电动扳手设计

电动扳手的设计【优秀机械全套课程毕业设计含26张CAD图纸】

【带开题报告+外文翻译】【35页@正文14600字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

中英文摘要.doc

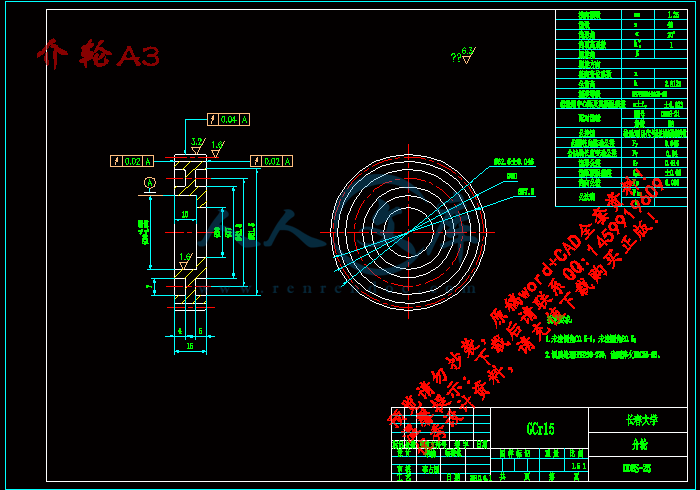

介轮A3.dwg

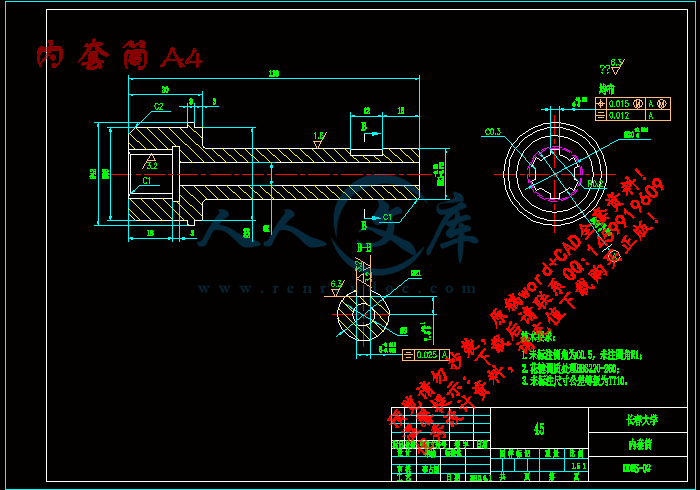

内套筒A4.dwg

内齿轮A2.dwg

刚轮A2.dwg

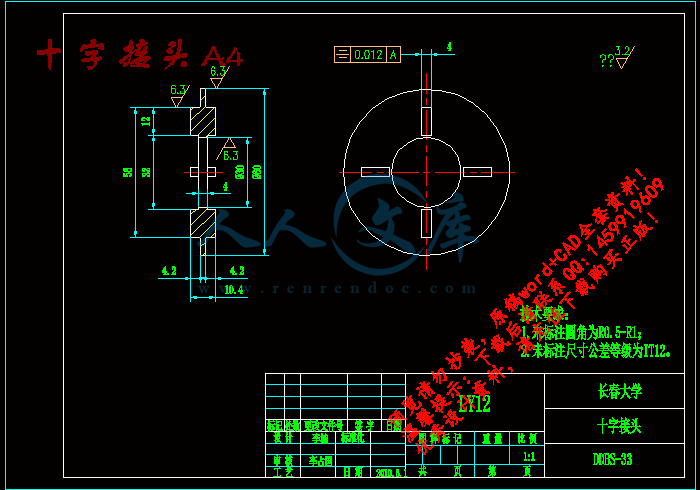

十字接头A4.dwg

发生器A3.dwg

后盖A2.dwg

外壳A2.dwg

外套筒A3.dwg

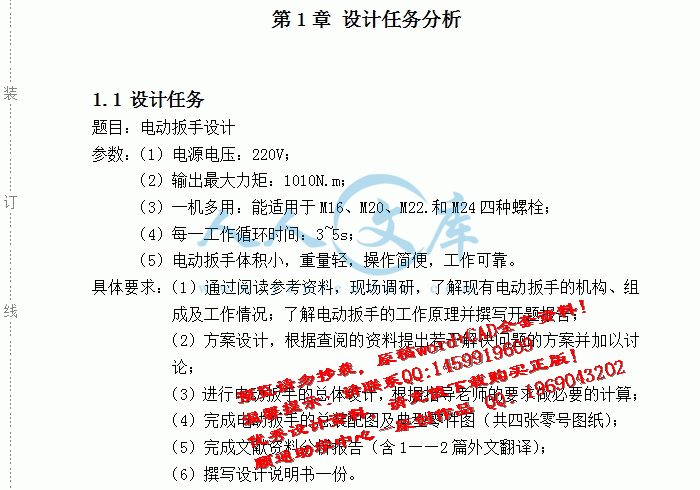

大齿轮3A3.dwg

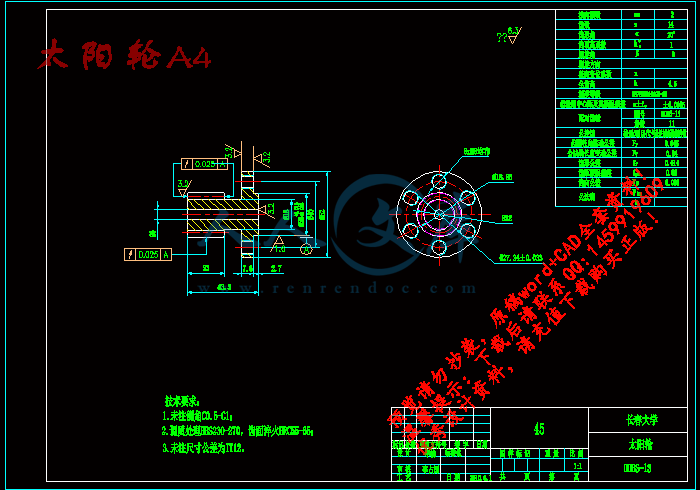

