!【详情如下】【汽车车辆工程类课题】CAD图纸+word设计说明书.doc[19000字,52页]【需要咨询购买全套设计请加QQ97666224】.bat

外文翻译.doc

设计说明书.doc[19000字,52页]

制动鼓.dwg

前制动.dwg

后制动.dwg

总装图.dwg

摘 要

制动系至少有两套制动装置即行车制动装置和驻车制动装置。行车制动装置是用作强制行驶中的汽车减速或停车,并使汽车在下坡时保持适当的稳定车速。驻车制动装置是用作是汽车停在原地或坡道上。

制动性能是车辆最重要的性能之一,车辆制动系统性能的好坏直接影响到车辆行驶的安全性。因此,有必要对车辆制动系统进行详细的研究。

本设计对鼓式制动器的结构形式进行综合的分析,对六种形式的优缺点作了比较,根据对各种制动器方案对比分析,本设计采用了领从蹄式制动器。其主要优点是:制动器的效能及稳定性均处于中等水平,但由于其在汽车前进与倒退时的制动性能不变,且结构简单,造价较低,也便于附装驻车驱动机构;易于调整蹄片与制动鼓之间的间隙。本次设计中,行车制动系采用人力液压式制动;驻车制动的驱动机构为手动驻车;串联双腔制动主缸,双回路结构。前后制动器都采用领从蹄式鼓式制动器。设计中根据总体参数和制动器的结构与参数,通过理论推导和计算,对该车制动时的制动力和制动力矩等做了细致的分析。

关键词:制动系统,制动器,行车制动系,应急制动

KD1060 TRUCK DESIGN

(BRAKE SYSTEM)

ABSTRACT

Break system consists of service break arrangement and parking break arrangment.Service break system used to force the vehicle to show down and keep a steady speed when downgrading.The parking break system intended to hold the vehicle immovable when parked on an incline.

The braking capability is one of the most important performances of vehicles, and the capability of the brake system directly affects the vehicles’ safety. Therefore, it is necessary to make a research about the vehicle’s braking system in detail.

This design carries on the synthesis analysis to the drum type of the brake structural style. It compares the advantages and disadvantages of six kinds of forms, and according to this contrast analysis of the kinds of the brake plan, the horseshoe type’s brake is adopted. Its main merits are that although the brake efficiency and the stability are in the medium level, because the automobile braking performance is invariable when going ahead and going backwards, the construction cost is lower, and it attaches installs in the vehicle’s driving mechanism and adjusts the gap between the brake shoe patch and the brake drum easily.The design uses manual hydraulic break and series connected double cavity general pump. Both the front and rear break is double leading-rear break.According to the vehicle’s parameters and the break’s parameter,after theory analytic and calculating, we analyzed the breaking force and direction stability when breaking specifically.

