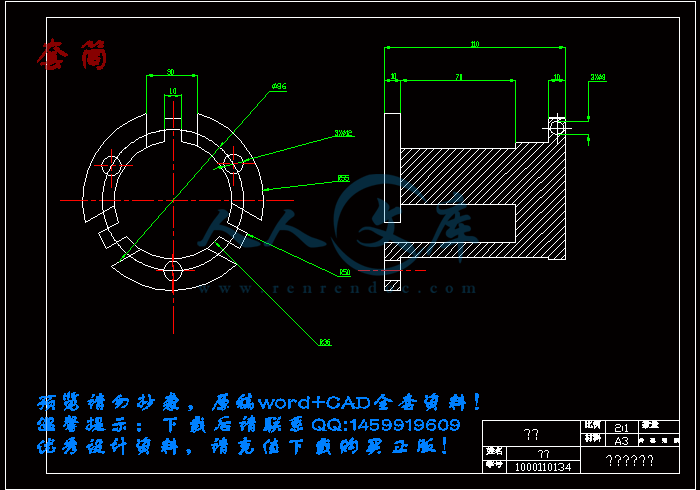

套筒.DWG

支板1.DWG

支板2.DWG

爪子.DWG

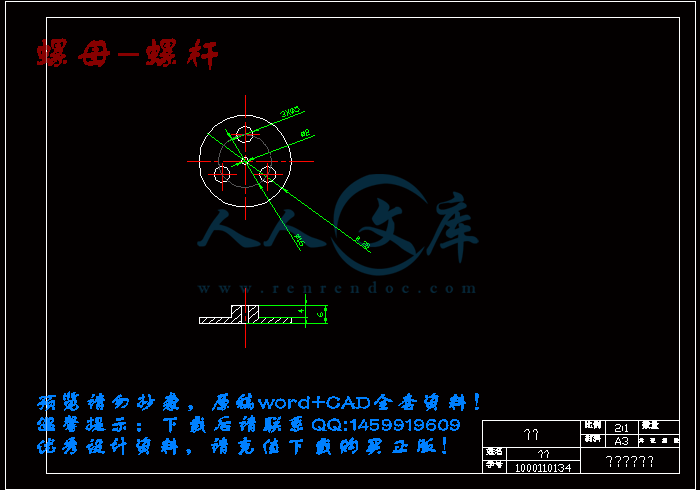

螺杆.DWG

螺母-螺杆.DWG

装配体1.DWG

设计文档

说明书打印版.pdf

转臂.DWG

轴啊.DWG

连杆.DWG

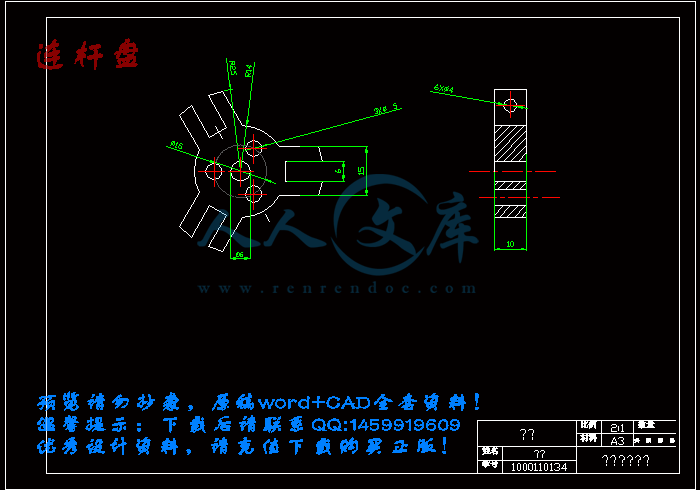

连杆盘.DWG

任务书

题 目: 基于Solidworks的抓物机器车机构设计及运动仿真

2013年12月13日

一、毕业设计(论文)的内容

机器人是自动执行工作的机器装置。它既可以接受人类指挥,又可以运行预先编排的程序,也可以根据以人工智能技术制定的原则纲领行动。它的任务是协助或取代人类工作的工作,例如生产业、建筑业,或是危险的工作。

本课题通过应用CAD软件技术对抓物机器车进行结构设计,使其能实现抓物运动,可以在地形复杂或恶劣、危险的环境里完成物体的搬运或者障碍的清除等工作。另一方面是进一步提升专业技能,为踏上工作岗位做好准备。本课题的主要工作内容有以下几点:

1、收集关于抓物机器车产品的相关知识,了解现有抓物机器车产品的结构;

