目录

绪论……………………………………………………………….…...5

1.磨削技术……………………………………………………………6

1.1磨削加工的发展历史……………………………………………6

1.2磨料磨具的简明知识…………………………………………….9

1.3现阶段国内磨削加工科学技术新进展…………………………10

1.4磨削原理…….. …….. …….. …….. …….. …………………… 14

1.5磨削技术的发展及关键技术…….. …….. ……………………..18

1.6磨削技术的优点……………………….. ……………………….24

1.7超高速磨削的发展及关键技术……. …………………………..24

2. 问题的提出及可行性研究.. …….. …….. .. …. ………………...32

2.1问题的提出及定义………………………………………………32

2.2对系统设计的可行性分析………………………………………34

3改装部分组成………………………………………………………38

3.1总体结构设计………………………………………………….…38

3.2电动机的选择….…………………………………………………52

4.设计结构选择和设计计算…….. ………….…….. ….……..……..54

4.1传动系统结构的设计………………………….……….………...54

4.2箱体的设计…………………………………………………….…63

5 结速语………………………………................................................68

6 致谢.....................................................................................................69

7 参考文献…….. …….. …….. …….. ………………………..….…..70

摘要

机械系统是机械零、部件同作用的整体,是零部件服务的目标。本次改装设计从分析机械系统设计的任务和目标开始,介绍改装和设计的各个组成部分,各组成部分之间的配置,选择和结构匹配性设计,以及进行整体改装和设计时应该考虑哪些问题,目的是培养多样性设计,结构设计创新和整体设计的能力。

齿轮珩磨是一种低速磨削,是机械制造业中缸孔光整加工的常用工艺手段。珩齿加工是近年发展起来的一种齿轮精加工方法.

本次设计主要是齿轮珩磨机的改装和设计,其主要包括主轴箱,珩磨头,主轴等零件的设计。

在论文中首先对珩齿机做了简单介绍,接着对珩齿机的部件组成进行了尺寸设计计算和校核。该设计代表了珩齿机改装和设计的一般过程。

珩齿机床作为复杂的生产工具,最根本的是加工工艺与结构布局改装和设计。在对机床的现有结构进行改装,对机床的使用工艺和装备进行革新的过程中,并不是一味的追求先进,而应该力争改装方案合理,结构简单巧妙,经济效果好.

关键词: 珩齿机、改装

Abstract

mechanical systems is a common mechanical components of the overall role of parts service goals. The design and modifications from the analysis of mechanical systems design tasks and goals, and design and modifications on the various components, between the various components of the configuration, selection and design of the structure matching, and the overall design modifications and what issues should be considered. The aim is to design diversity. Design innovation and the ability of the overall design.

Gear Honing is a low-speed grinding, mechanical manufacturing cylinder aperturestop finishing the commonly used techniques. Gear Honing in recent years developed a gear finishing method.

The design is the main gear honing machine modifications and design, including its main spindle box, honing head, and other parts of the spindle design.

In the paper first gear honing machine introduced briefly, then gear-honing-machine component parts of the size and design verification. The design represents the gear honing machine conversion and the general design process.

Heng Machine as a complex production tools, the most fundamental thing is processing technology and modified and design the structure and layout. The machine for the conversion of existing structures, the use of machine technology and equipment for the process of innovation, not blindly pursue advanced, and the conversion program should strive reasonable, simple structure clever and good economic results.

Keywords : Heng shaping machines, modified

3改装部分组成

3.1 总体结构设计

3.1.1:改装部分的组成

下图为车床改装进行珩齿加工的外观图.

改装主要由两部分组成.一是被珩齿轮的安装部分,有心轴、垫片、螺母等零件组成.心轴插入车床主轴锥孔里,用螺栓拉杆紧固.被珩齿轮安装在心轴上,用螺母拧紧;另一是珩磨头,它的滑座6安装在大拖板7上面的横向燕尾形导轨上,因此珩磨头既可以随大拖板作纵向进给运动,又可在横向进给的丝杆螺母作用下作横向进给运动.