太阳轮A4.dwg

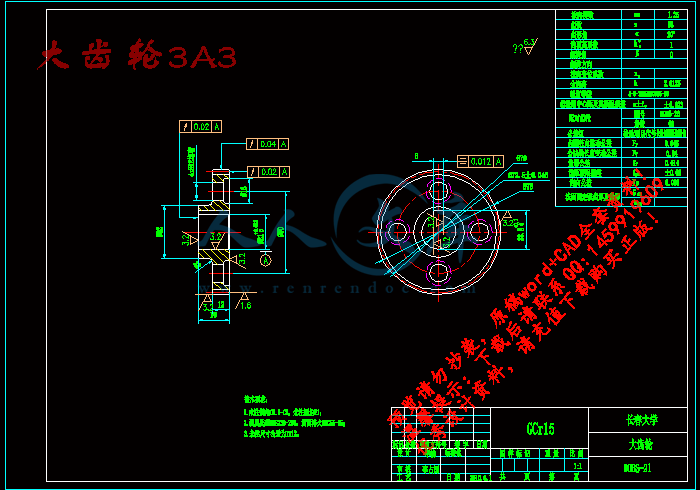

定位销A4.dwg

小齿轮A3.dwg

开题报告.doc

开题报告封面.doc

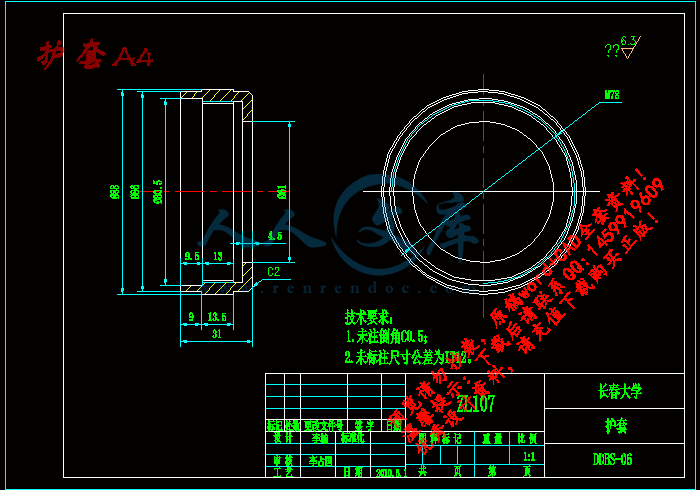

护套A4.dwg

柔轮A3.dwg

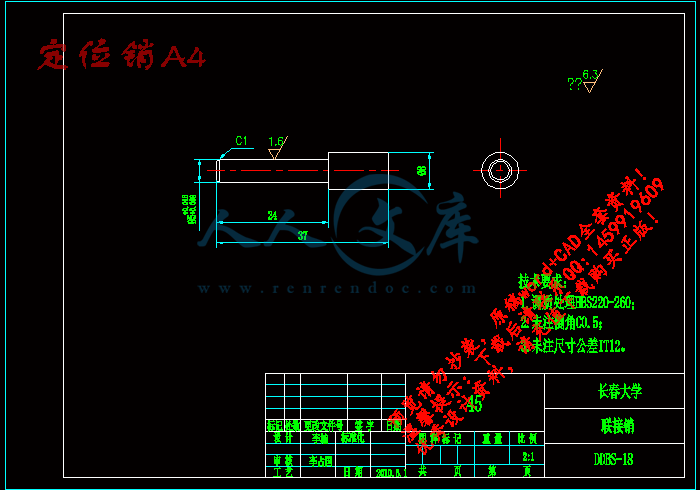

浮动轴承盖A4.dwg

电动扳手设计.doc

目录.doc

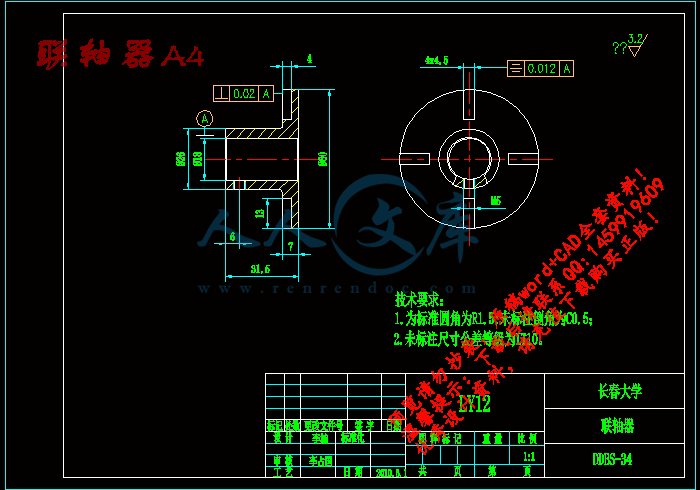

联轴器A4.dwg

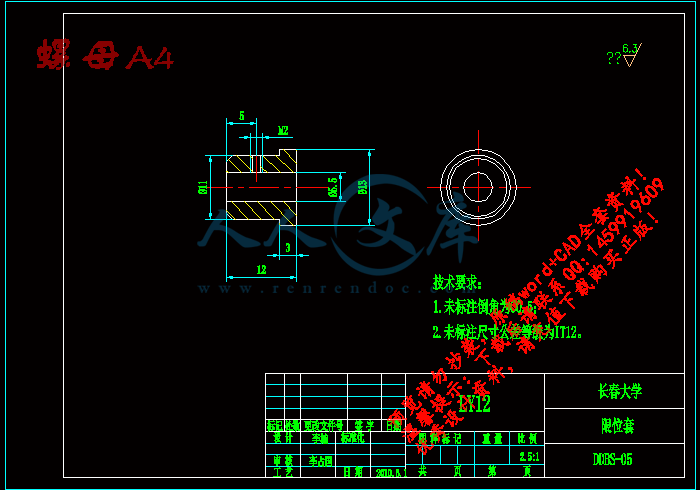

螺母A4.dwg

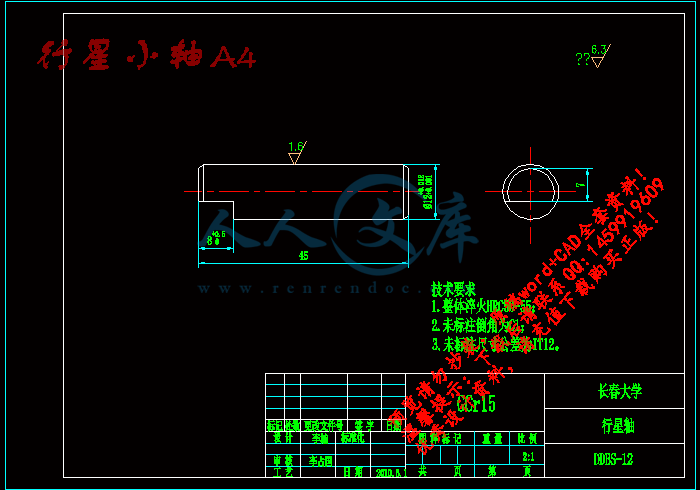

行星小轴A4.dwg

行星轮A4.dwg

行星轮支架A2.dwg