2、熟悉抓物机器车的工作原理及过程;

3、查阅相关资料,熟悉机械产品设计、机械设计基础、机械零件的加工工艺、工程力学、工程制图等与本毕业设计课题相关的知识内容;

4、熟练掌握计算机辅助设计软件(Solidworks);

5、对抓物机器车设计方案进行详细规划及分析,反复对方案进行论证,逐步进行修改及优化;

6、利用计算机及Solidworks软件完成抓物机器车的结构设计;

7、利用计算机及Solidworks软件完成抓物机器车相关机构的各种参数计算和分析;

8、完成抓物机器车相关零件材料的选用及其工艺分析;

9、利用计算机及Solidworks软件完成抓物机器车产品零件及装配部件的3D和2D工程图的绘制;

10、利用计算机及Solidworks 软件完成抓物机器车的运动仿真;

二、毕业设计(论文)的要求与数据

本毕业设计课题需要掌握机械产品设计、机械设计基础、机械零件加工工艺、工程力学、工程制图等相关知识及计算机辅助设计技能。本课题需要提交的数据资料及要求主要有以下几点:

1、设计方案的规划及分析对比必须在毕业设计说明书中体现出来;

2、抓物机器车产品结构设计要合理,提交合理、完整的3D模型;

3、抓物机器车相关机构的各种参数计算和分析(如抓取零件的最大重量、最大最小尺寸、抓取夹紧力及机械手受力情况的等),并提供结果;

4、零部件装配正确合理,并提供干涉分析结果;

5、2D工程图要整洁规范,必须符合国家标准,并提交规范完整图纸;

6、机构运动仿真及零件拆、装过程视频动画分辨率不小于720*480 px,并提交AVI格式视频文件;

7、外文资料翻译和毕业设计说明书(论文)的内容及字符要符合“毕业设计任务书”的要求;

8、毕业设计说明书的格式必须符合 “2014年毕业设计说明书统一格式”的要求;

9、各个文件资料所需填写的时间必须符合“2014年毕业设计(论文)管理办法”的要求;

10、答辩PPT课件能清晰体现毕业设计课题的设计思路,并且版面简介;

三、毕业设计(论文)应完成的工作

1、完成开题报告及进度计划表的撰写;

2、完成中期检查表的填写;

3、完成二万字左右的毕业设计说明书(论文);在毕业设计说明书(论文)中必须包括详细的300-500个单词的英文摘要;

4、独立完成与课题相关,不少于四万字符的指定英文资料翻译(附英文原文);

5、完成抓物机器车产品零件及装配部件的3D和2D工程图的绘制;

6、完成工作量折合A0图纸3张以上,其中必须包含两张A3以上的计算机绘制图纸;

7、完成零件拆、装过程及运动仿真视频动画的制作;

8、完成答辩PPT课件的制作;

四、应收集的资料及主要参考文献

[1]曹惟庆等.机构设计[M].北京:机械工业出版社,1993

[2]成大先.机械设计手册[M].北京:化学工业出版社,2004

[3]《机械设计手册》联合编写组.机械设计于册-下册[M].北京:化学工业出版社,1989

[4]张彪,叶军等.一种丝杆螺母机构型机械手的设计[J].中国西部科技,2010,(15):31-32.

[5]孙恒,陈作模.机械原理(第六版)[M].北京:高等教育出版社,2001

[6]詹友刚. SolidWorks快速入门教程(2012中文版)[M].北京:机械工业出版社,2004

[7]ASHBY, M. F. (1998). Engineering Materials (2nd ed.) (2 vols.)/Volume 1 - An Introduction to t heir Properties and Applications Engineering_Materials_2E_VOLUME1

五、试验、测试、试制加工所需主要仪器设备及条件

所需主要仪器设备及条件如下:

1、计算机一台

2、CAD设计软件(SolidWork)

摘 要

很多地方是我们人类没法进去的,因为其中的一些东西已经对我们造成了生命的威胁,但我们又有必须进去的理由。在这种场合下,机械就能为我们解决这些问题,因为它可以代替我们进行一些危险操作,用来取代人力来工作。我们设计的抓物机器车是在机械化,自动化生产过程中发展起来的一种将机械手和搬运车联系为一体的产品。使其能抓物运动,可以在地形复杂或恶劣、危险的环境里替人完成物体的搬运或者障碍的清除等工作。

