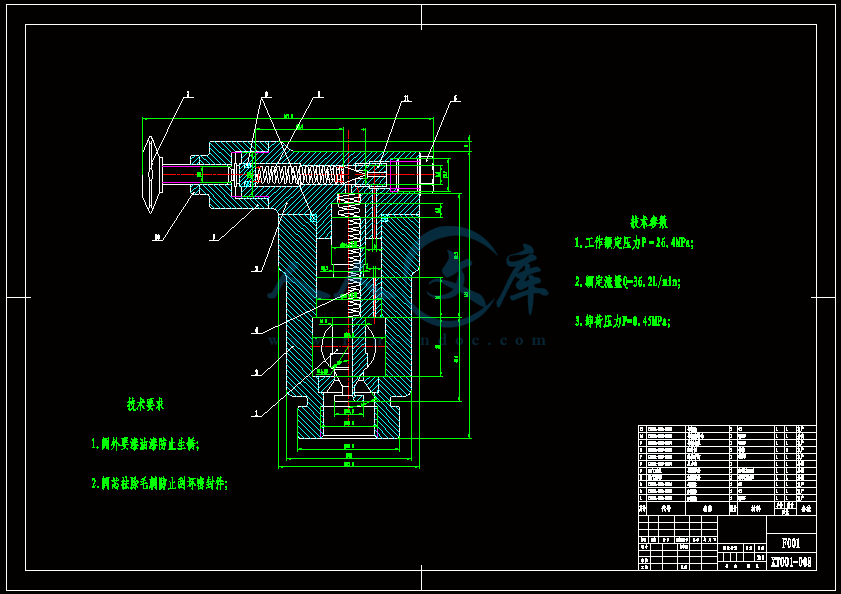

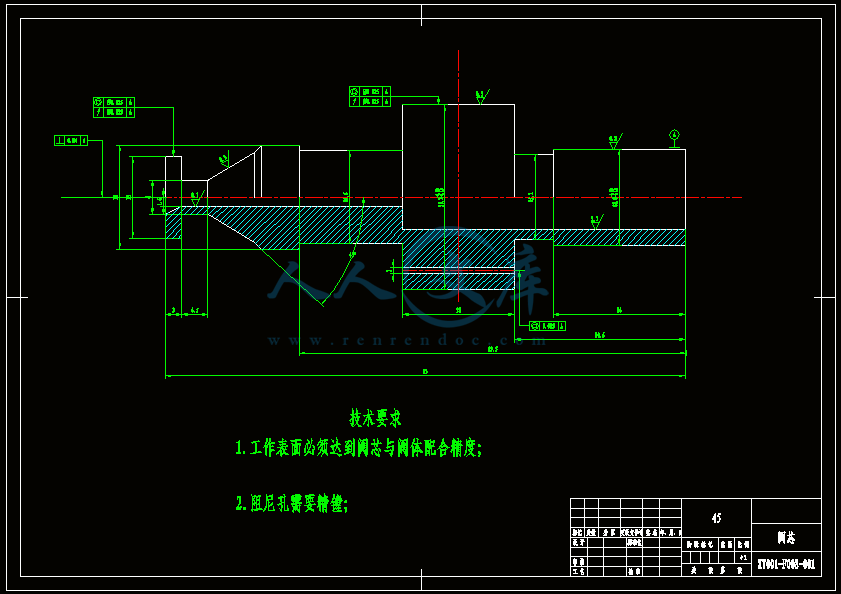

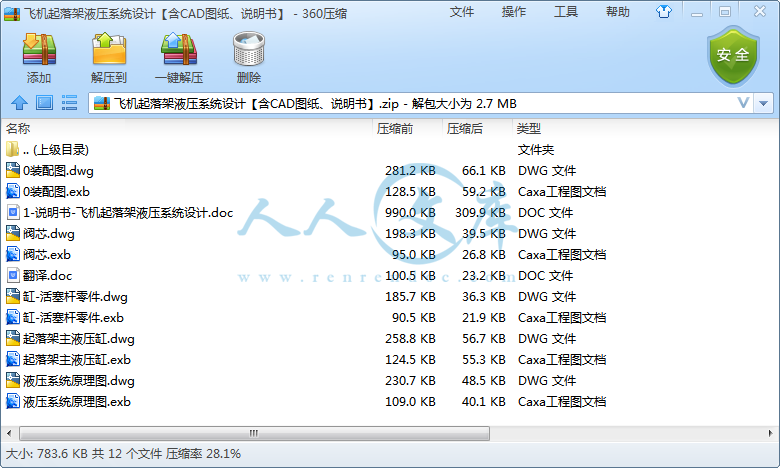

