!【包含文件如下】【机械结构类】CAD图纸+word设计说明书.doc[15000字,53页]【需要咨询购买全套设计请加QQ97666224】.bat

可通盖A4图板.dwg

摘要.doc

目录.doc

设计说明书.doc[15000字,53页]

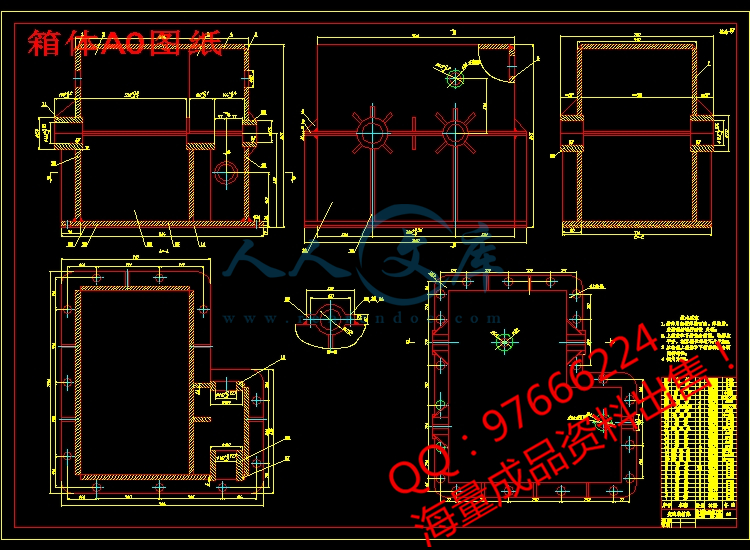

箱体A0图纸.dwg

花键轴A2图纸.dwg

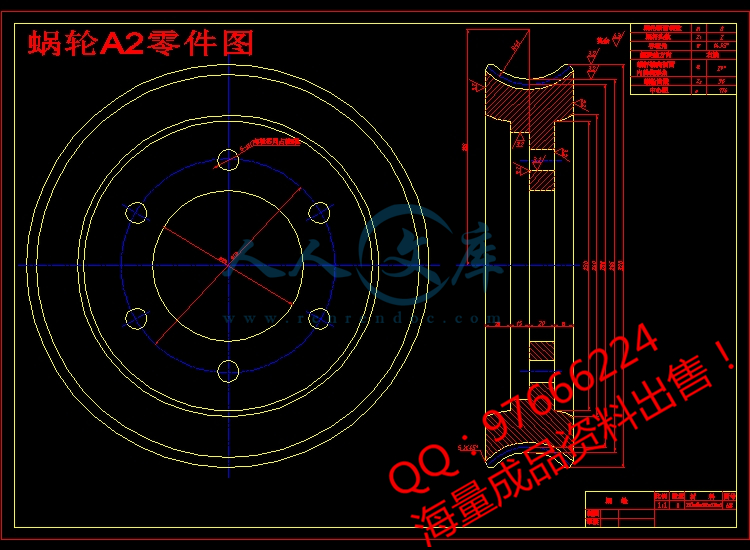

蜗轮A2零件图.dwg

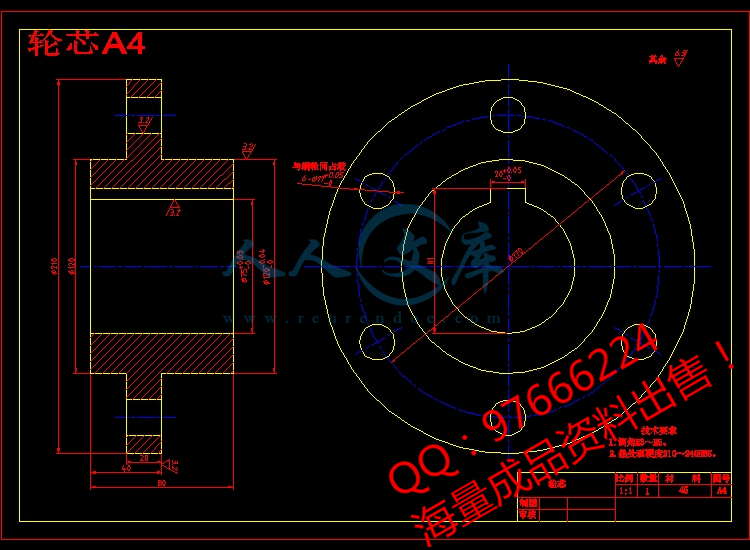

轮芯A4.dwg

齿轮A3.dwg

齿轮箱装配图AO.dwg

摘要

本文主要阐述了简易地坑式龙门刨床变速箱设计过程。

变速箱一般是由齿轮、轴、轴承及箱体等组成,用于原动机和工作机或执行结构之间,起匹配转速和传递转矩的作用,在现在机械中应用极为广泛。

变速箱的结构形式各种各样,但其设计方法和过程具有通用性和普遍性。该变速箱来源于生产实际,传动功率较大,属于专用部件。本文在采用传统设计方法的同时,也考虑了一些最新的设计方法。本文主要由以下部分组成:

变速箱的设计,包括齿轮、轴、键、花键、轴承及箱体的设计、计算与校核。

相比传统设计,本设计主要有以下特点:

1.以最高转速和最大输出扭矩为要求,平行计算,并将计算结果加以比较,以安全可靠为原则选择参数;

2.采用单输入结构,两种转速输出,并由拔叉机构控制其输出;

3.箱体采用焊接结构。

关键词:变速箱 单输入 两种转速输出 焊接结构

Abstract

This thesis mainly elaborated the design of transmission gear box in simply and dyadic planer machine process.

Transmission gear box generally constitutes of wheel gear, stalk, bearings and box body , the box body used for prime mover and work machine, transmission gear box have already and used for among the speed and deliver the turn jug, its application is extremely extensive in the machine in nowadays.

The structure form of the transmission gear box is various each kind, but its design method and process have used generally and catholicity. The transmission gear box comes from produce physically and move power bigly, belongs to an appropriation parts. This thesis also considered some latest design methods at the time of adopting a tradition design a method. This thesis mainly constitutes of the following parts:

The design of transmission gear box, calculation and school which include wheel gear, stalk, key, the flower key, bearings and box body check.

Compare a tradition design; this design mainly includes a following characteristic:

1. With highest speed with the biggest exportation turn Jud for request, parallelism calculation, and take into calculation as a result compare, with safety, credibility as principle to choice parameter;

2 .Used one input structure, 2 kinds of speed as output, and from pull out fork organization to control its exportation.

3. The body of transmission gear box used weld structure;

Key words: transmission gear box one input 2 kinds of speed output weld structure

目录

目录4

引言5

1 .龙门刨床运动形式及改造要求7

1.1龙门刨床结构7

1.2工作过程7

1.3主运动行程分析以及各阶段工作状况8

1.4刨台运动的机械特性曲线8

1.5龙门刨床变速箱设计目的及意义8

2. 变速箱传动系统的方案设计10

3. 变速箱传动系统的总体设计12

3.1 电动机的选择12

3.2 传动比的分配14

3.3 传动系统的运动和动力参数计算15

4. 变速箱传动零件的设计18

4.1蜗轮蜗杆传动设计计算18

4.2离合器右边齿轮传动设计计算22

4.3 离合器左边齿轮传动设计计算25

5. 变速箱轴及轴校核的设计28

5.1 2轴的传动设计计算28

5.2 2轴的校核计算30

5.3 3轴的传动设计计算33

5.4 3轴的校核计算35

6. 变速箱键连接设计38

6.1 2轴上的键连接设计38

6.2 3轴上键连接设计39

7. 变速箱中滚动轴承的选择与强度校核40

7.1 轴承的选择40

7.2 轴承的强度校核40

8. 变速箱箱体结构及附件的设计43

8.1 变速箱箱体的设计43

8.2 变速箱附件的设计44

8.3变速箱润滑方式的确定45

8.4变速箱联轴器的选择45

8.5密封方法和端盖的选取46

9. 附录46

附录1 刨台运动的机械特性曲线46

附录2 A-G-M调速系统图47

附录3工作台电气工作图48

10.结 论49

11.致 谢50

12.参考文献:51

川公网安备: 51019002004831号

川公网安备: 51019002004831号