轻型载重货车设计(转向系及前桥设计)

轻型载重货车转向系及前桥设计【优秀转向系前桥全套课程毕业设计含3张CAD图纸】

【带开题报告+外文翻译】【41页@正文12700字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

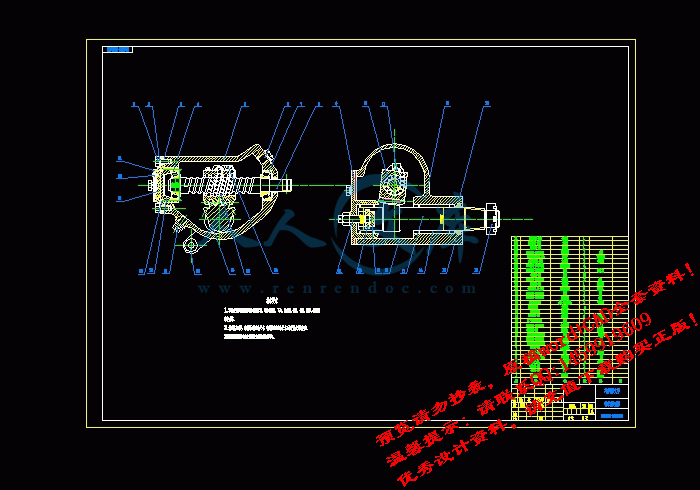

cad图集(3张).dwg

开题报告.doc

摘要.doc

翻译.doc

轻型载重货车转向系及前桥设计.doc

轻型载重货车设计(转向系及前桥设计)

摘 要

在本次毕业设计中,是关于轻型载货汽车的前桥及转向系统的设计。本着力争性能可靠,价优,易造的设计构想,同时也主要参照拖厂的同类车型,努力去改造,去创新。

转向从动桥是通过悬架和车相连,两侧安装着从动车轮,用以传递车架与车轮之间的各种力和力矩。汽车的转向系是利用转向节使车轮可以偏转一定角度以实现汽车的转向。汽车的转向系是用来改变或恢复汽车行驶方向的专设机构,在行驶中起到重要作用。主要可分为机械转向系,动力转向系和电动转向系。其中电动转向系是未来汽车转向系的发展方向。

综合各种因素,本次设计采用采用转向梯形机构布置在前轴之后的整体式车桥和采用了正效率很高,操纵方便且使用寿命长的机械式循环球式转向器。本次设计包括对转向从动桥结构形式的选择,主要是计算前轴、转向节、主销、主销上下轴承、转向节推力轴承或止推垫片等在制动和侧滑两种工况下的应力校核。还包括转向器的结构选择及其设计计算并对转向梯形进行优化设计。设计中水平有限,但希望能设计出一辆经济实用的轻型载货汽车。

关键词:运输车,前桥,主销,转向轴

THE DESIGNS OF THE STEERING SYSTEM AND

FRONT AXLE IN OWN UNLOAD AGRICULTURE

TRUCK TO TRANSPORT OF KD1080

ABSTRACT

In this graduated designs, my assignment is the light truck’s front axle and steering system. I shall try my best to design my assignment,I want the light truck’s capacity is secure and the price is low. It is also easy to make,at the same time,I refer to the light truck which made in YT factory.I want to improve and innovate it.

Steering front axle connects the frame by suspension.Driven wheel are installed at the sides of the fore axle,which transmits kinds of forces and torques into the wheels. The steering knuckle link to the front axle causes the front wheels to turn to the right or left .The steering system enables the driver to guide the automobile or wheeled tractor down the road and turn ringht or left.It is very important for the truck.there are mannnual steering,power steering and electric power steering.The electric power steering system will be the direction in the future.

In view of all the factors,I adopt the ladder-shaped organization assigns after the front axle and very efficient that can be handled easily and had long performance life steering box of the circulation ball type. The design includes selection of the structure of the fore axle but most calculate the streys inspection under the break and the second slide of front axle ,steering knuckle inserts, king pin and ball bearing, thrust bearing and stop last spacer. Still include choosing and designing aslo calculating and carrying on optimization design ladder-shapedly of steering. The level is limited in the design, but I hope to design a economical and practical agricultural light truck.

