【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

国内外已经有了相当成熟的封口机的技术,形成了成熟的生产线,各种有特定功能的封口机、拧瓶机在生产生活中随处可见,技术经过不断创新和改良,形式得到多样化发展。

拧瓶机是在灌装中旋紧瓶盖的专用设备,工作时必须保证适宜的旋紧力矩。力过小,则 瓶盖旋不紧;力若过大,则易损坏瓶嘴和瓶盖。为此,我们在吸收国内外先进设备的基础上研制了一种利用电磁力传递扭力矩实现瓶盖旋紧的旋盖头, 它不仅能根据需要方便地设定、调整旋紧力的大小, 还能适用于不同高度的瓶子。

本文介绍了本课题的研究背景和意义,论述了拧瓶机在国内外发展的状况,介绍了本次设计设计的内容及方法。本次设计的重点是拧瓶机的总体设计方案、封装过程的旋盖、输送方式和定位的方法,在此基础上进行了运动与结构设计。本次设计采用了回转式的封装方法,通过圆柱凸轮来实现旋盖头的上下升降运动。在满足包装机械原理的条件下,充分考虑了整机的布局和经济性。

关键词:拧瓶机;磁力;自动化;圆柱凸轮 ;

Abstract

At home and abroad has been quite mature technology sealing machine, forming a fairly mature production line, various specific functions sealing machine, capping machine can be seen everywhere in the production and living, technical innovation and improvement, form diversified development.

Capping machine is tightening the cap in the process of beverage filling equipment, work must ensure that appropriate tightening torque. Torque is too small, cap screw is not tight; Torque is too big, easy to damage the bottle mouth and bottle caps.Therefore, we developed on the basis of absorbing foreign advanced equipment from a use of magnetic transfer torque capping head cap tightened, can be easily set as required, adjust the tightening torque of the size, and can be applied to different the height of the bottle.

This paper introduces the research background and significance of the topic, discussed capping machine development at home and abroad, introduced the content and methods design research.This is designed to focus the overall design of the capping machine, Capping, transportation and positioning of the packaging process, Based on this the motion and structure design. The packaging design is the rotary type ,through the cylindrical cam contour the capping head up and down reciprocating of the motion. And take full account to meet the principle of the packaging machinery, machine layout and economy.

