目录

摘要 3

Abstract 4

第一章 绪论 4

1.1磨床的类型及其特点 4

1.2磨床的现状及其发展趋势 4

第二章 凸轮轴磨床概述 5

2.1凸轮轴磨床组成…………………………………………………………………………5

2.2 凸轮轴磨床技术参数……………………………………………………………………5

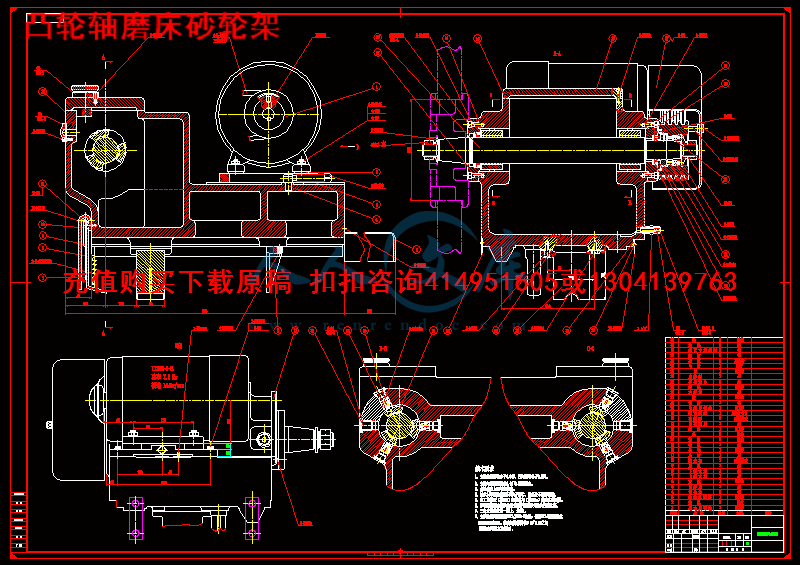

第三章 凸轮轴磨床砂轮架的设计 7

3.1砂轮架设计的基本要求 7

3.2砂轮架的传动装置 10

3.3砂轮架体壳设计的基本要求 17

3.4砂轮架主轴的设计 17

3.5轴承的设计 27第四章 凸轮轴磨床头架的设计 31

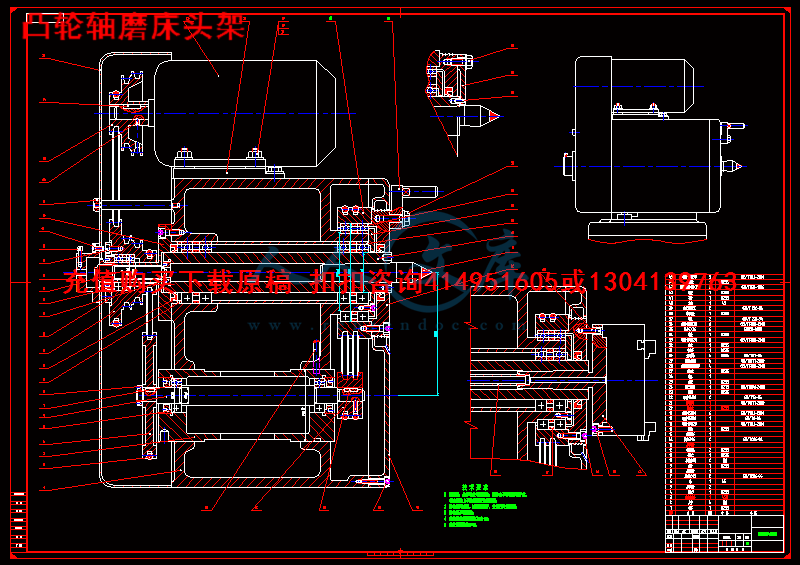

4.1 头架介绍……………………………………………………………………………31

4.2 头架结构……………………………………………………………………………32

4.3 头架齿轮设计………………………………………………………………………32

4.4 头架轴承设计………………………………………………………………………36

4.5 头架小轴设计………………………………………………………………………38

第五章 凸轮轴磨床尾架的设计 41

5.1 尾架结构设计………………………………………………………………………41

5.2 尾架工作原理………………………………………………………………………41

总结 42

参考文献 43

致谢 44

柴油机凸轮轴磨床夹具及附属件设计

摘要

磨床的砂轮架、头架和尾架是磨床附属件的关键部件,其精度对磨床的整体精度有着重要的影响。对磨床的关键部件进行结构优化设计对提高磨床精度是非常重要的。凸轮轴磨床适用于汽车、拖拉机和柴油机修理厂磨削发动机曲轴的曲柄颈,并可兼作一般外圆磨削。用以磨削范围为:最大工作长度为1250毫米,最大工件回转直径为180毫米。其具有加工精度高,表面粗糙度低、操作方便,效率高、能耗低、噪音小等特点,能满足多种产品的工艺要求及市场多方面的需求。

