履带拖拉机(中央传动及转向离合器设计)

352履带拖拉机的中央传动及转向离合器设计【优秀转向离合器课程毕业设计含4张CAD图纸】

【带任务书+外文翻译】【34页@正文8900字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

352履带拖拉机的中央传动及转向离合器设计.doc

任务书.doc

参考文献图

大锥齿轮.dwg

封皮1.doc

开题报告.doc

总装图.dwg

摘要.doc

摩擦片总成.dwg

电力机车简介--文献翻译.doc

目 录.doc

表格.doc

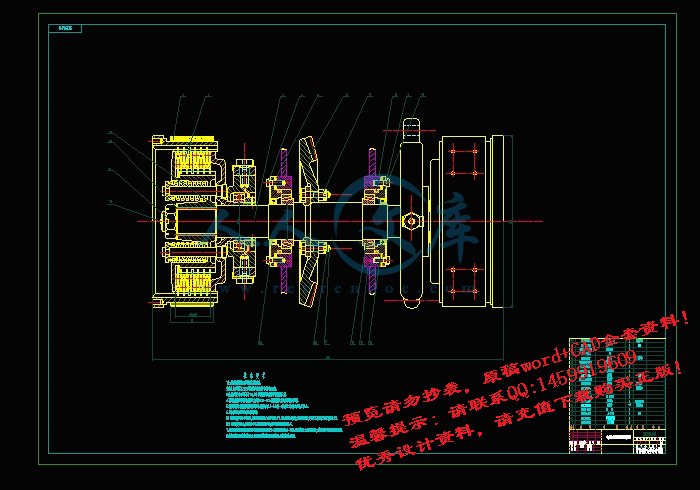

转向离合器总成.dwg

任务书

设计(论文)题目352履带拖拉机(中央传动及转向离合器设计)

主要研

究课题主要研究352履带拖拉机中央传动及转向离合器基本结构与设计方法。参照国内外拖拉机中央传动及转向离合器的基本参数,查阅有关资料,完成352履带拖拉机中央传动及转向离合器的性能计算与基本结构设计。

主要技术指标(或研究目标)

352履带拖拉机的基本参数:发动机功率25.8Kw,发动机转速2000r/min,整机速度范围2~10Km/h,整机使用重量3.5t,履带板节距125mm。

完成中央传动及转向离合器的设计计算,绘制中央传动及转向离合器装配图,完成总和不少于3张零号图纸的结构设计图、装配图和零件图,其中应包括计算机绘制的具有中等难度的1号图纸一张以上。

按要求格式独立撰写不少于12000字的设计说明书,全部用计算机打印(编排要求到河南科技大学网站查:毕业设计说明书(论文)的格式规定),查阅与课题相关的文献资料15篇以上,应有中英文摘要,独立完成10000以上印刷符号的外语译文。

进度计划(5周) 调研,搜集、分析资料;

(6周) 全组集体讨论,制定、确定总体方案;

(7-10周) 完成主要总图设计;

(11-14周) 完成零、部件图设计说明书;

(15周) 整理图纸及全部设计文件,最后交卷;

(16周) 审核、互审评阅设计;

(17周) 答辩,评定成绩。

352履带拖拉机(中央传动及转向离合器设计)

摘 要

中央传动用来增加传动系的传动比,以达到减速增扭的目的,通常还用来改变转矩的传递方向,使转矩从纵置的变速箱输出轴传递给横置的中央传动两侧输出轴。

中央传动应有适当的传动比,以保证拖拉机具有良好的牵引性与经济性;结构应紧凑,以减小后桥尺寸和和质量,保证后桥有足够的离地间隙;齿轮装置应有足够的承载能力和支承刚度,如系锥齿轮副,则还应便于调整。

中央传动的齿轮形式目前主要有圆柱齿轮和圆锥齿轮。圆柱齿轮结构简单,加工较容易,在传动时不致产生轴向力。但仅适用于采用横置变速箱的拖拉机。而圆锥齿轮应用则较为广泛。

履带拖拉机在行使过程中,需要经常改变行驶方向,这就需要有一套能够按照司机意志来改变或恢复拖拉机行驶方向的专设机构,它将司机踩下转向离合器踏板的动作转变为车轮的偏转动作,这就是所谓的转向系统。转向性能是保证车辆安全,减轻驾驶员劳动强度和提高作业效率的重要因素。

转向离合器转向系统由于构造简单,制造方便,维修容易,在拖拉机上广泛采用。它具有转向半径小,直线行驶性好等优点。但由于传递的转矩较大,只得采用多片式离合器,而多片式离合器分离彻底性比较差。这对转向离合器来说,除了使摩擦面的磨损略微增大外,对整机性能没有太大影响,不像主离合器分离不彻底会造成换档困难。

关键词:中央传动,转向离合器,锥齿轮,转向系统

352 TRACKED TRACTOR(CENTRAL TRANSMISSION AND STEERING CLUTCH DESIGN)

ABSTRACT

Central spread to use to increase to spread to move to fasten of spread and move ratio, the purpose that to attain to decelerate to increase to twist, usually return to use to change the torque to deliver the direction, make torque place become soon the box outputs the stalk to deliver to horizontal place central to spread to move the two sides exportation stalk.

