摘要

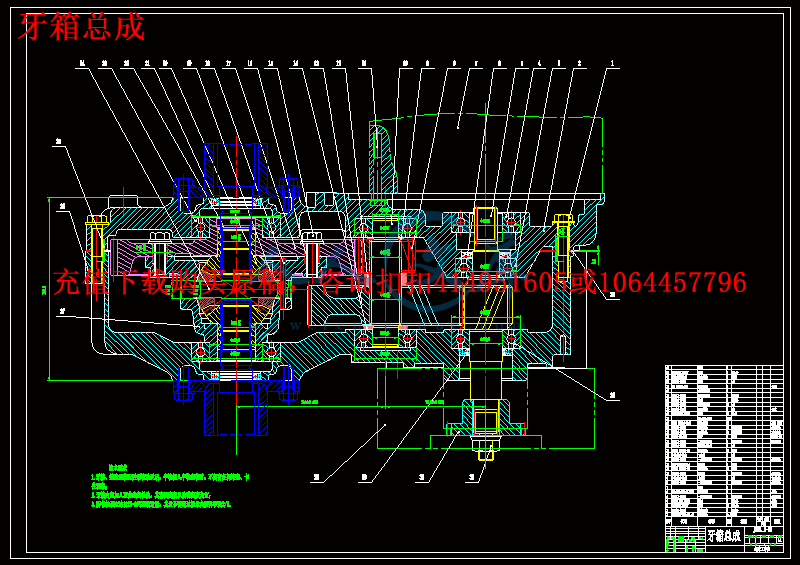

高尔夫球车后桥(驱动桥)作为汽车四大总成之一,它承载着高尔夫球车的满载荷负重及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;后桥(驱动桥)还传递着传动系中的最大转矩,桥壳还承受着反作用力矩。高尔夫球车驱动桥结构型式和设计参数除对汽车的可靠性与耐久性有重要影响外,也对汽车的行驶性能如动力性、经济性、平顺性、通过性、机动性和操动稳定性等有直接影响。另外,高尔夫球车驱动桥在汽车的各种总成中也是涵盖机械零件、部件、分总成等的品种最多的大总成。例如,驱动桥包含主减速器、差速器、驱动车轮的传动装置(半轴及轮边减速器)、桥壳和各种齿轮。由上述可见,高尔夫球车驱动桥设计涉及的机械零部件及元件的品种极为广泛,对这些零部件、元件及总成的制造也几乎要涉及到所有的现代机械制造工艺。本文参照传统驱动桥的设计方法进行了高尔夫球车驱动桥的设计。本文首先确定主要部件的结构型式和主要设计参数;然后参考类似驱动桥的结构,确定出总体设计方案;最后对一二级主,从动圆柱齿轮,半轴齿轮和全浮式半轴强度进行校核以及对支承轴承进行了寿命校核。

本设计有以下两大难题,一是将发动机输出扭矩通过万向传动轴将动力传递到后轮子上,达到更好的车轮牵引力与转向力的有效发挥,从而提高载重汽车的行驶能力。二是差速器向两边半轴传递动力的同时,允许两边半轴以不同的转速旋转,满足两边车轮尽可能以纯滚动的形式作不等距行驶,减少轮胎与地面的摩擦。

