拨叉831006的夹具设计

ca6140车床拨叉831006零件的机械加工工艺规程及工装夹具设计

拨叉831006的加工工艺规程及夹具设计

ca6140车床拨叉831006的夹具设计

CA6140车床拨叉831006的加工工艺规程及钻25孔夹具设计

CA6140车床拨叉831006的机械加工工艺规程及铣叉口左右侧面夹具设计

CA6140车床拨叉831006的加工工艺规程及铣16槽夹具设计

CA6140拨叉831006的加工工艺规程及夹具设计

拨叉831006零件的机械加工工艺规程及工装夹具设计

ca6140拨叉831006的机械加工工艺规程及工艺装备设计

CA6140车床拨叉831006加工工艺规程及夹具设计

CA6140拨叉831006的机械加工工艺规程及钻25孔与铣叉口左右侧面及铣16槽夹具设计

CA6140车床拨叉831006的机械加工工艺规程及钻25孔夹具设计【优秀】【带proe三维零件图】【word+4张CAD图纸全套】【工艺过程卡片、工序卡片】【毕设】【带任务书+开题报告+外文翻译+实习总结】【52页@正文17400字】【详情如下】【需要咨询购买全套设计请加QQ】.bat

xiaobocha.prt.1

xiaobochatongyonggeshi.igs

任务书.doc

外文翻译.doc

实习总结.doc

工序50的夹具设计参考.doc

工序卡片.doc

开题报告.doc

拨叉零件图.DWG

毛坯图.dwg

说明书.doc

钻孔夹具装配图.dwg

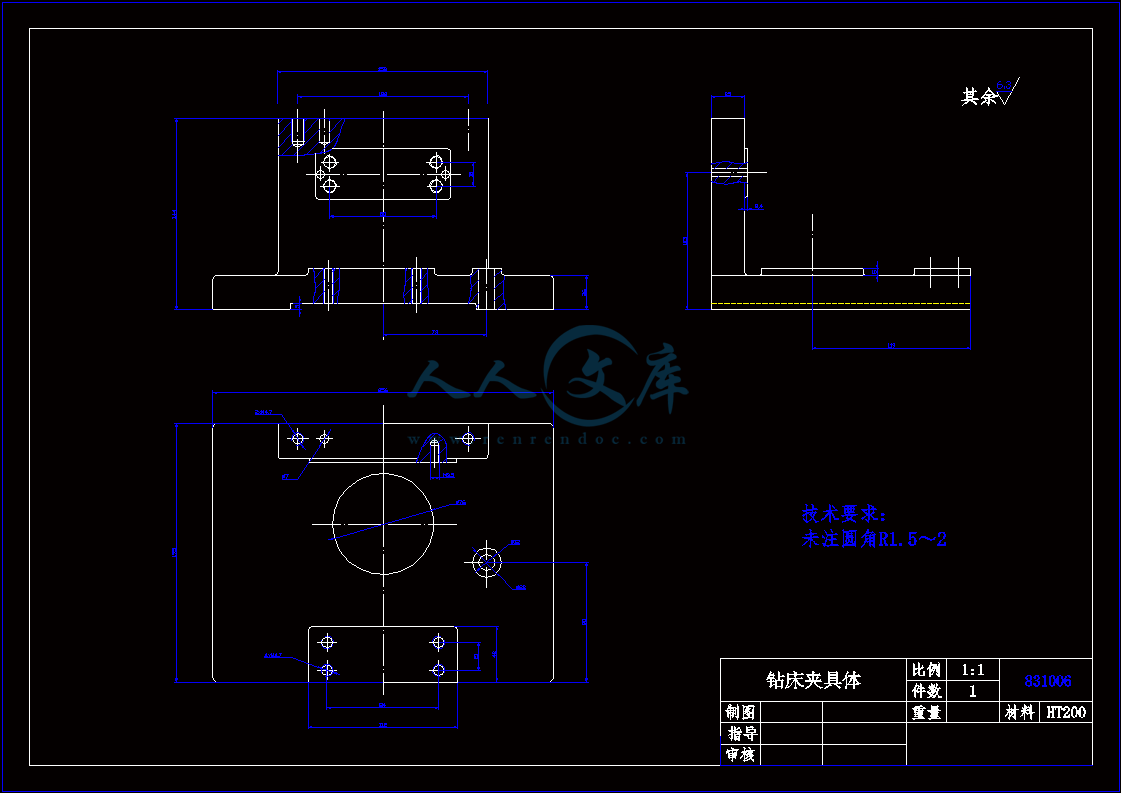

钻孔夹具体.dwg

任务书

一、设计题目:CA6140车床拨叉831006加工工艺规程及夹具设计

二、设计的主要内容:说明书:总计1.5万字以上,包括CA6140车床拨叉831006加工工艺规程的制定及夹具设计等。图纸:包括相关工序专用夹具的装配图以及主要零件图等,其中1张图必须徒手画。图纸合计2张零号图纸以上。

三、设计目标: 很据CA6140车床拨叉831006的加工要求,通过方案确定、设计计算,完成CA6140车床拨叉831006加工工艺规程编制及夹具设计,并通过该设计培养学生独立设计能力。

摘 要

随着科技的发展,机械制造行业已经是我国技术进步和社会发展的支柱产业之一。无论是传统产业,还是新兴的机械制造产业,都离不开形式各样的机械制造设备。本次毕业设计的内容主要内容就是对CA6140机床拨叉的工艺规程制定和对其中孔及若干平面加工工序的夹具设计进行研究和探讨。在工艺规程编制方面,主要通过仔细分析拨叉零件图和相关技术要求,查阅零件相关资料,考虑了零件的工艺结构要求、批量生产要求、经济性、可行性等多方面因素,最终安排工序,并完成加工,其中包括各道工序的加工方法,机床、刀具、夹具、辅具、量具的选择,基准面的选取,定位和夹紧方案的拟定,并将其编入工序卡片,清晰明了的表达出了整个加工过程。另外,在专用夹具设计方面,主要对一孔、一平面的加工工序进行了夹具方案的分析,计算和最终完成设计任务。

关键词:拨叉;工艺路线;定位与夹紧;专用夹具设计

Abstract

