半轴壳体左右两面孔加工组合机床总体设计【优秀组合机床全套课程毕业设计含4张CAD图纸】

【带任务书+开题报告+外文翻译】【51页@正文21800字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

RESEARCHOFINNERF_省略_PBASEDONOPENFOAM_.pdf

SW三维建模参考

中期教学检查表.doc

任务书.doc

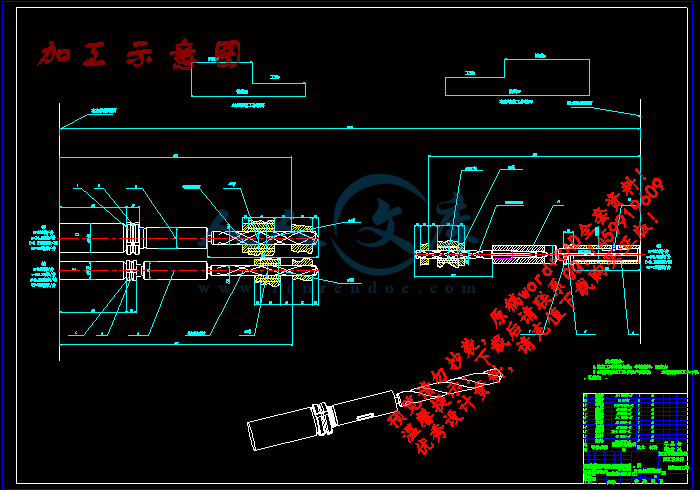

加工示意图.dwg

半轴壳体.dwg

外文翻译.doc

工序图.dwg

开题报告.doc

生产率计算卡2.doc

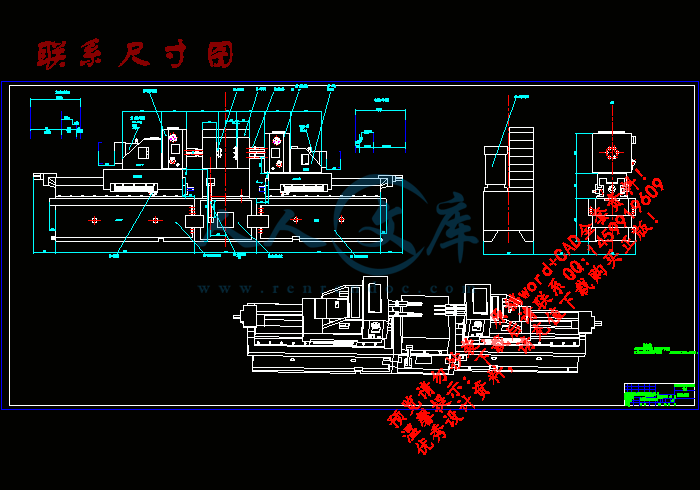

联系尺寸图.dwg

说明书.doc

任务书

题目 半轴壳体左右两面孔加工组合机床的总体设计

主要研究目标或研究内容)1.组合机床方案的拟定;

2.选择刀具、确定相应的切削用量;

3.绘制被加工零件工序图、加工示意图、机床联系尺寸图;

4.编制机床生产率计算卡

课题要求、主要任务及数量(指图纸规格、张数,说明书页数、论文字数等)独立完成不少于3张A0图纸的结构设计图、装配图和零件图,其中应包含1张以上用计算机绘制的具有中等难度的A1号图纸,同时至少有折合A1图幅以上的图纸用三维绘制,查阅15篇以上与题目相关的文献。并需翻译一万印刷符(或译出3000汉字)以上的有关技术资料(并附原文)。毕业论文的字数一般为1..5万字(约40~50页)。

进度计划第1~3周:借阅相关资料、了解相关知识,毕业实习,完成开题报告

第4~6周:熟悉加工零件、了解用途、绘制零件图

第7~13周:确定设计方案、分析、计算、绘图

第14~15周:编写说明书、定稿、打印、答辩前准备阶段

主要参

考文献[1] 沈阳工业大学 大连铁道学院 吉林工学院编.组合机床设计.上海:上海科学技术出版社,1985.

