抓手机器臂机电液集成系统设计【优秀机械手全套课程毕业设计含5张CAD图纸】

【带任务书+开题报告+评阅书+外文翻译】【38页@正文15400字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

任务书.doc

图纸目录.doc

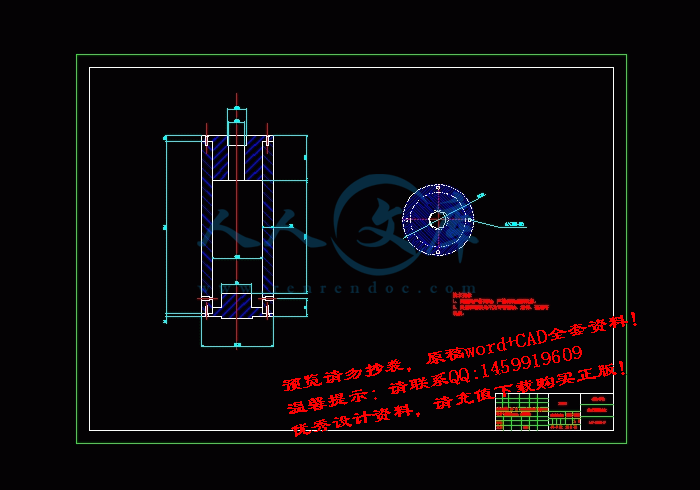

垂直升降油缸.dwg

垂直升降油缸活塞.dwg

垂直升降油缸活塞杆.dwg

开题报告.doc

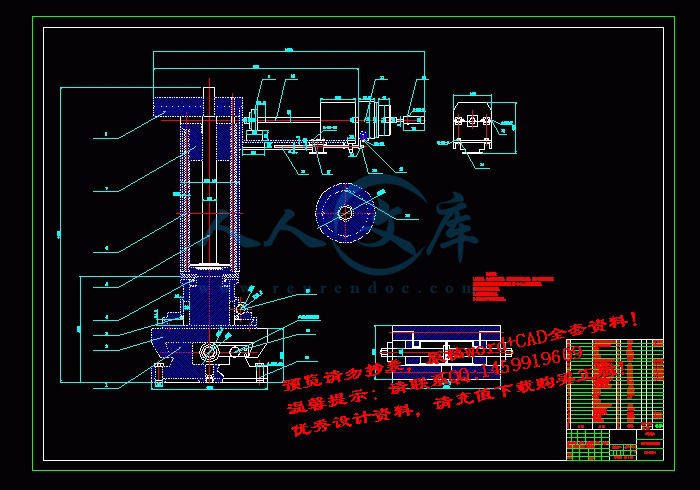

机器人手臂装配图.dwg

机器臂横移机构.dwg

机械手臂外文翻译.doc

评阅表.doc

说明书.doc

进度考核表.doc

任务书

课题名称抓手机器臂机电液集成系统设计

设计(论文)

一、课题研究的目的与主要内容

1、课题目的

培养学生综合运用所学知识的能力,能够独立地解决较为简单的工程问题,树立正确的设计思想和工作作风。本课题是抓手机器臂机电液集成系统设计,该课题来源于维克液压,通过课余时间参观学习和实地考察,给毕业设计提供参考。具体要求是通过毕业设计使学生用所学的知识解决实际问题,培养学生理论联系实际的能力。

2、主要内容

本文以抓手机器臂机电液集成系统为设计对象,对新产品的设计过程进行了研究。抓手机器臂机电液集成系统设计过程包括:抓手机器臂机械部分动力分析、机电液集成系统理论计算、机电液元件选型及核算、系统验算等。

主要工作内容如下:对抓手机器臂机电液集成系统的功能要求进行分析,确定抓手机器臂的运动姿态;对抓手机器臂的机电液集成系统结合国外先进资料进行分析整理,对抓手机器臂的各个运动部分的机电液集成系统详细分析,根据抓手机器臂的系统要求并结合具体情况对抓手机器臂机电液集成系统进行理论计算,并且对主要机电液元件选型;分析各个主要机电液元件的特性;部分液压缸的设计;系统的验算。

二、基本要求

1.熟悉运用CAD、PRO/E等绘图软件独立完成相关设计的原理图、零件图、装配图。

2.按学院毕业设计的编写规格要求,撰写设计说明书(1~2万字)。

3.设计完成与设计有关的外文资料翻译,译文要求准确,语言流畅。

注:1.此表由指导教师填写,经系、教研室主任审批生效;

2.此表1式3份,学生、系、教务处各1份。

三、课题研究已具备的条件(包括实验室、主要仪器设备、参考资料)

1.邵阳学院的实习工厂。

2.机械与能源工程系机械设计实验室,数控加工中心实验室,液压与气压传动实验室,主要仪器设备有:液压传动实验台,液压泵测试试验台,线切割加工机床,电火花成形加工机床,数控加工中心,类型较多的机械设计零件等。

3.邵阳学院图书馆。

4.主要参考资料:现具有《机械设计手册》、《液压传动与气压传动》、《电子技术》、《零件设计手册》等相关资料和液压泵、液压阀等液压元件的相关资料。除了以上的资料,还有AUTOCAD、PRO/E、OFFICE等相关的绘图软件和工作软件。

