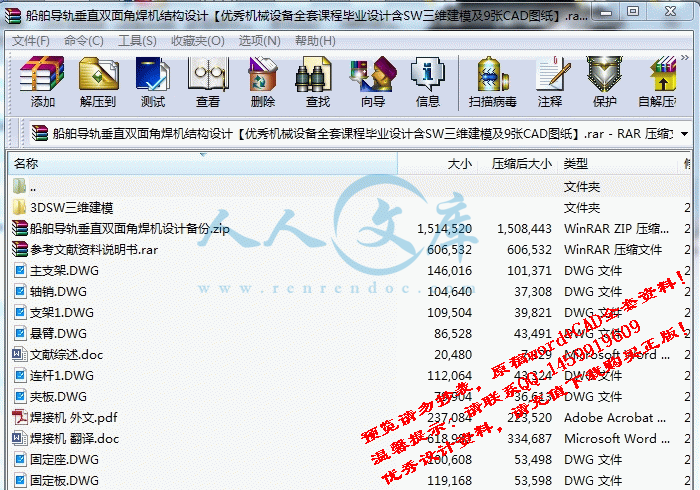

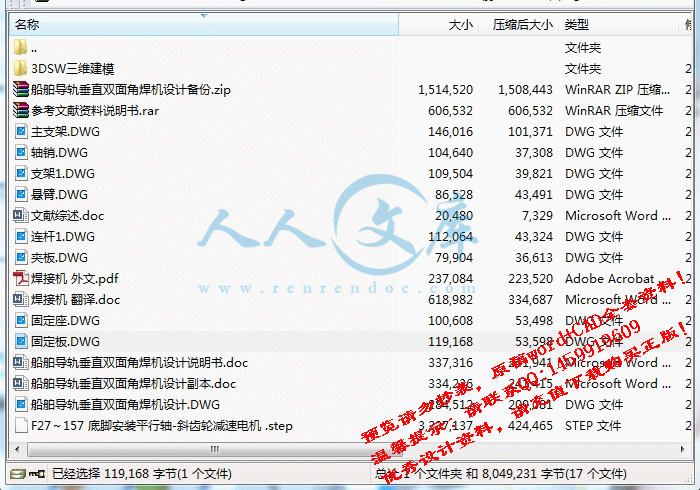

船舶导轨垂直双面角焊机结构设计【优秀机械设备全套课程毕业设计含SW三维建模及9张CAD图纸】

【带文献综述+外文翻译】【27页@正文13300字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

3DSW三维建模

F27~157 底脚安装平行轴-斜齿轮减速电机 .step

主支架.DWG

参考文献资料说明书.rar

固定座.DWG

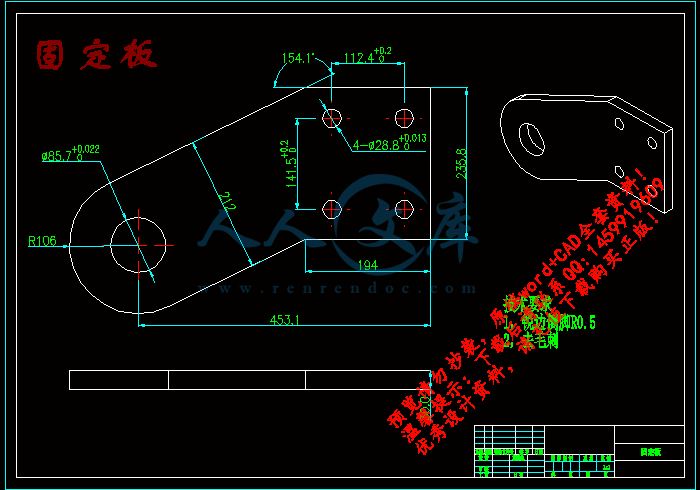

固定板.DWG

夹板.DWG

悬臂.DWG

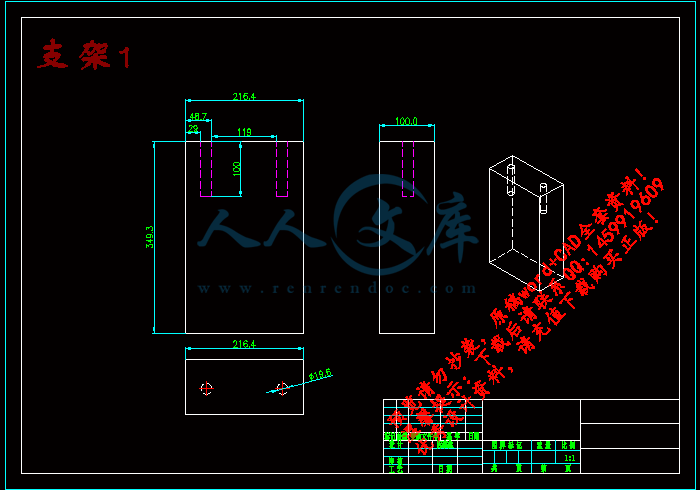

