金刚石线锯切割机设计

【摘要】 本文对金刚石线锯切割机进行了深入的研究。在理论上探讨了单晶硅各异性材料特性对电镀金刚石线锯切割硅晶片过程影响。分析了锯丝沿不同的晶面、晶向锯切对晶片的影响规律,并推荐了首选的锯丝切入方向。研究发现,在确定的工艺参数下,当锯丝切入方向使锯切两边材料的弹性模量分布关于锯丝切入方向呈对称性时,可有效地提高晶片面形质量。锯丝切入方向与被锯切晶面内的易开裂方向一致时,可有减少晶片表面破碎。

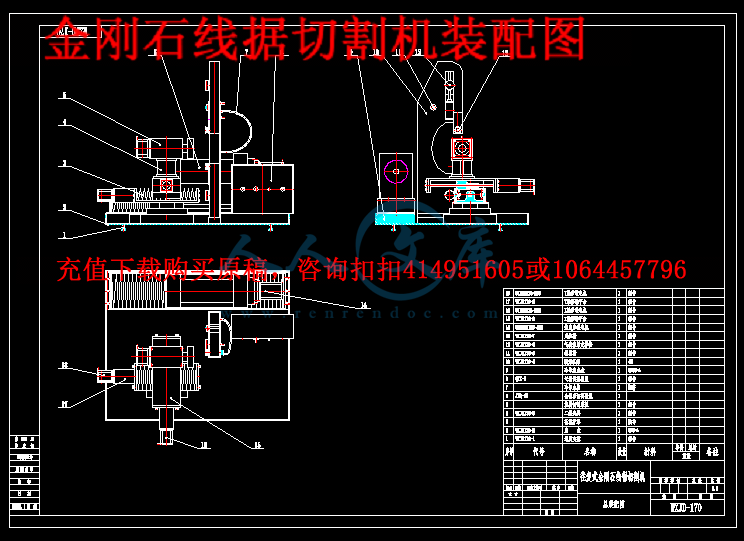

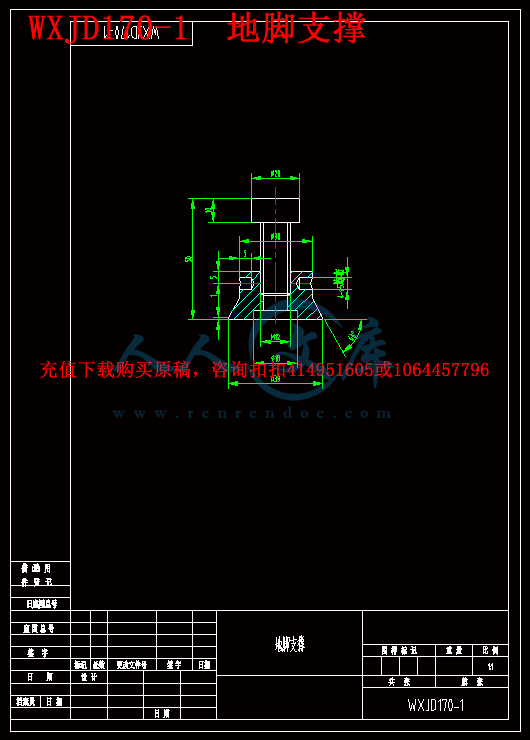

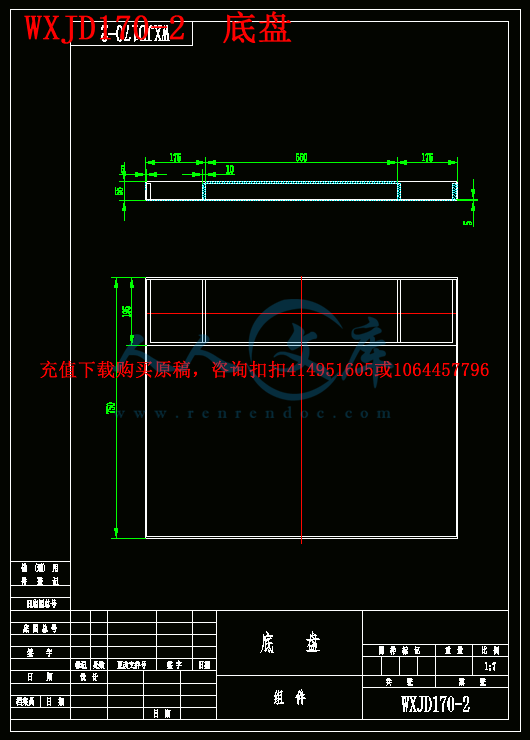

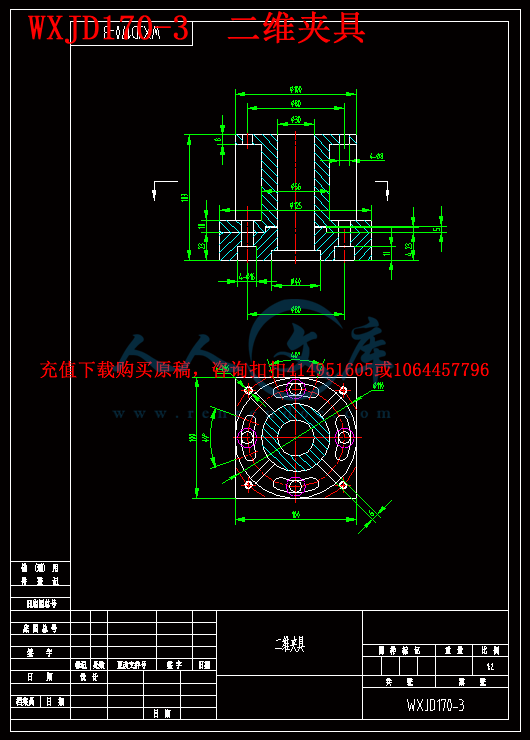

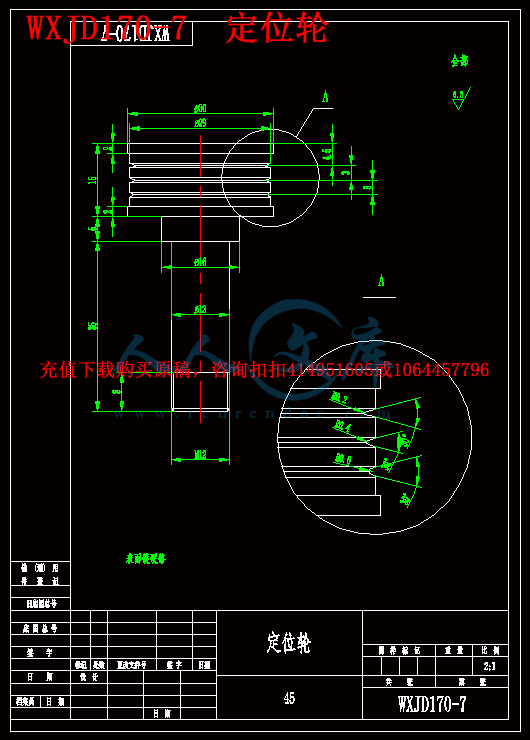

本课题主要对切割机导轨平台、工件夹具、缠绕筒及切割线张力调整装置的结构设计。通过搜集相关文献资料,了解本课题国内外研究动态,确定设计研究方案;完成金刚石线锯切割机滚珠丝杠、螺母、步进电动机、螺母等相关零部件及装配图的设计;完成相关零部件设计说明书及其图纸。

【关键词】 金刚石;线锯切割机;导轨平台

Design of Diamond Wire Cutting Machine

【Abstract】 In this paper, diamond wire saw cutting machine has conducted in-depth research. In theory of monocrystalline silicon anisotropic material properties of electroplated diamond wire saw cutting silicon wafer process affect. Wire sawing along the crystal surface, crystal and recommend a preferred saw Siqie into the direction of the influence of sawing the wafer. The study found that, when the saw wire into the direction of the cutting material on both sides of the elastic modulus distribution symmetrical saw cut wire into the direction, which can effectively improve the quality of the wafer surface shape to determine the process parameters. The saw wire into the sawing crystal surface easy to crack the same direction, the direction, may have to reduce the wafer surface broken.