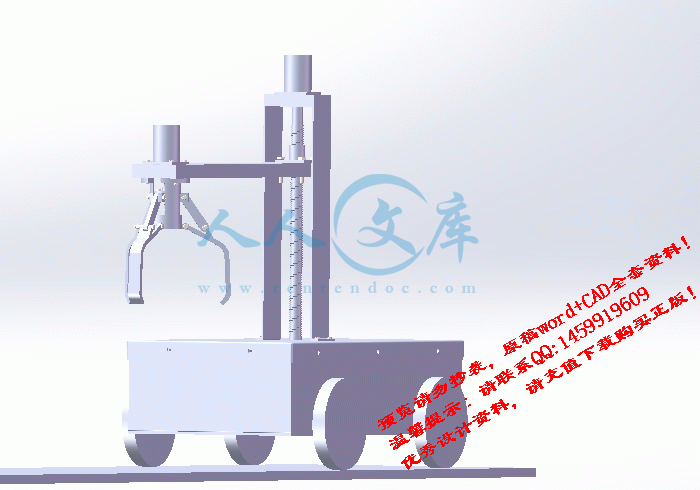

抓物机器车的设计主要是通过无线通信来控制小车的前进、后退或者转弯,并由螺杆转动,带动螺杆上的螺母上下移动,再通过连杆结构实现抓爪的闭合,从而实现抓物动作。丝杆竖直放置,转臂固定在丝杆螺母上,步进电机带动丝杆旋转,螺母会上下移动,转臂也会上下移动,也就是机械手上下移动,满足了机械手降下抓物,升高移动物体的情况。机械手的转动,在由齿轮带动固定丝杆的中间件转动而实现的。

关键词:机器车;抓物;丝杆

Abstract

Many things that we humans can not go , because some of these things have been a threat to our life , but the reason we have to go in there . In this case , our machinery will be able to solve these problems. Because it can replace us doing some dangerous operation , to replace manpower to work. Because it can replace us some dangerous operation, to replace manpower to work. We have designed the Grasping machine car that developed in the mechanization and automation of the production process and the robot van combined into one product. So that it can catch things exercise can help people complete the removal of an object or obstacle clearance work in complex terrain or harsh, dangerous environment.

Grasping machine car designed primarily controlled by a wireless communication car forward, backward, or turn. by the screw rotates, driven to move up and down the screw on the nut, and then realize gripper closure through the link structure to realize grasping objects actions . Screw placed vertically, and the arm is fixed on screw nut, stepper motor driven rotary screw, nut meeting next move, the arm will move up and down, which is under the robot moves down to meet the robot grasping objects, elevated movement of the object. Turn the robot, driven by fixed-gear screw rotation middleware

implementation.

Key words: machine car; grasping objects; screw

目 录

引言1

1 设计方案2

1.1 设计内容2

1.2 设计目的2

1.3 方案的选择2

2 机械手的设计3

2.1 抓手结构的设计3

2.2 爪片的设计5

2.3 螺杆的设计7

2.3.1确定螺纹中径8

2.3.2螺杆的强度计算9

2.3.3螺母螺纹牙的强度计算9

2.4 连杆盘的设计10

2.5 套筒的设计11

2.5.1套筒的尺寸11

2.5.2螺栓的选择11

2.5.3螺纹连接的防松13

3 转臂的设计13

3.1 受力分析13

3.2 转臂的尺寸计算14

3.3 螺栓的设计15

3.3.1螺栓组结构设计15

3.3.2螺栓受力分析15

4 滑动丝杆的设计16

4.1 螺纹牙型的选择16

4.2 螺距选择16

4.3 丝杆直径的确定16

4.4 螺杆的强度计算17

4.5 螺母螺纹牙的强度计算17

4.6 丝杆的长度18

4.7 丝杆螺母的传动形式18

4.8 丝杆的固定19

4.9 轴承的选择19

4.10 固定板的设计21

4.10.1固定板的结构22

4.10.2固定架的固定22

5 转盘的设计23

5.1 中间板的设计23

5.2 键的选择25

5.3 齿轮的设计25

5.3.1选定齿轮类型,精度等级,材料及模数25

5.3.2按齿面接触疲劳强度设计26

5.3.3按齿根弯曲疲劳强度设计27

5.3.4几何尺寸计算27

5.4 轴的设计28

6 车身的设计30

6.1 上车身的设计30

6.2 下车身的设计31

6.3 支板的设计35

6.3.1支板的结构35

6.3.2尺寸计算35

6.3.3支板的连接36

6.3.4轮子孔的设计36

7 solidworks的建模和仿真37

8 总结38

谢 辞39

参考文献40

引言

随着社会的进步,社会的分工也越来越细,特别是在现代化的生产中,有的人每天就只能做着同一件事,或者是拧同个部位的某个螺母,或者是接着同一个地方的线头,就像电影《摩登时代》中所演的,由于老是做同一个动作,身体相同的部位得不到休息,于是开始产生了各种职业病。于是人们强烈的希望能有什么东西能代替自己工作而自己不用那么的难受。于是机器人就被发明了出来,并替人完成那些很枯燥、单调、危险的工作。而且,机器人的发明大大的提高了工作效率,提高了工业的发展,为更多的人提供了机会。

