摘 要

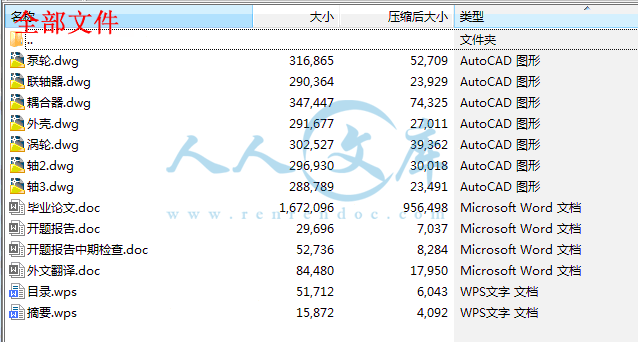

本次设计的闭锁式液力耦合器可以有效的弥补这方面的缺陷。闭锁式液力耦合器就是在限矩形液力耦合器上加装离心式摩擦离合器组成。其结构使用静压泄液力耦合器的腔型,这样有侧辅腔有足够的空间来放置离心式摩擦离合器而不影响涡轮和泵轮的工作,并采取复合泄液力耦合器的内轮传动式结构。动力通过两路传递:一路以液力传动方式通过外壳~泵轮—涡轮~输出轴,另一路以摩擦离合器方式通过外壳~摩擦离合器~输出轴。随着涡轮转速的升高,摩擦离合器传递的力矩与n成比例的增长,其值在总力矩中的比值也相应增长,当涡轮转速超过某值以后,全部力矩呦摩擦离合器传递,液力传动不再起作用,这时消除了转差损失而成为“直接转动”,传动效率达100%。

关键字:限矩型、静压泄液式、内轮传动、闭锁式、摩擦离合器

ABSTRACT

The closure of the design of hydraulic coupling can effective type for the defects. Atresia type hydraulic coupling in rectangular hydraulic coupling is limited on centrifugal friction of the clutch. The structure of the static pressure hydraulic coupling use discharge cavity type, so have the auxiliary chamber has enough space to place centrifugal friction clutch and does not affect the turbine and pump wheels work, and take composite relief of hydraulic coupling in wheel drive type structure. Power through the two road transfer: all the way through the shell with hydraulic drive to pump wheels-turbine ~ output shaft, and the other all the way to the friction clutch way through the shell ~ ~ friction clutch output shaft. With the rise of turbine speed, friction clutch transmission torque and n proportional growth, the value of the total torque ratio also corresponding growth, when turbine speed exceeds a certain value after, all round torque friction clutch transmission, hydraulic transmission no longer function, then eliminate the turn and become poor loss "direct turn", the transmission efficiency of 100%.

Key word: limited moment type, static pressure relief liquid type, the inner drive, locking type, friction clutch

