!【详情如下】【汽车车辆工程类课题】CAD图纸+word设计说明书.doc[15000字,44页]【需要咨询购买全套设计请加QQ97666224】.bat

352履带拖拉机-单级最终传动装置设计(有cad原图+中英文翻译).doc

A.1开题报告.doc

任务书.doc

摘要、目录.doc

翻译原文.doc

设计说明书.doc[15000字,44页]

转向系统--中英文翻译.doc

主动齿轮.dwg

从动鼓接盘.dwg

从动齿轮.dwg

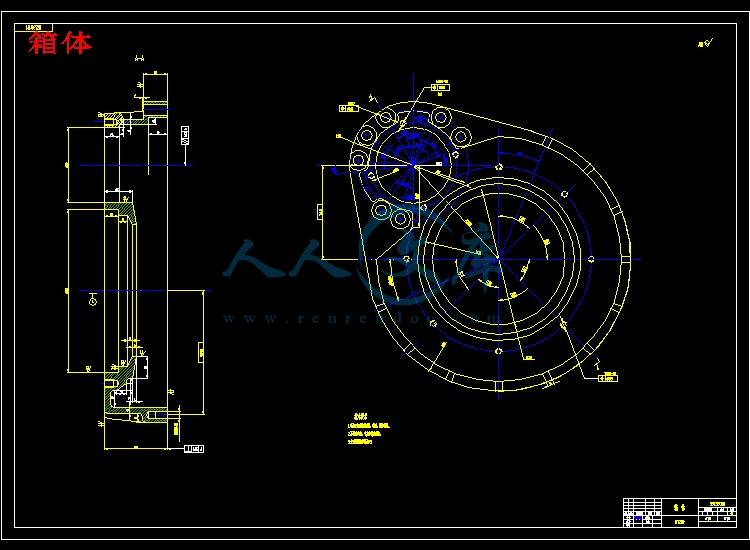

箱体.dwg

摘要

履带式拖拉机能够正常行驶,拖拉机驱动轮需要足够的驱动力。这就需要一套能够增加传动系的传动比的专署机构。它将进一步降低驱动轮转速,从而提高驱动轮的转矩,这就是所谓的最终传动。同时履带式拖拉机的最终传动还用来提高后桥的离地间隙。所以最终传动要有适当的传动比;保证后桥处有足够的离地间隙;齿轮要具有较高的支承刚度;靠近驱动轮布置的最终传动尤其要有可靠的密封。

外置式外啮合圆柱齿轮最终传动,使最终传动成为一个独立部件,便于拆装和维修。这种结构的主、从动齿轮在壳体内的支持可以布置成简支梁式,对提高支撑刚度有利。主动轮的啮合条件降低了轮齿上的载荷,提高了承载能力,但结构复杂。

最终传动的传动比较大,齿轮和轴受载严重,径向尺寸受到轮辋尺寸和离地间隙的限制而不能太大。为了在结构紧凑的情况下,保证齿轮有足够的强度,外啮合圆锥齿轮的最终传动常常采用较大的齿宽和较少的齿数。为了保持齿轮的良好啮合,必须保证两齿轮轴中心线的平行度。

关键词:主动齿轮,最终传动,直齿,保护板

TGHE FINAL DRIVES DESIN

ABSTRACT

Track type tractor can be normal to drive, the tractor drives a demand to drive the dint enough . This need a set of canning increase to spread to move is of spread the exclusive organization that move compare. It will further lower to drive the rotation soon, from but the exaltation drives a the round turns to be apart from, this is so-called of end spread to move .At the same time track type tractor of end spread to move to still use to leave a cleft after increasing to the bridge.

Outside install outside the place type matches the cylinder wheel gear the end spreading moves, making end spreading moved to become an independent parts, easy to dismantle to pack with maintain. This kind of structural lord, from move the wheel gear to can arrange in the hull support in a beam type, prop up to the exaltation just the degree is beneficial .Install of the active round matches the term lowers a ascends of is increases by dint, loading ability, but the construction sophisticates.

It is end to spread to spread to move dynamically bigger, the wheel gear suffers to carry with stalk seriously, the path is left by a size with toward size the restrict of a ground of clefts but can't be too big. For the sake of under the situation that construction tightly packed, guarantee to wheel gear contain enough strength, the outside match the cone wheel gear end to spread to move to usually adopt the bigger breadth with the number of the less.

KEY WORD:Drive gear wheel , The final drive, Spur gear,Guard

目 录

第一章 前言....................................... ....1

第二章 传动系统概述....................................2

第三章 最终传动概述....................................3

§3.1 最终传动装置的功用和要求.................... ..3

§3.2 最终传动的分类、结构分析及评价..................3

§3.2.1 外啮合圆柱齿轮最终传动.................... .3

§3.2.2 内啮合圆柱齿轮最终传动......................4

§3.2.3 行星齿轮最终传动............................4

§3.3 最终传动的传动方案及结构简图...................4

第四章 总体设计.....................................6

§4.1机械式传动系统总传动比及各部件传动比的确定......6

§4.1.1 传动系的总传动比............................6

§4.1.2 总传动比在各部件间的分配....................7

第五章 最终传动装置设计................................8

§5.1 最终传动装置主要参数的选择......................8

§5.2 最终传动装置强度校核..........................9

§5.2.1 齿轮强度校核............................... 9

§5.2.2 轴承寿命校核............................. .18

§5.2.3 轴强度校核.................................20

§5.2.4 螺栓强度校核...............................22

第六章 结论................................. .........26

参考文献...............................................27

致谢..................................... .............28

川公网安备: 51019002004831号

川公网安备: 51019002004831号