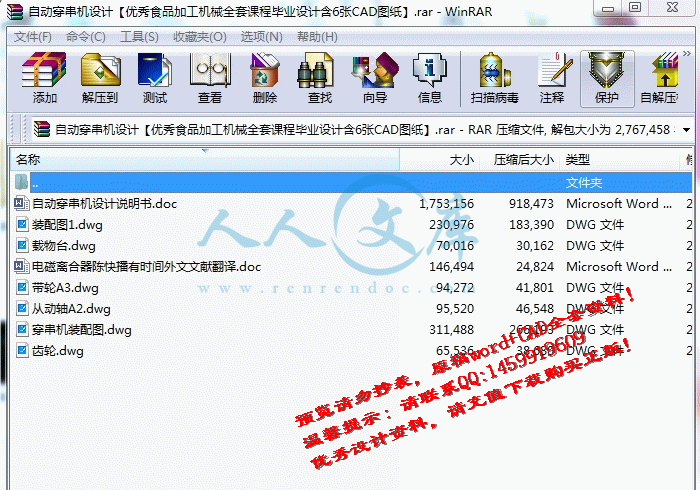

自动穿串机设计【优秀食品加工机械全套课程毕业设计含6张CAD图纸】

【带外文翻译】【43页@正文20000字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

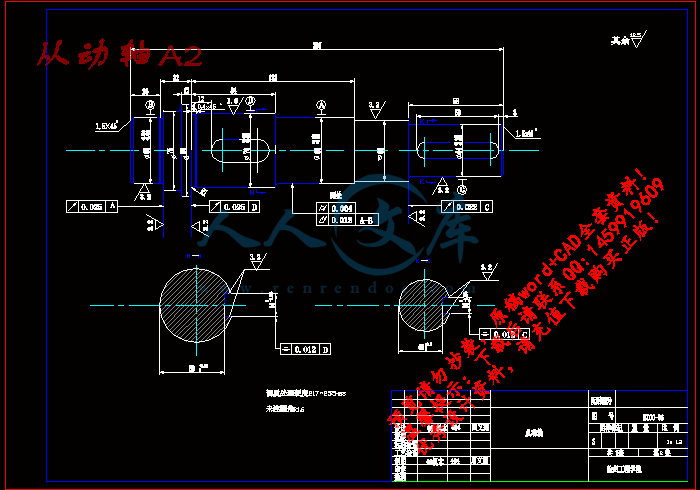

从动轴A2.dwg

带轮A3.dwg

穿串机装配图.dwg

自动穿串机设计说明书.doc

装配图1.dwg

载物台.dwg

齿轮.dwg

摘要

自动穿串机适用于新型食品加工行业。目的是研制一种自动穿插机构,能够代替手工

劳动, 提高工作效率, 降低劳动强度。 本文针对传动系统, 进给机构及自动控制系统设计。

并对所用的齿轮传动和轴进行计算。本产品采用电动机带动,通过各系统的相互协作,实

现穿插动作。本机构是在食品装料机械的基础上设计的。此机构具有结构简单、体积小、

成本低的优点。

设计要求完成入料、动力源的选定、传动系统、执行机构、落料机构。

入料选用排序机构,动力源的选定选用电动机,传动系统采用 V 带传动、齿轮传动、

连续传送机构,执行机构采用插签机构、压盘装置,落料机构一个挡棒和盘子。

关键词自动穿插;传动系统;自动控制系统

Abstract

Automatic wear string machine is suitable for new food processing industry. Purpose is to

develop a kind of automatic thrust institution, can replace manual labor, improve work efficiency

and reduce labor intensity. Based on transmission system, lathe and automatic control system

design. And on the gear and axis. This product adopts motor driving through the cooperation and

realizing the system into action. The agency is in charge of food machinery based on the design.

The agency has simple structure, small volume, low cost advantage.

Complete the design requirements of power and selected, transmission system, actuators,

blanking institutions.

The ranking selection, the selected chooses motor, power transmission adopts the V belt

transmission, gear, continuous transmission, actuator adopts inserted sign institutions, pressure

plate blanking institution, a block sticks and plates.

