摘 要

食品加工机械是机械的一个重要发展方向之一,也是国计民生的大事,肉食品加工尤其重要。肉食品加工机除满足生产力的需要外,还需满足全民食品安全卫生的需要。

我国是世界上饲养畜禽最多的国家,同时也是人口最多的国家。由于人口基数的过大,肉制品的需求也大,但是现有的肉糜加工机还是离不开大量的人工操作。由于我国的肉制品加工的基础较差,与国外先进的肉糜加工水平仍有较大差距,相信随着肉糜加工产业的不断发展,这些差距也会越来越小。肉糜切割的广阔市场,使得国内外科研工作者对肉糜加工技术进行不断深入的研究,推动者肉糜加工行业的不断发展。

现在普通的肉糜加工机还离不开大量的人工操作,这样的话肉糜生产的成本更高而且无法保证生产出来的肉糜的卫生;因此研究开发新型的肉糜加工机是必不可少的,只有肉糜加工机具有安全卫生,操作简便,切肉效果好以及加工成本低,加工过程实现自动化控制的特点,那么才能真正满足国人的需求。

关键词:食品加工;肉制品;肉糜加工技术;肉糜加工机。

ABSTRACT

Food processing machinery is one of an important development direction, is also a vital event, meat processing is particularly important. Meat processing in addition to meet the needs of the productive forces, but also need to satisfy the needs of the national food safety and hygiene.

China is a country with the largest breeding livestock and poultry in the world, at the same time is also the most populous country. Due to the large population base, the meat product demand is big, but the existing meat cutting machine still cannot leave a lot of manual operation. Because our country meat cutting of the foundation is bad, and the foreign advanced meat processing level there is still a large gap, believe that with the continuous development of the mince processing industry, the gap will be smaller and smaller. Mince cutting the broader market, make scientific research workers at home and abroad for the mince processing technology continues to in-depth study, promoters mince the continuous development of processing industry.

Now ordinary meat cutting machine still cannot leave a lot of manual operation, so the cost of producing the mince is higher and there is no guarantee that the mince health; So the research and development new meat cutting machine is indispensable, only meat cutting machine has a health and safety, easy operation, good cutting effect, and low processing cost, the characteristics of the cutting process is easy to realize automation control, then can we truly meet the needs of people.

Keywords: Food processing;Meat products;The mince processing technology;Meat cutting machine

目 录

摘 要I

ABSTRACTII

目 录i

第1章 绪论1

1.1 课题来源1

1.2 课题的意义1

1.3 国内外肉糜加工技术的发展1

1.3.1 国外肉类加工技术发展......................................................................................................................1

1.3.2 国内肉类加工技术发展......................................................................................................................1

