!【包含文件如下】【机电PLC单片机类】CAD图纸+word设计说明书.doc[15000字,74页]【需要咨询购买全套设计请加QQ97666224】.bat

1.txt

中英文对照版.doc

任务书.doc

出租车计价器系统设计正文.doc

外文翻译

摘要和目录.doc

调研报告.doc

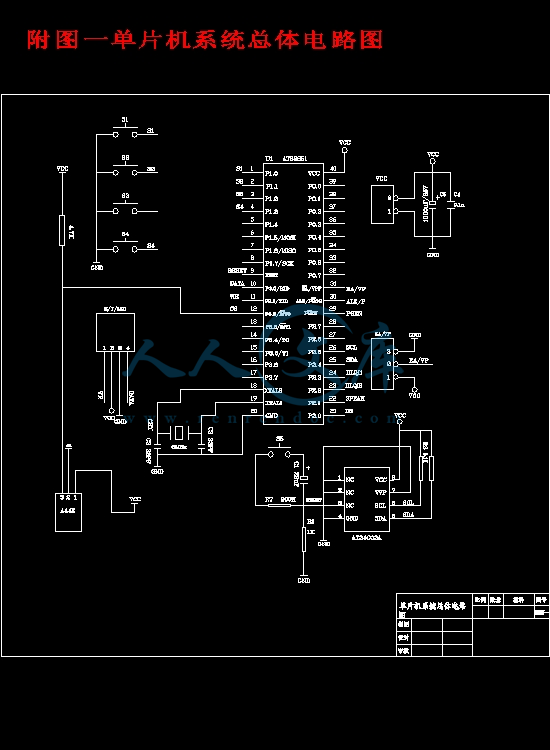

附图一单片机系统总体电路图.dwg

附图二显示电路的电路原理图.dwg

基于89S51单片机的出租车计价器系统设计

摘要:现在各大中城市出租车行业都已普及自动计价器,所以计价器技术的发展已成定局。而部分小城市尚未普及,但随着城市建设日益加快,象征着城市面貌的出租车行业也将加速发展,计价器的普及也是毫无疑问的,所以未来汽车计价器的市场还是十分有潜力的。

本电路以89S51 单片机为中心、附加A44E 霍尔传感器测距,实现对出租车计价统计,采用AT24C02 实现在系统掉电的时候保存单价和系统时间等信息,输出采用8 段数码显示管。本电路设计的计价器不但能实现基本的计价,而且还能根据白天、黑夜、中途等待来调节单价,同时在不计价的时候还能作为时钟为司机同志提供方便。

关键词:89S51单片机 A44E霍尔传感器 断电保存 8段数码显示管

Abstract: It is now the major cities in the taxi industry have universal automatic meter, meter technology development is a foregone conclusion. And some small cities not yet universal, but with increasing speed up urban construction, a symbol of urban landscape taxi industry will also accelerate development, and the popularity meter is no doubt, therefore, the future of the automobile market valuation is still potential .

The circuit of 89 S51 MCU as the center, additional A44E Hall sensor location and realize the Taximeter statistics, a brownout AT24C02 achieve in the system and when the system priced preservation time information, output by paragraph 8 of the digital display. The circuit design of the meter can not only realize the basic valuation, but also in accordance with the day, night, halfway to wait for price regulation, while also not denominated as a time clock to provide convenience for the drivers comrades.

Keywords: 89 S51 MCU A44E Hall sensor power preservation of digital display paragraph 8

目 录

第一章 引言………………………………………………………………………………………1

第二章 出租车计价器的设计内容………………………………………………………………2

2.1基本设计要求 …………………………………………………………………………………2

2.2拓展功能 ………………………………………………………………………………………2

第三章 方案论证…………………………………………………………………………………3

3.1方案比较 ………………………………………………………………………………………3

3.2确定方案 ………………………………………………………………………………………4

第四章 计价器系统设计…………………………………………………………………………5

4.1计价器工作原理 ………………………………………………………………………………5

4.2 单片机系统总体设计 …………………………………………………………………………6

第五章 硬件设计……………………………………………………………………………………7

5.1单片机总体电路图设计…………………………………………………………………………7

5.2 AT89S51单片机介绍……………………………………………………………………………8

5.3电源控制线路设计 ……………………………………………………………………………8

5.4里程计算、计价单元的设计 …………………………………………………………………12

5.5数据显示单元的设计…………………………………………………………………………15

5.6 AT24C02 掉电存储单元的设计………………………………………………………………18

5.7启动及清除电路………………………………………………………………………………19

5.8按键单元的设计………………………………………………………………………………19

第六章 软件设计 …………………………………………………………………………………20

6.1软件设计 ………………………………………………………………………………………20

6.2流程图…………………………………………………………………………………………25

第七章 程序设计…… …………………………………………………………………………28

7.1主程序清单……………………………………………………………………………………28

7.2计价器子程序清单……………………………………………………………………………38

第八章 测试分析 ………………………………………………………………………………67

8.1里程计价测试…………………………………………………………………………………67

8.2掉电存储测试测试……………………………………………………………………………68

第九章 设计总结及展望………………………………………………………………………62

9.1设计总结………………………………………………………………………………………69

9.2展望新型多功能出租车计价器………………………………………………………………70

9.3 新型产品的未来 ……………………………………………………………………………71

致谢 ………………………………………………………………………………………………72

参考文献 …………………………………………………………………………………………73

附件(系统设计总电路图)………………………………………………………………………74

川公网安备: 51019002004831号

川公网安备: 51019002004831号