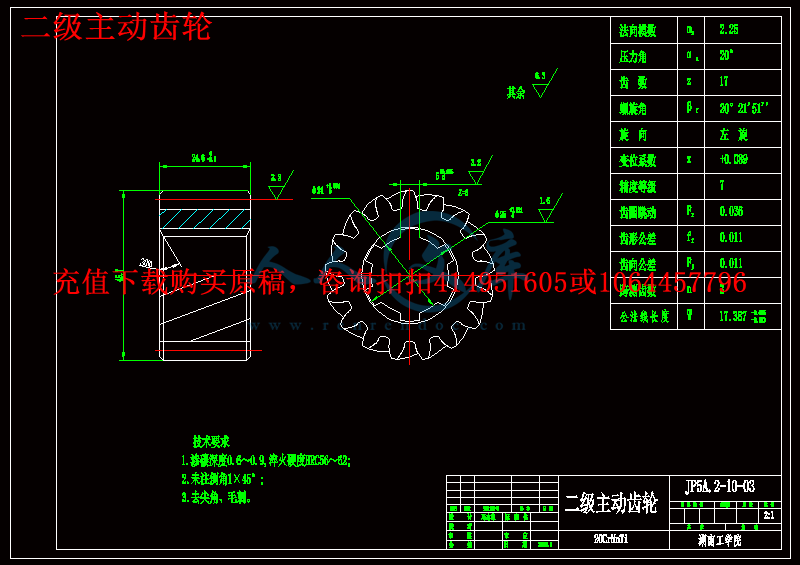

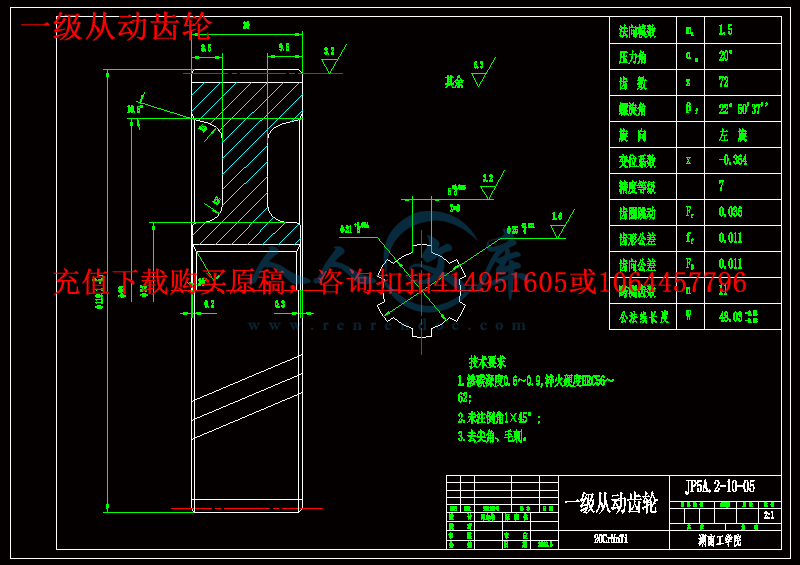

本设计具有以下的优点:由于的是采用二级圆柱斜齿轮主减速器,使得整个后桥 的结构简单,制造工艺简单,从而大大的降低了制造成本。并且,提高了传动的可靠性。

本设计的最大特点是:主减速器是采用传统的圆柱斜齿轮减速器,与其他的齿轮相比,具有工作平稳,噪音和振动小的优点,且经济性好。

关键词:高尔夫球车;后桥;二级主减速器;圆柱斜齿轮

Summary

The bridge(drive bridge) is a car after the golf car four greatly always become of a, it loads the capacity load lotus of golf car negative heavy and ground through car wheel, car and loading type carriage through hang the vertical dint that gives, lengthways dint, horizontal dint and its dint Ju, and the impact carries a lotus;The empress bridge(drive bridge) still delivers to spread to move to fasten medium biggest turn Ju, the bridge hull still bears recoil Ju.The golf car drives bridge structure pattern and in addition to having important influence to the credibility and durable of the car, design parameter also to driving of car the function is like motive, economy, going smoothly and pass sex, flexibility and hold to move stability etc. to contain direct influence.Moreover, the golf car drives bridge in the car of various always become in is also that the species that covers machine spare parts, parts and cent to always become etc. is at most greatly total.For example, drive bridge containment, the lord decelerates a machine, bad soon machine, drive felloe to spread to move device(half stalk and round side decelerate machine), bridge hull and various wheel gear.From above-mentioned it is thus clear that, the golf car drives the species of machine zero partses and components that the bridge design involves extremely extensive, also almost want to involve all modern machine manufacturings a craft to these zero partses, components and the manufacturing always becoming.This text according to the design method that the tradition drives bridged to carry on the design that the golf car drives bridge.This text makes sure the structure pattern and main design parameter of main parts first;Then make reference to similar drive the structure of bridge, make sure a total design of of project;Finally to 12 class lords, from move cylinder wheel gear, half stalk the wheel gear and the whole float type half stalk strength carry on pit in the school and accept bearings to carry on pit in the life span school towards paying.

