摘 要

数控机床是来自于数字控制机床的简称,这是一种装有可编程程序控制系统的自动化机床。该可编程程序控制系统能够逻辑处理数字控制编码或其他规定的指令程序,并将其译码成执行元器件的动作信号从而驱动机床动作以加工零件。数控机床的控制电路是由各种不同的控制电气元器件组成,进给伺服系统的控制性能在一定程度上决定了数控机床的等级。本次设计任务是以ZK5132数控立钻电气控制系统设计为中心,全面、系统地介绍了低压电器、电气控制系统、数控系统及接口、步进与伺服驱动器等内容,利用数控机床以机械与电气相结合的形势,完成相关电气控制线路排布以及各种保护控制线路的设计。

为使步进电动机的控制精度能达到所要求的步距角()精度,于是在该机床选配所用驱动电机时要考虑到该电机的过载能力和机床传动系统中丝杠与电机转子的惯量是否匹配以及所提供转矩是否足够,在该设计中的进给驱动系统选用混合式五相十拍步进电动机进行驱动控制。由于开环控制系统简单,精度要求不高,可靠性和稳定性相对于经济型数控机床好,故采用五相十拍的步进电动机进给驱动,同时也能因其相数大而达到明显的振动抑制效果。

随着设计的不断深入而不断熟悉了各种系统的适用条件,各种设备的选用标准及作用,各种电气线路的保护设计,驱动进给系统的控制等。通过掌握电气控制系统线路设计的原理、电气元器件在线路中的作用,进给驱动系统的设计,完成对电动机的精度控制。这次的电气控制部分设计也满足一些企业对机床电气高可靠高稳定性、电气使用寿命长等要求,具有进一步研发的潜力。

关键词:ZK5132;数控系统;机电结合;步进电动机

Abstract

CNC machine is referred to Digital control machine tool, is a machine equipped with the automated process control system. The control system can have a control logic to process the instruction codes or other symbols required, decoded and processed so that making machine action and machining parts. CNC machine control circuit is controlled by a variety of electrical components whose performance servo feed control system to some extent determines the level of CNC machine tools. The design task is designing ZK5132 CNC Vertical Drilling electrical control system, there is a comprehensive and systematic introduction to the low-voltage electrical appliances, electrical control systems, numerical control systems and interfaces, stepper and servo drives, etc. By combining CNC machine tools with electrical machinery, finish the completion of related electrical control circuit and various protection control design.

To control the stepping motor step to achieve the required angle ( α= 0.36 °) the control precision, the machine motor is optional to consider the motor overload, overload conditions, the machine screw and the motor drive system rotor inertia matching. This design’s feed servo drive system used Five-phase-ten-pat hybrid stepping motor control. Because the open-loop control system is simple, less precision, reliability and stability with respect to the good economic type CNC machine tools, so using Five-phase-ten-pat hybrid stepping motor drive, vibration suppression effect is obvious because of the large number of phases.

With the deepening of the design, we know more about the applicable conditions of various systems, selecting criteria and effects of various devices,various electrical circuit protection designing and feeding drive control system and so on . By mastering the principles of electrical control system circuit design,the role of the electrical components in the circuit and feeding drive system designing so we can well completed the motor accuracy control. My electrical control part of the design but also to meet the high reliability, high stability, long life and other electrical requirements for some company, thus it worth well potential for further development.