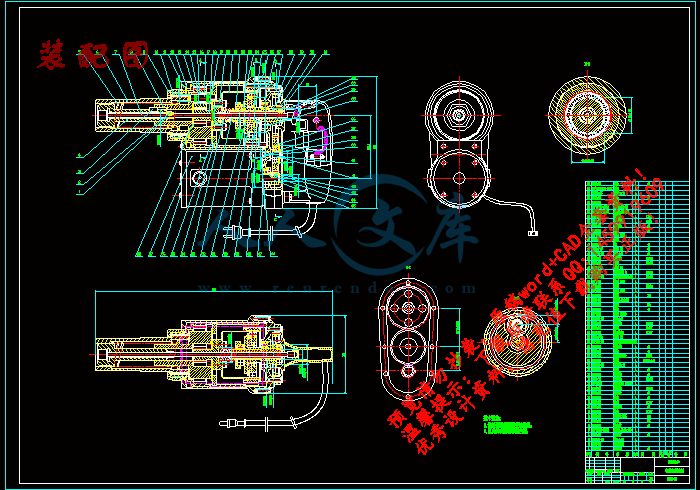

装配图带标注的.dwg

译文

译文封面.doc

说明书封面.doc

轴承支架A2.dwg

轴(齿轮1)A4.dwg

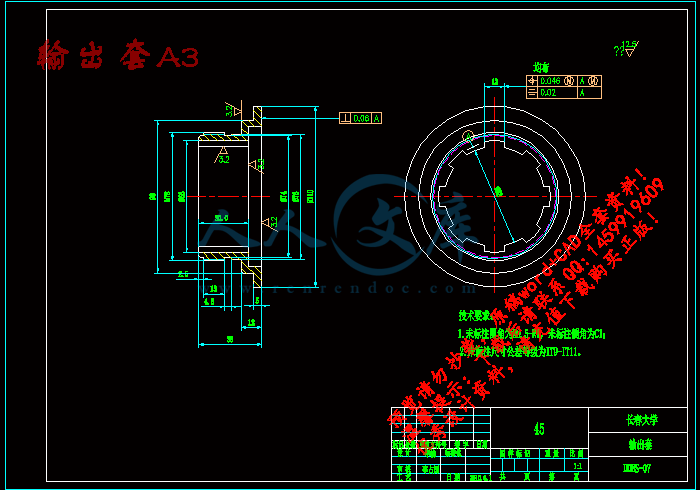

输出套A3.dwg

顶杆A4.dwg

电动扳手设计

[摘要] 在大型钢结构建筑中,广泛使用高强度螺栓链接。这种螺栓连接,在施工中要求用规定的拧紧力矩锁紧螺母,以保证链接的可靠性。

由于高强度螺栓的材料和热处理是严格控制和检查的,因此螺栓定力矩切口处的扭剪断裂力矩能够控制在一个比较准确的范围,从而能保证螺栓连接的可靠性。当拧紧力矩过大时,不能保证螺栓的强度;当拧紧力矩过小时,又不能保证连接的可靠性。因此这种螺栓连接,在施工中要求用规定的拧紧力矩锁紧螺母,以保证链接的可靠性。另外,高强度螺栓往往成批使用,并且工作的环境也比较坚苦,如果是用普通扳手进行定力矩拧紧,工人拧紧螺母的过程中会有很多不便,工作效率也会很低。综合以上三点原因,在拧紧高强度螺栓时,我们采用电动扳手代替手从扳手进行拧紧。

电动扳手以220V交流电源为动力进行工作,可以保证每个螺栓的拧紧力都在规定的范围内,同时,采用电动扳手代替手动扳手可以大大提高螺栓拧紧的速度,提高工人的工作效率,改善工人的劳动强度

[关键词] 电动扳手 谐波传动 柔轮

Electric Wrench Design

[Abstract] In large steel structures, widely used in high strength bolts links. This bolt connection, in accordance with requirements of the construction of torque lock nut and to guarantee the reliability of the link.