With the development of science and technology, machinery manufacturing industry of China has been technological progress and social development of pillar industries. Whether in traditional industries or new industries, it is inseparable from a wide range of machinery and equipment. This graduation of content which is the study about the protocol development process and the fixture design of the hole and some plane processing procedure. In terms of process rules, primarily through a careful analysis of the product parts and related technical requirements, check the parts relevant information considered part of the process of structural requirements, batch, and economics, feasibility, and more factors. The final arrangements for the operations to finish processing, including the operations of processing method, machine tools, tooling, fixtures, assistive devices, measurement apparatus selection, select datum, positioning and clamp authoring, and process card, clarity of expression out the whole processing procedure. In addition, in fixture design, the main design about a hole, a flat and a groove machining process has been analysised, computation and finally to complete the design task.

Key words: Plectrum; process route; positioning and clamping; dedicated fixture design

摘 要

随着科技的发展,机械制造行业已经是我国技术进步和社会发展的支柱产业之一。无论是传统产业,还是新兴的机械制造产业,都离不开形式各样的机械制造设备。本次毕业设计的内容主要内容就是对CA6140机床拨叉的工艺规程制定和对其中孔及若干平面加工工序的夹具设计进行研究和探讨。在工艺规程编制方面,主要通过仔细分析拨叉零件图和相关技术要求,查阅零件相关资料,考虑了零件的工艺结构要求、批量生产要求、经济性、可行性等多方面因素,最终安排工序,并完成加工,其中包括各道工序的加工方法,机床、刀具、夹具、辅具、量具的选择,基准面的选取,定位和夹紧方案的拟定,并将其编入工序卡片,清晰明了的表达出了整个加工过程。另外,在专用夹具设计方面,主要对一孔、一平面的加工工序进行了夹具方案的分析,计算和最终完成设计任务。

