【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

气流雾化喷枪的设计

摘要:高压喷涂是一种利用压缩空气为动力,不直接用压缩空气对涂料进行雾化,它用增压泵将涂料增压至10Mpa-25Mpa,高压涂料通过喷嘴的小喷孔高速喷出雾化分散成极细的雾滴,同时将雾化涂料微粒推至被涂工件表面。

利用高速气流而令喷枪局部真空,因而产生吸力把油漆从壶中吸到喷咀加以雾化喷出,主要作大面积喷涂,好处是油漆的雾化较佳,可以达到漆膜的厚度及光泽度要求。压力桶为圆柱形压力容器,一般用不锈钢或碳钢制作,桶盖上设置调压阀、压力表及安全阀等附件,调节输入压缩空气的压力可达到输出涂料的压力。压力桶有的还配置气动搅拌器,常用压力桶的容量为10L、20L、40L等。压力桶结构简单,维护方便,涂料输出压力较稳定,不足之处是清洗换色不便。

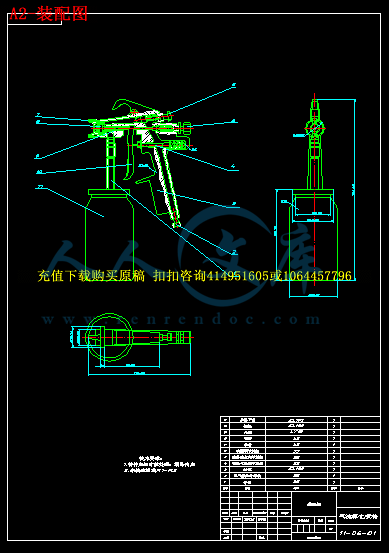

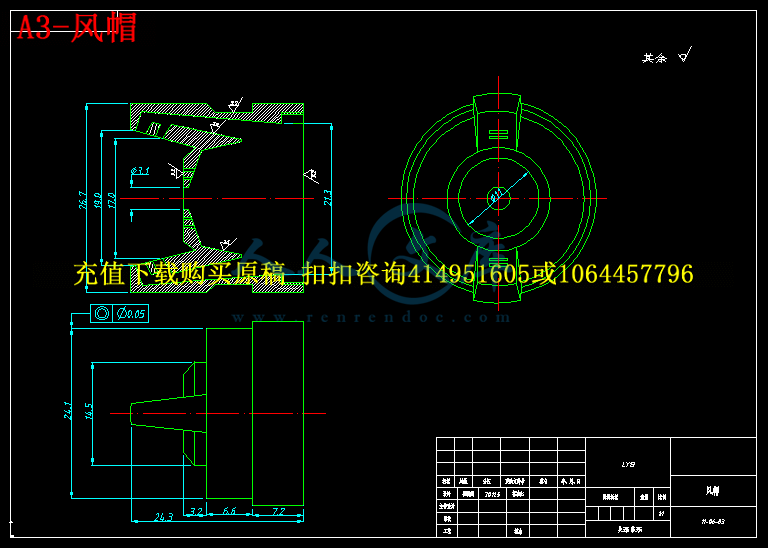

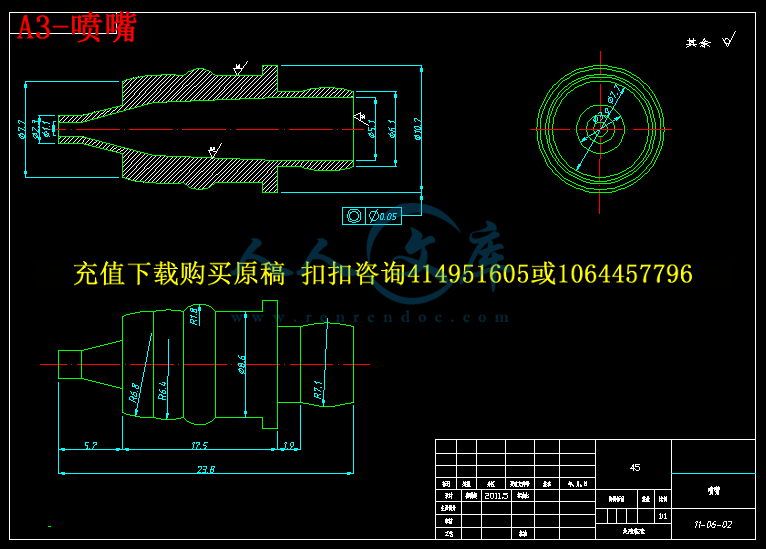

空气喷枪的空气帽(空气喷嘴)、喷嘴(涂料喷嘴)和顶针,习惯称为空气喷枪的三件套是决定空气喷涂的涂装质量关键部分。气动双隔膜泵,是利用压缩空气作动力,通过换向机构使空气压力作用在横隔膜的内侧,而横隔膜的外侧与泵体共同组成一个容积可以变化的涂料腔。 当左面涂料腔容积从小变大产生局部真空,下面一个单向阀开启,上面一个单向阀关闭,涂料桶中的涂料在大气压力下进入左面涂料腔,而右面涂料腔容积由大变小,下面一个单向阀关闭,涂料产生压力,顶开上面一个单向阀排出泵体。双隔膜泵的两侧有两个涂料腔,当一个容积由小变大,则另一个容积由大变小,周而复始,往返进行。所以双隔膜泵的每次往复都有两次涂料吸入和排出,使泵的输出效率提高,而且输出相对比较平稳。由于压缩空气的输入压力和涂料的输出压力的比率为1:1,故调节压缩空气的输入压力的大小可改变涂料的输出压力。

高压喷涂可以使用高粘度涂料,大面积喷涂速率达4m2/min-7m2/min,生产效率高。喷涂对涂料无压缩空气混入,漆雾反弹飞散的现象较空气喷涂少,降低了涂料消耗,改善了环境污染。 高压无气喷涂的出漆量较大且漆雾细度不够柔软,涂层厚度不易控制。精装饰涂膜喷涂不及空气喷涂细致。 一般适用于单品种粘度较高的涂料和形状简单、表面积较大的工件批量生产。广泛用于造船、集装箱、钢结构件、建筑内外墙、大型管道等行业。

关键词:压送式喷枪 压缩空气 空气喷枪 气动高压喷涂 气动柱塞泵

顶针 空气帽

Abstract: High pressure airless spray gun is a kind of to make use of the compredded air as power, not and directly use the compredded air carries on atomization to the coating, it presses pump to press the coating super - to the 10 Mpas Mpas-25ses with the super -, the high pressure coating passes nozzle of small spray gun hole the high speed spew out the atomization scatter into the most slender fog drop, at the same time atomization coating the corpuscle push into drive Tu Gong Jian's surface.

Make use of top speed air current but make air gun partial uvauum, as a result generate the vacuum force absorbs to spray Ju to take into atomization jet from the pot the paint and mainly make big area spray gun, the advantage is that the atomization of paint is better, can hit the thickness and water request of painting the film.The press barrel is the cylinder shape press container, generally use stainless clad steel or straight carbon steel