摘 要

随着经济社会的发展,当今城市的基础设施处于严重超载状态,尤其交通问题越来越严重,解决交通问题已是城市管理者面对一大挑战,人、车、路三者关系协调程度决定着交通状况的重要因素。而交通灯是人,车,路三者联系的纽带,引入智能控制技术对交通灯进行控制很有必要,传统的交通信号灯控制一般采用电子线路和继电器实现,结构复杂,可靠性低,故障率高,较难实现功能的变更,本文利用可编程控制器PLC作为交通灯系统控制中心,PLC可编程序控制器是以微处理器为基础,综合了计算机技术、自动控制技术和通讯技术发展而来的一种新型工业控制装置。它具有结构简单、编程方便、可靠性高等优点,已广泛用于工业过程和位置的自动控制中。据统计,可编程控制器是工业自动化装置中应用最多的一种设备。专家认为,可编程控制器将成为今后工业控制的主要手段和重要的基础设备之一, PLC、机器人、CAD/CAM将成为工业生产的三大支柱。

由于PLC具有对使用环境适应性强的特性,同时其内部定时器资源十分丰富,可对目前普遍使用的“渐进式”信号灯进行精确控制,特别对多岔路口的控制可方便地实现。因此现在越来越多地将PLC应用于交通灯系统中控制功能强大,使用灵活方便,编程容易,功能扩展方便,结合交通的实际情况阐述了交通控制系统的工作原理,设计出了一种简单实用城市交通灯控制系统方案。与此同时,PLC 本身还具有通讯联网功能,将同一条道路上的信号灯组成一局域网进行统一调度管理,可缩短车辆通行等候时间,实现科学化管理。通过实验验证该系统具有较高的稳定性,较高的智能化,便于维护等优点。

关键词:PLC;交通灯;十字路口

Abstract

With the development of economic and social infrastructure of today's state of the city is seriously overloaded , especially the traffic problem is getting worse , to solve the traffic problem is a major challenge facing the city manager , people, vehicles , road decide the relations between the degree of coordination important factor in the transport position . The traffic light is the link people, vehicles , road three links , the introduction of intelligent control technology necessary to control traffic lights , traffic signal control is generally conventional electronic circuits and relays , complex structure, low reliability , the failure rate high , difficult to achieve change function , we use a programmable controller (PLC) as the traffic light system control center , PLC programmable logic controller is a microprocessor -based , integrated computer technology, automatic control technology and communication technology development to a new type of industrial control devices. It has a simple structure, easy programming, high reliability, has been widely used for automatic control of industrial processes and location. According to statistics, the programmable controller is a device for industrial automation applications up to a device . Experts believe that the programmable controller will become one of the primary means of future industrial control and critical infrastructure , PLC, robotics , CAD / CAM will be the three pillars of industrial production.

Due to the use of PLC has strong environmental adaptability characteristics , while its internal timer resources are very rich, the current widespread use of " progressive " signal for precise control , especially for multi- fork can be easily controlled . So now increasingly used in the PLC control system of traffic lights powerful, flexible and easy to use , easy to program , easy functionality expansion , combined with the actual situation of traffic elaborated works traffic control system , designed a simple practical urban traffic light control system solutions . Meanwhile , PLC communication itself also has networking capabilities , will form a road with lights on the unified management of a local area network , you can shorten the waiting time for vehicles to achieve scientific management. Experimental verification of the system has a high stability, high intelligence, ease of maintenance and other advantages .