Keywords: ZK5132 ; CNC system ; Electrical components ; Stepping motor

目 录

引言1

1. 数控机床常用电气控制元件3

1.1 低压断路器3

1.2 接触器3

1.3 继电器、变压器及其他电器4

2. 数控系统5

2.1 数控钻床系统的组成5

2.1.1 操作面板6

2.1.2 输入/输出装置6

2.1.3 CNC装置6

2.1.4 伺服单元7

2.1.5 驱动装置7

2.1.6 机床本体7

2.2 数控机床驱动控制的分类以及选择7

2.2.1 开环控制8

2.2.2 闭环与半闭环控制8

2.2.3 数控系统类型8

2.3 数控钻床用途及特点9

2.4 数控钻床的相关技术参数9

2.5 数控机床对于进给驱动系统的相关要求10

3. 传动系统相关计算10

3.1 传动系统对驱动电机的相关要求11

3.1.1 X、Y水平直线运动轴11

3.1.2 Z垂直直线运动轴12

3.2 步进电动机速度的控制13

4. 步进电动机驱动进给系统13

4.1 步进电动机的选用原则以及性能指标13

4.1.1 选用原则13

4.1.2 步进电动机性能指标14

4.2 步进电动机的选择14

4.3 步进电动机的工作原理15

4.4 主轴步进电机的控制16

4.5 步进电动机的位置控制18

4.6 步进电动机的驱动电源19

4.7 步进电动机的正反转运动控制19

5. 机床的电气控制系统设计20

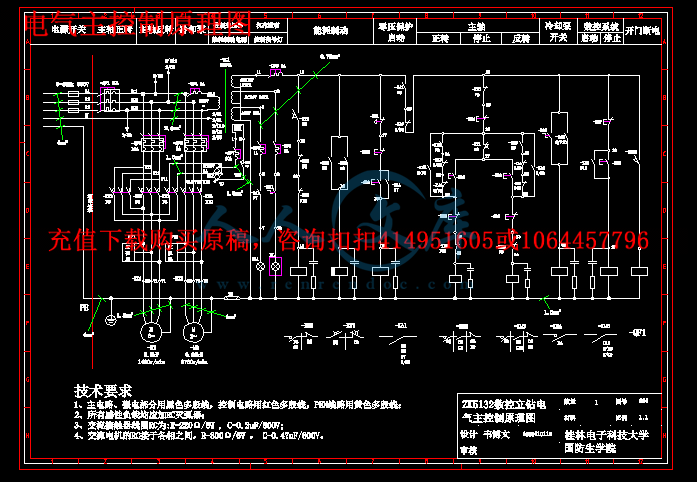

5.1 主电路电气控制设计20

5.1.1 主轴正转20

5.1.2 主轴反转21

5.1.3 主轴停转21

5.1.4 冷却泵21

5.2 电路电源分析21

5.3控制电路设计22

5.3.1 电机制动方式22

5.3.2 零压保护启动22

5.4 数控系统中的启动与停止23

5.5 输入/输出及各轴限位23

5.6 光轴输出接口23

5.7 M功能输出23

5.8 X、Y、Z轴的驱动控制信号接口24

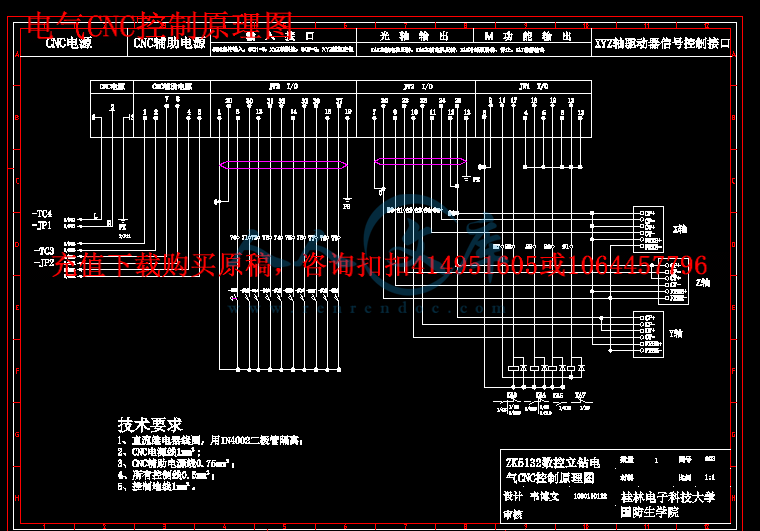

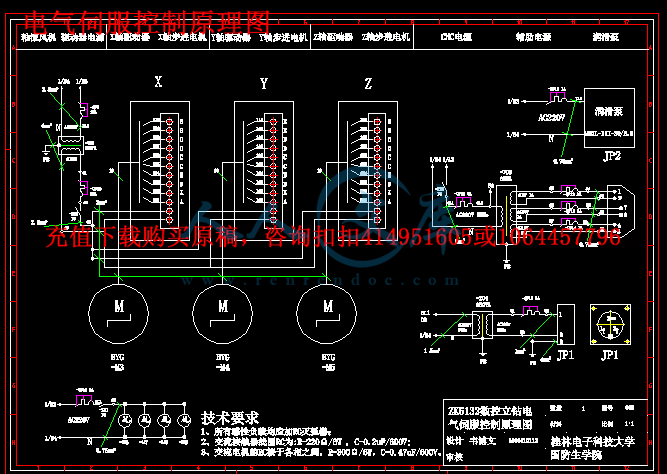

6. ZK5132数控立钻机床电气控制原理设计25

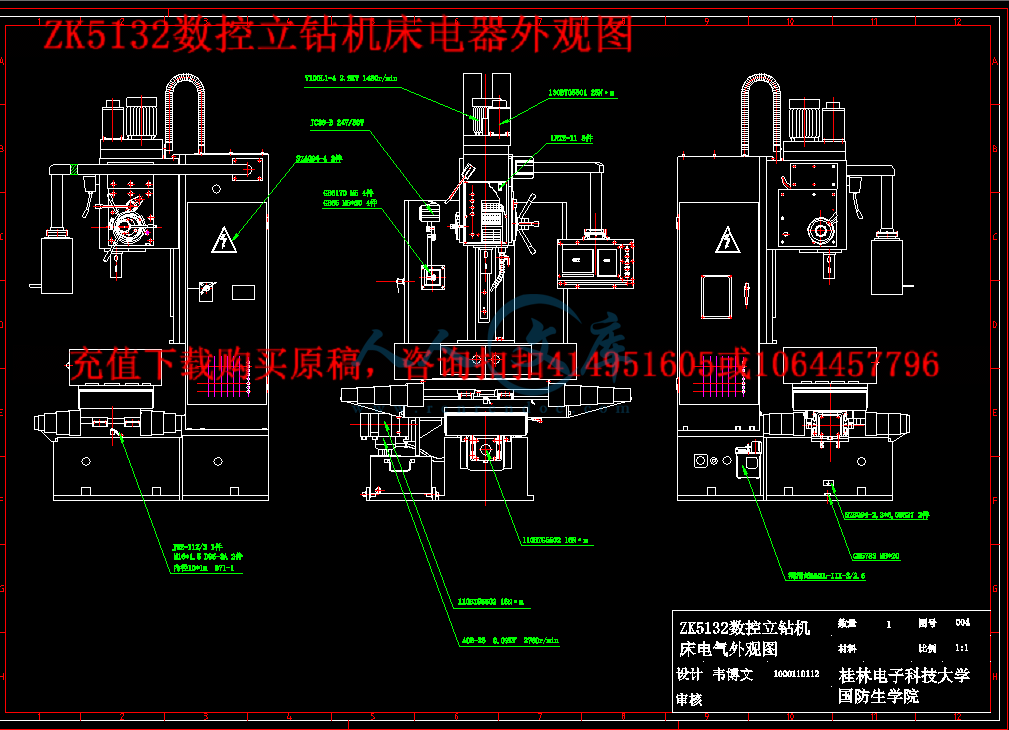

