重型自卸汽车设计(变速器设计)

重型自卸汽车变速器设计【优秀汽车变速器全套课程毕业设计含3张CAD图纸】

【带开题报告+外文翻译】【41页@正文16900字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

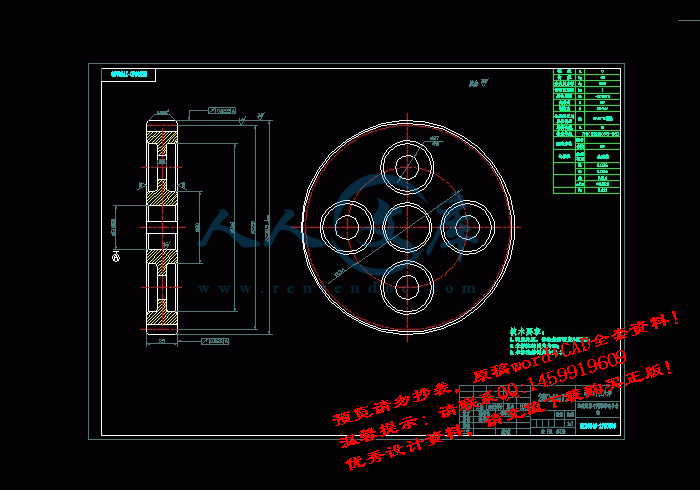

主变速器中间轴常啮合齿轮.dwg

外文翻译.doc

开题报告.doc

英文摘要最终版.doc

重型自卸汽车变速器总成1.dwg

重型自卸汽车变速器总成2.dwg

重型自卸汽车变速器设计.doc

重型自卸汽车设计(变速器设计)

摘要

重型自卸汽车因其运载量比较大,驱动力比较大、发动机功率、扭矩大,工作环境恶劣,在工程运输中运用比较广泛。

对于变速器的设计:我在设计中要首先确定变速器的布置形式,然后选择传动比的范围,确定各挡的传动比。之后确定中心距、外形尺寸。齿轮参数的选择:模数、压力角、螺旋角、尺宽。各挡齿轮的齿数确定。

变速器的各种布置中要分析各种变速器的布置对汽车整体以及各个部件的影响,选择合适的布置形式给变速器与更优化的布置。让变速器在汽车整体中的作用能够达到最佳的状态。

最后,就是变速器的操作机构布置与设计,主要考虑结构简单、操作轻便、档位清晰、操作杆的位置合理、换档准确、迅速、安全可靠。本设计选用机械式远距离操作,在换档与挂挡机构中,设置了互锁自锁装置;为防止误挂倒档,还设置了倒档锁。

设计中变速器的齿轮采用渐开线齿轮形式。变速器的轴应满足刚度、强度、耐磨性要求。

最后,还得进行变速器实验,进行室内台架试验。考核齿轮的可靠性与疲劳寿命;同步器和换档机构的工作性能与耐久性;测定传动的效率、噪声即刚度等。

关键词:操作机构,同步器,轴承,模数,传动比

HEAVY DUMPER TRANSMISSION DESSIGN

(ASSEMPLY DESIGN)

ABSTRACT

Heavy type from unload an automobile because it carries quantity more and greatly,driving the dint comparision big ,launch the power of the machine and big torque big work environment of bad.the usage is more and extensively in the engineering the conveyance.

For the design of the transmission:I want the decoration form of the certain transmission during the period of design first ,then choose to spread scope of move tatio.After make sure the center be part from,shape size.The choice of the gear parameter:The mode number,pressue Cape,spiral Cape,Chinese foot bread.Each gear that block gear counts to really settle.

Various decoration that want to analyze various tranmission in the decoration of the transmisssion is whole to automobile and the influence of each parts,choose a suitable decoration from to the transmission with more excellent turn of decoration.Let the transmission in the automobile of the whole of function can attian the best appearance.

Finally,the mainpulation organization of the derailleur assign and designs,Consider structure simple,handle light,self location clarity, gearshift lever position rational to transser to shelf,accurate,fast,safe,and reliable to transfer to shelf mainly.Design person who selects machinery for use handle remotely ,in shelf of transferring to hang shelf of the organization originally,Locked the device and lock device each other after setting up;In order to prevent hanging and pouring the shelf by mistake,have set up the shelf of pouring to lock.

Design gear wheel of derailleur adopt involute gear wheel form. The axle of the derailleur should meet the rigidity,intensity,wearability request.

Finally.must carry on the test of the derailleur.Go on the experiment of a shelf in the room.Examine the dependability and fatigue life of the gear wheel;Synchronous device transfer to shelf working performance and durability of organization,determine transmission efficiency,noise and rigidity,etc.