KEY WORD:braking system,brake ,service break system, emergency brake

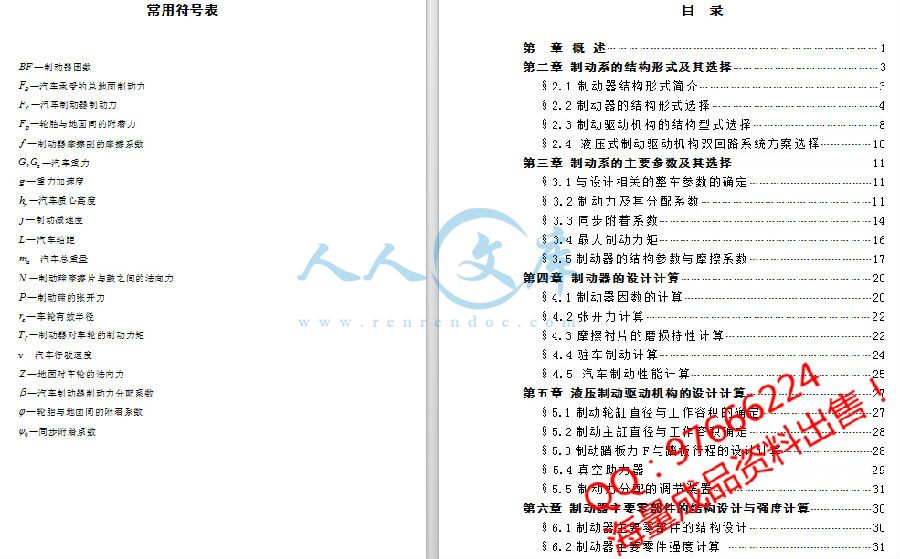

目 录

第一章 概 述…………………………………………………………………1

第二章 制动系的结构形式及其选择……………………………………3

§2.1制动器结构形式简介……………………………………………3

§2.2制动器的结构形式选择…………………………………………4

§2.3制动驱动机构的结构型式选择………………………………8

§2.4 液压式制动驱动机构双回路系统方案选择……………10

第三章 制动系的主要参数及其选择 …………………………………11

§3.1与设计相关的整车参数的确定………………………………11

§3.2制动力及其分配系数…………………………………………11

§3.3同步附着系数……………………………………………………14

§3.4最大制动力矩……………………………………………………16

§3.5制动器的结构参数与摩擦系数………………………………17

第四章 制动器的设计计算………………………………………………20

§4.1制动器因数的计算………………………………………………20

§4.2张开力计算………………………………………………………22

§4.3摩擦衬片的磨损特性计算……………………………………22

§4.4驻车制动计算……………………………………………………24

§4.5 汽车制动性能计算……………………………………………25

第五章 液压制动驱动机构的设计计算………………………………27

§5.1制动轮缸直径与工作容积的确定……………………………27

§5.2制动主缸直径与工作容积确定………………………………28

§5.3制动踏板力F与踏板行程的设计计算………………………28

§5.4真空助力器………………………………………………………29

§5.5制动力分配的调节装置………………………………………31

第六章 制动器主要零部件的结构设计与强度计算………………30

§6.1制动器主要零部件的结构设计………………………………30

§6.2制动器主要零件强度计算 ……………………………………31

结论……………………………………………………………………………33

参考文献………………………………………………………………………34

致谢……………………………………………………………………………

参考文献

[1] 刘惟信主编. 汽车制动系的结构分析与设计计算. 北京:清华大学出版社,2004 P667—P749

[2] 刘惟信主编. 汽车设计. 北京:清华大学出版社,2001

[3] 陈家瑞主编. 汽车构造(第2版下册). 北京:机械工业出版社,2004 P179-P197 P282-P371

[4] 余志生主编. 汽车理论. 北京:机械工业出版社,2003

[5] 王望予主编. 汽车设计(第4版). 北京:机械工业出版社,2004 P16-P39 P257-P285

[6] 刘鸿文主编. 材料力学.北京:高等教育出版社,1992 P44-P50

[7] 汽车工程手册编辑委员会. 汽车工程手册—设计篇.北京:人民交通出版社,2001 P492-P568

[8] 汽车工程手册编辑委员会. 汽车工程手册—制造篇.北京:人民交通出版社,2001 P186-P200

[9] 自动车技术会小林明等编. 汽车工程手册编译委员会译.汽车工程手册(第二分册).机械工业出版社,1984 P258-P294

[10]自动车技术会小林明等编. 汽车工程手册编译委员会译.汽车工程手册(第三分册).机械工业出版社,1984 P423-P524

[11]罗锦陵,宋美娟,周宏湖主编.汽车配件实用手册.上海:上海交通大学出版社,1997 P587-P607

[12]肖永清,杨忠敏主编.汽车制动系统的使用与维修.北京:中国电力出版社,2004

[13]薛汉池. QC/T 309—1999.制动鼓工作直径及制动蹄片宽度尺寸系列.长春. 长春汽车研究所

[14]陈广照.GB 16897—1997.制动软管.长春.中华人民共和国机械工业部

[15]南京汽车制造厂. GB 11611—1989.汽车液压制动系金属管、内外螺纹管接头和软管端部接头.中国汽车工业联合会

[16]方昆凡主编.工程材料手册非金属材料卷.北京:北京出版社,2000

[17]方昆凡主编.工程材料手册有色金属材料卷.北京:北京出版社,2000

[18]《钢铁材料手册》总编辑委员会编著.钢铁材料手册碳素结构钢第1卷.北京:中国标准出版社,2002

[19]周康年,丁为联主编.中国机械设计大典第2卷.南昌:江西科学技术出版社,2002

川公网安备: 51019002004831号

川公网安备: 51019002004831号