关键词:拨叉;工艺路线;定位与夹紧;专用夹具设计

Abstract

With the development of science and technology, machinery manufacturing industry of China has been technological progress and social development of pillar industries. Whether in traditional industries or new industries, it is inseparable from a wide range of machinery and equipment. This graduation of content which is the study about the protocol development process and the fixture design of the hole and some plane processing procedure. In terms of process rules, primarily through a careful analysis of the product parts and related technical requirements, check the parts relevant information considered part of the process of structural requirements, batch, and economics, feasibility, and more factors. The final arrangements for the operations to finish processing, including the operations of processing method, machine tools, tooling, fixtures, assistive devices, measurement apparatus selection, select datum, positioning and clamp authoring, and process card, clarity of expression out the whole processing procedure. In addition, in fixture design, the main design about a hole, a flat and a groove machining process has been analysised, computation and finally to complete the design task.

Key words: Plectrum; process route; positioning and clamping; dedicated fixture design

目 录

摘 要I

AbstractII

第1章 绪论1

1.1 夹具设计的意义1

1.2 夹具设计研究概述2

1.2.1 夹具的定义2

1.2.2 夹具发展概况2

1.2.3 夹具设计要解决的主要问题3

1.3 夹具的功能4

1.4 夹具组成4

1.4.1 夹具的基本组成部分4

1.4.2 夹具的其他组成部分5

1.5 夹具的分类5

1.5.1 按夹具的通用特性分类5

1.5.2 按夹具使用的机床分类5

1.6 夹具使用优点7

1.7 夹具设计要求7

1.7.1 夹具设计基本要求7

1.7.2 生产对其提出的新要求8

1.8 夹具设计特点8

1.9 现代夹具的发展发向9

第2章 工艺规程的编制10

2.1 零件的分析10

2.1.1 零件的作用10

2.1.2 零件的工艺分析11

2.2 确定毛坯的制造形式12

2.3 基面的选择13

2.4 制定工艺路线14

2.5 选择加工设备及刀具、夹具、量具15

2.6 机械加工余量、工序尺寸及毛坯尺寸的确定16

2.7 确立切削用量及基本工时19

第3章 工序30的夹具设计37

3.1 问题的提出37

3.2 夹具设计37

3.3 定位误差的分析40

3.4 夹具设计及操作的简要说明40

第4章 机床夹具优化设计及经济效益41

4.1 优化设计分析41

4.1.1成组夹具成本41

4.1.2 优化设计的现实意义42

4.2 机床夹具柔性化42

4.3 机床夹具经济效益分析43

结 论45

致 谢46

参考文献XLVII

第1章 绪论

随着科学技术的高速发展,机械产品不断更新换代,其产品型号越来越多,质量要求越来越高,更新周期越来越短,使机械制造工程飞速的发展。在机械加工过程中,夹具占有非常重要的地位。它可靠地保证了工件的加工精度,提高了加工效率,减轻了劳动的强度。夹具的设计过程中,应深入生产实际,对工件的图纸、工艺文件,生产纲领等分析,精心调查研究,吸取国内外的先进技术,制订出合理的设计方案[1]。

机械加工必须保证零件的加工质量,达到设计图纸规定的各项技术要求,同时还应该具有较高的生产率和经济性。因此,机械加工工艺规程设计就是一项重要的工作。它要求设计者必须具有丰富的生产实践经验和广博的机械制造工艺基础理论知识。

在指定工艺规程时,应根据零件的产量和现有的设备条件,综合考虑加工质量、生产率和经济性的要求,经过反复分析比较,确定最优方案。

1.1 夹具设计的意义

零件在工艺规程制定之后就要按工艺规程顺序进行加工。加工中除了需要机床、刀具、量具之外,成批生产时还要用机床夹具。他们是机床和工件之间的连接装置,使工件相对于机床或刀具获得正确的位置,机床夹具的好坏将直接影响工件加工表面的位置精度,所以机床夹具设计是装备设计中一项重要的工作,是加工过程中最活跃的因素之一[2]。

因此,好的夹具设计可以提高产品劳动生产率,保证和提高加工精度,降低生产成本等,还可以扩大机床的使用范围,从而使产品生产在保证精度的前提下提高效率,降低成本。在当今激烈的市场竞争和企业信息化要求下,满足企业对夹具的设计制造的更高要求。