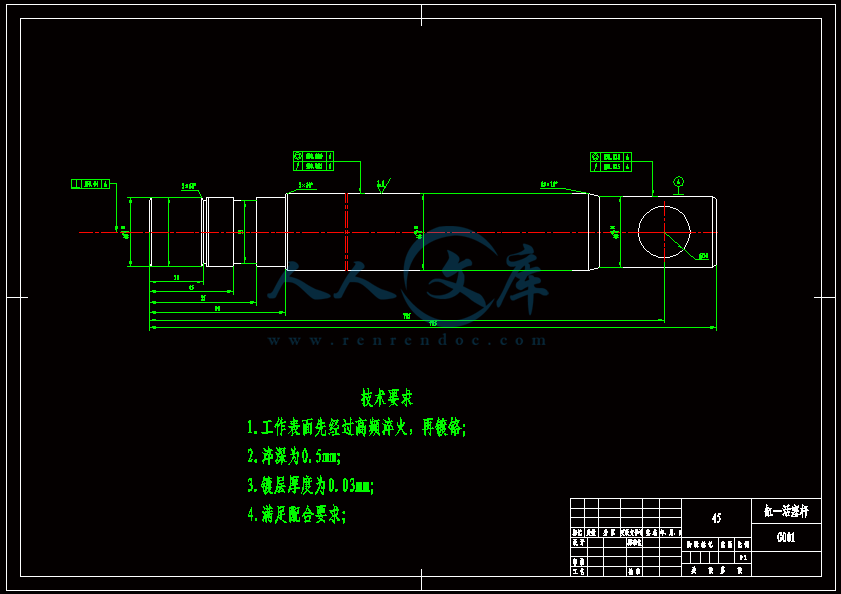

飞机起落架液压系统设计【含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:

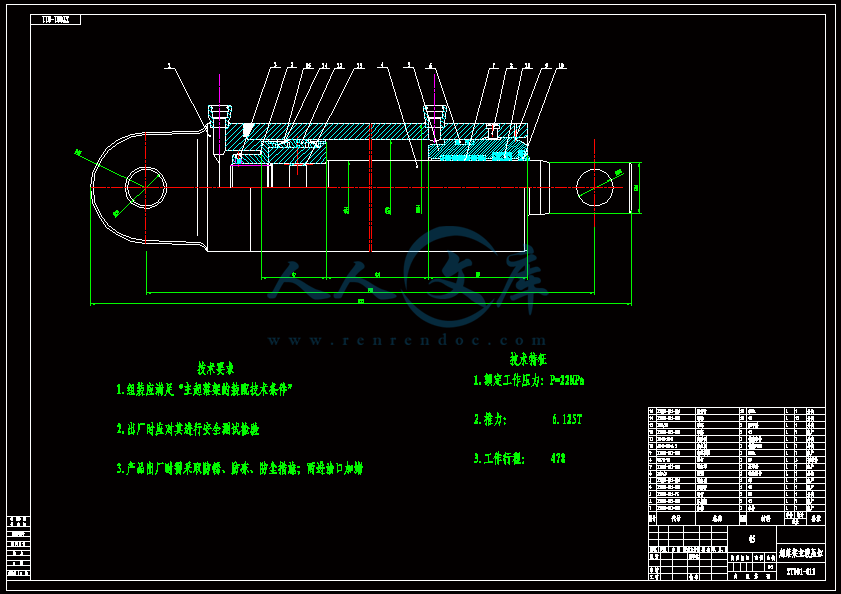

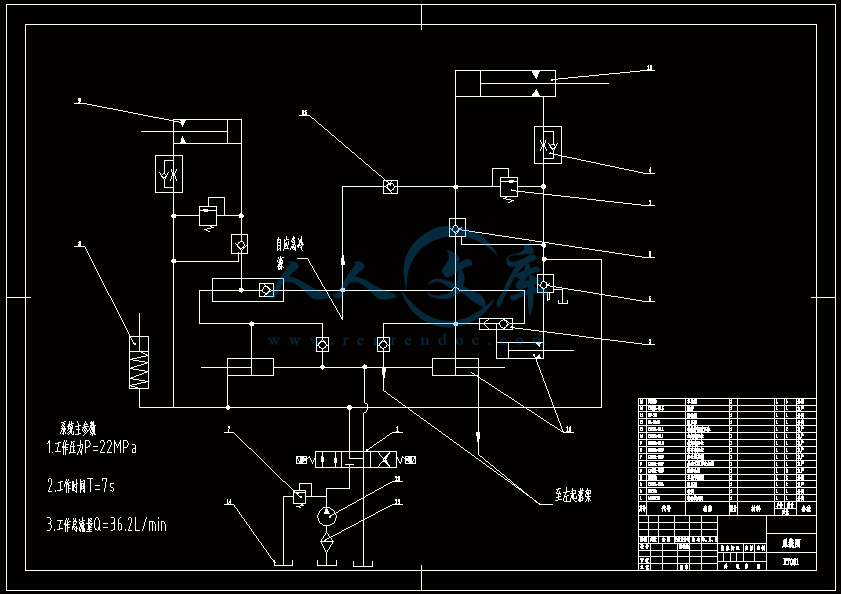

编号:59890847

类型:共享资源

大小:785.27KB

格式:ZIP

上传时间:2020-03-21

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

30

积分

- 关 键 词:

-

含CAD图纸、说明书

飞机

起落架

液压

系统

设计

CAD

图纸

说明书

- 资源描述:

-

- 内容简介:

-

1附录 A高分子材料的加工工艺性能1 高分子材料概述材料是科学与工业技术发展的基础。一种新材料的出现,能为社会文明带来巨大的变化,给新技术的发展带来划时代的突破。材料已当之无愧的成为当代科学技术的三大支柱之一。高分子材料科学已经和金属材料、无机非金属材料并驾齐驱,在国际上被列为一级学科。高分子材料科学是材料科学中的一个重要的分支学科。现代材料科学的范围定义为研究材料性质、结构和组成、合成和加工、材料的性能这四个要素以及它们之间的相互关系。高分子材料科学的基本任务是:研究高分子材料的合成、结构和组成与材料的性质、性能之间的相互关系;探索加工工艺和各种环境因素对材料性能的影响;为改进工艺,提高高分子材料的质量,合理使用高分子材料,开发新材料、新工艺和新的应用领域提供理论依据和基础数据。高分子材料科学是一门年轻而新兴的学科,它的发展要求科学和工程技术最为密切的配合,它的进步需要跨部门、多学科的最佳协调和共同参与。目前各种合成高分子的应用已遍及国民经济的各部门,特别是军事及尖端技术对具有各种不同性能的聚合物材料的迫切需要,促使了高分子合成和加工的技术有了更快的发展,高分子成型和加工已经成为一种独立的专门工程技术了。由于加工技术理论的研究、加工设备设计和加工过程自动控制等方面都取得了很大的进展,产品质量和生产效率大大提高,产品适应范围扩大,原材料和产品成本降低,聚合物加工工业进入了一个高速发展时期。加工过程中高分子表现出形状、结构、和性质等方面的变化。形状转变往往是为满足使用的最起码要求而进行的;材料的结构转变包括高分子的组成、组成方式、材料宏观与微观结构的变化等;高分子结晶和取向也引起材料聚集态变化,这种转变主要是为了满足对成品内在质量的要求而进行的,一般通过配方设计、材料的混合、采用不同加工方法和成型条件来实现。加工过程中材料结构的转变有些是材料本身固有的,亦或是有意进行的;有些则是不正常的加工方法或加工条件引起的。大多数情况下, 2高分子的加工通常包括两个过程:首先使原材料产生变形或流动,并取得所需要的形状,然后设法保持取得的形状。高分子加工与成型通常有以下形式:高分子熔体的加工、类橡胶状聚合物的加工、高分子液体的加工、低分子聚合物或预聚物的加工、高分子悬浮体的加工以及高分子的机械加工。除机械加工以外的大多数加工技术中,流动硬化是这些加工的基本程序。根据加工方法的特点或高分子在加工过程中变化的特征,可用不同的方式对这些加工技术进行分类。通常根据高分子在加工过程有否物理或化学变化,而将这些加工技术分为 3 类:第一类是加工过程主要发生物理变化的;第二类是加工过程只发生化学变化的;第三类则是加工过程同时兼有物理和化学变化的。这些加工技术大致包括一下四个过程:1.混合、熔融和均化作用;2.输送和挤压;3.拉伸或吹塑;4.冷却和固化(包括热固性高分子的交联和橡胶的硫化)。2 高分子材料加工原理1) 高分子材料的加工性质高分子具有一些特有的加工性质,如良好的可塑性,可挤压性,可纺性和可延性。正是这些加工性质为高分子材料提供了适于多种多样加工技术的可能性,也是高分子能得到广泛应用的重要原因。高分子通常可以分为线型高分子和体型高分子,但体型高分子也是由线型高分子或某些低分子物质与分子量较低的高分子通过化学反应而得到的。线型高分子的分子具有长链结构,在其聚集体中它们总是彼此贯穿、重迭和缠结在一起。在高分子中,由于长链分子内和分子间强大吸引力的作用,使高分子表现出各种力学性质。高分子在加工过程所表现的许多性质和行为都与高分子的长链结构和缠结以及聚集态所处的力学状态有关。根据高分子所表现的力学性质和分子热运动特征,可将其划分为玻璃态、高弹态和粘流态,通常称这些状态为聚集态。高分子的分子结构、高分子体系的组成、所受应力和环境温度等是影响聚集态转变的主要因素,在高分子及其组成一定时,聚集态的转变主要与温度有关。不同聚集态的高分子,由于主价健与次价健共同作用构成的内聚能不同而表现出一系列独特的性质,这些性能在很大程度上决定了高分子材料对加工技术的适应性,并使高分子在加工过程表现出不同的行为。