【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

前言·······························································1

第1章 设计任务书···············································2

第2章 总体设计················································3

第2.1节 设计依据···············································3

第2.2节 工作过程的拟定·········································3

第2.3节 传动方案的选择········································3

第2.4节 传动比的分配···········································4

第2.5节 筒体结构的初步设计····································5

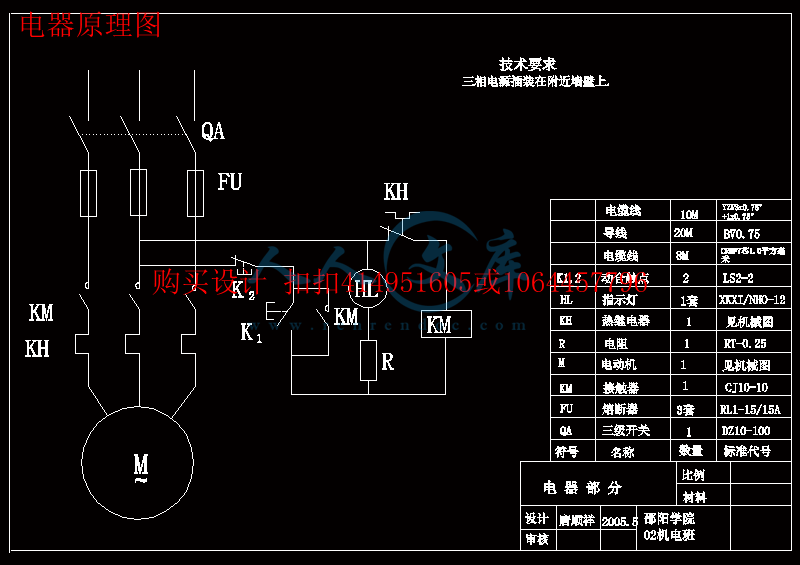

第3章 传动装置及电动机的选择·································5第3.1节 选择传动方案···········································5

第3.2节 电动机的选择···········································5

第3.3节 传动比的分配···········································6

第3.4节 计算传动装置的运动参数和动力参数···················7

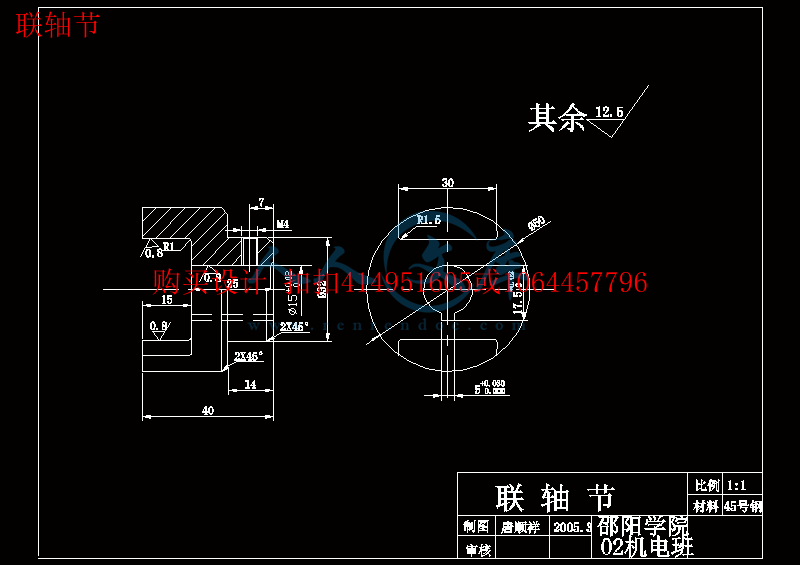

第4章 联轴器设计··············································9第4.1节 选择联轴器的类型······································9