CA6140车床拨叉铣、钻等工序使用的专用夹具设计应针对加工零件,应达到结构紧凑、操作简便、生产率高。所以对CA6140车床拨叉加工工艺及夹具设计,不但是我们对大学所学的知识的一个整合,而且是对结构设计和工艺设计方面的一次训练。

1.2 夹具设计研究概述

1.2.1 夹具的定义

夹具是一种装夹工件的一种工艺装备,它广泛地应用于机械制造过程的切削加工,热处理装配,焊接和检测等工艺过程中。

在金属切削机床工件是使用的夹具称为机床夹具,在现代生产过程中,机床夹具不可缺少。它直接影响着加工的精度,劳动生产率和产品的制造成本等,故机床夹具的设计在企业产品设计和制造以及生产技术装备中占有极其主要的地位。机床夹具设计是一项重要的技术工件[3]。

1.2.2 夹具发展概况

随着科学技术的不断进步,夹具已从一种辅助工具发展成为门类齐全的工艺装备。改革开放以来,机械工业充分利用国内外两方面技术资源,有计划的进行企业的技术改造,引导企业走依靠科技进步的道路,使制造技术、产品质量以及经济效益有了很大的提高,为繁荣国内市场,扩大出口创汇,推动国民经济的发展起了重要作用。

夹具最早出现在1787年,至今经历了三个发展阶段。第一阶段表现为夹具与人的结合。在工业发展初期。机械制造的精度较低,机械产品工件的制造质量主要依赖劳动者个人的经验和手艺,而夹具仅仅作为加工工艺过程中的一种辅助工具;第二阶段是随着机床、汽车、飞机等制造业的发展,夹具的门类才逐步发展齐全。夹具的定位、夹紧、导向(或对刀)元件的结构也日趋完善,逐渐发展成为系统的主要工艺装备之一;第三阶段,即近代由于世界科学技术的进步及社会生产力的迅速提高,夹具在系统中占据相当重要的地位。这一阶段的主要特征表现为夹具与机床的紧密结合。

我国的机械制造业经过50多年,特别是近20年的发展,已形成了品种繁多、门类齐、布局合理的机械制造工业体系。许多科研院所、大专院校和企业研制出了一大批成套技术装备和多种高精尖产品,有些已接近或达到国际先进水平。

现代机床夹具的发展为了适应现代机械工业向高、精,尖方向发展的需要和多品种、中小批生产的特点,机床夹具的主要发展方向表现为精密化[4]。

目前中国制造业发展迅猛,以前的我国制造业普遍使用刚性专机加工各种各样的零部件,导致改型和生产个零部件周期较长。随着我国制造业发展和各种各种零件的需求与日俱增,加工设备和工艺也向着柔性化的方向转变。

目前,除了在生产流水线、自动线配置相应的高效、自动化夹具外,在数控机床上,尤其在加工中心上出现了各种自动装夹工件的夹具以及自动更换夹具的装置,充分发挥了数控机床的效率。

为适应现代机械工业多品种、中小批量生产的需要,扩大夹具的柔性化程度,改变专用夹具的不可拆结构为可拆结构,发展可调夹具结构,将是当前夹具发展的主要方向,使机械产品不断更新换代,品种型号越来越多.质量越来越高,更新周期越来越短[5]。

1.2.3 夹具设计要解决的主要问题

夹具设计最关键是要求对工件定位正确,且满足定位精度要求。首先得了解影响定位精度的因素,然后采取措施解决具体的问题。如定位基准与定位元件的配合状况和影响定位精度,那么可以提高夹具的制造精度,减小配合间隙就能提高夹具在机床上的定位精度。

除此之外,选择夹具的类型与结构型式必须与零件生产批量大小相适应,夹具结构与零部件应具有足够的刚度和强度,从而保证夹具操作方便、夹紧可靠、使用安全、并有合理的装卸空间[6]。

1.3 夹具的功能

机床夹具的主要功能是定位和加紧。定位是确定工件在夹具中占有正确位置的过程。通过工件定位基准面与夹具定位元件的定位面接触或配合实现的,而夹紧则是工件定位后将其固定,使其在加工过程中保持定位位置不变的操作。