Due to the high strength bolts of material and heat treatment is strict inspection and control, thus shall the bolt torque incision torshear fracture in a moment can control the accuracy and can guarantee, the reliability of the bolt connection. When large torque, cannot guarantee the strength bolt, When the torque, and after hours cannot guarantee the reliability of the connection. Therefore the bolt connection, in accordance with requirements of the construction of torque lock nut and to guarantee the reliability of the link. Additionally, high strength bolts, and often used to working environment is hard, and if it's used for torque wrench on ordinary workers, tighten lock nut process will have a lot of inconvenience, the working efficiency is also very low. Three reasons, in comprehensive above tighten high strength bolts, we adopt electromotive spanner from wrench to replace hand tighten.

Electromotive spanner to ac power for power on 220V work, can guarantee each bolt tightened force within a prescribed scope, at the same time, using electric wrench instead of manual wrench screw bolts can greatly improve the speed, improve work efficiency, improve the worker labor intensity

[Key words] Electric wrench Harmonic Drive Flexspline

目 录

前 言 ……………………………………………………………………………1

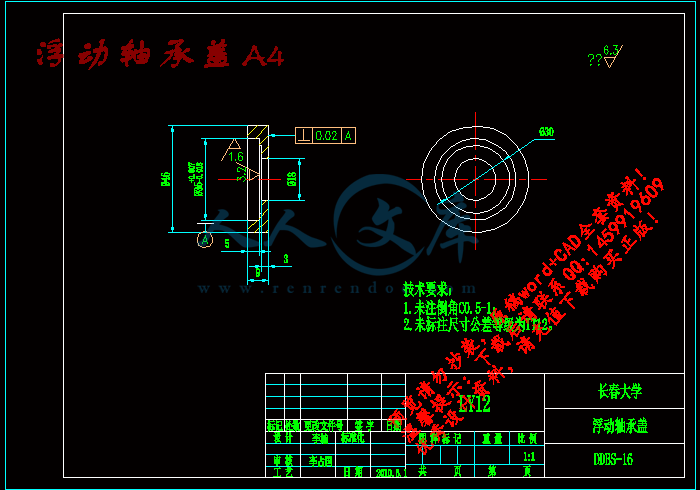

第 1 章 设计任务分析 ……………………………………………………………2

1.1 设计任务 …………………………………………………………………2

1.2 设计意义 …………………………………………………………………2

第 2 章 方案设计 …………………………………………………………………3

2.1 基本结构的分析与选择 …………………………………………………3

2.2 总体方案的拟定 …………………………………………………………5

第 3 章 电动扳手的动力与运动分析计算 ………………………………………8

3.1 整机传动比的确定 ………………………………………………………8

3.2 各传动比的确定 …………………………………………………………8

3.3 谐波齿轮传动和行星轮系运动分析 ……………………………………9

第 4 章 传动部件的设计与校核…………………………………………………11

4.1 定轴轮系的设计…………………………………………………………11

4.1.1 .按齿面接触疲劳强度设计 ……………………………………11

4.1.2 按齿根弯曲疲劳强度设计………………………………………12

4.1.3 设计计算…………………………………………………………13

4.2 谐波齿轮传动的设计……………………………………………………14

4.2.1 谐波齿轮传动参数的确定………………………………………14

4.2.2 柔轮结构形式的选择……………………………………………15

4.2.3 谐波齿轮轮齿的耐磨计算………………………………………15

4.3 柔轮强度计算……………………………………………………………16

4.4 行星齿轮传动的设计……………………………………………………17

4.4.1 齿轮啮合参数的确定……………………………………………17

4.4.2 齿轮强度计算特点 ……………………………………………17

第 5 章 标准件的选择与校核……………………………………………………21

5.1 轴承的选择与校核………………………………………………………21

5.1.1 轴承的选择………………………………………………………21

5.1.2 轴承的校核………………………………………………………22

5.1.3 轴承的润滑方式…………………………………………………22

5.2 键的选择与校核…………………………………………………………22

5.2.1 键的选择…………………………………………………………22

5.2.2 键的校核…………………………………………………………22

5.3 圆柱螺旋压缩弹簧的设计………………………………………………23

第 6 章 电动扳手中重要零件的材料……………………………………………27

结 论 ………………………………………………………………………………29

致 谢 ………………………………………………………………………………30

参 考 文 献 ………………………………………………………………………31

前 言

螺栓连接是一种普遍可靠的连接方式。其中高强度螺栓链接广泛使用在大型钢结构建筑中。

由于高强度螺栓的材料和热处理是严格控制和检查的,因此螺栓定力矩切口处的扭剪断裂力矩能够控制在一个比较准确的范围,从而能保证螺栓连接的可靠性。当拧紧力矩过大时,不能保证螺栓的强度;当拧紧力矩过小时,又不能保证连接的可靠性。因此这种螺栓连接,在施工中要求用规定的拧紧力矩锁紧螺母,以保证链接的可靠性。另外,高强度螺栓往往成批使用,并且工作的环境也比较坚苦,如果是用普通扳手进行定力矩拧紧,工人拧紧螺母的过程中会有很多不便,工作效率也会很低。综合以上三点原因,在拧紧高强度螺栓时,我们采用电动扳手代替手从扳手进行拧紧。

