摘 要

曲柄压力机广泛应用于冲裁,弯曲,校正,模具冲压等工作。本次设计的为单点闭式中型,公称压力为160吨曲柄压力机。

此次设计由于分工不同,主要完成的是曲柄压力机曲柄滑块机构的设计。在设计中主要是根据总体设计确定的压力机主要参数,公称压力,滑块行程等参数参考相关手册初步估算曲柄,连杆,滑块,导轨相关尺寸,然后分别校核,修正,最终确定各零部件尺寸,并根据要求完成装模高度调节装置设计。最后写出详尽曲柄滑块机构设计说明书,绘出主要零件图。

关键字:公称压力,曲轴,连杆,导轨,调节装置。

Abstract

It was crank press slider crank mechanism design that crank press extensive use to blanking,bent,adjustment,mould stamping quiescent. This degree rated for single-point closed type mesotype skill pressure for 160 ton crank press.

This degree design owing to division of labour differ. Mostly finished at design suffer primarily as per overall design final contractor major parameter,nominal pressure,slide stroke is isoparametric reference correlation manual general estimate winch,pitman,slipper rack correlation size,then parting check,amend,ultimately ascertain each spare size,combine or finish fit design up with. be the last written out at large slider crank mechanism design specifications,out major parts chart to.

key word:nominal pressure,crankshaft,pitman,rack,regulating block.

目录

前 言………………………………………………………………………..

1 曲柄压力机构成及工作原理和相关参数

1.1曲柄压力机构成及工作原理……………………………………………..

1.1.1曲柄压力机一般有工作部分构成……………………………………

1.1.2.曲柄压力机工作原理…………………………………………………

1.2 曲柄压力机的主要技术参数…………………………………………….

1.2.1曲柄压力机的主要技术参数…………………………………………

1.2.2曲柄压力机的型号介绍………………………………………………

2 曲柄压力机滑块机构的运动分析与受力分析

2.1压力机曲柄滑块机构的构成………………………………………………

2.2曲柄压力机滑块机构的运动规律分析……………………………………

2.2.1滑块的位移和曲柄转角之间的关系…………………………………..

2.2.2滑块的速度和曲柄转角的关系……………………………………….

2.3曲柄压力机滑块机构的受力分析…………………………………………

2.3.1忽略摩擦情况下滑块机构主要构件的力学分析……………

2.3.2考虑摩擦情况下滑块机构主要构件的力学分析……………

3 齿轮传动

3.1齿轮传动的介绍…………………………………………………………..

3.1.1齿轮在应用的过程中对精度要求………………………………….

3.2直齿轮传动……………………………………………………………….

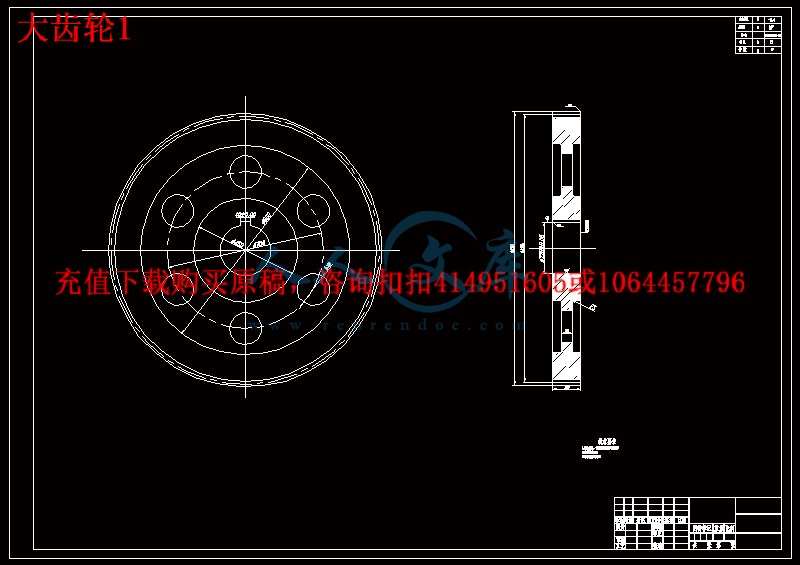

3.2.1齿轮参数确定

3.2.2齿轮的尺寸初步计算

3.2.3 齿轮的强度校核

3.3锥齿轮传动………………………………………………………………

3.3.1几何参数的计算........................................

3.3.2 核算弯曲应力..........................................

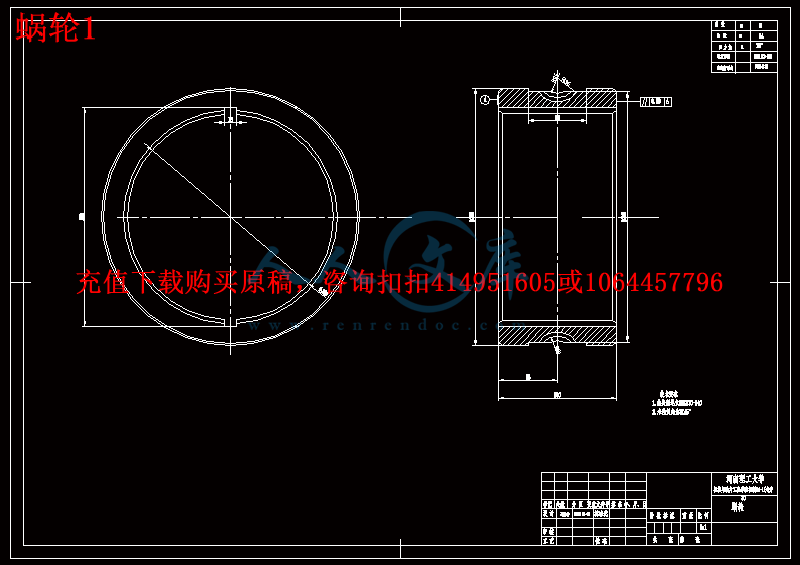

3.4蜗杆蜗轮传动……………………………………………………………

3.4.1蜗杆传动的特点.......................................

