目 录

第一章 设计原则及设计依据

1.1设计依据………………………………………………………………(1)

1.2 设计原则………………………………………………………… (1)

第二章 国内外客车行业现状及形势分析

2.1国外大中型客车行业技术特点………………………………………(2)

2.2我国客车行业的现状…………………………………………………(2)

2.3现代客车行业的未来发展趋势………………………………………(4)

2.4我国客车行业近两年产销状况 …………………………………… (5)

2.5大中型客车行业的发展中的问题 ………………………………… (6)

2.5.1大中客车类上市公司透视…………………………………………(7)

2.5.2大中型客车市场分析………………………………………………(9)

2.6大中型客车上市公司现状分析………………………………………(10)

第三章:总布置设计

3.1车身总体尺寸及车身结构确定………………………………………(13)

3.1.1车身总体尺寸………………………………………………………(13)

3.1.2车身结构确定………………………………………………………(13)

3.2车身内部尺寸确定……………………………………………………(16)

3.2.1驾驶区布置及尺寸确定……………………………………………(16)

3.2.2乘客区布置及尺寸确定……………………………………………(17)

3.3主要总成及附件………………………………………………………(17)

3.4总体特点………………………………………………………………(18)

第四章 整车性能计算

4.1整车整备质量、满载质量、重心位置及轴荷分配计算………………(19)

4.2整车参数………………………………………………………………(23)

第五章 动力性和燃油经济性的计算

5.1动力性计算

5.11汽车驱动力……………………………………………………………(24)

5.12汽车行驶阻力…………………………………………………………(25)

5.13汽车行驶加速度………………………………………………………(26)

5.14汽车行驶坡度角………………………………………………………(26)

5.2燃油经济性的计算………………………………………………………(28)

第六章 驾驶员视野校核计算

6.1概论……………………………………………………………………(29)

6.2眼椭圆样板的制作……………………………………………………(29)

6.3眼椭圆样板在车身视图上的位置的确定……………………………(29)

6.4校核结果………………………………………………………………(30)

第七章车轮跳动校核……………………………………………………………(31)

第八章 存在的问题与解决的途径……………………………………… (32)

结论………………………………………………………………………… (33)

致谢…………………………………………………………………………(34)

主要参考文献……………………………………………………………………(35)

附录…………………………………………………………………………(36)

摘 要

随着国民经济快速增长,人民物质生活水平的不断提高,国内公路网络越来越发达,人们出行对安全、舒适的高性能客车需求日益增长。但我国的大多数人都住在农村,经济发展水平很不平衡,随着城市化进程的加快,以及我国逐步步入老龄化社会,这些事实都预示着这样一个结果:发展中低档城乡间的中型客车在我国有很大的优势。为满足国内市场的需要,适应用户对经济、环保客车的需求,并在对国内市场进行调研的基础上,设计和开发出这款中型客车。

