KD1110型载货汽车后桥总成设计

KD1110型载货汽车后桥总成设计【优秀汽车后桥全套课程毕业设计含4张CAD图纸】

【带外文翻译】【52页@正文17500字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

3中英文摘要.doc

4附录符号说明.doc

5目录.doc

KD1110型载货汽车后桥总成设计.doc

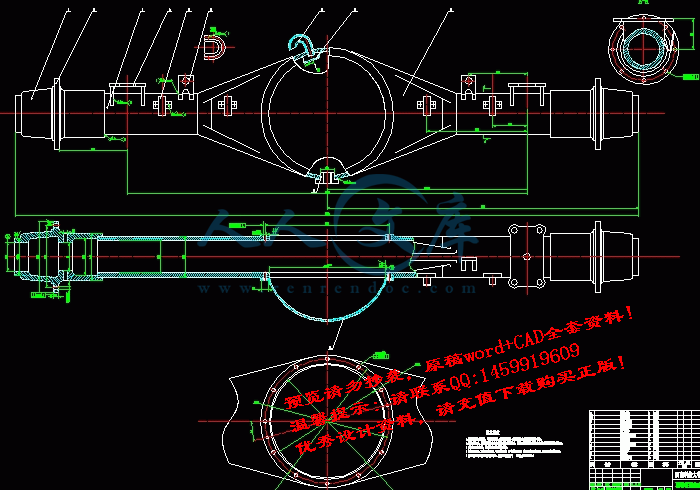

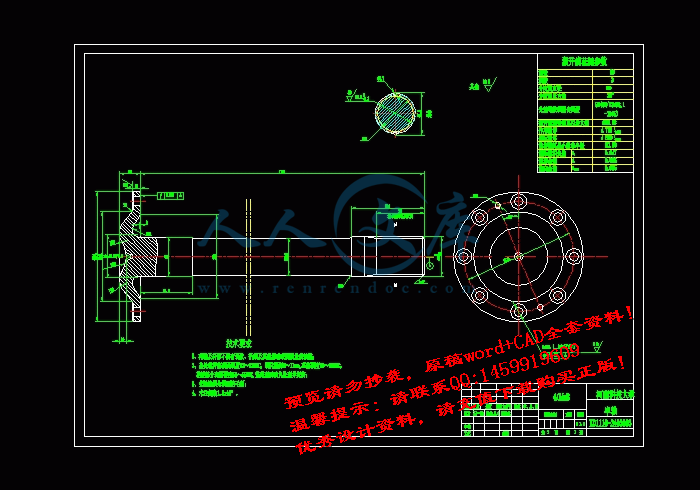

后桥装配图图纸合计4张.dwg

后桥装配图图纸合计4张.exb

英文翻译译文.doc

轻量化设计的汽车零部件用高强度钢来抗凹--文献翻译.doc

KD1110型载货汽车后桥总成设计

摘要

本设计为中型载货汽车的后桥总成设计,在本设计中后桥为驱动桥。驱动桥是汽车传动系主要总成之一,具有承载车身和驱动汽车的功用。驱动桥主要包括驱动桥壳、主减速器、差速器和两个后桥半轴。

根据本车的各项具体参数,经过必要的论证分析,确定了本次所设计的驱动桥的结构方案。驱动桥壳为非断开式驱动桥壳。主减速器为双级主减速器,双级主减速器包括一对双曲面齿轮和一对圆柱齿轮。主动双曲面齿轮和中间轴凸缘上的双曲面齿轮啮合,中间轴和第二级传动中主动圆柱齿轮做成一个整体,圆柱齿轮与固定在差速器壳上的从动圆柱齿轮啮合。差速器为对称式圆锥行星齿轮差速器,这种差速器结构简单,使用可靠。半轴采用全浮式半轴,这样半轴只承受转矩。主减速器支撑轴承选用圆锥滚子轴承。

在说明书的计算部分,说明了主要参数选择的依据,对主减速器,差速器,半轴和驱动桥壳进行了尺寸和强度计算。此外,还计算了主减速器支撑粥承的寿命。本文提供了关于以上计算的详细计算依据、步骤和计算数据。

关键词:双曲面齿轮、差速器、驱动桥、半轴

KD1110 DESIGN OF REAR AXLE FOR GOODS VEHICLE

ABSTRACT

The aim of this project is to design the rear axle for the medium goods vehicle. The rear axle acts as the driving axle in this project. The rear axle is an important component of the truck, which is used to bear the frame and drive the truck. The driving axle includes a shell of drive axle, a main decelerator, a diff, and two axle shafts.

