!【详情如下】【注塑塑料模具课题】CAD图纸+word设计说明书.doc[19000字,38页]【需要咨询购买全套设计请加QQ97666224】.bat

任务书.doc

设计说明书.doc[19000字,38页]

开题报告书.doc

摘要.doc

目录.doc

翻译材料(最终).doc

侧型芯.dwg

凹模.dwg

动模垫板.dwg

动模座板.dwg

动模板.dwg

右垫块1.dwg

型心.dwg

塑件图.dwg

定位环.dwg

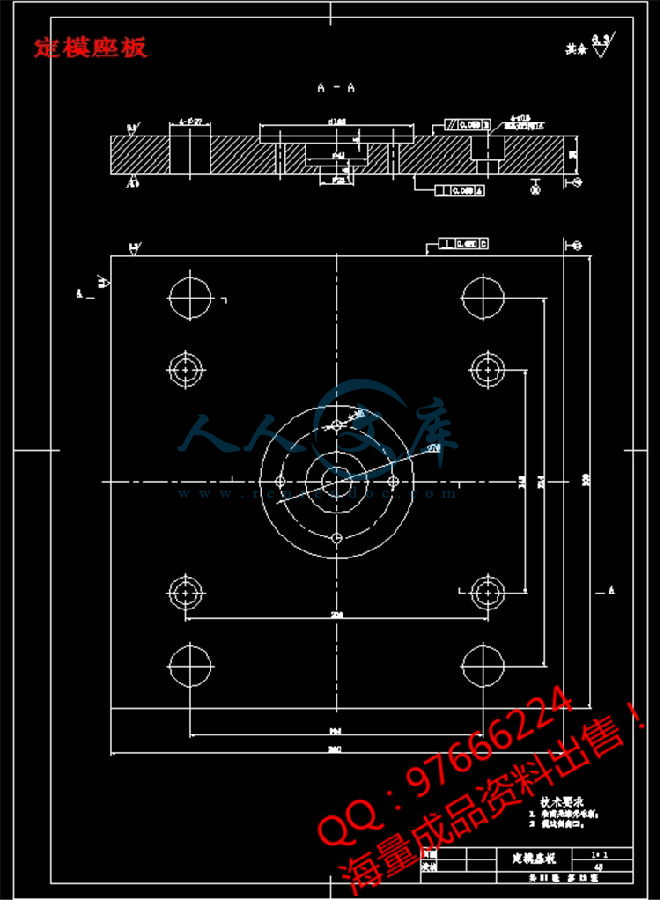

定模座板.dwg

定模板.dwg

左垫块.dwg

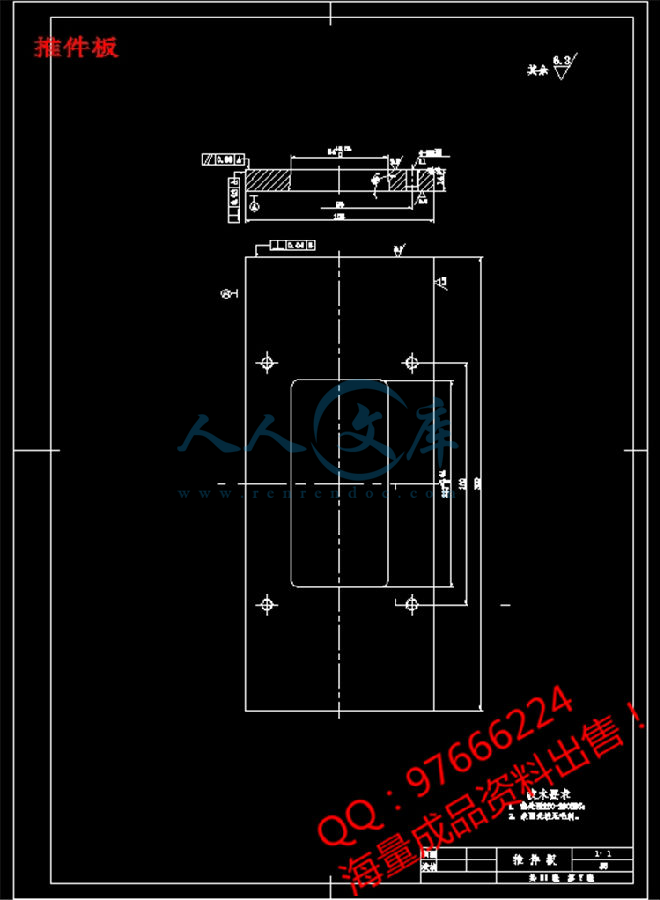

推件板.dwg

推板.dwg

斜导柱.dwg

楔紧块.dwg

江南大学

浇口套.dwg

滑块.dwg

装配图.dwg

限位拉钉.dwg

顶杆固定板.dwg

[摘 要]:

本文详细介绍了加热缸体注塑模的设计过程。首先分析原始资料,包括塑件材料(聚炳烯)的性能和结构工艺特点,然后确定分型面和型腔排列方式,接着设计侧抽芯机构以及导滑槽和滑块,还对成型零件、型腔壁厚、加热和冷却等进行了计算,最后对注塑机进行校核。本设计介绍了中等复杂程度注射模具的设计过程,并对模具设计进行优化和改进,提高了模具设计的质量,缩短了设计时间。

[关键词]:注塑模设计 抽芯 注射成型

[Abstract]:

This paper was detailed to introduce a design process of pipe frame injection mold. First to analysis original data, including the properties of the material (polypropylene) and technological characteristics of the plastic part, then decide the divide surface of cavity and the arrange way of mold cavity, designing the side take out core outfit and guide runner and slide block, still carried on the calculation towards modeling part, cavity deep and thick, hot up and cooling, at last, check the data of injection molding machine. This design introduces the design process of a middle complexity injection mold, and optimizes and improves the molding design so that to increase the quality of molding design and shorten the design time.

[Key words]: the design of injection mold core drawing injection molding

目 录

摘要

前言·····················································································(1)

第一章 塑料制件的设计·········································································(3)

1.1 塑件材料的性能······························································(3)

1.2 塑件的体积与重量······································································(5)

1.3 塑件工艺分析及结构设计····················································(6)

第二章 总体设计方案的确定·····························································(8)

2.1 分型面的选择·······························································(8)

2.2 排气方式的确定········································································(8)

2.3 型腔数目和排列方式的确定···············································································(9)

2.4 注塑机的选择·······································································································(9)

第三章 浇注系统的设计及计算······················································································(11)

3.1 流道设计············································································································(11)

3.2 浇口设计············································································································(11)

3.3 流动比校核········································································································(12)

第四章 成型零件设计·····································································································(13)

4.1 成型零件结构设计····························································································(13)

4.2 成型零件工作尺寸计算····················································································(13)

4.3 成型零件的力学计算························································································(18)

第五章 导向与定位机构设计·························································································(21)

5.1 导向机构的设计································································································(21)

5.2 定位机构设计····································································································(22)

第六章 脱模机构设计···································································································(23)

6.1 脱模力的计算····································································································(23)

6.2 推出机构形式的确定························································································(24)

6.3 推出零件尺寸的确定························································································(24)

第七章 侧向分型与抽芯机构设计···············································································(26)

7.1 侧向分型和抽芯机构的类型············································································(26)

7.2 抽拔距的确定····································································································(26)

7.3 抽拔力的计算····································································································(26)

7.4 斜导柱的设计····································································································(27)

7.5 滑块与导滑槽设计····························································································(29)

7.6 楔紧块的设计····································································································(29)

第八章 温度调节系统的设计·························································································(30)

8.1 求塑件在固化时每小时释放的热量Q····························································(30)

8.2 求冷却水的体积流量························································································(30)

第九章 标准模架的选用··································································································(31)

第十章 注塑机参数校核··································································································(32)

10.1 最大注塑量校核······························································································(32)

10.2 锁模力校核······································································································(32)

10.3 模具与注塑机安装部分相关尺寸校核··························································(33)

10.4 开模行程校核··································································································(33)

第十一章 模具装配与试模······························································································(34)

11.1 模具的装配·······································································································(34)

11.2 模具的安装·······································································································(35)

11.3 试模···················································································································(35)

毕业设计总结····················································································································(36)

后记···································································································································(37)

参考文献···························································································································(38)

川公网安备: 51019002004831号

川公网安备: 51019002004831号