Key words:Handle the organization,the synchronous device,the bearing,Modulus,transmission ratio

目 录

第一章 前 言3

第二章 概述5

第三章 变速器传动机构布置7

§3.1 传动机构布置方案分析7

§3.1.1固定轴式变速器7

§3.1.2倒挡布置方案10

§3.2零部件结构方案分析11

§3.2.1齿轮形式11

§3.2.2 换挡机构形式11

§3.2.3 变速器轴承12

第四章 变速器主要参数的选择14

§4.1 各档传动比的分配14

§4.2 中心距A14

§4.3 齿轮参数的选取15

§4.3.1模数15

§4.3.2 压力角16

§4.3.3 螺旋角的选取17

§4.4 各挡齿轮齿数的分配及传动比的计算18

§4.4.1 确定第一轴常啮合齿轮参数:18

§4.4.2 确定六档齿轮参数及传动比:18

§4.4.3 确定七档齿轮参数及传动比:18

§4.4.4 确定四档齿轮参数及传动比:19

§4.4.5 确定爬坡档齿轮参数及传动比:19

§4.4.6 确定倒档档齿轮参数及传动比:19

第五章 变速器的设计与计算21

§5.1 轴的计算与校核21

§5.1.1中间轴的受力分析21

§5.1.2 X-Z面受力分析:22

§5.1.3 X-Y面受力分析:22

§5.1.4 作力矩图22

§5.1.5校核计算24

§5.2齿轮的计算与校核24

§5.2.1齿轮的计算校核公式:24

§5.2.2校核 齿轮:25

§5.2.3 校核齿轮:26

§5.2.4校核 齿轮:26

§5.2.5校核 齿轮:27

§5.2.6校核 齿轮:27

§5.3 轴承的计算与校核28

§5.3.1角接触球轴承的校核计算28

§5.4 键的校核计算28

§5.4.1花键的校核计算29

§5.4.2平键的校核计算29

第六章 同步器的设计30

§6.1 环式同步器主要尺寸的确定31

§6.2主要参数的确定31

第七章 变速器操纵机构设计33

结 论34

参考文献35

致 谢36

第一章 前 言

汽车的诞生,车的发展,在历史的长河中给我们留下了点点滴滴。汽车自上个世纪末诞生以来,已经走过了风风雨雨的一百多年。从卡尔.本茨造出的第一辆三轮汽车以每小时18公里的速度,跑到现在,竟然诞生了从速度为零到加速到100公里/小时只需要三秒钟多一点的超级跑车。这一百年,汽车发展的速度是如此惊人!同时,汽车工业也造就了多位巨人,他们一手创建了通用、福特、丰田、本田这样一些在各国经济中举足轻重的著名公司。这篇资写着许多有趣的故事,在中国已经成为世界五大汽车强国之际,让我们一起来回望汽车的发展历史,体会汽车给我们带来的种种欢乐与梦想……

参考文献

[1] 刘惟信主编. 汽车设计第1版. 北京: 清华大学出版社,2001年7月,158-194

[2] 王望予主编. 汽车设计第4版. 北京: 机械工业出版社,2004年8月,78-111

[3] 陈家瑞主编. 汽车构造第2版. 北京: 机械工业出版社,2005年1月,40-91

[4] 高维山主编. 汽车设计丛书变速器. 北京: 人民交通出版社,1990年8月,6-224

[5] 余志生主编. 汽车理论第3版. 北京:机械工业出版社,2000年10月,5-42

[6] 张毅主编. 机械变速器. 北京: 化学工业出版社,2005年8月,128-265

[7] 濮良贵,纪名刚主编. 机械设计第7版. 北京: 高等教育出版社,2001年6月,62-419

[8] 刘鸿文主编. 简明材料力学. 北京: 高等教育出版社,1997年7月,54-128

[9] 吴宗泽主编. 机械设计使用手册. 北京: 化学工业出版社,2001年5月,468-472

[10] 蔡春源主编. 机械零件设计手册第3版. 北京: 冶金工业出版社,1995年10月,387-389

[11] 全国栋主编. 汽车概论. 北京:机械工业出版社,2000年8月,12-22

[12] 徐谨主编. 机械设计手册. 北京: 机械工业出版社,2000年6月,231-240

[13] 孙恒,陈作模主编. 机械原理第六版. 北京: 高等教育出版社,2004年3月,109-150

[14] 张则曹主编. 汽车构造图册. 北京: 人民交通出版社,1998年2月,23-24

[15] 林清福主编. 国外汽车构造最新构造图册. 北京: 机械工业出版社,1996年5月,26-29

川公网安备: 51019002004831号

川公网安备: 51019002004831号