Central spread to move and should have appropriate of spread and move ratio, with the assurance that the tractor has to lead the sex and economy goodly; structure should tightly packed, after to let up the bridge size and and quantity, the assurance is behind the bridge has to leave a ground of cleft enough;The wheel gear device should have the enough loading ability and pay to accept just degree, return if department the bevel gears is vice, should easy to adjustment.

Central spread the dynamic wheel gear form to mainly have the cylinder wheel gear and the bevel gearses currently.The cylinder wheel gear structure is simple, processing to compare easily, produce the stalk toward dint unlikely while spread move.But be applicable to the adoption only horizontal place to become soon the tractor of the box.But the cone wheel gear the application then compare extensively.

The track tractor professional makes in the process, needing to usually change to drive the direction, this need to be have a set of can change or recover the tractor to drive the particularly establish of the direction organization according to the driver will, it deflect the action change that the driver tramples bottom to change direction the clutch pedal for the felloe action, this is to change direction the system so calledly.Change direction the function is to guarantee the vehicle safety, easing the pilot the labor strength and raise important factor of the homework efficiency.

steering mechanism changes direction the system because of structure in brief, make convenience, maintain easily, in the dalliance on board extensive doption.It has the radius of change direction small, drive sex good etc. advantage straightly.But because the torque that deliver compare greatly, have to several type clutches of adoption, but several types clutch separate thoroughly sex is worse.This says towards steering mechanismcome, in addition to making rub to face of wearing away the inching aggrandizement, having no to the whole machine function to affect too greatly, be unlike the main clutch separation ill success and will result in shift gear the difficulty.

Key words: Central transmission , steering clutch ,bevel gears, steering system

目 录

第一章 前 言1

第二章 中央传动及转向离合器概论2

§2.1 履带拖拉机转向机构概述2

§2.2 中央传动的概述3

第三章 中央传动及转向离合器方案分析5

§3.1 转向离合器方案分析5

§3.2 中央传动方案分析10

第四章 转向系统设计计算 14

§4.1 螺旋锥齿轮的计算14

§4.2 转向离合器设计计算17

§4.3 带式制动器的设计计算19

第五章 主要零件的强度校核与计算21

§5.1 螺旋锥齿轮的承载能力计算21

§5.2 轴强度计算22

§5.3 轴承寿命计算24

第六章 结 论28

参考文献29

致 谢30

第一章 前 言

拖拉机的主要任务是用来拖带农机具进行各种田间作业(如翻地、播种、中耕等);也可作为其他农业机械(如脱谷机、扬场机等)的动力;另外拖带拖车可进行运输作业。为适应农业生产中各项作业的需要,拖拉机分有履带式和轮式两种。

履带式拖拉机的特点是行走部分与地面的接触面积大,压强小,对土壤压实的作用小,而且不易打滑,可以在湿度较大的土壤上进行作业。一般履带式拖拉机的离地间隙小而功率大,适用于大面积的翻地、播种等主要农业作业。如东方红-54和75拖拉机。

参考文献

[1]王望予.汽车设计.北京:机械工业出版社,2004.8

[2]臧杰,阎岩.汽车构造.下册 北京:机械工业出版社,2005.8

[3]张文春.汽车理论.北京:机械工业出版社,2005.7

[4]甘永立.几何量公差与检测.上海:上海科学技术出版社,2004.7

[5] 辽宁省农业机械化学校《拖拉机构造》北京:机械工业出版社,1972.10

[6]王昆,何小柏.机械设计课程设计.北京:高等教育出版社,1996

[7]吉林工业大学拖拉机考研室.拖拉机构造.下册 北京:机械工业出版 社,1972.10

[8][苏]李沃夫斯基.拖拉机传动装置.北京:中国农业机械出版社, 1979.3

[9]濮良贵,纪名刚.机械设计.北京:高等教育出版社,2001

[10]孙桓,陈作模.机械原理.北京:高等教育出版社 2000.8

[11]第一机械工业部机械研究院农业机械研究所.农业机械设计手册.北京:机械工业出版,1972.2

[12]文九巴.机械工程材料.北京:机械工业出版社,2002.7

[13]侯洪生.机械工程图学.北京:科学出版社,2001

[14]刘鸿义.简明材料力学.北京:高等教育出版社,1997

[15]徐灏.机械设计手册.北京:机械工业出版社,1991

川公网安备: 51019002004831号

川公网安备: 51019002004831号