机床夹具的特殊功能是对刀和导向,通过调整工件切削刃相对工件或夹具的正确位置。而导向则是如钻床夹具中的钻模板和钻套,能迅速的确定钻头的位置,并引导其进行钻削。

机床夹具能够降低对操作工人的技术要求和工人的劳动强度。由于多数专用夹具的夹紧装置只需厂人操纵按钮、手柄即可实现对工件的夹紧,这在很大程度上减少了工人找正和调整工件的时间与难度[7]。

夹具设计

为了提高劳动生产率,保证加工质量,降低劳动强度,需要设计夹具。本次夹具设计主要有三个,首先是对mm孔进行加工,其夹具为专用夹具,利用Z550立式升降台钻床,锥柄机用铰刀,实现对mm孔的精铰加工其粗糙度为1.6。

其次是对C、D面进行加工,其夹具为专用夹具,利用X52K立式升降台铣床,硬质合金端铣刀,实现对C、D面的半精铣加工,其粗糙度要求为3.2;最后再完成槽的加工,其夹具为专用夹具,利用X52K立式升降台铣床,三面刃铣刀,实现对槽的加工,使其达到精度要求。

为了提高劳动生产率,保证加工质量,降低劳动强度,需要设计夹具。本次夹具设计主要对mm孔进行加工,其夹具为专用夹具,利用Z550立式升降台钻床,锥柄机用铰刀,实现对mm孔的精铰加工其粗糙度为1.6。

3.1 问题的提出

本夹具主要用来精铰mm的孔,其粗糙度要求为1.6。由于孔的加工精度要求较高,因此,在本道工序加工时在考虑精度的前提下,还应考虑到降低劳动强度,提高劳动生产率。

参考文献

1 魏康民.机械加工技术[M].山西:西安电子科技大学出版社,2005:351.

2 李青.机床夹具的设计[J].机械工程与自动化,2004,(6):56-67.

3 冯辛安.机械制造装备设计[M].北京:机械工业出版社,2005.

4 内蒙古机械工艺管理协会.实用机械技术问答.内蒙古:内蒙古人民出版社,1993.

5 余光国.机床夹具设计[M].四川:重庆大学出版社,1995:228.

6 王素琴,钱瑾红.组合夹具的研究状况与应用[J].电子机械工程,2004,(5) :56.

7 王凤鲜.浅谈组合夹具的重要作用[J] .科技情报开发与经济,2008,(34) :4.

8 王隆太.先进制造技术[M].北京:机械工业出版社,2003:133.

9 易家琛.机床夹具类型的选择[J].机械工人冷加工,1993,(1):156.

10 张捷.机械制造技术基础[M].成都:西南交通大学出版社,2006.

11 金永昕,王沛民.试论设计方法学的范畴和体系[J].浙江大学教育研究1986,(1).

12 陈恒高,田金.机械夹具设计原理[M].黑龙江:哈尔滨工程大学出版社,1998:248.

13 陶建平.通用可调夹具[J].机械工人冷加工,1982,(2).

14 刘守勇.机械制造工业与机床夹具[M].北京:机械工业出版社,2000:249.

15 崇凯.机械制造技术基础课程设计指南.北京:化学工业出版社,2007.

16 李春胜,黄德彬.机械工程材料手册[M].北京:电子工业出版社,2007.

17 张树森.机械制造工程学[M].沈阳:东北大学出版社, 2003.

18 骆素君,朱诗顺.机械课程设计简明手册[M].北京:化学工业出版社,2006,8.

19 田春霞.数控加工工艺[M].北京:机械工业出版社,2006:254-315.

20 吴锡英.论成组技术在机械工业技术改造中的作用[J].组合机床与自动化加工技术,1983:24-35.

21 谢友宝,吴竹.夹具夹紧方案优化设计[M].现代制造工程,2005,(6) :78-105.

22 王黎明.适应现代机床要求的新型夹具[M].世界制造技术与装备市场,1999,(4) .

23 于维民.浅论绿色制造理念下的机械制造工艺[J].装备制造,2009,(6):4-15.

川公网安备: 51019002004831号

川公网安备: 51019002004831号