超声深孔枪钻机床的设计【以CA6140普通车床为基础】【优秀机床全套课程毕业设计含8张CAD图纸+带开题报告+实习报告+外文翻译+46页@正文20500字】

【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

中心架A1图纸.dwg

中期报告.doc

变幅杆A4.dwg

外文文献翻译

实 习 报 告.doc

开题报告.doc

扶正器A2.dwg

换能器A3.dwg

机床装配A0.dwg

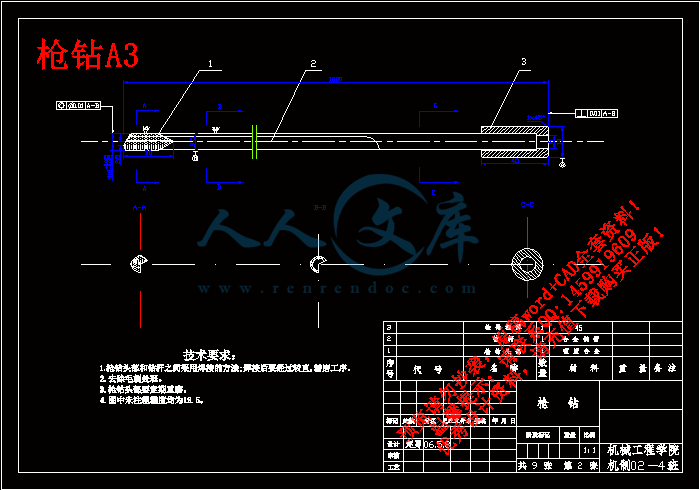

枪钻A3.dwg

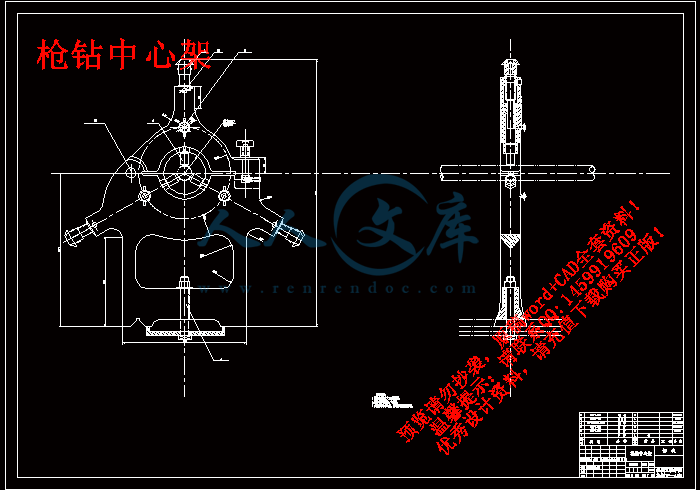

枪钻中心架.dwg

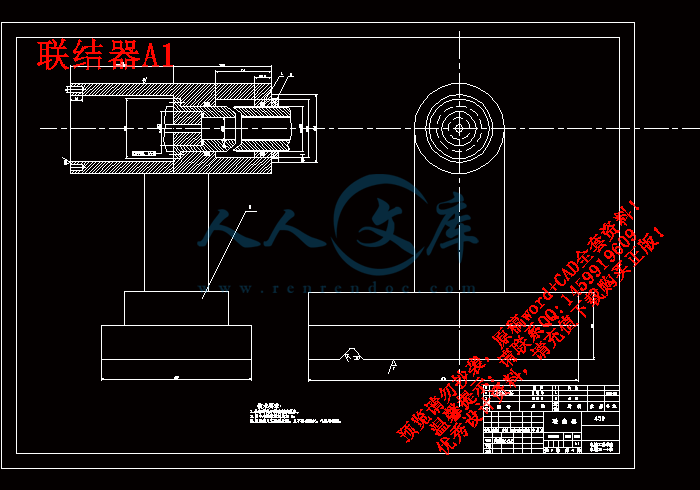

联结器A1.dwg

说明书.doc

摘 要

本次毕业设计我们小组的题目是超声深孔枪钻机床,我们以CA6140普通车床为基础,对其传动系统、进给系统、床身等进行全面系统地分析,采取合理的技术措施,对车床进行改造,同时,又加上超声装置,改变其钻削条件,从而获得较高的加工精度和表面质量。本设计立足于“改”,使机床改装后既满足加工要求,又结构简单、方案合理。

