!【详情如下】【注塑塑料模具类】CAD图纸+word设计说明书.doc[8000字,26页]【需要咨询购买全套设计请加QQ97666224】.bat

指导记录表.doc

设计说明书.doc[8000字,26页]

毕业设计任务书.doc

毕业设计开题报告.doc

毕业设计课题审批表.doc

动模型腔.dwg

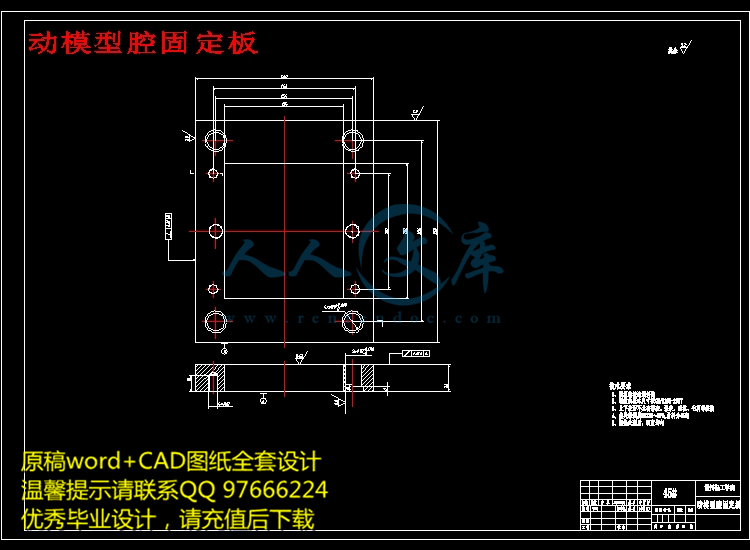

动模型腔固定板.dwg

型芯.dwg

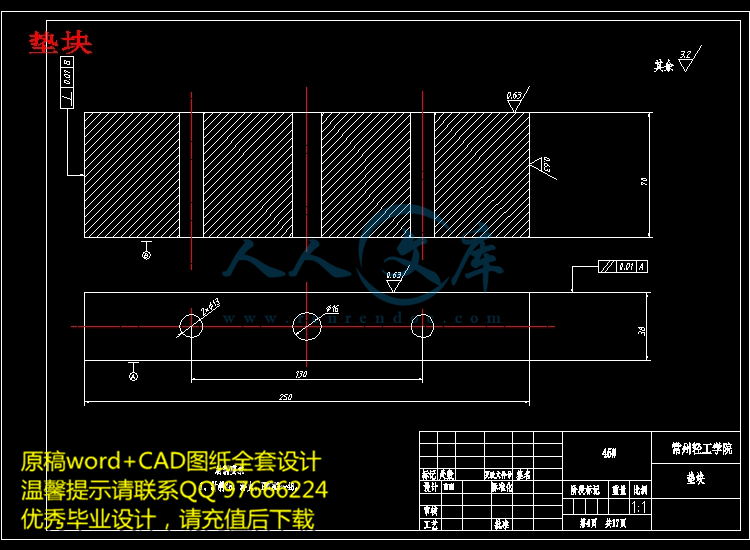

垫块.dwg

塑件图.dwg

复位杆.dwg

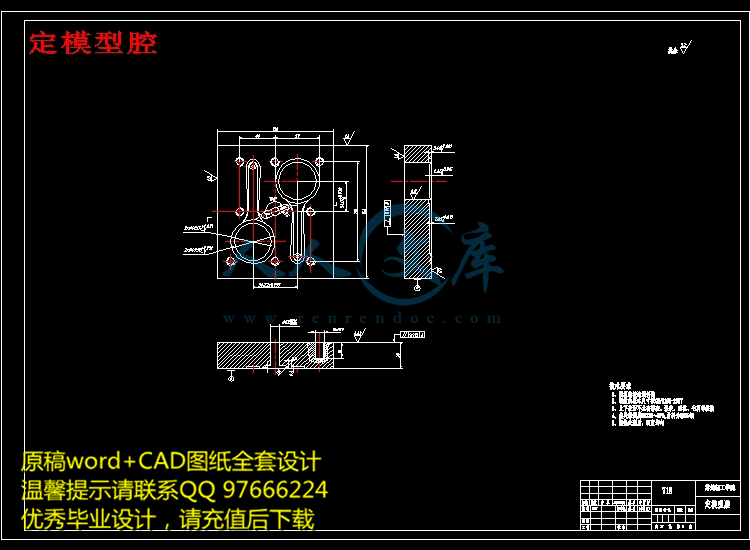

定模型腔.dwg

定模型腔固定板.dwg

定模座板.dwg

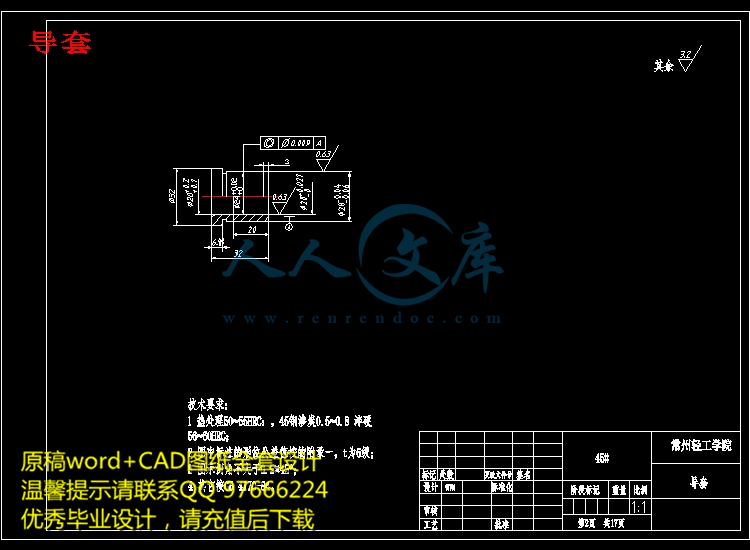

导套.dwg

导柱.dwg

推料杆.dwg

支承板.dwg

文件

水嘴.dwg

浇口套.dwg

装配图.dwg

顶杆固定板.dwg

摘要

注塑模具是在成型中赋予塑料以形状和尺寸的部件。模具的结构虽然由于塑料品种和性能、塑料制品的形状和结构以及注射机的类型等不同而可能千变万化,但是基本结构是一致的。模具主要由浇注系统、成型零件和结构零件三部分组成。其中浇注系统和成型零件是与塑料直接接触部分,并随塑料和制品而变化,是塑模中最复杂,变化最大,要求加工光洁度和精度最高的部分。

对此次放大镜无多大要求,它的整体尺寸不大,但要大批生产,为提高生产率,降低成本,故采用模具成批注射生产。并且该产品为放大镜要透光,所以材料采用聚苯乙烯(PS)做为材料。

对于浇注系统和成型零件的设计;浇注系统是指塑料从射嘴进入型腔前的流道部分,包括主流道、冷料穴、分流道和浇口等。成型零件是指构成制品形状的各种零件,包括动模、定模和型腔、型芯等。

此套放大镜模实现部分机械操作自动化,浇注系统采用普通流道,进行一模二腔注射。顶出机构由2条型芯和一条推杆顶出,型腔分动模型腔和定模型腔。

关键词 主流道 冷料穴 浇口 型腔 型芯

Abstract

Injection mold is given in the plastic molding to the shape and size of parts. Although the structure of mold species and performance of plastics, plastic products, as well as the shape and structure of the type of injection molding machine may be different from the ever-changing, but the basic structure is the same. Mainly by die casting systems, and structural components forming parts of three parts. Gating system and forming one part in direct contact with the plastic parts and products as plastics and change is the most complex modeling, the biggest change to require smoothness and accuracy of processing some of the highest.