7. ZK5132数控立钻机床电气外观设计28

结论29

谢辞30

参考文献31

引言

随着科学技术日益发展、制造技术的突飞猛进和人类生活水平提高物质要求增加,以及社会对产品质量和品种的多样化要求趋势不断增强,中小批量生产的比例明显增加,由此要求数控机床更高的的柔性和通用性。人们迫切希望能提供不同加工需求且成本低迅速高效又面向普通用户的控制系统,同时期待在维护和培训成本上有大幅降低。若该系统具备网络功能能够适应以后车间面向任务定单的批量或零碎生产管理模式将更能俘获用户的青睐。在此大背景下,计算机数字技术在近十年来以极快的速度高歌猛进,不断酝酿产生多种不同层次的开放式数控系统。数控系统行业现阶段正向标准化开放体系结构的大方向迈进。单就体系结构来说,现世全球的数控系统大致可以分为以下四类:传统数控系统、“PC嵌入NC”结构数控系统、“NC嵌入PC”结构开放式数控系统、开放式数控系统。特别是进入21世纪之初,拌随着全球大环境计算机技术的迅猛发展,计算机控制等领域的技术成就陆续引进到数控技术的开发中去。现阶段高速高精度、高效率高自动化、高柔性、高可靠性、高智能化复合化网络化、开放式体系结构是国外数控机床性能的发展方向,这要求更高的数控机床机械结构设计和制造的质量及可靠性。机床工业是一个国家综合实力的重要标志和产业地位的重要象征。“十一五”期间,我国机床工具行业平均以百分之三十的高增长率快速发展,已连续10年成为世界第一机床消费大国,并成为世界机床第一生产大国。而“十二五”期间,我国进一步加速对高速铁路的建设、日益加快的城镇化进程都为机械行业带来最直接最大化的收益。

当前我国的机床数控系统正处在一个发展的关键时期,正寻求由研究开发向推广应用转变,也正是从封闭型的系统向开放型的系统寻求转变的时期。我国的机床数控系统在重大关键技术、核心技术上日趋成熟,开发及衍生出数控系统八十余种,已赶上国外先进水平。近几年以来,借由对国内外机床数控机床从机械结构解剖分析到使用性能用户需求的调研,思考钻研了机床数控机床在机械结构设计方面和制造方法方面的新技术。但现时还主要存在以下几个问题函待解决:一是缺乏产业规模,没有足够规模的产业集群;二是缺乏专门针对发展数控产业的政策和相应的技术配套体系;三是缺乏技术创新,产品更新;四是缺乏产业调整的内在动力;五是面临国外强手竞争,扩展海外市场压力巨大。

川公网安备: 51019002004831号

川公网安备: 51019002004831号