Key words: capping machine; magnetic force; automation; cylindrical cam

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 本课题的设计内容和意义1

1.2 国内外的发展概况1

1.3 本课题应达到的要求2

2 拧瓶机的总体设计3

2.1 拧瓶机的简介3

2.1.1 拧瓶机系统的构成3

2.2 拧瓶机的设计3

2.2.1 拧瓶机的整体传动设计3

2.2.2 拧瓶机的外形设计3

2.2.3 拧瓶机自动化控制系统的设计3

2.2.4 旋盖头装置的结构设计3

2.2.5 转盘装置的结构设计4

2.3 拧瓶机总体方案的确定4

2.3.1 方案一的介绍4

2.3.2 方案二的介绍4

2.3.3 方案三的介绍5

2.3.4 方案比较6

2.4 拧瓶机重要参数的确定6

2.4.1 设计参数:6

2.4.2 设计要求6

3 拧瓶机的组成及部件设计7

3.1 拧瓶机的组成7

3.2 圆柱凸轮的设计7

3.3 理盖装置的设计7

3.3.1 送盖自动料斗8

3.3.2 螺旋形供盖滑道8

3.3.3 输盖槽部件10

3.3.4 理盖机机架10

3.4 旋瓶转盘的设计12

3.5 拨杆机构的设计13

3.6 输送轨道的设计14

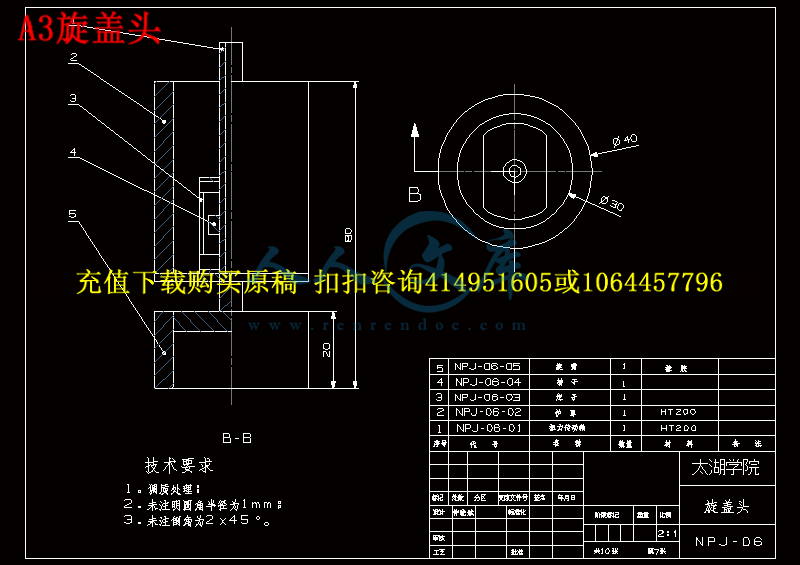

3.7 旋盖头的设计14

3.7.1 初级的外靠摩擦轮形式15

3.7.2 摩擦片扭矩限制机构15

3.7.3 电磁力扭矩限制机构16

4 拧瓶机传动部分的设计17

4.1 电动机的选择17

4.1.1 类型和结构型式的选择17

4.1.2 功率的确定17

4.1.3 转速的确定17

4.2 传动比的分配18

4.2.1 传动比分配的参考数据18

4.3 减速器的设计选择19

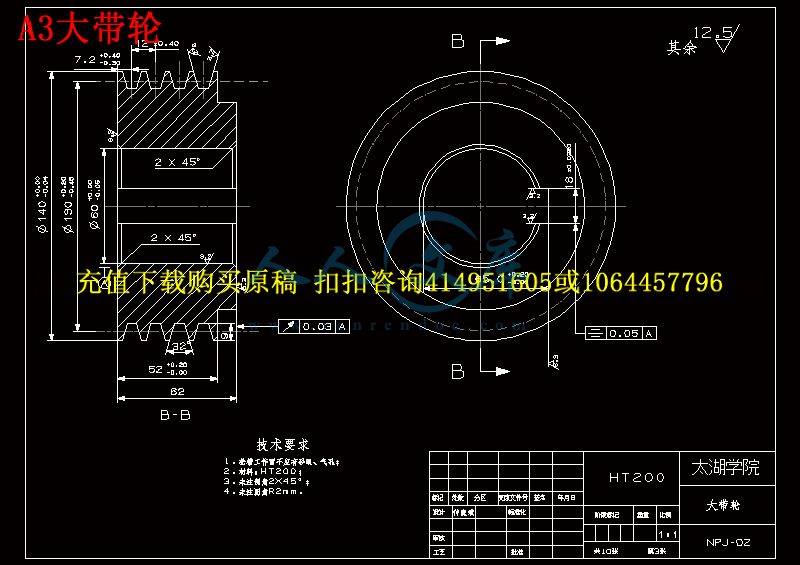

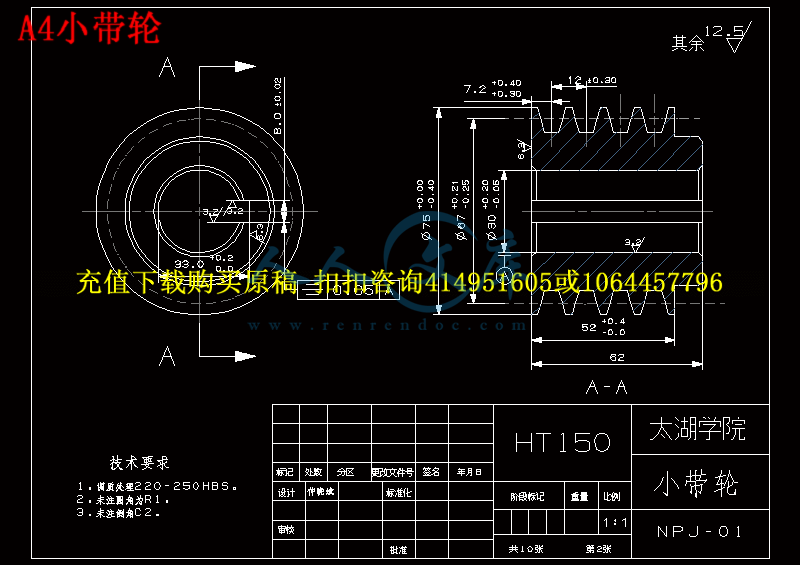

4.4 带传动的设计19

4.5 轴的设计及校核21

4.5.1 轴的材料21

4.5.2 轴的计算21

4.6 键的选择和键链接强度计算22

4.6.1 键的选择22

4.6.2 平键链接强度计算22

4.7 锥齿轮的设计计算23

4.8 滚动轴承选择原则27

5 拧瓶机控制系统29

5.1 控制要求29

5.2 控制系统的选择29

5.2.1 为何采用PLC控制29

6 拧瓶机的安装、维护和安全30

6.1 安装30

6.2 维护保养30

6.3 安装要求30

7 结论与展望31

7.1 结论31