KEY WORDS: transporter, the front axle, king pin, steering shaft

目录

前言3

第一章 概述3

第二章 从动桥的方案确定6

§2.1 从动桥总体方案确定6

第三章 转向系的方案确定8

§3.1 转向系整体方案确定8

§3.2 转向器结构形式及选择8

§3.3 循环球式转向器结构及工作原理9

第四章 从动桥的设计计算11

§4.1从动桥主要零件尺寸的确定11

§4.2 从动桥主要零件工作应力的计算11

§4.3 在最大侧向力(侧滑)工况下的前梁应力计算13

§4.4 转向节在制动和侧滑工况下的应力计算15

§4.5 主销与转向节衬套在制动和侧滑工况下的应力计算16

§4.6转向节推力轴承的计算19

第五章 转向系统的设计计算20

§5.1 转向系主要性能参数20

§5.1.1转向器的效率20

§5.1.2传动比的变化特性20

§5.2 主要参数的确定21

§5.2.1 给定的主要计算参数21

§5.2.2 选择主要转向参数21

§5.2.3 车轮的左右最大转角确定22

§5.3 转向梯形的选择设计23

§5.4 转向梯形的优化24

§5.5 循环球式转向器的设计27

§5.5.1 转向器(循环球式)的效率27

§5.5.2 主要参数的选择27

§5.5.3 螺杆、钢球和螺母传动副28

§5.5.4 齿条、齿扇传动副设计29

§5.6 转向系主要性能参数确定30

§5.6.1 转向系的角传动比30

§5.5.2 转向盘旋转圈数n30

§5.6 循环球式转向器零件强度的校核31

§5.6.1钢球与滚道间的接触应力31

§5.6.2齿的弯曲应力32

§5.7 转向系其他元件的选择及材料的确定32

第六章 转向系主要零件的强度计算34

§6.1 计算载荷的确定34

§6.2 主要零件的强度计算34

总 结35

致 谢37

参考文献38

前言

在目前金融危机的大环境下,伴随着汽车行业的发展,轻型货运汽车在国民生产中扮演着更重要的角色。

轻型载货汽车各个领域得到了广泛应用,对于它的设计是依据以往理论知识及实践经验,在满足其功用的前提下来进行的。转向系统是用来保持或改变汽车行驶方向的机构,它在整体设计中亦有其重要地位,对转向时车轮正确运动和汽车的安全行驶有重大影响,这就要求其工作可靠、操纵轻便。

在目前的设计和使用方面,转向系统由机械式和动力式两类,由于动力式转向系统能减轻驾驶员的负担,而且操作方便,所以到广泛使用。机械式转向系统由于造价低廉,而且能够满足轻型货车等一大部分汽车的转向需要,固也得到了广泛的使用。机械式转向系由操纵机构、转向器和转向传动机构组成,其重点是转向器和传动机构的设计。现今国内轻型汽车多才用整体式循环球式转向器,整体式后置梯形。

本毕业设计说明书,主要讲述了前桥前悬和转向系统的选择设计和方案分析。对前桥前悬和转向系统的分类和工作原理进行了深入的对比和分析,选出最优方案来进行设计;对于转向系统的重要组成部分转向器和转向传动机构进行分析设计,选择合适的机构和零件。

参考文献

1. 刘惟信.汽车设计.北京:清华大学出版社,2000

2. 王望予.汽车设计(第三版). 北京:机械工业出版社,2000

3. 陈家瑞.汽车构造(下册). 北京:机械工业出版社,2005

4. 余志生.汽车理论(第三版) 北京:机械工业出版社,2000

5. 张洪欣.汽车设计(第二版). 北京:机械工业出版社,1996

6. 吴宗泽.机械设计实用手册. 北京:化学工业出版社,1999

7. [日].自动车技术协会.小林明.汽车工程手册. 北京:机械工业出版社,1996

8. 刘鸿文.材料力学. 北京:高等教育出版社,1991

9. 祖业发.工程制图.重庆:重庆大学出版社,2001

10.浙江交通学校.汽车构造教学图册.人民交通出版社,1986

11. 徐灏.机械设计手册(3、4卷)北京:机械工业出版社,1991

12. 陈军.汽车拖拉机转向梯形优化设计.西北农业大学学报,

2000年,第7期,N0.18

13. 陈思忠.拖拉机与农用运输车, 2000年,第8期,N0.32

14. 安徽飞彩有限公司.农用运输车的发展趋势,2001年第3期,N0.12

15. 张武农.我国汽车工业创新的策略研究,2001年,第6期,N0.9

16. 钱振为.汽车工业研究,2001年,第4期,N0.17

17. 阎荫棠.几何量精度设计与检测.北京:机械工业出版社,1996

川公网安备: 51019002004831号

川公网安备: 51019002004831号