!【详情如下】【注塑塑料模具课题】CAD图纸+word设计说明书.doc[18000字,38页]【需要咨询购买全套设计请加QQ97666224】.bat

z.dwg

型腔.dwg

型腔固定板.dwg

型芯.dwg

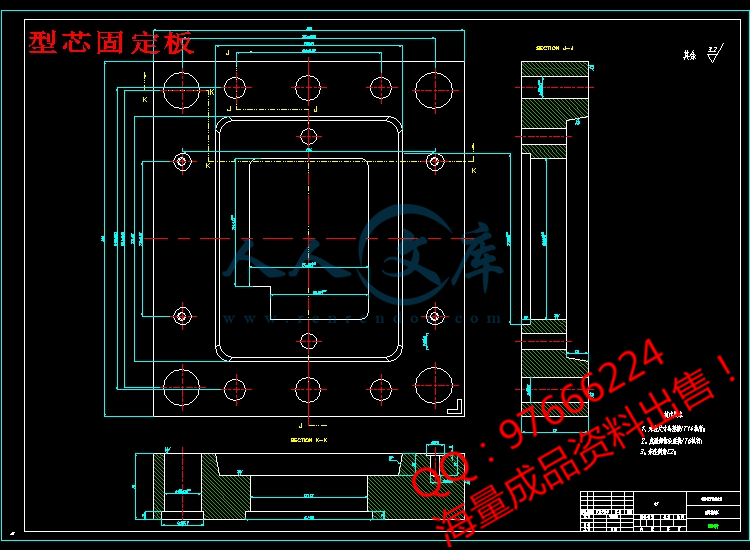

型芯固定板.dwg

塑件.dwg

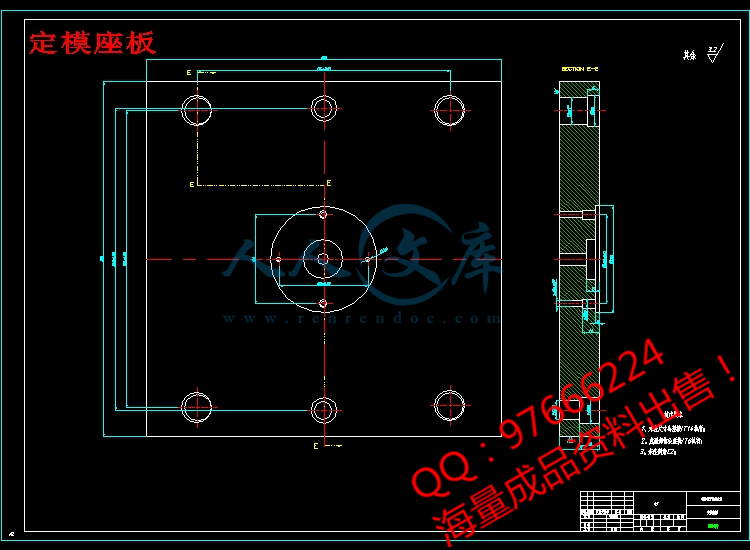

定模座板.dwg

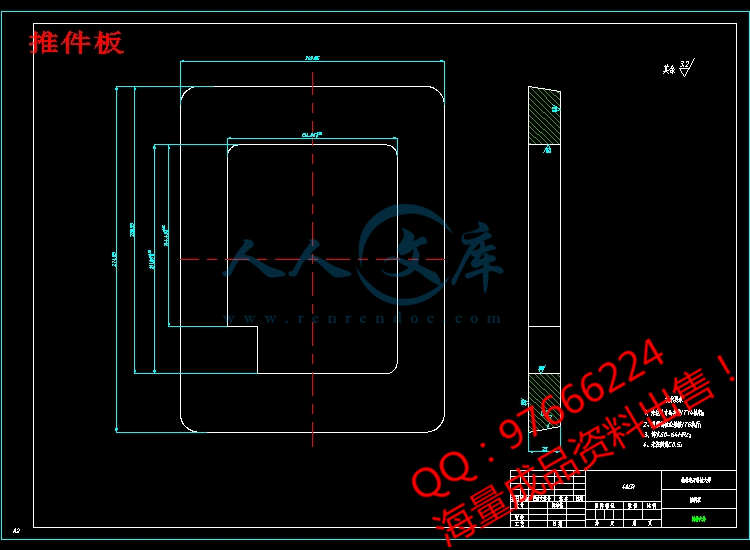

推件板.dwg

支撑板.dwg

脱料板.dwg

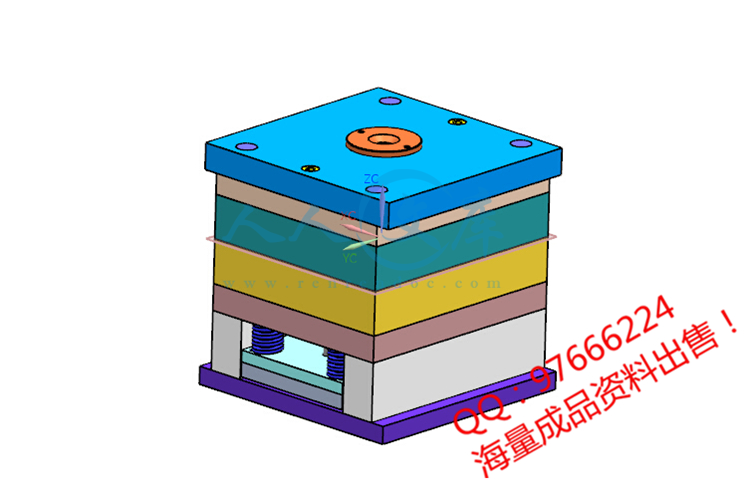

3D全套图纸

任务书.doc

外文译文(中文).doc

外文译文(英文).doc

开题报告.doc

毕业设计中期检查表.doc

设计说明书.doc[18000字,38页]