第4.2节 计算联轴器的转矩·····································10

第4.3节 联轴器的确定以及其基本尺寸·························10

第4.4节 联轴器的附加说明····································10

第5章 蜗杆的设计···············································12

第5.1节 选择蜗杆传动类型·····································12

第5.2节 选择材料··············································12

第5.3节 按齿面接触疲劳强度进行设计·························12

第5.4节 蜗杆与蜗轮的主要参数与几何尺寸·····················13

第5.5节 验算传动比············································14

第5.6节 校核齿根弯曲疲劳强度································14

第5.7节 精度等级公差和表面粗糙度的确定··························15

第5.8节 初步确定蜗杆上的最小直径····························15

第5.9节 蜗杆的结构与各段直径和长度·························16

第5.10节 初步选取滚动轴承·····································16

第5.11节 蜗杆上零件的周向定位·······························17

第6章 主动轴的设计············································18

第6.1节 初步确定轴的最小直径································18

第6.2节轴的结构设计·········································18

第6.3节求轴上的载荷·········································19

第6.4节求作用在轴上的力·····································20

第6.5节按弯扭合成应力校核轴的强度·························20

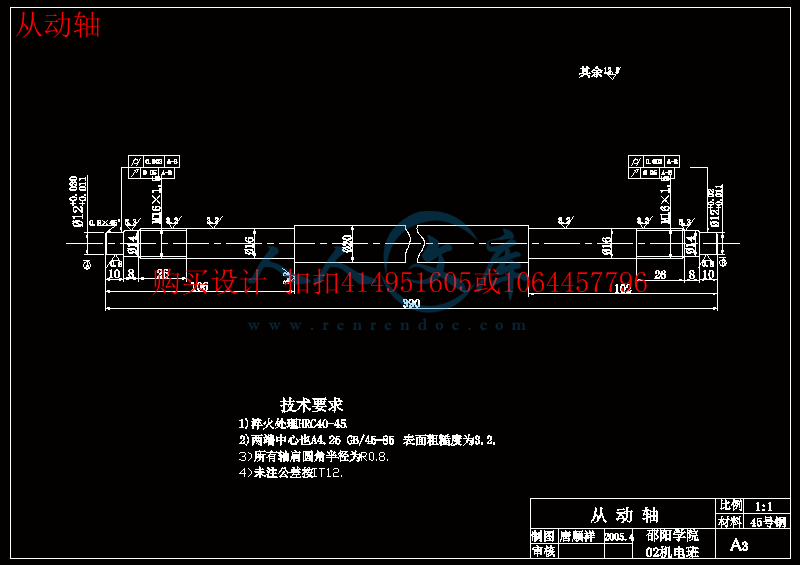

第7章主动轴的设计···········································21

第7.1节 从动轴的结构设计·····································21

第7.2节从动轴的工作结构图··································21

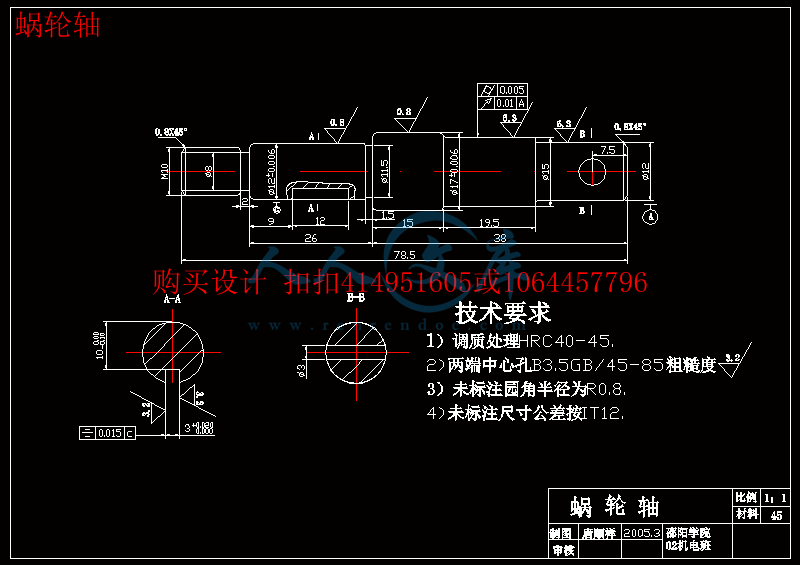

第8章蜗轮轴的结构设计及蜗轮的结构设计····················22

第8.1节 蜗轮结构··············································22

第8.2节 求出蜗轮上的功率P转速n·····························22第8.3节 求作用在蜗轮上的力···································22第8.4节 轴的结构设计··········································23