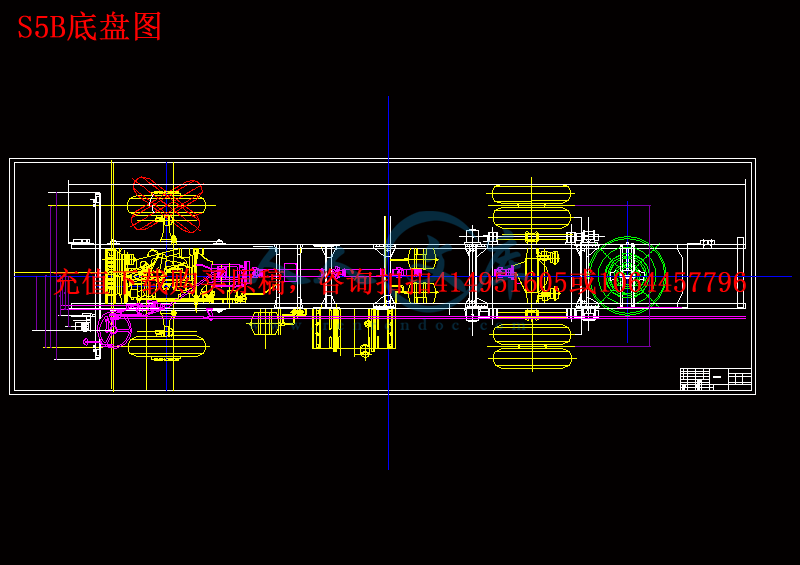

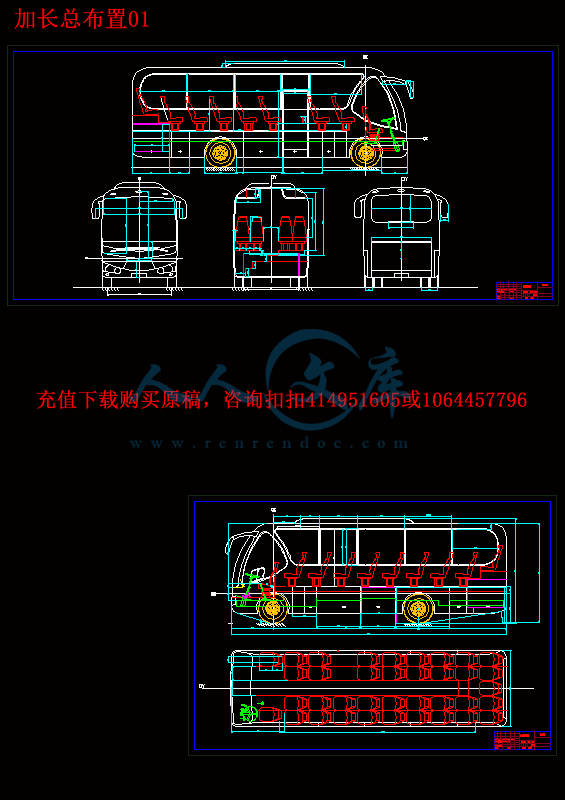

中型客车按中型中级标准设计,主要用于城乡之间公路客运。设计为36+1座,最大满足第三类车型的座椅要求,提高客车营运的经济性。中型客车的开发思路是侧重于经济性、实用性和可靠性,利用S5B底盘进行设计,设置大容量油箱及规格行李仓(3.30立方米),车内采用软装饰减震消音材料,实现车内空间宽敞。在适应用户需要及法规要求的前提下,合理选择各总成配置及结构设计,尽量采用通用结构,通过降低成本和提高客车经济性增加市场竞争力。本论文简要地介绍了此中型客车的设计目的,主要的结构特点、参数和技术参数。

关键词 长途汽车,结构参数,技术参数

ABSTRACT

Nowadays our China has a very quick increasing of economy and the quality of life of we Chinese has improved rapidly, and the net of highway is forming day by day, thus the traveling people’ requirements of safe and comfortable coach is also increasing day by day. But the truth is that the majority of people live in countryside, the economic level is imbalance. For another, there is a trend of forming city in China and our society will have more and more old people. All these facts predict that semi-low coach will have a superiority in domestic market. In order to meet the demand of economic and ‘green’ coach in our market, we design EQS5B coach in terms of study domestic market.

We design EQS5Bby the standard of middle-class and aiming to travel these people from city to country. The coach has 36+1 seats and trys to satisfy the demand of class 3 style’ requirements for its seats and hit the target of ‘low price’. The principle of design this coach is to have more economic and practicality and reliable characters. Our chassis is EQS5Band we try to equip fitting gasoline tank and baggage box (nearly 3 stere). We have flexible material to decorate the inner of coach body and try to achieve an abundant space inside the coach. We make great effort to use current configuration and enhance our competitive ability by the way of decreasing price and making more economic character of the coach. This paper briefly introduces the design purposes, main structure characteristics and technical parameters about EQS5B coach.

KEY WORDS coach, structure parameters, technical parameters

绪论

随着国民经济快速增长,人民物质生活水平的不断提高,国内公路网络越来越丰富,人民出行对安全、舒适的高性能客车需求日益增长。但我国的大多数人都住在农村,经济发展水平很不平衡,随着城市化进程的加快,以及我国逐步步入老龄化社会,这些事实都预示着这样一个结果:发展中低档大型客车在我国有很大的优势。为满足国内市场的需要,适应用户对经济、环保客车的需求,并在对国内市场进行调研的基础上,设计和开发出EQS5B中型客车。

国外企业十分看好我国中高档大中型客车市场,是因为国内客车行业合资和引进的产品现在已基本和国外原装产品处于同一档次,且价格具有明显优势,这迫使以赚取利润为目的的国外企业更加在中国积极寻找合资、合作的机会。这也将给我国客车生产企业带来参加国际合作、参与国际竞争的机遇。

中国入世,在对我国大中型客车行业增加竞争压力的同时,必然也对外国企业进入中国市场参与竞争增大了压力。入世前,外国整车和零部件公司被高关税等保护措施挡在国门之外,入世后,他们将会涌入我国市场寻求合作伙伴和发展空间。他们中有的已经成立合资企业,或以技术合作方式在华建立起了桥头堡、大本营。我国入世后将在项目投资、技术转让、市场营销、售后服务体系等方面的政策变得更灵活。这无疑给我国大中型客车企业提供了与国外跨国公司再次联系的机遇,并借用外方国际贸易的关系,进入国际市场,从而增加步入国际大循环的机会,提升出口的能力,增融入全球化体系的可能,为我国客车工业的健康发展提供了更大的空间。

我们因该有自己的特点,设计开发出有自己特色的汽车,这样才会在全球市场一体化中有自己的优势。目前国内外各大汽车公司都忽略了中型中低端客车这一块,这正好为我们提供了机会;另一方面,对于我们这样的经济上不发达国家来说,开发这样中型客车也是社会公益事业的一部分。

本中型客车按中型中级标准设计,主要用于城乡之间公路客运。设计为36+1座,最大满足第三类车型的座椅要求,提高客车营运的经济性。本中型客车的开发思路是侧重舒适性、实用性和可靠性,利用S5B底盘进行设计,设置大容量油箱,车内采用软装消音减震饰材料,实现车内空间宽敞。在适应用户需要及法规要求的前提下,合理选择配置及结构设计,尽量采用大曲面圆弧结构,是整车曲线流畅,美观大方,动感效果好。通过降低成本和提高客车经济性增加市场竞争力。

川公网安备: 51019002004831号

川公网安备: 51019002004831号