The main subject of the cutter rail platform, work holding, reel and cutting thread tension adjusting device structure design. Through the collection of relevant literature, research trends about this topic, and to determine the design of research programs; completion of the diamond wire saw cutting machine ball screws, nuts, stepper motors, nuts and other related parts and assembly drawings of design; complete the relevant parts design specification and its drawings.

【Key Words】 Diamond;Wire Saw Cutting Machine;Rail Platform

目 录

1 绪 论1

1.1 概述1

1.2 国内外研究现状及发展趋势1

1.3 金刚石线锯切割机的简介4

2 金刚石线锯切割机的设计方案5

2.1 有关首选参数5

2.2 切割机特点6

2.3 金刚石线锯切割机设计方案6

2.3.1 原理分析和总体结构设计7

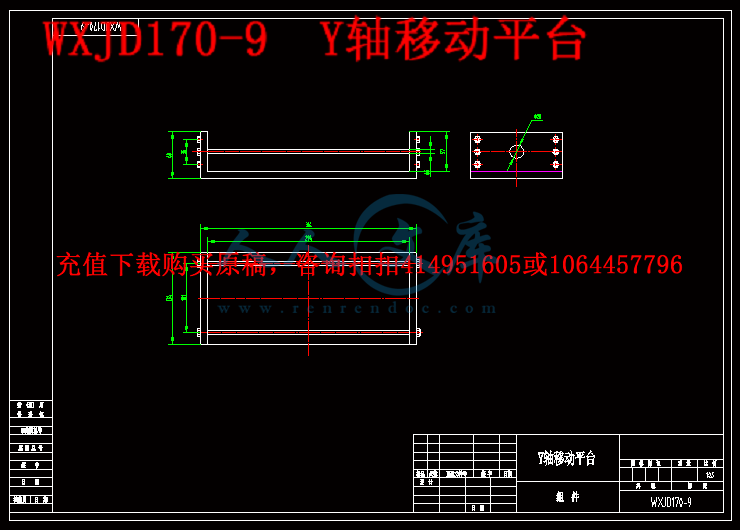

2.3.2 传动系统和工作台的设计7

2.3.3 张力调整装置设计8

3 金刚石线锯切割机传动设计10

3.1 滚珠丝杆的选择与计算10

3.1.1 滚珠丝杆的定义10

3.1.2 滚珠丝杆副间隙调整法11

3.1.3 滚珠丝杆的循环方式13

3.1.4 滚珠丝杆的计算14

3.1.5 滚珠丝杆安装方式17

3.2步进电动机的选择18

3.3张紧轮设计21

3.4绕线轮的设计25

3.5二维夹具的设计27

结 论28

参考文献29

致 谢30

1 绪 论

1.1 概述

脆性材料,如单晶硅、多晶硅、宝石、玻璃、陶瓷等,具有优良、稳定的物理和化学性能耐磨损性、抗腐蚀性、电绝缘性等,在电子、光学及其它领域得到广泛应用,特别是单晶硅、多晶硅、陶瓷材料被广泛用于太阳能光伏产业、半导体、真空电镀等高精端产业中。伴随半导体、光伏材料技术的发展,需求量不断增加,切割加工量大幅增长,由于硬脆材料硬度高、脆性大,因此加工难度较大。锯切是硬脆材料机械加工的第一道工序,锯切加工成本约占加工总成本的50%以上,因此,切割工艺、工具及设备受到越来越广泛的关注,并得到迅速发展[1]。金刚石线锯切割机是近十几年来获得快速发展的一种硬脆材料切割设备,包括使用游离磨料和固结磨料两类。根据锯丝的运动方式和机床结构,也可分为往复式和单向线锯。金刚石线锯使用高硬度的金刚石作为磨料,其典型磨粒尺寸为数十个微米,同时具备线锯切割的特点,能够对硬脆材料进行精密、窄锯缝切割,且可实现成形加工。随着在大尺寸半导体和光电池薄片切割中的应用和发展,金刚石线锯逐渐显现出一系列无可比拟的优点:加工表面损伤小、挠曲变形小,切片薄、片厚一致性好,能切割大尺寸硅锭,省材料、效益高,产量大,效率高等[2]。

川公网安备: 51019002004831号

川公网安备: 51019002004831号