1.4 国内外肉糜加工机的发展趋势2

1.5 课题主要内容及任务2

1.5.1 主要内容2

1.5.2 主要任务2

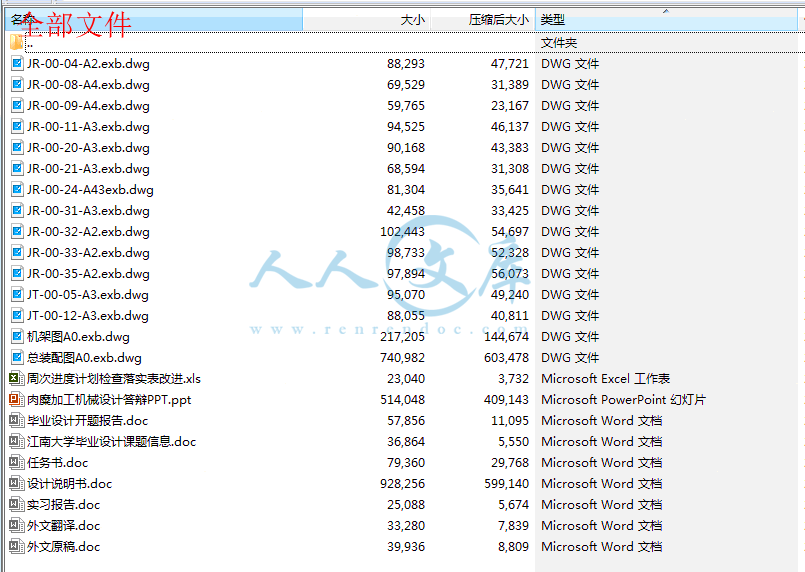

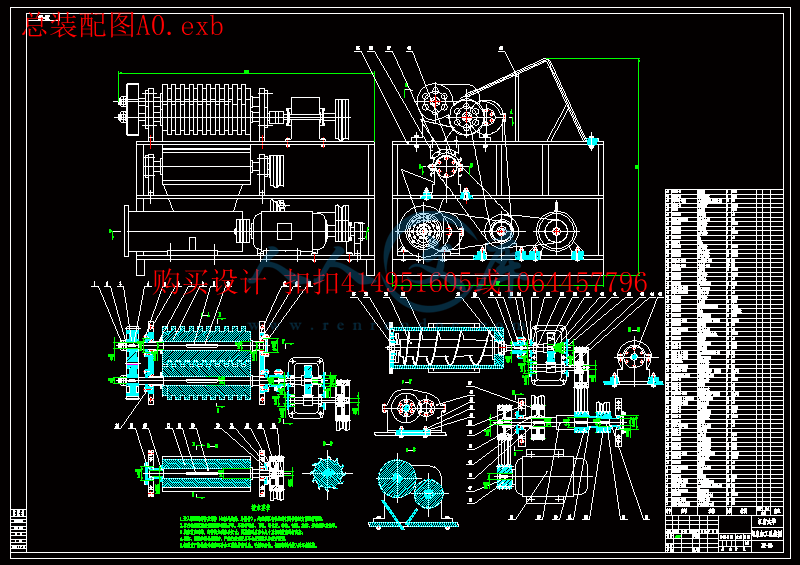

第2章 肉糜加工机整体设计3

2.1 肉糜加工机机总体方案设计3

2.2 设计方案的选择与设计3

2.2.1 肉糜加工机设计原理的选择3

2.2.2 切条机构的选择4

2.2.3 切块机构的选择5

2.2.4 切肉糜机构的选择6

2.2.5 电机机构的选择6

2.2.6 料筒机构设计....7

2.3 本章小结7

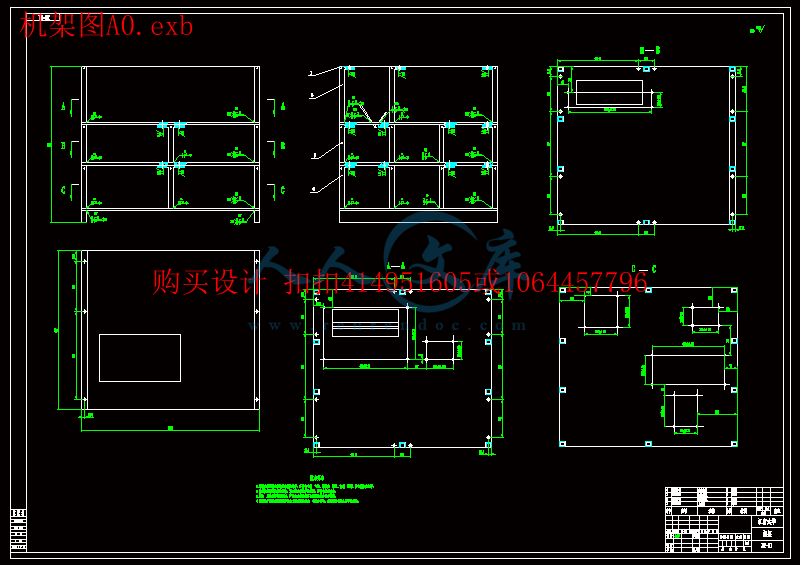

第3章 轴与轴上零件9

3.1 轴承的选用标准及其润滑和密封和定位9

3.1.1 传动轴轴承类型的选择......................................................................................................................9

3.1.2 轴承的固定形式................................................................................................................................10

3.1.3 轴承的润滑与密封............................................................................................................................11

3.1.4 轴承定位............................................................................................................................................11

3.2 轴.........................................................................................................................................13

3.2.1 轴的设计标准....................................................................................................................................13

3.2.2 轴的设计与强度校核........................................................................................................................14

3.3齿轮的选用标准及校核......................................................................................................17

3.3.1 齿轮的失效形式和设计准则............................................................................................................17

3.3.2 齿轮的材料........................................................................................................................................17

3.3.3 齿轮的校核........................................................................................................................................18

3.4 联轴器的选择.....................................................................................................................21

3.4.1 联轴器类型的选择............................................................................................................................21

3.4.2 常用联轴器的种类及其功能介绍....................................................................................................21

3.4.3 联轴器尺寸、型号的确定................................................................................................................22

3.5 电机的选择.........................................................................................................................24

3.3.1 电动机选择的基本要求....................................................................................................................24

3.3.2 一般电动机的选择方法....................................................................................................................24

第4 章 润滑与密封...............................................................................................27

4.1 润滑方式...............................................................................................................................................27

4.2 润滑油种类和选择...............................................................................................................................27

第5 章 结论与展望...............................................................................................29

5.1 结论.......................................................................................................................................................29

5.2 不足之处及未来展望...........................................................................................................................29

参考文献.................................................................................................................31

致谢...................................................................................................................33

第1章 绪论

1.1 课题来源

食品加工机械是机械的一个重要发展方向之一,也是国计民生的大事,肉食品加工尤其重要。肉食品加工除满足生产力的需要外,还需满足全民食品安全卫生的需要。

研究肉糜加工的方法,肉糜的大小形状体积与口感的关联,研究提高肉糜加工生产力的方法,研究加工时的安全卫生措施。

1.2 课题的意义

我国是世界上饲养畜禽最多的国家,同时也是人口最多的国家。由于人口基数的过大,肉制品的需求也大,但是现有的肉糜加工机还是离不开大量的人工操作。由于我国的肉制品加工的基础较差,与国外先进的肉糜加工水平仍有较大差距,相信随着肉糜加工产业的不断发展,这些差距也会越来越小。肉糜切割的广阔市场,使得国内外科研工作者对肉糜加工技术进行不断深入的研究,推动者肉糜加工行业的不断发展。

川公网安备: 51019002004831号

川公网安备: 51019002004831号