According the specific parameters of the driving system and necessary reasoning, the structure of the driving axle is adopted: the integrated driving axle housing, two-stage main reducing gears which consist of a pair of hypoid gears and a pair of spur gears. The driving hypoid gear that is fixed to the flange of the intermediate shaft forms an integral with the 2nd-stage driving spur gear. The spur gear meshes with the driven spur gear, which is fastened to the case of the diff. The diff with the symmetric taper planetary has a relatively simple structure, and it is reliable. The diff axle is full floating type; such axle shafts are acted upon only by the torque. The bearings that the rear axle uses are both taper roller bearings

The calculation section of this paper is mainly concerning about the physical dimension of the gear of the main drive, the diff, the driving axle, the driving axle housing and the strength of them. In addition, the life of the bearing of the main drive is also calculated in this section. Majority of computations basis, the step and the estimated data for these project are advanced in paper.

KEY WORDS: double camber gear, differential ,driving axle ,Axle shaft

目 录

前言...............................................1

第一章 驱动桥总体设计 ...........................2

§1.1驱动概桥述.....................................2

§1.2 驱动桥总成的结构形式及选择......................2

第二章 主减速器的设计.................................3

§2.1主减速器的结构形式和选择.........................3

§2.2 主减速比的确定和分配...........................3

§2.3主减速器齿轮计算载荷的确定.....................3

§2.4 主减速器齿轮参数的确定..........................6

§2.5主减速器齿轮的强度校核.........................11

第三章 差速器的设计......................................28

§3.1差速器的结构形式的选择.........................28

§3.2 对称式圆锥行星齿轮差速器的设计...................28

第四章 驱动车轮的传动装置.............................33

§4.1半轴概述....................................33

§4.2 半轴的设计计算.............................. 33

第五章 驱动桥桥壳........................................36

§5.1驱动桥桥壳受力和强度计算..........................36

结 论.....................................................41

参考书目..................................................42

致谢...................................................43

参考文献

[1] 刘惟信编著. 汽车车桥设计. 北京:清华大学出版社. 2004.

[2] 汽车工程手册编辑员.汽车工程手册: 基础篇.北京:人民交通出版社.2001

[3] 汽车工程手册编辑员.汽车工程手册:设计篇.北京:人民交通出版社.2001

[4] 刘惟信.汽车驱动桥设计. 第三版. 北京:清华大学出版社,2004年

[5] 王望予编著. 汽车设计第4版. 北京:机械工业出版社. 2004

[6] 刘惟信.汽车设计.北京:清华大学出版社,2001

[7] 徐灏.机械设计手册.北京.机械工业出版社:2004

[8] 刘惟信主编.圆锥齿轮与双曲面齿轮传动.北京:人民交通出版社.1985

[9] 余志生编著. 汽车理论第四版.北京: 机械工业出版社.2008

[10] 陈家瑞主编. 汽车构造第二版 .北京:机械工业出版社. 1995.

[11] 成大先主编.机械设计手册第四版.北京:化学工业出版社,2002

[12] 张洪欣.汽车设计.北京:机械工业出版社, 1989

[13] 张文春主编.汽车理论.北京.机械工业出版社:2007

[14] 刘惟信.汽车驱动桥设计. 第三版. 北京:清华大学出版社,2004年

[15] 濮良贵,纪名刚主编.机械设计(第八版).北京:高等教育出版社.2006

[16] 孙恒,陈作模,葛文杰主编.机械原理.北京:高等教育出版社.2006

川公网安备: 51019002004831号

川公网安备: 51019002004831号