前 言1

第一章 液力偶合器的基础知识3

1.1 传动机构及液力传动3

1.2 液力传动的基本原理4

1.3 液力传动的分类4

第二章 液力偶合器的工作原理6

第三章 闭锁式液力偶合器的结构9

3.1 液力偶合器的分类9

3.2 限矩型液力偶合器12

3.2.1 静压泄液式液力偶合器13

3.2.2 动压泄液式液力偶合器14

3.2.3 复合泄液式液力偶合器15

3.2.4 闭锁式液力偶合器17

第四章 闭锁式液力偶合器的参数设计20

4.1 设计原始参数及其分析20

4.1.1 所传功率和转速20

4.1.2 额定转速比与效率20

4.2 工作腔型参数设计及其选择21

4.2.1 液力偶合器有效直径D的确定21

4.2.2 工作腔模型选择及设计22

4.2.3 轮叶设计24

4.2.4 挡板的设计选择26

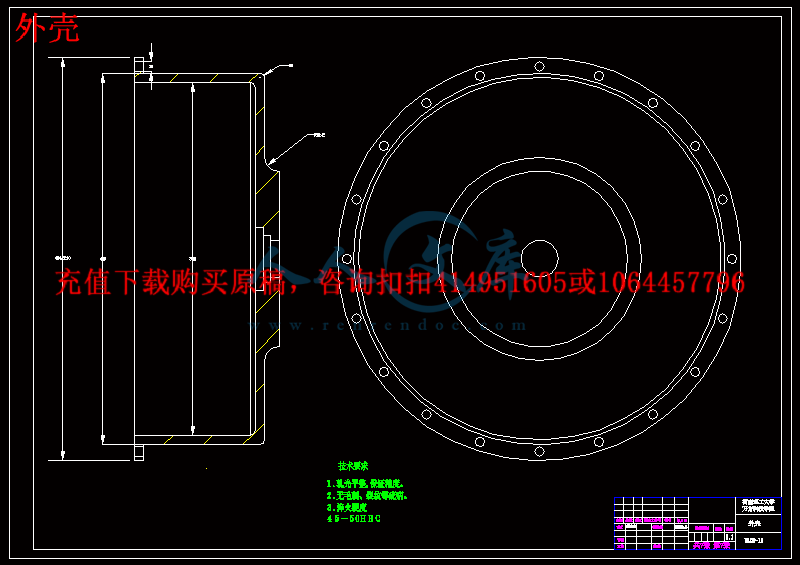

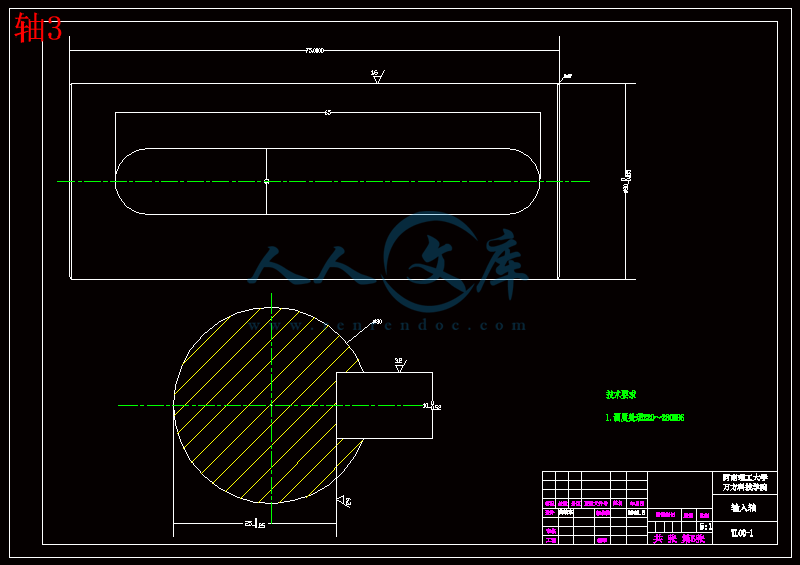

4.3 轴的设计27

4.3.1 轴上各轴段直径和长度的确定27

4.3.2 强度校核28

4.3.3 刚度校核29

4.3.4 键的选择29

4.3.5 轴承的选择30

4.4 离心式摩擦离合器32

4.4.1 初选摩擦片外径D、内径d、厚度b32

4.4.2 后备系数β32

4.4.3 离合器传递的最大静摩擦力矩Tc33

4.4.4 单位压力P033

4.5 离心块的设计34

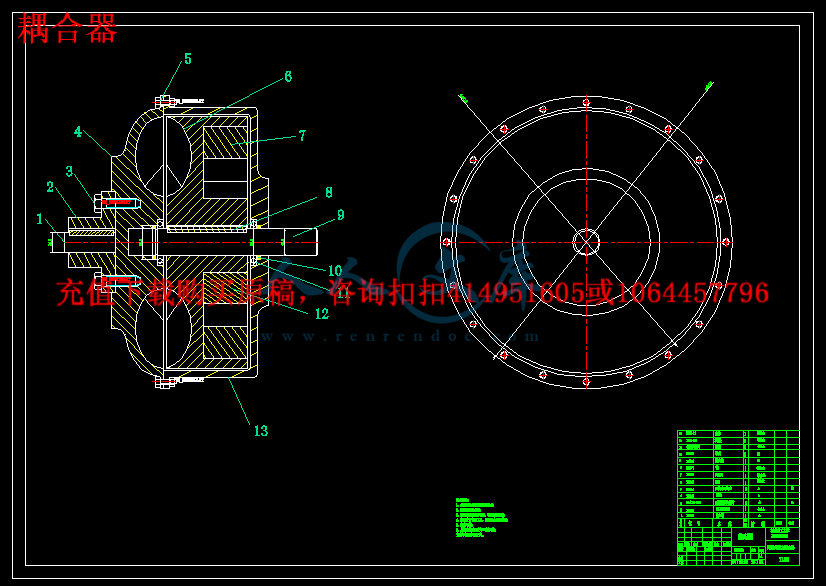

4.6 壳体设计和螺栓螺钉选择34

4.6.1 壳体设计34

4.6.2 螺栓螺钉选择与强度计算36

4.7 发热和散热计算38

4.8 辅助系统39

总 结40

致 谢42

参考文献43

前 言

进入二十一世纪以来,随着我国国民经济的高速发展,我国液力耦合器行业保持了多年高速增长,并随着我国加入WTO, 近年来,液力耦合器行业的出口也形势喜人,2008年,全球金融危机爆发,我国液力耦合器行业发展也遇到了一些困难,如国内需求下降,出口减少等,液力耦合器行业普遍出现了经营不景气和利润下降的局面,2009年,随着我国经济刺激计划出台和全球经济走出低谷,我国液力耦合器行业也逐渐从金融危机的打击中恢复,重新进入良性发展轨道,进入2010年,全球经济复苏的前景面临波折,国内经济结构调整的呼声逐