Keywordsautomatically alternates, Transmission systems, Automatic control system

目录(论文 )

1 绪论……………………………………………………………………………………………..1

1.1 序言…………………………………………………...………………………………….1

1.2 自动穿串机的设计思路……………………………………………………………….1

2 自动穿串机各机构的选择及设计设计思路………………………………………………......2

2.1 入料机构的选择及设计……………………………………………………………….2

2.2 振动筛的设计………………………………………………………………………………2

2.3 穿插机构的设计…………………………………………………………………….…..5

2.3.1 插签机构……………………………………………………………………………..5

2.3.2 压盘装置……………………………………………………………………………..5

2.4 落料机构的设计………………………………………………………………………...6

3 轴承的选定………………………………………………………………………………..…....7

3.1 概述………………………………………………………………………………………7

3.2 滚动轴承的主要类型、特点和代号…………………………………………………8

3.3 轴承的寿命计算…………………………………………………………………….…10

3.3.1 滚动轴承的基本额定寿命……………………………………………………..…..10

3.3.2 基本额定动负荷………………..………………………………………………..…..10

3.3.3 寿命计算公式 …………………….………………………………………………....11

3.3.4 额定寿命的修正……………..………………………………………………..…..11

3.3.5 滚动轴承的当量动载荷……………………………………………………..…..11

3.3.6 角接触轴承的计算…………...……………………………………………..…..12

3.3.7 主动轴轴承的校核……………………………..………………………………..…..12

3.3.8 从动轴轴承的校核………………………..……………………………………..…..13

4 传动机构设计………………………………………………………………………………....14

4.1 传动系统的选择……………………………………………………...…………..……14

4.1.1 带传动的类型和特点………………………..…………………………………..…..14

4.1.2V 带传动的设计………………………..………………………………………..…..15

4.2 电动机的选择 ………………………………...……………………….....………………18

4.2.1 电动机类型和结构的选择………………………..……………………………..…..18

4.2.2 电动机功率的选择………………………..……………………………………..…..18

4.2.3 确定电动机转速………………………..………………………………………..…..18

4.2.4 电动机型号的确定………………………..……………………………………..…..18

4.3 齿轮传动的设计…………………………....………………………...…………..……19

4.3.1 选择齿轮材料并确定许应应力………………………..………………………..…..19

4.3.2 按齿面接触强度设计计算………………………..……..……………………..…..19

4.4 传动装置运动、动力参数计算 ……………...………………………...………..………21

4.4.1 总传动比的确定………………………..……..…………………………..…..…..21

4.4.2 分配各级传动比………………………..……..………………………..……..…..21

4.4.3 计算各轴转速 ………………………..……..…………………………………...…..21

4.4.4 计算各轴的功率………………………..……..…………………..…………..…..21

4.4.5 计算各轴转矩………………………..……..……………………..………..…..21

4.4.6 传动装置运动、动力参数汇总表………………………..…………………..…..22

4.5 轴的设计计算 ……………...…………………………………………...……………..…22

4.5.1 输入轴的设计计算………………………..……..….……………..………..…..22

4.5.2 输出轴的设计计算………………………..…………………..………..…..25

4.6 输送机的设计 ……………...…………………………………………...……………..…26

5 减速器的选择………………………………………………………………………………....31

5.1 概述……………...………………………………………………..…...…………..……31

5.2 减速器的机构和附件的设计…………...…………………………...……………..…31

5.3 减速器的润滑和密封…………….........……………………………...…………..……32

结论…………………………………………………………...………………………………....33

致谢………………………………………………………………………………………...…....34

参考文献………………………………………………………...……………………………....35

参考文献

[1] 许林成 《包装机械原理与设计》 上海科学技术出版社 1988 年 09 月

[2]吴宗泽主编。机械结构设计。北京:机械工业设计出版社。1988

[3] 邱宣怀 《机械设计》第四版 高等教育出版社 1997 年 7 月

[4](美)米什克主编。机械设计通用手册。河海大学机械学院译。1993

[5].周开勤主编。机械零件手册。第四版。1994

[6]许尚贤编著。机械零件的现代设计方法。1994

[7]陈伸文主编。圆弧齿圆柱齿轮传动。1995

[8]徐灏主编。机械设计手册。北京:机械工业出版社。1995

[9](美)伯尔著。机械分析与机械设计。北京:工业机械出版社,1998

[10] 胡继强 《食品机械与设备》 中国轻工业出版社 1999 年 07 月第 1 版

[11] 任家隆 《机械制造基础》 高等教育出版社 2003 年 3 月

[12] 武予鲁 《带式输送机综合保护装置的工作原理和使用》 煤炭工业出版社 2003年04

[13] 薛焱等 《中文CAD2004基础教程》 清华大学出版社 2003年7月

[14 张春林 《机械创新学设计》 机械工业出版社 2008年7月

川公网安备: 51019002004831号

川公网安备: 51019002004831号