3.4.2蜗杆蜗轮的材料.......................................

3.4.3蜗杆蜗轮尺寸的计算...................................

3.4.4 校核蜗轮蜗杆..........................................

4 曲柄压力机滑块机构的设计与计算。

4.1曲柄压力机滑块机构的构成……………………………………………

4.1.1选定轴的材料…………………………………………………………

4.1.2估算曲轴的相关尺寸

4.1.3 设计轴的结构并绘制结构草图

4.1.4 校核轴劲尺寸

4.1.5曲轴的危险阶面校核

4.2曲轴设计与计算…………………………………………………………

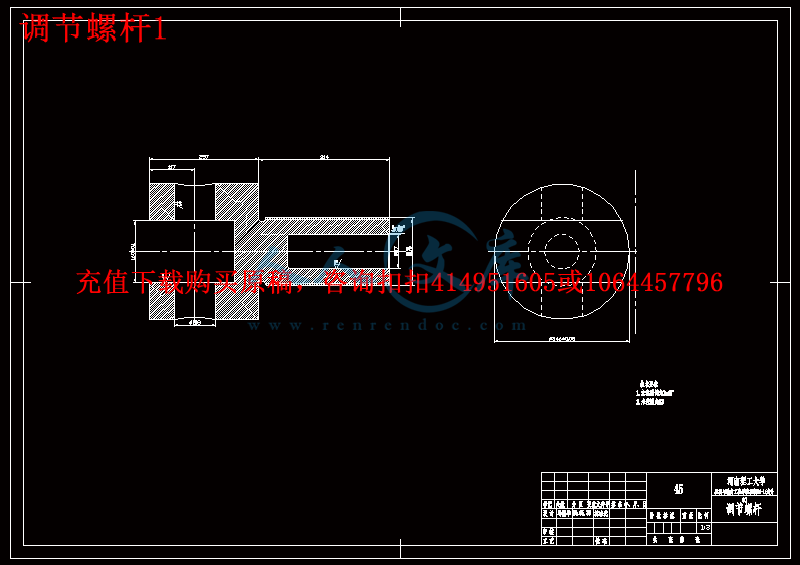

4.2.1 连杆和调节螺杆初步确定

4.2.2校核调节螺杆的和连杆尺寸

4.3连杆设计与计算…………………………………………………………

4.4导轨的设计与计算……………………………………………………..

4.5高度调节装置的设计……………………………………………………

5 轴承的选用

5.1滑动轴承的选用………………………………………………………….

5.1.1连杆大端滑动轴承选用与校核

5.1.2曲轴颈上滑动轴承选用与校核

5.2滚动轴承的选用………………………………………………………….

翻译………………………………………………………………………….

英语原文………………………………………………………………………..

后记………………………………………………………………………….

致谢………………………………………………………………………………

参考资料…………………………………………………………………………

前言

制造业是一个国家经济发展的重要支柱,其发展水平标志着该国家的经济实力、科技水平和国防实力。压力机是机械制造业的基础设备。随着社会需求和科学技术的发展,对机床设计要求越来越高。尤其是模具制造的飞速出现,使机床向高速、精确,智能化的方向发展。因此,对压力机的精度和生产率等各方面的要求也就越来越高。

本次设计是结合中型压力机的工作实际,对JB31-160型曲柄压力机进行改造性设计。由于传统JB31-160型曲柄压力压力机,存在滑块运动精度底,装模高度调节麻烦,滑块行程量小等缺点,严重影响了生产效率。本次设计鉴于以上缺点对其进行了如下改正:1改进部件结构设计,采用新型材料。例如离合器部件,尽量减小其从动惯量,采用新兴摩擦材料。2调节装置方面,采用二级的锥齿——蜗杆蜗轮调节,节省了工人劳动量,又提高了精度。3采用了曲轴代替同类型的偏心轴,用变位齿轮代替普通齿轮,这样就减小了机身的高度,更方便按装。

压力机是冲压模具制造的常用设备,而提高冲压模具坯料精度,提高生产率,提高使用寿命,减少劳动劳动量的有效方法,此外,还要考虑到人机结合的合理性,使机床更人性化,便于工人的操作,减轻劳动强度和增加安全性。

1曲柄压力机的工作原理及主要参数

1.1 曲柄压力机的构成及工作原理.

1.1.1曲柄压力机一般有工作部分构成

1)工作机构,一般为曲柄滑块机构,由曲柄、连杆、滑块等零件

成。

2)传动系统,包括齿轮传动、皮带传动等机构。

3)操作系统,如离合器、制动器。

4)能源系统,如电动机、飞轮。

5)支撑部件,如机身。

上述除了的基本部分以外,还有多种辅助系统与装置,如润滑系统、安全保护装置以及气垫等。

川公网安备: 51019002004831号

川公网安备: 51019002004831号