creation, the barrel covers setup to adjust to press accesserieses such as valve, pressures gauge and safety valves etc., and the conditioning inputs the press of compredded air to hit the press of outputting the coating.Press barrel have of still install agitator air, the capacity of the wirking pressure barrel is for the 10 Ls, 20 Ls, and 40 L...etc..Press barrel the structure is simple, the maintenance is convenient, the coating outputs press more stable, scarcity of section is cleaning change a color inconvenience.

Air cap(air noozle), nozzle(coating nozzle) and vertex needle that compresses an air gun, habitually be termed three sets of compressing the air gun is decide air to spray Tu Zhuang mass key fraction.The gas moves a pair of septums pumps, is to make use of compredded air to make power, pass to change to make to get empty a barometric pressure action in the diaphragmatic seamy side toward the mrvhsnidm, while diaphragmatic outside side and pump body constitute a coating chamber that volume can change together.When the left side coating chamber volume became big to generate partial uvauum since the childhood, underneath an one-way valve opened, up an one-way valve locks, the coating in the coating barrel entered a left side coating chamber under the atmospheric pressure, but right surface coating chamber volume from greatly diminished, underneath an one-way valve lock, the coating generated press, the vertex opened over - an one-way valve discharged to pump a body.Two sides of double septum pump contain two coating chambers and be a volume from small become big, then another volume from greatly diminish, go round and begin again, go back and forth progress.So double the septum pump of every time back and forth have two coating suction and discharge and make the output efficiency of pump exaltation, and output contra more steady.Because the ratio of the input press of the compredded air and the output press of the coating is 1:1, the output press of the dimension convertibility coating of the input press of past conditioning compredded air