支架1.DWG

文献综述.doc

焊接机 外文.pdf

焊接机 翻译.doc

船舶导轨垂直双面角焊机设计.DWG

船舶导轨垂直双面角焊机设计副本.doc

船舶导轨垂直双面角焊机设计备份.zip

船舶导轨垂直双面角焊机设计说明书.doc

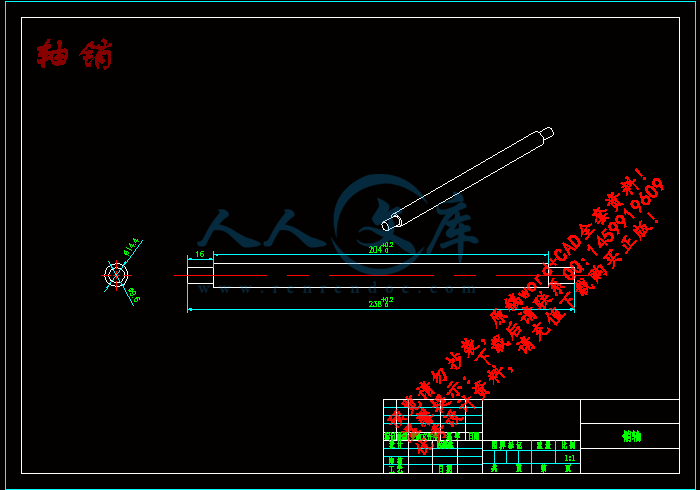

轴销.DWG

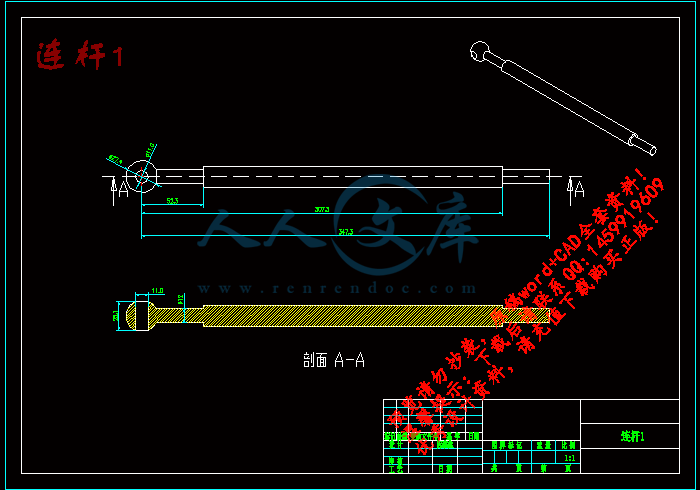

连杆1.DWG

摘要

运输是油气运输中最主要、最快捷、经济、可靠的方式,可用于输送水、原油、天然气、成品油等,具有输量大、距离长、安全性高、成本低等优点,在各国发展迅速。运输业的主体是,工程的核心工作是管口的焊接。因此研究高效率、性能可靠的全位置自动焊接机具有十分重要的意义。