This design contains following two greatest hard nut to crackses, one is twist motor exportation the Ju pass ten thousand to spread to move stalk to deliver the motive to behind wheel up, attain better car wheel to lead dint with change direction effective exertion of dint, thus exaltation carry heavy car of drive ability.Two is bad soon while machine is delivering motive toward the both sides half stalk, allow both sides half stalk with dissimilarity of turn to soon revolve, satisfy both sides car wheel possibly with purely roll over of the form make not etc. be apart from to drive, reduce the friction of tire and ground.

This design has a following advantage:Because of is adopt a second class cylinder wheel gear lord to decelerate a machine and make whole after the structure of the bridge simple, manufacturing the craft is simple and thus and consumedly lowered a manufacturing cost.And, raised to spread dynamic credibility.

The biggest characteristics of this design is:The lord deceleration machine adopts traditional cylinder wheel gear to decelerate a machine and have to work compared with other wheel gears steady, noise and vibrate a small advantage, and economy good.

Key word:Golf car;Empress bridge;The second class lord decelerates a machine;Cylinder wheel gear

目录

前言5

1 高尔夫球车发展简介6

1.1.1 国内电动车行业发展现状6

1.1.2 国内电动车行业发展前景7

2 主减速器设计9

2.1 主减速器的结构形式9

2.1.1 主减速器的齿轮类型9

2.1.2 主减速器的减速形式10

2.1.3 主减速器主,从动锥齿轮的支承形式10

2.2 主减速器的基本参数选择与设计计算10

2.2.1 电机的选择10

2.2.2 主减速器传动装置的总传动比及其分配11

2.2.3 主减速器传动装置的运动和动力参数计算12

2.2.4 主减速器圆柱齿轮零件的设计计算13

2.2.5 主减速器轴的设计及其计算21

2.2.6 主减速器轴承寿命的校核34

2.2.7 润滑与密封37

结论39

参考文献40

致谢41

前言

汽车后桥(驱动桥)位于传动系的末端。其基本功用首先是增扭,降速,改变转矩的传递方向,即增大由传动轴或直接从变速器传来的转矩,并将转矩合理的分配给左右驱动车轮;其次,驱动桥还要承受作用于路面或车身之间的垂直力,纵向力和横向力,以及制动力矩和反作用力矩等。驱动桥一般由主减速器,差速器,车轮传动装置和桥壳组成。

对于高尔夫球车来说,要传递的转矩较乘用车和客车,以及轻型商用车都要小得多,以便能够在高尔夫球场上行驶,所以选择功率较小的发动机,对传动系统的要求不是很高,而驱动桥在传动系统中起着举足轻重的作用。随着目前国际上石油价格的上涨,汽车的经济性日益成为人们关心的话题,所以电瓶装置驱动的电力车就成了新型的贵族,而设计相适应的经济性高的传动机构就显得尤其重要了。

设计后桥时应当满足如下基本要求:

1)选择适当的主减速比,以保证高尔夫球车在给定的条件下具有最佳的动力性。外廓尺寸小,保证高尔夫球车具有足够的离地间隙,以满足通过性的要求。

2)齿轮及其他传动件工作平稳,噪声小。

3)在各种载荷和转速工况下有较高的传动效率。

4)具有足够的强度和刚度,以承受和传递作用于路面和车架或车身间的各种力和力矩;在此条件下,尽可能降低质量,减少不平路面的冲击载荷,提高汽车的平顺性。

5)与悬架导向机构运动协调。

6)结构简单,加工工艺性好,制造容易,维修,调整方便。

在本设计中还采用了CAD绘图软件分别进行了工程图的绘制,运用CAD绘制了、行星齿轮轴以及传动机构半轴的零件图,通过对CAD的编辑工具与命令的运用,掌握了从CAD基础图形的绘制→基础零件的绘制→各类零件图的创建与绘制的方法,并且理解了机械图绘制的工作流程,为今后更好的学习和掌握各种应用软件和技能打下坚实的基础。

川公网安备: 51019002004831号

川公网安备: 51019002004831号