High pressure airless spray gun can use higher - viscosity coating, big area spray gun speed reach to the 4 ms 2/ms min-7s 2/min, the production efficiency is high.Spray has no compredded air vs the coating interfusion, paint fog rebound to fly a loose phenomemon compare air spray gun Tu Shao, lowered coating dissipation, improved public nuisances. High pressure airless spray gun's lacquer measures a little bit greatly and paints fog thin degree not enough soft, Tu Ceng's thickness doesn't easily control.The Jing decorates a spray gun of Tu Mo to cannot compare with air spray gun meticulous. Generally compliant unipole species viscosity the higher coating is as simple as shape, the surface accumulate a bigger work piece quantity production.Extensively used for a shipbuilding and gather vanning, the steel structure crafts, such as piece, outside wall inside the building and large piping...etc..

Keywords: Press a send type air gun Compredded air Compress an air gun The gas moves high pressure airless spray gun The gas moves plunger pump Vertex needle Compress a cap

Signature of Supervisor:

目录

1 前言……………………………………………………(8)

2 喷枪简介………………………………………………(9)

2.1 喷枪的类型……………………………………………………(9)

3 雾化原理………………………………………………(9)

4 气流雾化喷枪的通堵结构方案…………………… (9)

5 喷枪的主要零件………………………………………(12)

5.1 现将喷头的三个主要件特性介绍 ……………………………(13)

5.2 喷涂输漆可分为压力桶、气动双隔膜泵……………………(14)

5.3 喷枪结构技术改造………………………………………………(14)

6 按喷枪工作原理分三类………………………………(24)

6.1 吸上式、重力式和压送式三种吸上式喷枪………………………(24)

6.2 喷枪操作及其要点…………………………………………………(25)

7 喷枪的维护与故障处理………………………………(26)

8 气流雾化喷枪的设计与功能………………………(28)

8.1 特点及应用……………………………………………………(28)

9 供料方式喷枪的雾化技术及其发展趋势……………(29)

结论…………………………………………………………(31)

参考资料……………………………………………………(32)

致谢…………………………………………………………(32)

前言

喷枪作为一种生产工具,广泛的应用于社会的各个行业,无论是用于涂装、绘画喷涂、喷漆,还是应用于汽车、钢琴、家电、家具、等表面层的喷漆处理。虽然应用广泛,得到了普遍认可,但同样存在诸多问题如:现象一:喷幅分裂 ,导致其原因:1、涂料黏度太低 2、喷涂压力太高 3、扇面控制孔内径偏大 4、涂料不够 5、雾化空气通道堵塞 。对此采取对策:1、调高涂料黏度 2、调低喷涂压力 3、更换喷嘴套装 4、添加足够的涂料 5、清洁喷枪(spray gun)的空气通道 。又如现象二:跳枪 ,导致其原因:1、喷嘴没拧紧或没装好 2、枪针密封套件松动 3、喷枪(spray gun)的连接螺母松动(下壶喷枪(spray gun)) 4、壶里涂料不足 5、喷嘴套装损坏 ,为此我们采取对策:1、旋紧喷嘴或清洁并安装喷嘴套装 2、紧固顶针密封套件 3、旋紧连接螺母 4、补充涂料 5、更换喷嘴套装 。所以我们致力于一次又一次的发现问题,研究问题,进而改进。我们这次的改进同样也基前人丰硕成果,根据所看到的问题加以研究改装。

在这里对给予本人论文支持和帮助的老师表示衷心的感谢。

1、喷枪简介

喷枪是漆装修理的关键设备。喷枪是将涂料(油漆)均匀地喷涂在车身表面,得到良好的防腐与漆装效果。利用压缩空气对进入喷枪的涂料进行雾化并对车身表面涂敷(简称空气喷射)是车身表面装饰最重要的工艺之一。

1.1 喷枪的类型:

空气喷枪的类型主要有三种,且每种类型都有其优点及缺点。以下是根据喷枪对油漆的进给方式将喷枪大至分为三类。

川公网安备: 51019002004831号

川公网安备: 51019002004831号