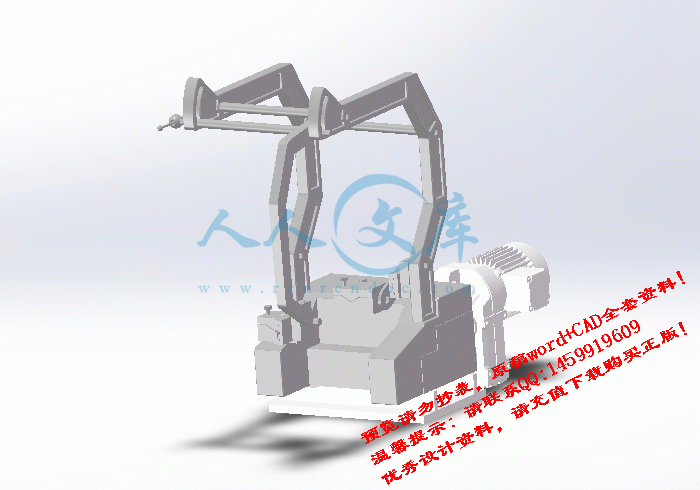

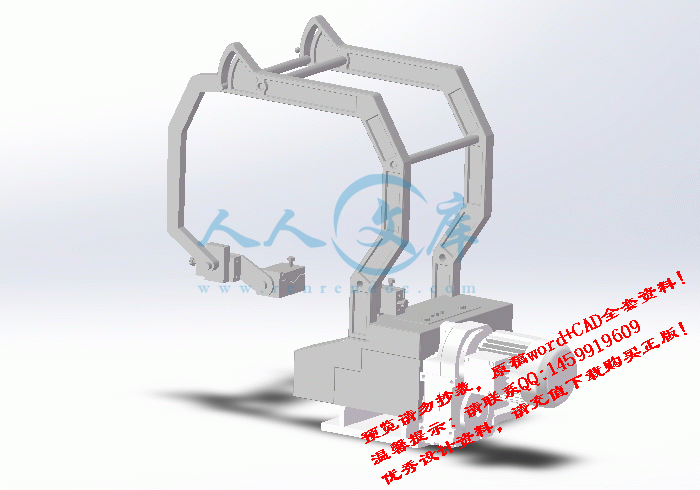

为解决建设野外作业的自动化焊接的难题,研制了一种导轨式焊接机,其关键技术包括:研制新型的行走机构、焊枪摆动机构、及机轨道、焊枪机械手。介绍了导轨式焊接机结构的设计和焊接机控制,着重对其结构特点、动作原理、设计要点进行设计分析和说明。现场应用表明,该机能沿导轨平稳、可靠的行走,进行全位置焊接,其操作简便,成本低,适合我国现场施工作业及工人的技术水平,既保证了焊接质量,又提高了劳动效率。

关键词:轨道式焊接机 ;结构设计; ;机械手

Abstract

Pipeline transportation is the most important, quickest, economical and reliable method in petroleum transportation. It can transport water, crude oil, natural gas, oil product etc. It has a number of advantages: high transmission volumes, long distance, safety and cost-effectiveness, which is rapid developed in all the world. The subject of pipeline transportation is pipeline; the core of pipeline project is nozzle welding. So, it has very important significance to develop high efficient and reliable performance pipeline all-position automatic welding machine.

An orbit pipeline welding robot has been developed to solve the problem of automatic welding during pipeline construction in the fields. Its key techniques consist of developing a new type of travel unit, welding torch as cillating unit, robot orbit and intelligent control system etc. The development work of the orbit pipeline welding robot mechanic system is introduced in the paper. The main illustration is about the system's structure,action principle,key points of design and machining technies and verifying calculation for selecting reduction gearbox with the wire feeder motor and the diameter of the wire-feed wheel. The application in fieldwork shows that the robot can trave1 along the orbit stably and reliably and carry through all-position welding. The welding is easy with low cost that is fit for fieldwork and worker in our country,guarantees the welding quality and improve working efficiency.