渐升温,贸易保护主义的抬头,液力耦合器行业中技术含量低的人力密集型企业,缺乏品牌的出口导向型企业面临发展危机,而注重培养品牌和技术创新能力较强的企业将占得先机,液力耦合器行业企业如何面对新的经济环境和政策环境,制定适合当前形势和自身特点的发展策略与竞争策略,是液力耦合器行业企业在未来两年我国经济结构调整大潮中立于不败之地的关键,本报告也将从宏观和微观环境对我国液力耦合器行业的发展现状,政策环境、竞争策略,投资前景,市场容量,进出口形势等方面进行全面而权威的分析。

随着我国加入WTO及全球一体化的深入我国对液力偶合器的应用还不是很普遍,但液力偶合器所具有的改善品质和节约能源等优点,表明了它具有较强的生命力。在许多固定的机械设计上,在动力机与工作机构之间也多设有传动装置,其主要功能不外乎满足工作机调速和调节功率的要求,也有的主要是为了改善起动机加速性能、过载保护、提高运用可靠性和工作寿命。因而传动装置的功用就不仅仅是简单地将动力机之动力传至走行部分,而主要在于将动力机的特性转变为适应车辆运行要求的特征。液力偶合器是一种应用很广泛的通用传动元件,它置于动力机与工作机之间,传递两者的动力。其作用似乎和联轴器相同,但实质并不相同。在改善启动性能、过载保护、无级变速、对载荷有自动适应性等方面,液力偶合器的特性是联轴器所没有的。随着我国科学技术的发展,以及人们对液力偶合器的认识不断加深,其应用领域将会日益扩大。在对相关著作的学习、研究中得到更多、更深层的理论知识。

当前,国际能源日益紧张,人们不得不把注意力放到如何提高能源利用率和节约能源方面来。因此,可以在应用中节约能源的调速型液力偶合器和液力偶合器传动装置得到了迅速发展。由于液力偶合器传动装置结构复杂、技术精密、加工精度高、难度大、利润高,因而西方各大公司竞相研制生产,竞争很激烈。对于有形资产,各行业都有不同之处,需要分别进行探讨。国外对有形资产要比国内更加重视,他们在理论上有很多需要我们借鉴的地方。尤其一提的是,国外对开发成本的研究日趋成熟,值得我们研究并学习。

我国对液力偶合器的应用还不是很普遍,但液力偶合器所具有的改善品质和节约能源等优点,表明了它具有较强的生命力。随着我国科学技术的发展,以及人们对液力偶合器的认识不断加深,其应用领域将会日益扩大。

本次我的毕业设计做的就是液力偶合器,因为自己也是初次接触设计液力偶合器,不足之处希望老师多提宝贵意见。

川公网安备: 51019002004831号

川公网安备: 51019002004831号