3.1.2:珩齿加工原理

珩齿所用的珩轮外形结构和剃齿刀相似,珩轮材料是有磨料(通常为80~180号粒度的刚玉)、树脂等混合而成的.在轮芯上浇铸成螺旋齿轮(见下图),其主要结构尺寸:分度圆直径有240毫米和180毫米两种;螺旋角有15°和5°两种;宽度现在多为35毫米.

本改装采用了常见的双面变压珩齿法,珩轮与工件的啮合关系运动情况和剃齿大致相同:工件带动珩轮正反转动;珩轮沿轴线作直线往复运动(见上图).但径向运动不像剃齿那样在每一往复行程后有一次进给,而是按珩齿需要的初压力(一般为20公斤左右)调整好珩轮与工件的中心距,开车后一次进给到预定位置.珩齿开始时齿面压力较大,随后压力渐减(即所谓变压),直至接近消失时珩齿结束.

3.1.3 珩磨头结构及使用方法

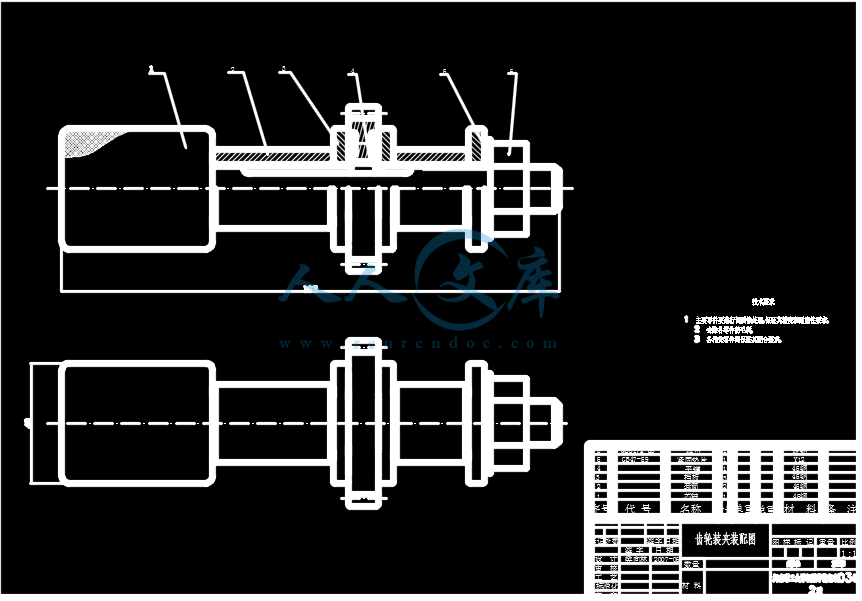

珩磨头的结构如下图所示:

它是根据上述珩磨原理设计与制造的.由主轴1﹑弹性夹头4﹑胎盖5﹑压盘6﹑摩擦盘7﹑偏心盘8﹑心轴11﹑弹簧14﹑壳体18﹑滑座29等零件组成. 珩齿加工时,珩轮与工件啮合。于是珩轮在工件的带动下旋转,其动力通过弹簧夹头4传给胎盖5.由于胎盖5﹑压盘6﹑摩擦盘7之间均是用螺钉连接,所以摩擦盘7等件随胎盖5一起转动.旋动弹簧调节螺母,可调节弹簧14作用在主轴1上的作用力。由图可以看出,摩擦盘7紧紧的压在偏心盘8上.因此,当摩擦盘7转动时,在摩擦力的作用下,偏心盘8绕心轴11转动,其外形轮廓上各点到心轴11圆心的尺寸不等,则使主轴1随着珩磨轮37的旋转二作轴向往复运动。也就是说,在珩齿加工中,珩磨轮既与工件啮合旋转,又沿着主轴1的轴向往复直线运动。

应当指出,珩磨轮直线往复运动行程的大小,受偏心盘8的控制。当被珩齿轮的宽度不同时,偏心盘8的偏心距也应不同,所以偏心盘8是可更换件,对不同齿宽的齿轮,需换成偏心距相适应的偏心盘。为了减少不同尺寸偏心盘的数量,在生产中可按照下表中的情况使用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号