回转体的工艺规程及工装夹具设计(曲轴零件)

摘 要

本文是通过利用回转体零件诸如曲轴零件的工艺规程及工装夹具设计为例子,完成回转体曲轴零件的数控加工工艺规程设计。

曲轴是柴油发动机的重要零件,它的作用是把活塞的往复直线运动变成旋转运动,将作用在活塞的气体压力变成扭矩,用来驱动工作机械和柴油发动机各辅助系统进行工作。曲轴在工作时承受着不断变化的压力、惯性力和它们的力矩作用,因此要求曲轴具有强度高、刚度大、耐磨性好,轴颈表面加工尺寸精确,且润滑可靠。

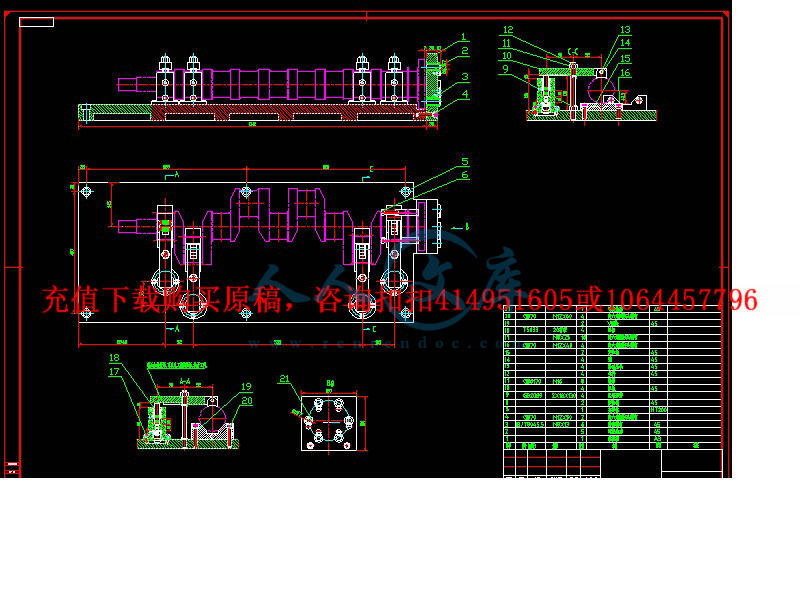

本设计是根据被加工曲轴的技术要求,进行数控加工工艺规程设计,然后运用夹具设计的基本原理和方法,拟定夹具设计方案,完成夹具结构设计。主要工作有:绘制产品零件图和三维建模,了解零件的结构特点和技术要求;根据生产类型和所在企业的生产条件,对零件进行结构分析和工艺分析;确定数控加工工艺过程;拟定零件的数控加工工艺,制定数控加工工艺过程卡,并利用MASTERCAM对工件进行数控编程及模拟,并对曲轴零件进行工装夹具设计并绘制夹具装配图和零件图。

关键词:回转体零件,曲轴,数控加工,夹具

Crankshaft Machining Process And Fixture Design

Abstract

In this paper, through the use of rotary parts, such as process planning and fixture design crankshaft for example, NC machining process planning to complete the rotating crankshaft parts.

Crankshaft is a vital part of the diesel engine. Its role is turning the linear reciprocating motion of the piston into a rotary motion and making the gas pressure acting on the piston into a torque. In that way it can drive working machinery and various auxiliary systems of diesel engines to work. Crankshaft suffer constantly changing pressure, intreia force and their moment of force. Therefor, crankshaft is required to achieve the characteristics such as high strength, stiffness and wear resistance.Meanwhile, the machining size of the journal surface should be precise and lubrication reliable.

Based on the technical requirement of the machined crankshaft, this design includes proceeding mechanical process planning, protocoling fixture design planning and completing fixture design though the basic principles and methods of fixture design. Main tasks include the following. Firstly,draw the product detail drawing and realize the structure of parts and technical requirements. Secondly, carry on structural analysis and process analysis of the parts according to the production type and production conditions. Thirdly,confirm the rough types and the manufacturing methods. Fourthly, protocol the machining process of the parts and select each step of the processing equipment and process equipment and confirm the allowance and step size of each process and then calculate the cutting and fixed working hours of each process. Fifthly,fill in machining process card and so on. Then design the designated special fixtures and draw assembly figure and the figure of major parts.

Key Words: Roatary parts, Cam, CNC, Fixture

目 录

1绪论1

1.1毕业设计的背景及目的1

1.2曲轴制造技术现状与趋势1

1.2.1概述1

1.2.2曲轴制造技术现状2

1.3本设计应解决的主要问题4

1.4零件图5

2零件分析6

2.1零件的作用6

2.2曲轴工艺分析6

3零件的三维建模7

3.1 proe三维软件介绍6

3.2 曲轴零件的三维建模6

4 工艺规程设计7

4.1 确定毛坯的材料7

4.2制定工艺路线8

4.3零件的数控加工工艺分析8

4.4数控加工工艺过程卡片9

5 MASTERCAM数控加工与编程设计7

5.1 MASTERCAM软件介绍7

5.2 MASTERCAM数控车加工工艺过程设计7

6 专用夹具设计16

6.1 工序尺寸精度分析16

6.2 定位方案确定16

6.3 定位元件确定16

6.4 定位误差分析计算17

6.5 夹紧方案及元件确定18

结 论19

致 谢20

参考文献21

1绪论

1.1毕业设计的背景及目的

制造业生产的是具有直接使用价值的产品,而这些产品与社会的生产活动和人民活动息息相关。当今制造业不仅是科学发展和技术发明转换为现实规模生产力的关键环节,并已成为为人类提供生活所需物质财富和精神财富的重要基础。

机械制造工艺与机床极具设计是机械制造工艺与机床夹具教学的一个必不可少的辅助环节。他是学生全面综合运用本课程及有关选修课程的理论联系实际的一次重要实践。他对于培养学生编写机械加工工艺规程和机床夹具设计的能力,及以后到工厂从事工艺与夹具设计具有十分重要的意义。机械制造工艺是机械加工的基础,是机械产品的生产的基本技术,工艺工作是每一个机械企业基本的生活内容,加工工艺技术研究,提高工艺水平,搞好工艺管理是提高机械产品质量,降低消耗的根本措施。此次设计的目的在于:根据被加工零件的技术要求,运用夹具设计的基本原理和方法,制定夹具设计方案,完成夹具设计。

川公网安备: 51019002004831号

川公网安备: 51019002004831号