[2] 周诵明. 机械类专业 毕业设计指导书. 武汉:华中理工大学出社,1993.

[3] 赵雪松,任小中, 于华. 机械制造装备设计.武汉:华中科技大学出版社, 2009.

[4] 谢家瀛. 组合机床设计简明手册.北京:机械工业出版社,2002.

半轴壳体左右两面孔加工组合机床总体设计

摘 要

半轴壳体左右两面钻孔组合机床总体设计是根据加工零件,拟定工艺和结构方案,选择合适的刀具,拟定合适的结构方案和工艺,定出通用部件,并进行绘图和相关方案和技术文件的设计。

满足加工内容如下:对左右端面经行钻孔加工,左端面上孔径为23.4mm和17.4mm的孔各两个,右端面上是孔径为13mm的六个孔。组合机床总体设计和普通机床的设计过程是相似的,组合机床使用多刀同时加工的,因此自动化程度高,因而比普通机床生产效率高,产品质量高,所需劳动力少。组合机床的总体设计是通过对零件分析等,用三图一卡表达出总体方案,包括绘制零件加工的工序图、加工示意图、联系尺寸图,及生产率计算卡。设计组合机床满足生产要求,符合实际情况,并且节约材料,满足市场需求,经济实惠。

关键词:半轴壳体,组合机床,总体设计

HALF SHAFT CASING AROUND TWO FACE PROCESSING AND THE OVERALL DESIGN OF COMBINED MACHINE TOOL

ABSTRACT

Overall design about half shaft shell sides drill combination machine tools is according to the machining parts, drafting process and the structure scheme, choosing the right tool, to formulate appropriate structure scheme and process, set general components, and for the design of drawing and relevant scheme and technical documents.

About satisfy processing content is as follows: to end the row drilling processing, on the left end face diameter of 23.4 mm and 17.4 mm hole of the two, on the right end is size for six of the 13 mm hole. Overall design of combined machine tool and the design process of ordinary machine tool is similar, combination machine tools using multiple blade processing at the same time, so a high degree of automation, and thus is higher than common machine tool production efficiency, product quality is high, you need less labor. The overall design of the modular machine tool is based on the component analysis and so on, with three figure one card expresses the overall scheme, including map parts processing process, processing sketch, contact size chart, and productivity calculation card. Design combination machine tools to meet production requirements, in line with the actual situation, and save material, meet market demand, economical and practical.

KEY WORDS: Half shaft casing, Combination machine tools, general design

目 录

前 言1

第1章 组合机床总体设计步骤3

1.1制定方案3

1.1.1确定工艺方案3

1.1.2机床的配置型式及结构方案3

1.1.3总体设体—三图一卡4

第2章 制定组合机床方案5

2.1影响组合机床方案制定的那些因素5

2.1.1被加工零件的加工精度和加工工序5

2.1.2被加工零件的特点5

2.1.3零件的生产批量6

2.1.4机床应用条件6

2.2制定工艺方案7

2.2.1工艺方法达到的制造要求7

2.2.2工艺原则的确定7

2.2.3定位基准及夹紧点的确定8

2.3确定机床配置型式及结构方案9

2.3.1机床各项注意内容9

第3章 刀具部分10

3.1关于切削用量的内容10

3.1.1切削用量选择特点及注意问题10

3.1.2切削用量选择方法12

3.2切削力、扭矩、功率及刀具耐用度计算13

3.2.1各计算内容13

3.3刀具结构15

3.3.1选择刀具注意内容15

第4章 图纸内容及要求16

4.1被加工零件16

4.1.工序图作用及内容16

4.1.2工序图注意事项17

4.2加工示意图17

4.2.1示意图作用及内容17

4.2.2示意图的画法及注意事项17

4.2.3相关部件确定18

4.2.4动力部件工作循环及工作行程22

4.3联系尺寸图作用及内容22

4.3.1联系尺寸图22

4.3.2选择动力部件23

4.3.3需考虑的问题25

4.3.4联系尺寸的画法和过程27

第5章 组合机床生产率计算28

结 论30

谢 辞31

参考文献32

前 言

机床在现代机械制造业中占有最重要的地位。通常在机械制造厂中,机床所担负生产总量,大约是机械制造业的90%,机床结构和工艺是对机械加工产品的质量及经济性影响的重要因素,它是衡量国家制造水平重要依据。另外,通过这么多年来机床的不断的发展,一次次的更新,出现了现在这么多、结构优良和性能较好的机床,才使现代制造业出现了翻天覆地的变化,组合机床的发展,节约了大量人力,释放了劳动力,提高了生产力,在现代机械领域,组合机床的设计非常重要的意义。