此次设计该机床是为了钻削细长孔,工件材料为45钢,孔的直径=10mm,长度=500mm,钻孔精度为IT8,改造对象为CA6140普通车床。此次设计,我的具体任务是设计枪钻系统,超声系统和机床导轨。设计总共分为四章。

第一章首先进行工艺分析,制定总体设计方案,结合CA6140普通车床自身特点和深孔枪钻机床的设计要求和工作情况,并巧妙地加工超声装置。

第二章根据加工要求设计深孔枪钻系统,包括枪钻、中心架、扶正器、联结器等。

第三章为超声系统设计,包括超声波发生器、换能器、变幅杆,以及各部件之间地连接,其中,变幅杆的设计是一个重点。

第四章根据机床的总体要求和特点设计导轨。

关键词:车床,枪钻,超声,表面质量

Abstrct

The gun drilling lathe is introduced in this Graduate design .The design is regarding the ordinary CA6140 lathe as fundation . Towards the machine, after we have analaysised its vedrivetrain system ,the body of the machine tools and so on , comprehensively.we transform it by plenty of technology measures rationaly. Morever,

some Ultrasonic devices are used in order to improve the conditions of drilling.In this way , better surface quality and processing precision would be obtainded. Reforming is the basis of this design ,The reformed machine tools not only meet the requirements of process , but also has a simply structure and a reasonable process plan .

To drilling the long and small holes,we design the machine tools.The material of the workpiece is 45,the diameter of the hole is 10mm and the longth is 500mm,the processing precision is IT8. In this design,my task is designing the system of gun drilling ultrasonic and Caterpillar Track ,The design consists of four chapters in a total.

Chapter 1 has two parts . The first , processing the craft analysis to refit CA6140 lathe as the double boring machine , principal axis of lathe is used as the indirect power ,and arousing two boring principal aixs are used as the boring active-line, and the struction of the feed completes the mation of boring . Second , CA6140 lathe is proceeded analysis and refitted the total layout .

Chapter 2 . According to the requirement of the process , design the gung drilling system.

Chapter 3 . the design for Ultrasonic devices are the primary importance of the design . Because they relate to the quality of workpiece .Morever,how to get the right linking among the developments must be thunk over. This part includes the generator,transducer and straight conical hone.

Chapter 4 In this part, Caterpillar Track is designed according to the overall requirements of the gun drilling lathe.

Key Words: CA6140 lathe , gun drilling , ultrasonic , surface quality

目 录

前 言………………………………………………………………………………..6

1、制定设计机床方案…………………………………………………………………8

1.1任务…………………………………………………………………………...8

1.2车床的分析和改装总体布局………………………………………….……..8

1.2.1分析机床的技术状态…………………………………………………..8

1.2.2改装的总体布局……………………………………………………….10

2、枪钻的设计…………………………………………………………………….......11

2.1深孔加工的特点和发展状况………………………………………………...11

2.2枪钻结构及其尺寸的设计…………………………………………………...12

2.2.1枪钻头部的设计………………………………………………………..13

2.2.2枪钻钻杆的设计………………………………………………………..15

2.2.3枪钻柄部的设计………………………………………………………..16

2.2.4枪钻几何参数的设计…………………………………………………..16

2.3工件中心架的设计…………………………………………………………...18

2.4扶正器的设计…………………………………………………………………19

2. 5联结器的设计………………………………………………………………..20

2.6枪钻中心架的设计……………………………………………………………21

2.7枪钻辅助部分设计……………………………………………………………21

2.8枪钻使用的具体要求…………………………………………………………22

3、超声系统的设计…………………………………………………………………….25

3.1超声振动的装置和原理………………………………………………………..25

3.2超声深孔钻削的优点…………………………………………………………..26

3.3超声波发生器和换能器的设计…………………………………………….. .28

3.4超声变幅杆的设计……………………………………………………………30

3.4.1变幅杆的设计原理……………………………………………………...30

3.4.2变幅杆的设计…………………………………………………………….32

3.5变幅杆与其它零件的连接………………………………………………….39

4、导轨的设计……………………………………………………………………...40

4.1导轨的作用及要求………………………………………………………..…..40

4.2滑动导轨的磨损形式…………………………………………………………41

4.3导轨材料的设计………………………………………………………………41

4.4导轨截面形状的设计…………………………………………………………42

4.5导轨的结构尺寸设计…………………………………………………………43

4.6导轨的润滑和防护……………………………………………………………44

致 谢……………………………………………………………………................45

川公网安备: 51019002004831号

川公网安备: 51019002004831号