Keywords: Orbital welding machine ;construction design ;pipeline; Manipulator

目 录

摘要1

Abstract2

1. 绪 论5

1.1课题背景及研究意义5

1.2船舶导轨垂直双面角焊机的发展及应用5

1.2.1焊接机的发展历程5

1.2.2焊接机国内外应用现状6

1.2.3焊接机技术展望7

1.3船舶导轨垂直双面角焊机的研究现状8

1.3.1船舶导轨垂直双面角焊机国外研究现状8

1.3.2船舶导轨垂直双面角焊机国内研究现状9

2.船舶导轨垂直双面角焊机总体结构设计11

2.1自动焊接机总体要求和技术指标11

2.2 自动焊接机总体方案的确定11

2.3 自动焊机的设计基本思路12

2.4小车行走机构12

2.4. 1 基本工作原理12

2.4.2 行走机构车体设计要点13

2.4.3 行走机构滚动组件的设计要点13

2.5 焊丝送进机构14

2.6 焊枪摆动机构15

2.7 焊接轨道15

2.8行走机构的设计计算16

2.8.1 等效负载转矩计算17

2.8.2 等效转动惯量的计算18

3 焊接小车行走机构的机械传动19

3.1 电机的选择20

3.2 减速器的结构及传动比21

3.3 送丝机构的机械传动21

3.3.1 送丝电机的选择21

3..3.2 减速器23

3.4 焊枪姿态调整机构的机械传动23

3.4.1 电机的选择23

4. 结 论25

参考文献25

致 谢26

1. 绪 论

1.1课题背景及研究意义

船舶焊接技术是我国现代造船模式中的关键技术之一,船舶工业把缩短造船周期作为永恒的主题“要缩短造船周期必然要提高生产效率,正如古人云‘工欲善其事,必先利其器’”,先进的造船高效焊接技术,在提高船舶的建造效率、降低船舶建造成本、提高船舶建造质量上的作用是不可小视的,也是企业提高经济效益的有效途径。

采用先进的船舶高效焊接技术还会涉及船舶制造中的工艺设计、计算机数控下料、小合拢、中合拢、大合拢、平面分段、曲面分段、平直立体分段、管线法兰焊接、型材部件装焊等工序和工位的焊接工程,同时也会牵动着与之相关的焊接产业链,如钢铁、金属加工、金属热切割、焊材、焊剂、保护气体、无损探伤、焊接接头性能与质量评估、焊接电源、焊接能源、电子控制系统、焊接专用自动化工装、焊接辅器具和环保、焊工技能培训、焊接质量管理与控制、焊接接头设计、焊接标准与规范等,由此可见船舶焊接技术在船舶制造中占有重要的地位,是一项技术性、专业性很强的系统工程。为此,在我国两大船舶集团公司的领导下于1986年组建了船舶工业高效焊接技术指导组,开展了规划、决策、指导、协调、咨询和信息交流等方面的有效活动,圆满地完成了“十五”提出的推广应用高效焊接技术的各项指标,提高了我国造船焊接技术的水平。目前,船舶建造中CO2气体保护半自动焊接技术已在船厂广泛应用,其应用率达到60%~65%。

1.2船舶导轨垂直双面角焊机的发展及应用

1.2.1焊接机的发展历程

自1959年美国推出世界上第一台Ultimate型机以来,工业机的数量在世界范围内不断增长,通常他们用在焊接、喷涂、变薄拉伸、装配、拾取搬运、检测和测量中,其中有半数为焊接机。在重工业的很多领域中,大直径环缝焊需要高劳动强度的手工焊,这对操作者来说需要有严格的技能要求和集中力。由于人们对焊接柔性和焊接产量的高需求和高要求,自动焊接机就为很多工业领域提高焊接速度尤其是提高焊接质量提供极大的可能。到目前为止,焊接机大致可分为三代:第一代是基于示教再现工作方式的焊接机,由于操作简便,不需要环境模型,示教时可修正机械结构带来的误差等特点,在焊接生产中得到大量使用;第二代是基于一定传感器信息的离线编程焊接机;第三代是指装有多种传感器,接受作业指令后能根据客观环境自行编程的高度适应智能机。焊接机主要从事弧焊和点焊工作。弧焊机大多采用二氧化碳或二氧化碳与氩、氮混合气体保护。焊接机的结构型式,主要有多关节型、直角坐标型、极坐标型和圆柱坐标型四种。点焊机以直角坐标型较多;弧焊机以多关节型居多。弧焊机工作机构一般较点焊的复杂,通常具有五个以上的自由度。目前功能较完善的焊接机已具有七个自由度。我国目前研制的焊接机,一般均为五个自由度。国外为了提高工件(特别是大型工件)的焊接生产率,十分重视辅助设备的自动化水平,如配备自动更换喷嘴,供应焊丝,监视电弧和过程异常等功能的机构。

参考文献

1机械设计手册编委会.机械设计手册.北京:机械工业出版社,2004.

2 成大先.机械设计手册(机械传动).北京:化学工业出版社,2004.

3 焦向东等.球罐外圆焊接机智能控制系统.焊接学报,2000,21(4):1~4.

4 朱进满.焊接机的应用[J].现代制造,2005,12:42~47.

5 W.-S Yoo,J.-D. Kim,S.-J. Na.A Study on A Mobile Platform-manipulator Welding System for Horizontal Fillet Joints[J].Mechatronics,2001,11:853~868.

川公网安备: 51019002004831号

川公网安备: 51019002004831号