电动扳手以220V交流电源为动力进行工作,可以保证每个螺栓的拧紧力都在规定的范围内,同时,采用电动扳手代替手动扳手可以大大提高螺栓拧紧的速度,提高工人的工作效率,改善工人的劳动强度。

在长期的使用中,电动扳手充分发挥了它的设计有点——体积小、重量轻、操作方便快捷、安全可靠,从而使电动扳手成为施工现场不可缺少、不可替代的专用工具。从总体上看,电动扳手基本上可在设计寿命范围正常工作,无需大修,施工现场也未发生任何由于漏电等原因引起的安全事故,从而得到使用单位的好评。

个别的电动扳手,在使用中曾发生柔轮筒体底部断裂失效的现象,这一事实验证了柔轮光弹性试验得到的结论——柔轮工作时的切应力及壳壁内的正应力的最大值均发生在柔轮的根部(并有应力集中的影响),根部是最危险的截面。因此,改善柔轮根部的结构和加工品质是提高强度和使用寿命的关键措施。

多年的生产实践表明,自行研制的电动扳手成功替代了进口产品,为国家节省了大量外汇,也为生产研制单位带来了可观的经济效益。

由于时间仓促和作者的知识水平有限,论文中的错误和不足在所难免,请各位老师给予批评指正。

参考文献

[1] 钱中主编.列车牵引计算.第一版. 北京:中国铁道出版社.1996

[2] 张文质等主编.起重机设计手册. 北京:第一版.中国铁道出版社.1998

[3] 马鞍山钢铁设计院等编.中小型轧钢机设计计算. 北京:冶金出版社,1979

[4] 陈立周.飞剪机剪切机构的合理设计. 北京:钢铁学院学报 1980年1月

[5] Simon,J.M.Computerized Synthesis of Straight Line Four-Bar Linkages from Inflection Circle Properties . Transactions of the ASME.Journal of Engineering for Industry. August 1977:610-614

[6] R.Strawertron.Flying Shears for Bars and Beams.Journal of the Iron and steel Institute.1958

[7] 李克涵.应用鲍尔点(Ball Point)理论设计连杆直移机构.机械设计.1982

[8] 李克涵.新型150kN曲柄连杆式钢坯飞剪机的研制.冶金设备.1991

[9] 李克涵.工业机械手运动参数的分析与综合.机械设计.1993

[10] 沈允文,叶庆泰.谐波齿轮传动的理论和设计. 北京:机械工业出版社.1985

[11] 许洪基主编.现代机械传动手册. 北京:机械工业出版社.1995

[12] 沃尔阔夫等主编.谐波齿轮传动.项其权等译. 北京:电子工业出版社.1985

[13] 雷廷权等主编.30CrMnSiA钢调质-旋压-时效工艺研究.黑龙江机械.1981,No.3

[14] M.Frocht.光测弹性力学.陈森译. 北京:科学出版社,1994

[15] 罗祖道,吴连元.弹性圆柱薄壳的一般稳定性.力学学报.1962,Vol.5,No.1

[16] 徐灏.机械设计手册.机械工业出版社.1995年12月

[17] 王启义主编.中国机械设计大典.南昌:江西科学技术出版社.2002年1月

[18] 卜炎主编. 中国机械设计大典.南昌:江西科学技术出版社.2002年1月

[19] 朱孝录主编. 中国机械设计大典.南昌:江西科学技术出版社.2002年1月

[20] 王太辰主编. 中国机械设计大典.南昌:江西科学技术出版社.2002年1月

[21] 张展主编.非标准设备设计手册.兵器工作出版社.1993年9月

[22] 龚桂义主编.机械设计课程设计图册.第三版.高等教育出版社.1989年5月

川公网安备: 51019002004831号

川公网安备: 51019002004831号