摘 要

本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。

手柄座的工艺规程及钻Φ10孔的工装夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

关键词:工艺、工序、切削用量、夹紧、定位、误差。

Abstract

The design of the content relates to the machinery manufacturing technology and machine tool fixture design, metal cutting machine tool, tolerance and measuring and other aspects of knowledge.

Handle technological process and the drill hole of Φ10 fixture design including machining process design, process design and fixture design in three parts. In the design process should first of all parts for analysis, to understand the parts of the process to design the structure of the blank, and select good parts processing base, design parts of the process route; and then the various parts of process dimension calculation, is the key to decide all processes equipment and cutting parameters; then special fixture design, selection and design of a jig for the various components, such as positioning devices, clamping elements, the guide element, clamp and the machine tool connecting parts and other components; calculate fixture is produced when the positioning error of fixture structure, rationality and deficiency, and later in the design of improved.

Key words: process, process, cutting dosage, clamping, positioning, error.

目 录

1、手柄座的工艺分析及生产类型的确定1

1.1、手柄座的用途1

1.2、手柄座的技术要求:2

1.3、审查手柄座的工艺性2

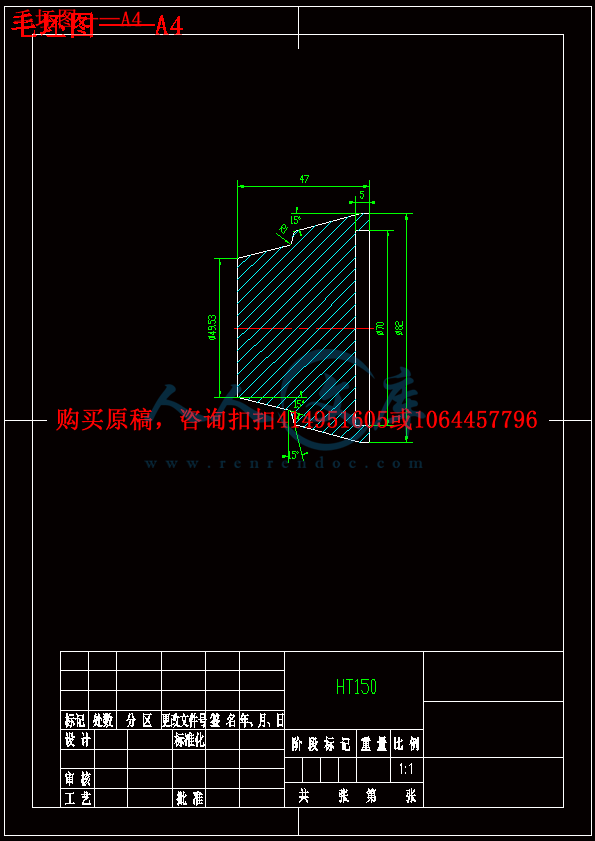

2、确定毛胚、绘制毛胚简图3

2.1选择毛胚3

2.2确定毛胚的尺寸公差和机械加工余量3

2.2.1公差等级3

2.2.2手柄座铸造毛坯尺寸工差及加工余量3

2.2.3绘制手柄座毛坯简图4

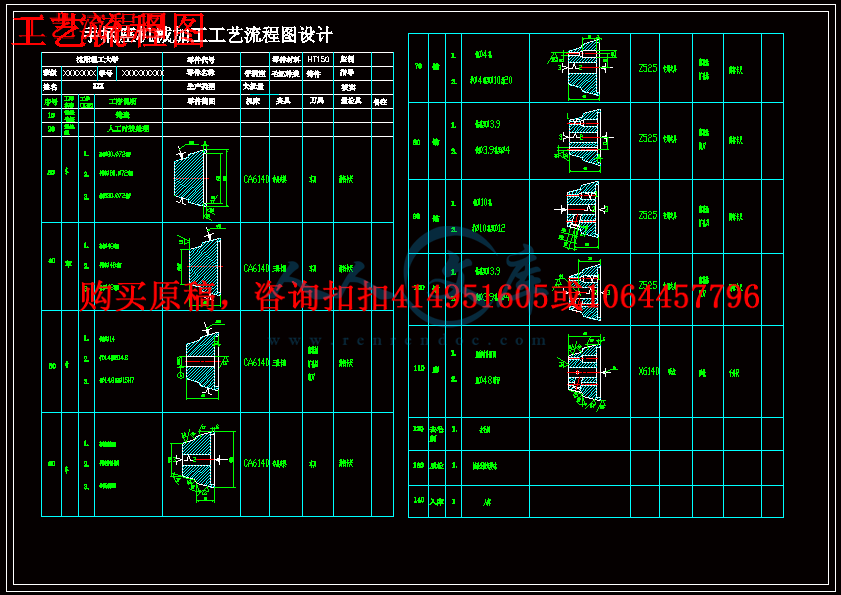

3、拟定手柄座工艺路线5

3.1、定位基准的选择5

3.1.1.精基准的选择5

3.1.2.粗基准的选择5

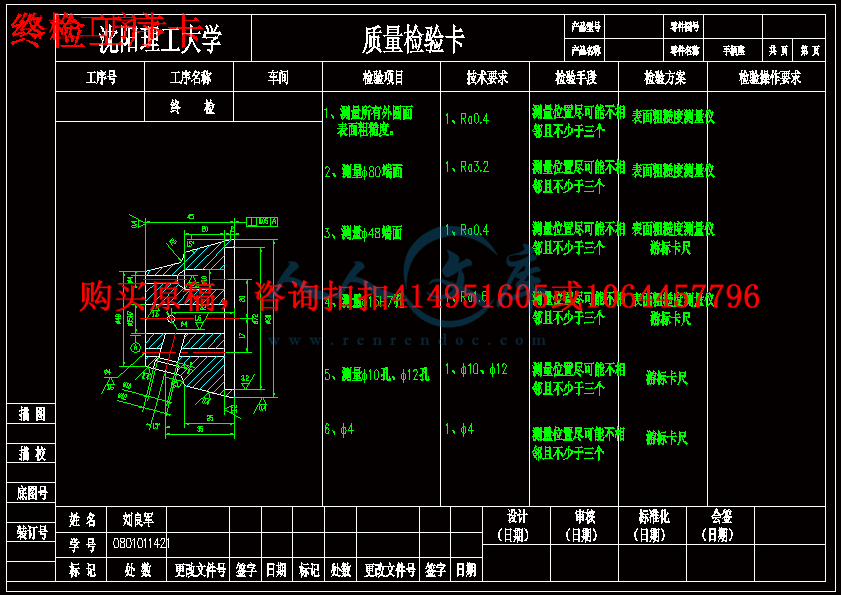

3.2 、表面加工方法的确定6

3.3、加工阶段的划分6

3.4、工序的集中与分散6

3.5、工序顺序的安排6

3.5.1机械加工工序6

3.5.2.热处理工序6

3.5.3.辅助工序6

3.6、确定工艺路线7

4、加工余量、工序尺寸和工差的确定8

5、切削用量、时间定额的计算9

5.1、切削用量的计算9

5.2、时间定额的计算10

5.2.1.基本时间tj的计算10

5.2.2.辅助时间ta的计算10

5.2.3. 其他时间的计算10

5.2.4.单件时间tdj的计算11

6.夹具设计12

6.1提出问题12

6.2设计思想13

6.3夹具设计13

6.3.1定位分析13

6.3.2切削力及夹紧力的计算13

6.3.3夹具操作说明15

7. 体会与展望16

参考文献17

川公网安备: 51019002004831号

川公网安备: 51019002004831号