【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

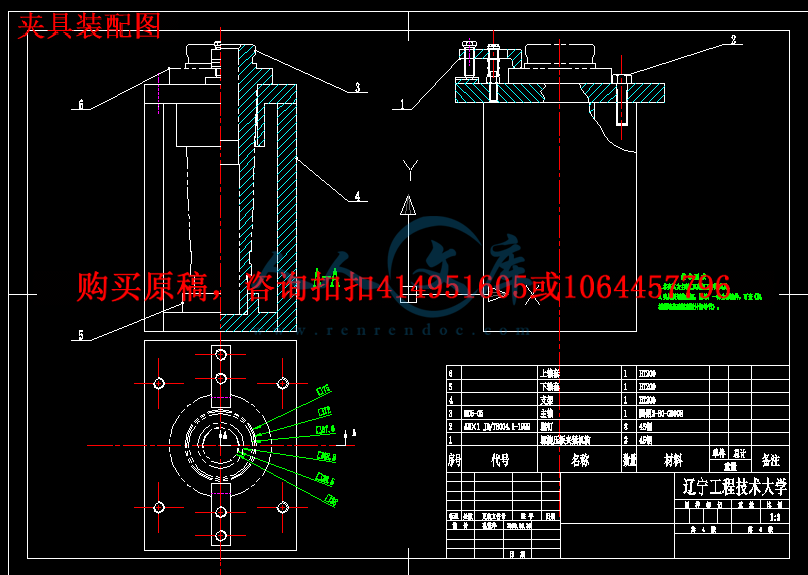

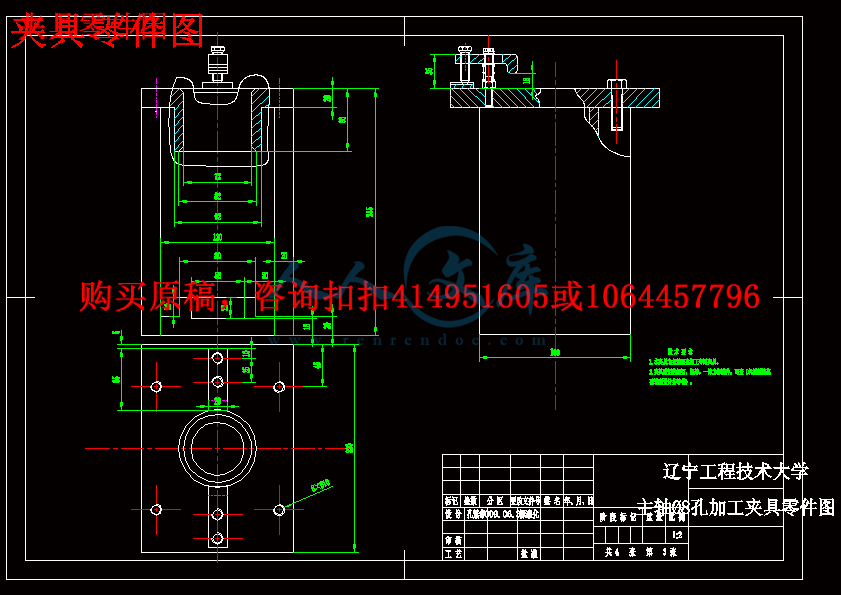

这次设计的是主轴的8孔的加工夹具。包括零件图、毛坯图、装配图各一张,机械加工工艺过程卡片和与工序卡片各一张。根据零件的性质和零件图上各端面的粗糙度确定毛坯的尺寸和机械加工余量。最后拟定主轴的8孔的加工夹具的工艺路线图,制定该工件的夹紧方案,画出夹具装配图。

机械制造工艺学课程设计是我们学完了大学的全部基础课、技术基础课以及大部分专业课之后进行的.这是我们在进行毕业设计之前对所学各课程的一次深入的综合性的总复习,也是一次理论联系实际的训练,因此,它在我们四年的大学生活中占有重要的地位

就我个人而言,我希望能通过这次课程设计对自己未来将从事的工作进行一次实际的训练,从中锻炼自己分析问题、解决问题的能力。由于能力所限,设计尚有许多不足之处,恳请各位老师给予指导。

目 录

1.主轴的工艺分析及生产类型的确定·····················8

1.1主轴的用途········································8

1.2主轴的技术要求···································9

1.3审核主轴的工艺性·································9

1.4确定主轴的生产类型······························10

2.确定毛坯,绘制毛坯简图·······························10

2.1选择毛坯··········································10

2.2确定毛坯的尺寸公差和加工余量···················10

2.2.1公差等级······································10

2.2.2锻件的材质系数·······························10

2.2.3锻件的分模线形状·····························10

2.2.4零件表面粗糙度·······························11

3.拟定主轴工艺路线·····································11

3.1选择定位基准······································11

3.2表面加工方法的确定·······························11

3.3加工阶段的划分···································12

3.4工序的集中与分散·································12

3.5工序顺序的安排···································13

3.6确定工序路线·····································13

4机床设备及工艺装备的选用····························14

4.1机床设备选用·····································14

4.2工艺装备··········································15

5. 8孔的切削用量的计算······························15

6.夹具设计··············································15

6.1问题的提出········································16

6.2夹具设计··········································16

6.2.1定为基准的选择·······························16

7体会与展望············································16

8参考文献··············································18

1. 主轴的工艺分析及生产类型的确定

1.1 主轴的用途

该主轴在顶杆工作时要受到冲击载荷及扭转载荷的作用,因此该零件应具有足够的强度、钢度和韧性,以适应主轴的工作条件。该零件的主要工作表面为主轴的外圆柱表面、内圆柱表面,键槽表面以及孔。

川公网安备: 51019002004831号

川公网安备: 51019002004831号