!【详情如下】【汽车车辆工程类课题】CAD图纸+word设计说明书.doc[15000字,43页]【需要咨询购买全套设计请加QQ97666224】.bat

制动系统总成1.dwg

底盘主视图.dwg

底盘俯视图.dwg

底盘俯视图1.dwg

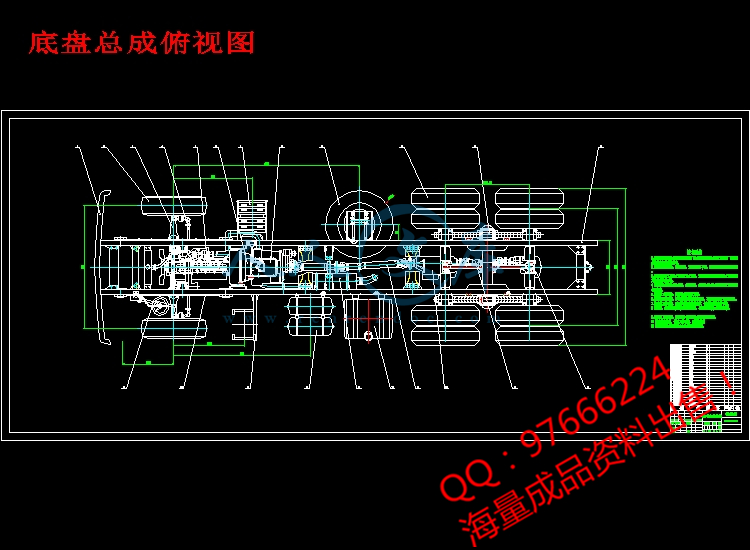

底盘总成俯视图.dwg

自卸车底盘总成正视图.dwg

草图 (1).dwg

草图 (2).dwg

草图 (3).dwg

货箱( 举升视图).dwg

参数

设计说明书.doc[15000字,43页]

摘要

此次设计的非公路自卸车适应于多种特定用途,是土方运输和各种露天矿剥岩、沙土运输的经济、高效、低耗的运输设备。该车具有为适应重载工况而特殊设计的悬挂系统、加强型宽体驱动桥、14.00-20型宽大工程轮胎,使该车具有超强承载能力,同时提供了超强的附着能力,保证了车辆的制动稳定性和良好的通过性,采用了大速比工程驱动桥,其输出转矩比同功率公路车大30%以上,爬坡能力强劲,重载起步顺畅。

本说明书主要是对KD3400整车总体布置做了一个详细的说明,其中包括整车主要尺寸(长*宽*高),前后轴距,轮距,轴荷分配的选择和计算以及各总成(发动机,传动系)的主要参数的选择。

特别对整车的动力性和经济性做了比较全面而细致的分析和计算,对动力性分析时,分别作出了驱动力—行驶阻力平衡图,动力特性图,功率平衡图。求出汽车的最大速度,另外也对汽车在不同的路面上行驶时,分别计算出了其最大爬坡度,并根据加速度倒数曲线求出汽车的加速时间,估算了该车的加速性能。在计算汽车的经济性时,根据发动机万有特性曲线,作出了9挡时的燃油消耗曲线,同时计算得整车的百公里燃油消耗量。通过计算结果显示,此汽车在动力性和经济性方面满足了设计任务书的要求。

另外本文也对汽车的稳定性和最小转弯半径做了计算和分析,并根据经验估算出了空载和满载时汽车的质心位置以及轴荷分配。

关键词:承载能力,附着能力,制动稳定性,通过性,动力性,经济性

DESIGN OF HEAVE –DUTY DUMP (CHASSIS DESIGN)

ABSTRAC

The non –highway heavy-duty dump truck of this design can adapt many kinds of given purpose.It is an economical,efficient and low useful conveyance for hillock transport,sand transport and all kind of outdoor mineral.It has especially desingned suspension system,strengthen widen project driving axle and 14-20type big wide project tales,this cause the truck possess preeminent bearing,at the same time ,this kind of tale can cause big climbing force,assuring the truck has brake stability and good transition.It is counted high rate riving axle,its output torque is 30 point bigger than the road vehicle which are at the same power.

This book mainly give an expatiation about the vehicle general layout of the heavy dumper KD3400,including the vehicle dimensions(long*wide*high),the distribution of axle load in front and back ,the choice and calculation about the main parameter of the vehicle’s main components(engine,transmission)and so on.

Especially in the dynamic property and economic performance,we give an overall and meticulo us analysis and calculation .In the dynamic property ,we made the driving force-road resistance equilibrium diagram,the dynamic factor diagram and the power balance diagram.From those diagram,we can get the maximum speed.We also calculated the maximum grade ability at different road ,according the acceleration curve:we can get the accelerating ability.According to the engine-cross sectional characteristic diagram,we made the fule consumption of 100km. In fact,the vehicle’s main parameters all come to the misson book ‘request.

Morever ,we made an anlysis and calculation of the stability and minimum turning radius and estimated the distribution of axle load when there is no load and full load and the position of the vehicle’s center of mass.

Key words:carrying capacity, adhesive ability, braking stability, trafficability characteristic, power performance, economical efficiency.

目 录

第一章前言……………………………………………………………………………….4

第二章参考车型技术数据……………………………………………………………6

第三章汽车主要技术参数的确定………………………………………….7

§3.1 汽车主要尺寸的确定……………………………………………………………7

§3.2 汽车质量参数的确定……………………………………………………………8

§3.3 发动机主要参数…………………………………………………………………9

§3.4 轮胎的选择………………………………………………………………………10

§3.5 传动比的选取……………………………………………………………………10

§3.6 最大传动比的选取………………………………………………………………11

§3.7 变速器各挡传动比………………………………………………………………12

第四章轴荷分配及质心位置的计算………………………………………………13

第五章稳定性计算………………………………………………………….15

§5.1 纵向稳定性………………………………………………………………………15

§5.2 横向稳定性………………………………………………………………………15

§5.3 最小转弯半径的计算……………………………………………………………16

§5.4 在横向坡上转向时的稳定性……………………………………………………16

第六章汽车动力性计算…………………………………………………….17

§6.1 汽车各挡速度的计算……………………………………………………………17

§6.2 汽车各挡驱动力的计算…………………………………………………………17

§6.3 汽车空气阻力的计算……………………………………………………………18

§6.4 滚动阻力系数的计算……………………………………………………………19.

§6.5 汽车行驶时动力因数D的计算………………………………………………...19

§6.6 各挡牵引功率Pe的计算………………………………………………………..20

§6.7 阻力功率的计算…………………………………………………………………21

§6.8 汽车加速度的计算………………………………………………………………21

§6.9 加速度倒数的计算………………………………………………………………22

§6.10 汽车爬坡度的计算………………………………………………………………23

第七章汽车的燃油经济性……………………………………………………………24

第八章结论……………………………………………………………………………….26

参考文献……………………………………………………………………………………27

致谢………………………………………………………………………………………….28

川公网安备: 51019002004831号

川公网安备: 51019002004831号