The little magnifying glass on the requirements of the overall size of it, but to a large number of production, to increase productivity, reduce costs, and therefore the use of injection mold production batch. And the product is a magnifying glass to light, so the material used polystyrene (PS) as a material.

For the gating system and forming part of the design; gating system is the plastic nozzle into the cavity from the previous part of the flow channel, including the mainstream Road, cold cave, such as diversion channel and gate. Forming part refers to the shape of a variety of products constitute components, including dynamic simulation, and the cavity mode is scheduled, such as core.

This mode sets the realization of part of the magnifying glass machinery automation, pouring the ordinary flow system to carry out a two-cavity injection mold. Top two from the body core and a top of a putter, dynamic model of sub-cavity cavity cavity model and the set.

?

Keywords mainstream cold feed gate cavity core hole

目录

中文摘要1

Abstract2

第一章 塑件工艺分析5

1.1中国模具的发展史5

1.2 分析塑件使用材料的种类及工艺特征6

1.3 分析塑件的的结构工艺性7

1.4 塑件精度确定7

1.5 明确塑件批量生产7

1.6 根据塑件的形状估算其体积和重量8

1.7 确定型腔数8

第二章 确定模具结构方案9

2.1 确定型腔排列9

2.2确定分型面9

2.3 脱模原理10

2.4 浇注系统形式10

2.4.1 主流道设计10

2.4.2 分流道设计11

2.4.3、浇口设计11

2.5冷却及加热系统11

第三章 模具设计的有关计算13

3.1模具主要零件的有关尺寸设计13

3.1.1型腔和型芯计算13

3.2 型腔厚厚度的确定14

3.3确定零件结构及尺寸14

3.3.1定模座板设计15

3.3.2定模型腔固定板设计16

3.3.3 动模型腔固定板设计17

3.3.4 支撑板设计设计17

3.3.5 推杆固定板设计18

第四章 注塑机的选定19

4.1计算浇注系统体积19

4.2注塑机选定19

第五章 校核注射机有关工艺参数22

5.1最大注塑量参数校核22

5.2锁模力校核22

5.3、模具厚度H与注射机闭合高度23

结论24

参考文献25

致谢26

川公网安备: 51019002004831号

川公网安备: 51019002004831号