Keywords: PLC; traffic lights; Crossroads

目 录

引言1

1 交通灯控制系统概述2

1.1 智能交通灯系统的发展背景2

1.1.1英国TRANSYT路面交通控制系统2

1.1.2澳大利亚SCAT路面控制系统2

1.1.3英国SCOOT路面控制系统2

1.1.4日本城市路面控制系统3

1.2 交通控制存在的问题3

1.3 本课题的主要研究内容4

2 PLC功能介绍4

2.1 PLC的基本概念和基本结构4

2.1.1 PLC的基本概念4

2.1.2 PLC的基本结构4

2.2 PLC的特点和应用领域6

2.2.1 PLC的特点6

2.2.2 PLC的应用领域7

2.3 PLC的工作原理7

2.3.1输入采样阶段8

2.3.2.用户程序执行阶段8

2.3.3.输出刷新阶段8

2.4 PLC的性能指标和软件系统9

2.4.1 PLC的性能指标9

2.4.2 PLC的软件系统9

2.5 PLC编程语言10

2.5.1梯形图10

2.5.2语句表10

2.6 PLC基本编程指令12

2.6.1输入输出指令(LD/LDI/OUT)12

2.6.3 电路块的并联和串联指令(ORB、ANB)13

2.6.4 程序结束指令(END)14

2.7 PLC控制系统设计概要14

2.7.1设计的基本原则和内容14

2.7.2设计的步骤和实现过程15

3 交通灯控制系统设计15

3.1 PLC型号的选定以及可行性分析15

3.1.1 FX2N-64MR 控制器主要性能指标16

3.2 设计思路16

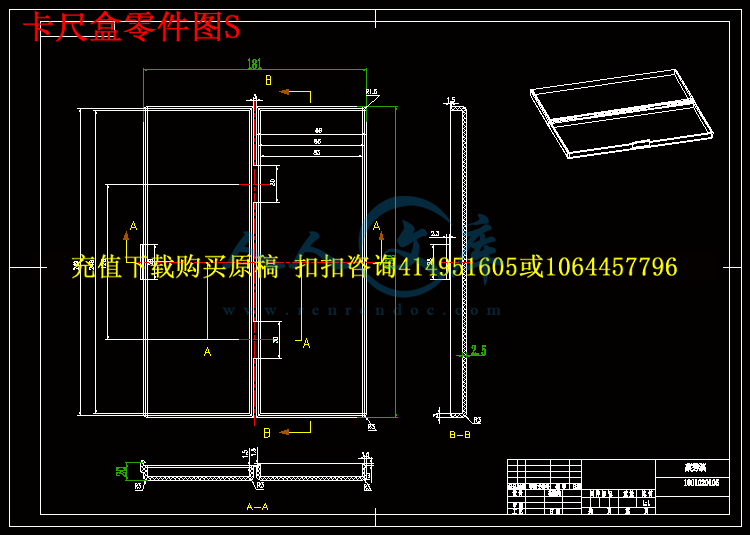

3.3 模拟十字路口交通灯规则设计实物模型设计18

3.3.1控制要求18

4 控制系统程序设计24

4.1 PLC程序流程图设计24

4.2 PLC程序实现24

4.2.1 梯形图程序(状态步进形式的梯形图)26

4.2.2 指令表(梯形图对应的指令语句)40

5 总结47

5.1 设计总结47

5.2 检测和调试47

5.2.1硬件调试47

5.2.2软件调试48

谢 辞49

参考文献50

引言

据一项对美国主要城市交通状况的调查显示:1982年至2000年,美国城市在上下班高峰期间的交通堵塞状况不断加剧,由交通堵塞造成的时间和汽油浪费而带来的经济损失每年高达680亿美元。以广州为例来讲,现在市区平均车速只有每小时12公里。用这个目标速度代入欧美标准计算,广州人为交通堵塞所付出的经济代价总值:每年耗费1.5亿小时,减少生产总值117亿元。相当于该市整个生产总值的7%。

在北美、澳大利亚等大城市,道路面积率高达35%--40%,而北京只有20%。缓解交通拥堵,加快道路建设是当务之急。据悉,到2010年,北京将投资500亿元用于城市道路建设,到2005年,北京仅高速公路通车里程就达到600公里。但一味发展城市道路,也会刺激私家车超常规发展,两者发展速度的失衡,最终还是逃不出“拥堵—修路—再拥堵”的怪圈。

当今时代是一个自动化时代,交通灯控制等很多行业的设备都与计算机密切相关。因此,一个好的交通灯控制系统,将给道路拥挤、违章控制等方面给予技术革新。随着大规模集成电路及计算机技术的迅速发展,以及人工智能在控制技术方面的广泛运用,智能设备有了很大的发展,是现代科技发展的主流方向。本设计介绍了一个智能交通灯系统的设计。该智能交通灯控制系统可以实现的功能有:对某市区的四个主要交通路口进行监控;各路口有固定的工作周期,并且在道路拥挤时中控中心能改变其周期;对路口违章的机动车能够即时拍照,并提取车牌号。在世界范围内,一个以微电子技术,计算机和通信技术为先导的,以信息技术和信息产业为中心的信息革命方兴未艾。而计算机技术怎样与实际应用更有效的结合并有效的发挥其作用是科学界最热门的话题,也是当今计算机应用中空前活跃的领域。本文主要从单片机的应用上来实现十字路口交通灯智能化的管理,用以控制过往车辆的正常运作。

交通信号灯的出现,使交通得以有效管制,对于疏导交通流量、提高道路通行能力,减少交通事故有明显效果。为了实现交通道路的管理,力求交通管理先进性、科学化。用可编程控制器实现交通灯管制的控制系统,以及该系统软、硬件设计方法,实验证明该系统实现简单、经济,能够有效地疏导交通,提高交通路口的通行能力。分析了现代城市交通控制与管理问题的现状,结合交通的实际情况阐述了交通灯控制系统的工作原理,给出了一种简单实用的城市交通灯控制系统的PLC设计方案。可编程序控制器简称为PLC,它的应用面广、功能强大、使用方便,已经成为当代工业自动化的主要支柱之一。PLC已经广泛地应用在各种机械设备和生产过程的自动控制系统中,PLC在其他领域,例如在民用和家庭自动化设备中的应用也得到了迅速的发展。

随着微处理器、计算机和数字通信技术的飞速发展,计算机控制已经广泛的应用在所有的工业领域。现代社会要求制造业对市场需求做出迅速的反应,生产出小批量、多品种、多规格、低成本和高质量的产品。为了满足这一要求,生产设备和自动生产线的控制系统必须具有极高的可靠性和灵活性。可编程序控制器(Programmable Logic Controller)正是顺应这一要求出现的,它是以微处理器为基础的通用工业控制装置。

1 交通灯控制系统概述

1.1 智能交通灯系统的发展背景

1.1.1英国TRANSYT路面交通控制系统

英国道路研究所花费了十几年的时间,在大量的实验和经验的基础之上,研制出了TRANSYT路面交通控制系统。被全球400多个车市广泛采用,可以说TRANSYT系统的成功是显而易见的。TRANSYT内部通过有线来经行通信。采用静态模式来控制交通信号灯,这种控制方案中通过数学模型来控制绿信比和相位差。但是这种交通控制系统还是存在一定的缺陷,例如它无法优化周期,而且想要获得最优的整体分配方案是相当困难的。如果想要经行离线优化,必须采用大量的路网几何和交通数据流。

1.1.2澳大利亚SCAT路面控制系统

70年代末期,澳大利亚开发了SCAT路面控制系统 。SCAT采用分层递阶的计算机形式,这是一种较为先进的计算机网络控制技术。SCAT通过有线来通信。在地区联机,在中央即采用联机也采用脱机模式。在控制的过程中,SCAT会预先设定几个参数,在对路面情况经行分析的基础之上,根据实际的情况来选定具体采用那个数据。计算机结构好改变,控制方案好变换,而SCAT系统充分的利用了计算机的这些优点

川公网安备: 51019002004831号

川公网安备: 51019002004831号