第8.5节 根据轴向定位要求确定轴的各段直径和长度··········23第8.6节 确定轴上圆角和倒角尺寸······························25

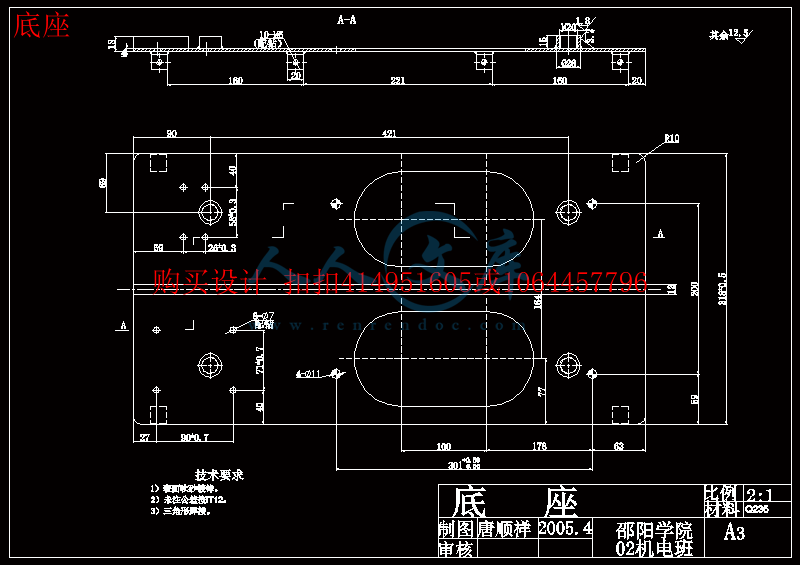

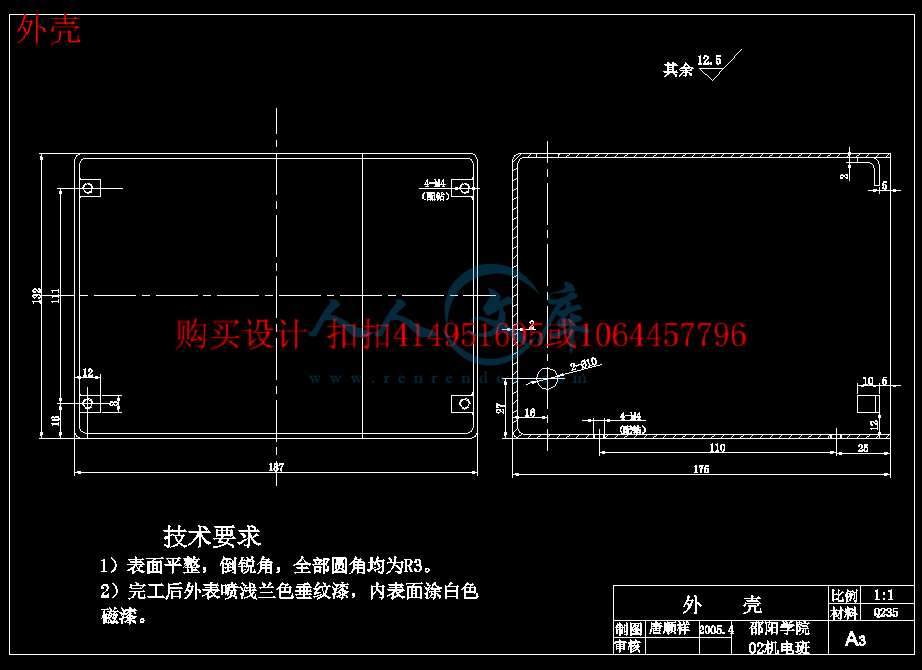

第9章 筒体的设计··············································26第9.1节 筒体结构的确定·······································26第9.2节 确定筒体的壁厚·······································26

