!【详情如下】CAD图纸+word设计说明书.doc[10000字,21页]【需要咨询购买全套设计请加QQ97666224】.bat

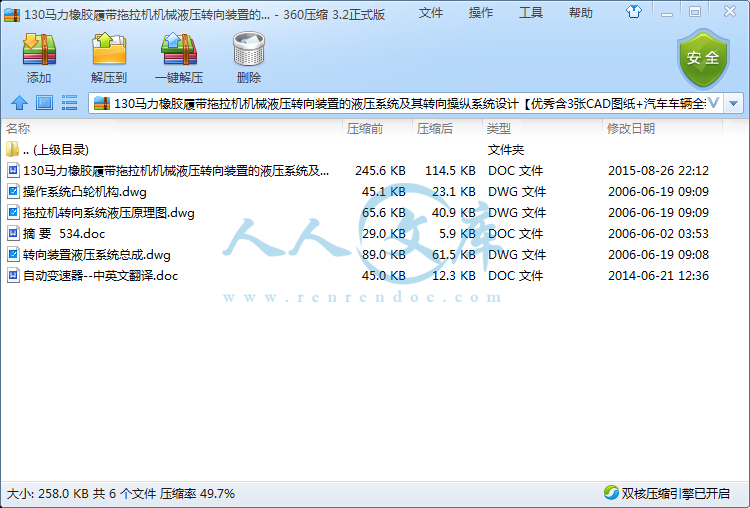

130马力橡胶履带拖拉机机械液压转向装置的液压系统及其转向操纵系统设计(有cad原图+中英文翻译)

拖拉机转向系统液压原理图.dwg

转向装置液压系统总成.dwg

操作系统凸轮机构.dwg

摘 要 534.doc

自动变速器--中英文翻译.doc

摘 要

本次主要设计130马力橡胶履带拖拉机机械液压转向装置的液压系统及其转向操纵系统,是机械液压双功率流转向装置的液压部分。

为了满足设计要求,即:方向盘操纵,能实现原地转向即倒车操作;转向半径可平滑过度;实现最小转向半径;满足转向力矩要求,本次设计的液压系统是一个采用液压先导排量控制的典型容积调速闭式回路。系统采用排量大,转速高,压力大的轴向柱塞泵和轴向柱塞马达,能够较好的满足液压泵变量机构和液压马达的双向运转特性。系统两侧的管道容积相等,安全阀的调定压力相等,保证了车辆转向时液压马达速度变化的动态特性一致,为了保证系统正常稳定的工作,还加入了溢流阀,单向阀和补油泵。在定量液压马达中集中了溢流阀和换向阀,换向阀把马达输出的热油通过溢流阀流回油箱,再通过补油泵和滤清器补进冷油,进入下一个工作循环,从而保证系统的正常油温和油液的清洁。为使驾驶员操作简便,系统通过方向盘来控制整个转向过程,方向盘的转角决定转向半径的大小,方向盘的左右转向决定车辆的转向方向。由方向盘操作的液压先导阀,通过变量液压泵内的伺服阀,实现对液压泵排量的控制,进而控制定量马达的转向和转速。

关键词:轴向柱塞变量泵,轴向柱塞定量马达,压力,阀

ABSTRACT

This mainly designs the hydraulic system and it’s control system of 130 horsepower rubbers caterpillar tractor mechanical hydraulic pressure diverting device, it is part of the mechanical hydraulic pressure double power installment hydraulic pressure.

In order to satisfy the design request, namely: The steering wheel operation, can satisfy in-situ changes and the back-draft operation; The radial turning may be smooth excessively; satisfy the smallest radial turning; satisfy rotating torque request, the hydraulic system uses the hydraulic pressure forerunner displacement to control the typical volume velocity modulation close route. The system uses axial ram pump and the axial plunger motor of large displacement, high rotational speed, high pressure, can satisfy hydraulic pump variable organization and the oil motor bidirectional revolution characteristic. System’s two sides pipeline volumes is equal, the safety valve accent decides the pressure equally, and guaranteed the vehicles change when the oil motor speed change dynamic characteristic consistently, in order to guarantee the system normal stability work, it also has joined the overflow valve, the cone-way valve and makes up the oil pump. Has concentrated the overflow valve and the cross valve in the quota oil motor, the cross valve the hot oil which outputs the motor flows through the overflow valve and return to the fuel tank, makes up the oil pump and the filter makes up the cold oil, enters the next operating cycle, thus guarantee system normal oil temperature and fat liquor is clean. In order to cause the pilot to operate easily, the system controls entire process by the steering wheel’s change, the size of radial turning depend on the steering wheel’s, steering wheel’s changes decide the vehicle to change the direction. Hydraulic pressure first pilot valve is operated by the steering wheel, through the servo valve which is in variable hydraulic pump, to satisfy the hydraulic pump displacement control, then control quota motor change with rotational speed.

KEY WORDS: axial plunger variable pump, axial plunger quota motor , pressure,valve

目 录

前言

第一章、转向技术的发展及趋势

§1.1、转向技术的发展过程及优缺点

§1.2、双功率流转向机构

§1.2.1、双功率流技术的发展

§1.2.2、双功率流履带车辆转向控制研究的意义

第二章 液压系统工作原理及参数选择

§2.1 、液压系统工作原理

§2.2 、转向液压系统参数的确定

§2.2.1 、转向液压马达参数的确定

§2.2.2 、变量液压泵参数的确定

§2.2.3 其它元件的选择

总结

致谢

参考目录

参考文献

[1] 葛安林.车辆自动变速理论与设计.机械工业出版社,1993:

153一213

[2] 吉林工业大学.北京农机学院等合编,拖拉机底盘结构设计图册.机械工业出版社,1976:315-334

[3] 徐灏.机械设计手册.机械工业出版社,1992:10-678

[4] 程悦荪,拖拉机设计.中国农业机械出版社,1981:87-95

[5] 镇江农机学院,洛阳农机学院合编. 拖拉机理论.中国农业机械出版社.1981: 58-82

[6] 过学讯.汽车自动变速器一一结构·原理.机械工业出版社,

2001: 105-114

[7] 李国政. 拖拉机机械变速箱自动换档控制技术研究:[硕士参考文献学位论文]。中国农业大学,2004,18-32

[8] 付主木,张文春,周志立等.拖拉机电控机械式自动变速器动力性换档规律研究.农业机械学报,2003,19 (4),114-117

[9] 朱红军,葛安琳,张广成等.电子控制机械式自动变速器.汽车

电器,2000, (1), 11-13

[10] 李君,张建武,冯金芝等.电控机械式自动变速器的发展、现状

和展望.汽车技术,2000, (3), 1-3

[11] 周学建,张文春等.车辆自动变速器换档规律的研究现状与展望.农业机械学报,2003,34 (3),139-141

[12] 杨为民,贾鸿社.电控机械式自动变速箱在拖拉机上的应用探讨.

拖拉机与农用运输车,2001, (4), 23-25

[13] 钟绍华.电控机械式自动变速器的起步与换档过程的研究:[硕士参考文献学位论文].吉林工业大学,1992,61一72

[14] 田全忠.现代大功率拖拉机自动换档控制系统.拖拉机与农用运

输车2001,(3),3一7

[15] 张文春,方在华.小型拖拉机挂车机组发动机载荷的动态匹配.

农业机械学报,1992, 23 (2), 6-10

川公网安备: 51019002004831号

川公网安备: 51019002004831号