进度计划表.doc

摘 要

近几年好多国家都在发展机械行业,与机械相关的各个行业都越来越重视CAD/CAM技术,如今CAD/CAM技术已发展成为一项比较成熟的共性技术,我国家电工业的高速发展对模具工业,尤其是塑料模具提出了越来越高的要求,国内塑料模具市场以注塑模具需求量最大,其中发展重点为工程塑料模具。同时还因为塑料制品及模具的3D设计与成型过程中3D分析正在塑料模具工业中发挥越来越重要的作用。

在本次毕业设计中,通过运用三维实体造型高端软件UG NX对“温控器垫块”外形进行3D造型,同时也设计了其塑料注塑模的3D模型。在正确分析塑件工艺特点和ABS的性能的基础上,介绍了对凸模,凹模,浇注系统,脱模机构,顶也机构的设计,选择标准零件,设计非标件的设计过程。由于模具生产的塑料制品具有高精度、高复杂程度、高一致性、高生产率和低消耗等特点,涉及模具结构、强度、寿命计算及熔融塑料在模具中流动预测等复杂的工程运算问题;CAD、UG NX等不同的软件可分别用于模具的设计、制造和产品质量进行分析。塑料注射成型所用的模具称为注射模成型模具,该模具特点是模具先由注射机合模机构闭和紧密,然后由注射机注射装置将高温高压的塑料熔体注入模腔内,经冷却或固化成型后,在侧向分型的作用下开模取出塑件。还根据所设计的模具尺寸选择安装了相应的模架,最终生成了直观的结构设计图;此外还利用CAD绘制了模具装配图以及各种成型零件图。

关键词:温控器;注塑模;CAD/CAM;ABS塑料;3D

Abstract

A lot of countries in the development of machinery industry in recent years, every industry pay more and more attention to related to mechanical CAD/CAM technology, CAD/CAM technology has now developed into a relatively mature technology, with the rapid development of our country home a ABS liance industry of mold industry, puts forward higher and higher requirements, especially plastic mould, in 2004, as a proportion of the plastic mold in the mold industry has risen to 30%, according to experts predict that in the next few years, China plastic mould industry will continue to maintain an annual growth rate of more than 10% of the high speed of development. Domestic demand in injection mold plastic mold market is the largest, the key for engineering plastic mold development. Also because of the plastic products and mould Three-Dimensional design and molding process of Three-Dimensional analysis is the plastic mold industry plays a more and more important role.

In this graduation design, the high-end software UG NX three-dimensional entity model is used to shape of "t type mounting bracket" Three-Dimensional modeling, and design the Three-Dimensional model of the plastic injection mold.On the basis of the correct analysis of the characteristics and ABS plastic parts process performance, the introduction of the punch,die,casting system, stripping agencies,top agency also design, selection of standard parts,the design of non-standard parts of the design process.Due to mold plastic products with high precision,high complexity,high consistency,high productivity and low consumption, etc,involve mold structure, strength,life span,and the molten plastic in the mold flow projections and other complex engineering computing problems; CAD,different software may be designed such UG NX molds are used,the manufacturing and product quality analysis.Plastic injection molding mold used for injection molding is called a mold injection machine is characterized first by a mold clamping mechanism and tightly closed, and then the injection machine injection device of the high temperature and pressure of the plastic melt into the mold cavity, cooling or after curing,in the role of the lateral parting remove mold plastic parts.Also according to the design of the mould size choose to install the corresponding mold frame, the resulting intuitive structure design; In addition to use CAD draw the mold assembly drawing as well as a variety of molding part drawing.

Key words:Thermostat;plastics mold;CAD/CAM;ABS plastic;Three-Dimensional

目 录

引言1

1 注塑模设计的相关理论概述3

1.1 注塑成型的相关概念3

1.1.1 注塑成型的基本概念3

1.1.2 注塑成型的特点3

1.1.3 注塑成型的工艺过程3

1.2 注塑模的定义4

1.3 注塑模的分类4

1.4 注塑模设计流程及关键环节6

1.5 注塑模设计软件——UG简介7

1.6 注塑模主要加工方法简介9

2 温控器垫块注塑模设计10

2.1 温控器垫块相关参数计算10

2.2 温控器垫块成型工艺要求10

2.2.1 塑件工艺性分析10

2.2.2 塑件材料的基本特性11

2.2.3 ABS的性能指标11

2.2.4 塑件材料成型性能11

2.2.5 尺寸精度分析11

2.2.6 表面质量分析11

2.2.7 模塑设备的选择12

2.3 注射模的结构设计13

2.3.1 分型面的选择13

2.3.2 确定型腔的排列方式13

2.3.3 浇注系统的设计14

2.3.4 浇注系统的平衡16

2.3.5 推件机构的设计16

2.4 模架的选择17

2.5 型腔工作尺寸的计算17

2.6 型芯工作尺寸的计算19

2.7 模具的其他相关计算20

2.8 冷却装置的设计20

2.8.1 冷却时间的计算21

2.8.2 冷却水管直径21

2.8.3 冷却水道的结构21

2.9 开模行程的校核22

2.10 注射机的校核22

2.11 模具外形尺寸校核22

2.12 注射模的安装与调试23

3 温控器垫块注塑模的仿真实现24

3.1 模具开发流程24

3.2 产品建模24

3.3 温控器注塑模装配仿真25

4 温控器垫块注塑模型腔加工工艺及流程28

5 机械加工工艺卡30

6 结论31

致 谢32

参考文献33

川公网安备: 51019002004831号

川公网安备: 51019002004831号