半轴壳体左右两两面钻孔组合机床总体设计,主要同过对加工工艺的要求,选择合适刀具,根据切削用量算出切削力,一步步选择主轴,进而确定工进长度,选择通用部件,绘制出三图一卡,来完成总体部分的相关设计。以达到的技术要求目的,即满足加工精度,耐用度,生产效率及节约资源。在设计中主要面对工艺分析,刀具选择,通用部件合理性等问题。通过认真分析计算一步步完成设计。

半轴壳体左右两面钻孔组合机床设计主要是让我们全面合理的分析理解,最终加工精度要求及达到生产率要求。同过理论计算,让理论和标准相结合,然后选择合适的通用部件。

全球第一台组合机床在1908年被设计出来,在这30年后组合机床在全球各国得到快速发展。时至今日,组合机床成为现代机械制造业的必不少设备。现代机械制造业全方位对组合机床提出了更高的要求,它也在连绵不绝的接受新技术,不断更新发展。

我国也不甘于落后,我国面对国际机床的发展,我国也不断发展,产生了生产和销售都不错的势头,到2005年,我国组合机床产量已达10000多台,产值达3.9亿,我国加入WTO以后,机械制造业我国所面临前所未有的挑战,组合机床不断发展。随着我国的发展,组合机床不断发展,使产品销售不断增长。关于组合机床的各项经济指标均有所增长。新机床不断出现,新技术的不断运用,促使我国组合机床不断发展。

参考文献

[1] 李理. 设计图学. 北京:化学工业出版社,2006.

[2] 陈立德.北机械设计基础. 北京:高等教育出版社,2006.

[3] 冯辛安.机械制造装备设计.第二版.北京:机械工业出版社,2005.

[4] 王昆.何小柏.汪信远 机械设计. 机械设计基础课程设计.北京:高等教育出版社, 2010.

[5] 文九巴.机械工程材料. 北京:机械工业出版社,2009.

[6] 吴宗泽.机械零件设计手册. 北京:机械工业出版社,2005.

[7] 于志伟.Pro/ENGINEER零件设计完全手册[M].北京:人民邮电出版社,2007.

[8] 任小中.机械制造技术基础. 北京:科学出版社,2012.

[9] 吴宗泽.罗盛国.机械设计课程设计手册[M].4版.北京:高等教育出版社,2006.

[10] 江德涛.林亨耀.设备润滑手册[M].北京:机械工业出版社,2009.

[11] 刘朝儒.彭福荫.高政一.机械制图[M]. 4版.北京:高等教育出版社,2001.

[12] 吴圣庄.金属切削机床概论[M].北京:机械工业出版社,2004.

[13] 余梦生.吴宗泽.机械零部件设计手册:选型、设计、指南[M].北京

机械工业出版社,2006.

[14] 李梦群. 先进制造技术导论[M].北京:国防工业出版社,2005.

[15] 赵雪松.任小中.于华. 机械制造装配设计. 武汉:华中科技大学出版社,2009.

[16] 何铭新.钱可强.徐祖茂. 机械制图. 北京:高等教育出版社,2010.

[17] 牛永生.吴隆.李力.姜春英主编.机械制造技术.西安:陕西科技出版社,2012.

[18] 郑金兴. 机械制造装配设计[M].哈尔滨:哈尔滨工程大学出版社,2008.

[19]马玉录. 刘东雪主编. 机械设计制造及其自动化专业英语.北京:化学工业出版社, 2013

川公网安备: 51019002004831号

川公网安备: 51019002004831号