本文首先根据有关资料的探讨,分析总结了磨床砂轮架、头架和尾架的设计准则,并对凸轮轴磨床的砂轮架、头架和尾架作了进一步的分析,根据设计准则对其进行了结构优化设计,改善其精度。首先对传动系统进行了总体设计,然后主要是对头架部件进行了详细的设计,在分析头架设计要求的基础上对头架的带传动、主轴、轴承、体壳等主要零件进行了比较详细的设计,包括头架电机的选择、皮带的选择与带轮的设计、主轴的设计和校核、轴承的选择和校核、体壳的设计。

通过对凸轮轴砂轮架的计,提出了一种新的改进方案,该方案达到了预期的目的,使得砂轮架架在运行平稳的基础上加工精度得到提升。

关键词:凸轮轴磨床、砂轮架、头架、尾架

The engine camshaft grinder fixture and accessory design

Abstract

grinding machine grinding carriage is the key part, grinder its dynamic characteristics on the grinding machine performance which have had a significant impact. The key part of the grinder for structural optimization to improve grinder accuracy is very important. MQ8240-crankshaft grinding machines for cars, tractors and diesel engine repair plant grinding engine crankshaft crank neck, and doubles as a general odd. For grinding range: the maximum length of 1000 mm work, maximum work piece diameter is 400 mm, in the center of the frame on the grinding diameters up to 80 mm and a minimum of 30 mm, crankshaft maximum diameter of 30 mm, longitudinal grinding outside diameters up to 200 mm, with a minimum of 30 mm, piece maximum weight is 80 kg, Max swiveling angle clockwise 1°30 ´, 3° counterclockwise. It has a high precision machining, surface roughness, convenient operation, high efficiency, low energy consumption, low noise, and other characteristics, can meet a wide variety of products of technological requirements and market needs.

This article first in accordance with the relevant documentation and design engineers of that analysis summarizes grinding machine grinding carriage design guidelines, and on MQ8240 the head of the crankshaft grinder for further analysis, according to design criteria for structural optimization, and improve its accuracy. First on the transmission system for the overall design, and then the main thing frame parts for a detailed design, the analysis of head frame design requirements on the basis of the right frame of the belt drive, spindle, bearings, body shells, and other major components compares the detailed design, including head frame motor choice, belt and pulley design, spindle design and verification, bearing selection and verification, the design of the body shell.

MQ8240 by on the crankshaft grinder grinding carriage design, a new improvement scheme that reached the intended purpose, making the grinding carriage running smoothly, grinding crankshafts chatter also disappeared. Even though production process again chatter defects, by excluding other factors that could be resolved.

Key words: crankshaft Grinder grinding carriage accuracy

第一章 绪论

1.1磨床的类型及其特点

用磨料磨具(砂轮、砂带、油石和研磨料等)为工具进行切削加工的机床,统称为磨床(英文为Grinding machine),它们是因精加工和硬表面的需要而发展起来的。

磨床可以加工各种表面,如内、外圆柱面和圆锥面、平面、渐开线齿廓面、螺旋面以及各种成形表面。磨床可进行荒加工、粗加工、精加工和超精加工,可以进行各种高硬、超硬材料的加工,还可以刃磨刀具和进行切断等,工艺范围十分广泛。

磨床种类很多,主要有:外圆磨床、内圆磨床、平面磨床、工具磨床和用来磨削特定表面和工件的专门化磨床,如花键轴磨床、凸轮轴磨床、曲轴磨床等。对外圆磨床来说,又可分为普通外圆磨床、万能外圆磨床、无心外圆磨床、 宽砂轮外圆磨床、端面外圆磨床等。以上均为使用砂轮作切削工具的磨床。此外,还有以柔性砂带为切削工具的砂带磨床,以油石和研磨剂为切削工具的精磨磨床等。

磨床与其他机床相比,具有以下几个特点:

(1)、磨床的磨具(砂轮)相对于工件做高速旋转运动(一般砂轮圆周线速度在 35米/秒左右,目前已向200米/秒以上发展);

(2)、它能加工表面硬度很高的金属和非金属材料的工件;

(3)、它能使工件表面获得很高的精度和光洁度;

(4)、易于实现自动化和自动线,进行高效率生产;

(5)、磨床通常是电动机---油泵---发动部件,通过机械,电气,液压传动---传动部件带动工件和砂轮相对运动---工件部分组成。

1.2磨床的现状及其发展趋势

十八世纪30年代,为了适应钟表、自行车、缝纫机和枪械等零件淬硬后的加工,英国、德国和美国分别研制出使用天然磨料砂轮的磨床。这些磨床是在当时现成的机床如车床、刨床等上面加装磨头改制而成的,它们结构简单,刚度低,磨削时易产生振动,要求操作工人要有很高的技艺才能磨出精密的工件。

川公网安备: 51019002004831号

川公网安备: 51019002004831号