机器人的出现,使人们摆脱了那些繁琐、危险的工作。一般的,在有危险,对人体有害的场合,你总能看到他们的身影。如喷漆行业,油漆发出的气味很难闻,那是有毒气体,闻多了会对人体造成难以想象的伤害;还有电焊的场合也是对人眼睛的伤害也很大,也是有了专门用来焊接的机器人。这样的地方很多,在工业里已经屡见不鲜了。特别是在汽车和工程机械行业里,喷漆和焊接那是必不可少的。也正是这些工作对汽车行业的不可或缺,近几年来,国内生产的工业机器人大多是用于服务汽车行业的,也正因为这样,汽车工业的发展也推动了机器人的增长。

在一些对灰尘要求很严的重要场合或者实验室中,一旦灰尘的量超过了标准,就会有废品的出现。例如要在 10级洁净室中制造的电脑重要器件。按国际标准,10级洁净室就是要在一立方英尺内不得出现超过10个以上的直径大于0.5微米的尘埃。100级洁净室就是在一立方英尺内不得出现100个同样大小的尘埃。可就是想进入100级洁净室,工作人员也要换上特制的装备才可以进去,而且,在进去之前的5个小时都不可以使用化妆品或者吸烟等,这条件可见很难做到了。所以10级洁净室也只能由机器来完成了,想进去,条件太苛刻了。

而有些场合,由于被环境的限制,如有放射性物质,被有害气体包围等,我们很难进去,也没法找里面的东西出来研究。于是特制的抓物机器车就很有必要设计出来。

这次设计是基于三维软件Solidworks设计的。该软件的功能很强大,组件也很多。 Solidworks是现在最主流的三维CAD解决方案,因为他具有了功能强大、易学易用、技术创新等特点。 而且SolidWorks可以提供不同的设计方案、减少了设计过程中的错误以便提高产品质量。对工程师和设计者来说,SolidWorks 不仅提供如此强大的功能,操作更是简单方便、易学易用。

1 设计方案

1.1 设计内容

因为是要进行比较精密的抓取物体,所以采用无线通信技术实现对机器车的控制。通过无线接通电机,电机驱动轮子来实现小车的前进、后退与转向。而在小车的上面则是抓物机械手的部件。要实现机械手的上下移动还有一定范围的转动,还有爪片的自由张合。

参考文献

[1] 濮良贵,纪名刚.机械设计(第八版)[M].北京:高等教育出版社,2005

[2] 成大先.机械设计手册[M].北京:化学工业出版社,2004

[3] 《机械设计手册》联合编写组.机械设计于册-下册[M].北京:化学工业出版社,1989

[4] 张彪,叶军等.一种丝杆螺母机构型机械手的设计[J].中国西部科技,2010,(15):31-32.

[5] 孙恒,陈作模.机械原理(第七版)[M].北京:高等教育出版社,2005

[6] 詹友刚. SolidWorks快速入门教程(2012中文版)[M].北京:机械工业出版社,2004

[7] 单辉祖. 材料力学 (第三版)[M].北京:高等教育出版社

[8] 哈尔滨工业大学理论力学教研室.材料力学(第七版)[M].北京:高等教育出版社

[9] 范崇洛.机械加工工艺学.东南大学出版社,2009

[10] ASHBY,M.F..An Introduction to their Properties and Applications Engineering_Materials_2E_VOLUME1 Engineering Materials (2nd ed.) (2 vols.)/Volume 1 (1998)

[11] 胡兆国.机械加工基础.西南交大出版社,2007

[12] 傅水根.机械制造工艺学基础.清华大学出版社,2011

[13] 冯辛安.机械制造装备设计.机械工业出版设,2004

[14] 王春福.机床夹具设计手册.上海科学技术出版社,2000

[15] 冯道.机械零件切削加工工艺与技术标准实用手册

川公网安备: 51019002004831号

川公网安备: 51019002004831号