7.2不足之处及未来展望31

致 谢32

参考文献33

1 绪论

1.1 本课题的设计内容和意义

拧瓶机是灌装生产线的主要设备之一,它被广泛用于玻璃瓶或PET瓶的螺纹盖封口。伴随着社会的发展,产品的包装质量要求对人们来说也越来越重要。在饮料,调味料,酒类,化妆品及药品等瓶包装的封口就大量采用螺纹盖封口。因为螺纹盖具有封口快捷,开启方便及开启瓶后又可重新封好等优点。目前已有全自动洗瓶机、全自动灌装机、全自动拧瓶机三合一的机型。

许多大型零售商都要求饮料和食品生产商采用塑料包装,为了减少包装破损和运输重量,并满足消费者的安全需要。带有螺旋密封盖的瓶子具有快速、便捷和密封等优点,使它越来越广泛的应用于许多产品包装。现在竞争日趋猛烈,自动封口机的高度自动化,智能化,高配置、高效率和低消费越来越受到行业的青睐。为了提高生产效率,特进行本课题磁力拧瓶机的设计。

第二章主要介绍了拧瓶机的总体设计,简单介绍了下拧瓶机的几种设计方案并与自己的方案比较了下以及拧瓶机的设计要求等。第三章介绍了拧瓶机的组成以及各部件设计,包括圆柱凸轮、理盖装置、转盘、输送轨道和旋盖头的设计。第四章主要介绍了拧瓶机传动部分的设计,包括电动机的选择、减速器的选择、带传动设计、轴校核、键的选取、滚动轴承的选取和锥齿轮的计算等等。第五章讲的是拧瓶机控制系统,分析后决定采用PLC控制系统。第六章主要讲拧瓶机的安装和维护。

1.2 国内外的发展概况

国内外已经有相当成熟的封口机技术,形成了相当成熟的生产线,各种有特定功能的封口机、拧瓶机也在生产生活中随处可见,技术不断创新和改良,形式多样化发展。

但目前国内自主研发的拧瓶机还存在可靠性低、稳定性差、旋盖质量低、返工率高等问题,国内灌装生产线中广泛使用的拧瓶机大多为直线式拧瓶机,采用瓶颈挂盖。经定位、预封后使盖平稳坐落在瓶口上,最后由皮带对盖顶部搓压摩擦而将盖旋紧。旋盖头主要结构型式经历了弹簧摩擦片式和磁力耦合式2种。弹簧摩擦片式在满足恒扭矩要求方面效果 较差,如经长时间使用后弹簧力会减小,摩擦片使用一段时间后也需进行更换和调整。目前,国内普遍使用的旋盖头为磁力耦合式。为了适应现代包装机高速、高效和高可靠性生产的需要, 研制出了FX12 型拧瓶机[1]和XG12回转型拧瓶机。近几年来随着食品饮料工业向大规模高效率方向发展。

拧瓶机是饮料灌装过程中旋紧瓶盖的专用设备,工作时必须保证适宜的旋紧力矩。力矩过小, 瓶盖旋不紧; 力矩过大, 易损坏瓶嘴和瓶盖。为此, 我们在吸收国外同类先进设备的基础上研制了一种利用磁力传递扭力矩实现瓶盖旋紧的旋盖头, 能根据需要方便地设定、调整旋紧力矩的大小, 并能适用于不同高度的瓶子,它具有效率高、速度快、可靠性好和自动化程度高等特点[2]。

川公网安备: 51019002004831号

川公网安备: 51019002004831号