第9.3节 送料孔和卸料孔的设计································26第9.4节 筒体各部分尺寸的确定································27第9.5节筒体的技术要求··········································27第10章 振动频率的设计········································28

第10.1节 用瑞利法求筒体的固有频率··························28第10.2节 振幅的设计···········································30

小结 ·····························································33

参考文献 ························································34致谢·····························································35

摘要

此小型搅拌器是在原传统的搅拌器基础上把它改小并加一个振动装置,同时也改变转动结构。它通过电动机带动,经蜗轮减速器减速改变方向,通过弹性柱销联轴器连接,带动筒体下的主动轴转动,因而使筒体转动,筒体在转动的同时,由于筒体本身和重力,以及微体内物料的冲击力,从而筒体底座下的弹簧来回收缩弹起,从而达到边转动边振动的目的。其内容包括:总体设计,传动装置及电动机的选择,联轴器的设计,蜗杆的设计,主动轴的设计,从动轴的设计,蜗轮轴及蜗轮的设计,筒体的设计,振动频率的设计。此搅拌器的创新之处就在于联轴器的选择和振动装置,本次设计是通过本人平时的观察思考以及查阅各种资料,以及指导老师的指点和自己的所学的理论知识的基础上完成的。

关键词:传动装置,蜗轮减速箱,弹性柱销联轴器,主动轴,从动轴,筒体,振动频率。

Summary

This small-scale agitator changes it small and adding a vibration device on the basis of original and traditional agitator , change the structure of rotating at the same time . It drives through the motor, is moderated the direction of changing by the worm gear decelerator, sell the shaft coupling to join through the elastic post, drive the initiative axle under the barrel to rotate, therefore make the barrel rotate, the barrel, while rotating, because of barrel and gravity, and a little internal shock power of supplies, thus spring , barrel of base is it blow to play to shrink to go back to come, thus achieve rotate purpose of vibration. Its content includes: Design overallly, the transmission device and choice of the motor, the design of the shaft coupling , the design of the worm, the design of the initiative axle , the design of the driven axle , the designs of snail's shaft and worm gear, the design of the barrel, the design of the vibration frequency. The innovation of this agitator lies in the choice of the shaft coupling and vibration device , this design is to think and consult various kinds of materials through my observation at ordinary times , and the one that finish on the counselor's instruction and foundation of one's own theory knowledge studied.

Keyword: Transmission device , worm gear gearbox, the elastic post sells the shaft coupling , initiative axle , driven axle , the barrel, vibration frequency.

前 言

搅拌操作在食品工业以及化学工业中占有十分重要的地位,大多数面糖类食品以及化学药品都离不开搅拌,搅拌是借助于流动使两种或多种物质在彼此之中相互散布的一种操作。其作用可以实现物质的均匀混和,也可以促进溶解,气体吸收,强化热交换等物理化学的变化,“通过机机械动作,使物质按一定的规律流动的方法称为机械搅拌,简称搅作,这种机械称为搅拌机械”[1]

传统搅拌器一般都只作纯旋转流动,被搅拌的物品易粘在筒体上且混合不均匀,或者就只是搅拌杆在运动,搅拌效果并不理想效率较低,而且引进结构复杂,质量较大。

本搅拌器在传统的设备上有较大的改进,是通过电动机带动蜗轮减速器减速后用弹性联轴器直接连接起来,功率损耗小,能够实现装料筒体在转动时,给其以振动力,不仅可使物品混合均匀,而且可避免粉状物品粘在筒体壁上,可以根据实际需要方便操作控制振动力的大小有无,由于重量较轻,使用方便且不受环境的限制,所以适用范围比较广泛,适用于各种实验室以及各种食品工业以及化学工业等领域。

随着人们对物质文化的需要越来越高,这就对生产力的要求也就越来越高,生产工具的改进是提高生产力的主要途径,只有生产工具不断的改进,生产率、产品质量不断的提高,才会在竞争日益激烈的社会中才有立锥之地。本搅拌器作为一种改进创新的生产设备,对生产效率和产品质量的提高有着举足轻重的作用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号