内容提要

本次设计的液压传动机械手根据规定的动作顺序,综合运用所学的基本理论、基本知识和相关的机械设计专业知识,完成对机械手的设计,并绘制必要装配图、液压系统图、PLC控制系统原理图。机械手的机械结构采用油缸、螺杆、导向筒等机械器件组成;在液压传动机构中,机械手的手臂伸缩油缸,手腕回转采用回转油缸,立柱的转动采用齿条油缸,机械手的升降采用升降油缸,立柱的横移采用横向移动油缸;在PLC控制回路中,采用的PLC类型为FX2N,当按下连续启动后,PLC按指定的程序,通过控制电磁阀的开关来控制机械手进行相应的动作循环,当按下连续停止按钮后,机械手在完成一个动作循环后停止运动。

Abstract

The design of hydraulic transmission of the manipulators according to the order of the integrated use of the basic theory, basic knowledge and related mechanical design professional knowledge, to complete the design of manipulator, and draw the necessary assembly drawing, the principle diagram of the hydraulic system diagram, PLC control system. The mechanical structure of the manipulator with oil cylinder, screw, guide tube and other mechanical parts; In hydraulic transmission mechanism, the manipulator arm telescopic oil cylinder, wrist rotation using rotating cylinder, post rotation using rack cylinder, lifting adopts lifting oil cylinder of the manipulator, column the transverse use transverse moving oil cylinder; In PLC control circuit, the use of FX2N PLC type, when press the row after the start, PLC according to the specified procedures, by controlling the switch of the solenoid valve to control the manipulator for corresponding action cycle, when press the stop button continuously, manipulator stop moving after cyclic to complete an action.

目 录

内容提要I

AbstractII

1 前 言1

1.1 工业机器人简介1

1.2 国外工业机器人发展2

1.3 国内工业机器人的发展3

1.4 我要设计的机械臂3

2 机器臂的机械结构设计总体来实现的设计及方案论证5

2.1 机器臂的结构及工作原理5

2.2 机器臂运动形式及方案论证5

2.3 典型机器臂的机构8

3 机器臂液压系统设计与校核11

3.1 液压系统简介11

3.2 液压系统的组成11

3.3 机械臂液压系统的控制回路11

3.4 机器臂简单液压系统的计算13

3.5 机器臂的液压系统图19

4 电气系统设计与分析21

4.1 可编程序控制器的选择及工作过程21

4.2 可编程序控制器的使用步骤22

4.3 机械手可编程序控制器控制方案22

总 结25

参考文献26

致谢27

1 前 言

1.1 工业机器人简介

工业机器人一般指的是在工厂车间环境中,配合自动化生产的需要,代替人来完成材料的搬运、加工、装配等操作的一种机器人。能代替人完成搬运、加工、装配功能的工作可以是各种专用的自动机器,但是使用机器人则是为了利用它的柔性自动化功能,以达到最高的技术经济效益。 有关工业机器人的定义有许多不同说法,从中可以对工业机器人的主功能有更深入的了解。

(1)美国机器协会(RIA):机器人是“一种用于移动各种材料﹑零件、工具或专用装置的,通过程序动作来执行各种任务,并具有编程能力的多功能操作机(manipulator)”。

(2)日本工业机器人协会:工业机器人是“一种装备有记忆装置和末端执行装置的、能够完成各种移动来代替人类劳动的通用机器”。它又分以下两种情况来定义:

①工业机器人是“一种能够执行与人的上肢类似动作的多功能机器”。

②智能机器人是“一种具有感觉和识别能力,并能够控制自身行为的机器”。

(3)国际标准化组织(ISO):“机器人是一种自动的、位置可控的、具有编程能力的多功能操作机,这种操作机具有几个轴,能够借助可编程操作来处理各种材料、零件、工具和专用装置,以执行各种任务”。

参考文献

[1] 濮良贵.机械设计.北京:高等教育出版社,2003.6

[2] 张普礼.机械工程手册.北京:机械工业出版社,1992.5

[3] 邓光敏.工业机械手册.北京:机械工业出版社,1995.8

[4] 何发昌,邵远.多功能机械手的原理及应用.北京:高等教育出版社,2002.1

[5] 吴延本,刘世华.机械设计手册.吉林:吉林科技出版社,1996.7

[6] 刘跃南.机械零件设计问题解析.北京:中国致公出版社,1999.4

[7] 徐福玲.液压与气压传动.北京:机械工业出版社,2004.2

[8] 邓星钟.机电传动控制[M].华中科技大学出版社,2002

[9] 孙志礼,冷兴聚,魏延刚等.机械设计[M].东北大学出版社,2003

[10] 徐灏.机械设计手册[M]第五卷.机械工业出版社,1992

[11] 吴宗泽.机械设计师手册[M].机械工业出版社,2002

[12] 成大先.机械设计手册[M].化学工业出版社,2002年

[13] 罗洪量.机械原理课程设计指导书[M](第二版).高等教育出版社,1986

[14] JJ.杰克(美).机械与机构的设计原理[M](第一版).机械工业出版社,1985

[15] 王玉新.机构创新设计方法学[M](第一版).天津大学出版社,1996

[16] 张建民.工业机器人[B][M].机械工业出版社,1991

[17] 马香峰.机器人结构学[B][M].机械工业出版社,1991

[18] 黄继昌,徐巧鱼,张海贵等.实用机械机构图册[B][M].人民邮电出版社,1993

[19] 天津大学《工业机械手设计基础》编写组.工业机械手设计基础[B][M].天津科学技术出版社,1981

[20]金茂菁.我国工业机器人发展现状[J].机器人技术与应用,2001,01(4)

川公网安备: 51019002004831号

川公网安备: 51019002004831号