高分子在加工过程中都要经历聚集态转变,了解这些转变的本质和规律就能选择适当的加工方法和确定合理的加工工艺,在保持高分子原有性能的条件下,能以最少的能量消耗,高效率地制备良好的产品。玻璃态高分子不宜进行引起大变形的加工,表现为坚硬的固体,但可通过车、铣、削、刨等进行加工。在玻璃化温度 Tg 以下的某一温度,材料受力容易发生 3断裂破坏,这一温度称为脆化温度,它是材料使用的下限温度。在 Tg 以上的高弹态,高分子的模量减少很多,形变能力显著加大。在 TgTf 温度区靠近 Tf,由于高分子的粘性很大,可进行某些材料的真空成型、压力成型、压延和弯曲成型等。把制品温度迅速冷却到 Tg 以下温度是这类加工过程的关键。Tg 是选择合理应用材料的重要参数,同时也是大多数高分子加工的最低温度。在 Tf 以上,高分子化合物转变为粘流态,通常又将这种液体状态的高分子称为熔体。材料在 Tf 以上不高的温度范围表现出类橡胶流动行为。这一转变区域通常用来进行压延成型、某些挤出成型和吹塑成型等。比 Tf 更高的温度使分子热运动大大激化,材料模量降到最低值,这时高分子熔体形变的特点是不大的外力就能引起宏观流动,这时形变中主要是不可逆的粘性变形,冷却高分子就能将形变永久保持下来,这一温度范围常用来进行熔融纺丝、注射、挤出、吹塑和贴合等加工。过高的温度将使高分子的粘度大大降低,不适当的增大流动性容易引起溢料、形状扭曲、毛丝断裂等现象。温度高到分解温度 Td 附近还会引起高分子化合物的分解,以致降低产品物理机械性能或引起外观不良。高分子在加工过程中常受到挤压作用,可挤压性是指高分子化合物通过挤压作用变形时获得形状和保持形状的能力。在挤压过程中,高分子熔体主要受到剪切作用,故可挤压性主要取决于熔体的剪切粘度和拉伸粘度。大多数高分子化合物熔体的粘度随剪切力或剪切速率增大而降低。如果挤压过程材料的粘度很低,虽然材料有良好的流动性,但保持形状的能力较差;相反,熔体的剪切粘度很高时则会造成流动和成型的困难。材料的挤压性质还与加工设备的结构有关。挤压过程高分子熔体的流动速率随压力增大而增加,通过流动速率的测量可决定加工时所需要的压力和设备的几何尺寸。材料的挤压性质与高分子的流变性,熔融指数和流变速率密切有关。高分子的可模塑性是指材料在温度和压力作用下形变和在模具中模制成型的能力。具有可模塑性的材料可通过注射、模压和挤出等成型方法制成各种形状的模塑制品。可模塑性主要取决于材料的流变性,热性质和其他物理力学性质等,在热固性高分子的情况下还和高分子的化学反应性有关。过高的温度,虽然熔体的流动性大,易于成型,但会引起分解,制品收缩率大;温度过低熔体粘度大,流动困难,成型性差;因弹性发展,明显的使制品形状稳定性差。适当增加压力,通常能改善高分子的流动性,但过高的压力将引起溢料和增大制品内应了;压力过低时则造成缺料。模塑条件不仅影响高分子的可模塑性,且对制品的力学性能、外观、收缩以及制品中的结晶和取向等都有广泛影响。热性能影响高分子加工与冷却的过程,从而影响熔体的流动性和硬化速度,因此也会影响高分子制品的性质。模具的结构尺寸也影响聚合物的模塑性,不良的模具结构甚至会使成 4型失败。可纺性是指高分子材料通过加工形成连续的固态纤维的能力。它主要取决与材料的流变性质,熔体粘度、熔体强度以及熔体的热稳定性和化学稳定性等。纺丝材料,首先要求熔体从喷丝板毛细孔流出后能形成稳定细流。细流的稳定性通常与由熔体从喷丝板的流出速度,熔体的粘度和表面张力组成的数群有关。纺丝过程由于拉伸和冷却的作用都使纺丝熔体粘度增大,也有利于增大纺丝细流的稳定性。但随纺丝速度增大,熔体细流受到的拉应力增加,拉伸变形增大,如果熔体的强度低将出现细流断裂。故具有可纺性的高分子还必须具有较高的熔体强度。不稳定的拉伸速度容易造成纺丝细流断裂。当材料的凝聚能较小时也容易出现凝聚性断裂。对一定高分子,熔体强度随熔体粘度增大而增加。作为纺丝材料还要在纺丝条件下,高分子有良好的热和化学稳定性,因为高分子在高温下要停留较长的时间并要经受在设备和毛细孔中流动时的剪切作用。可延性表示无定形或半结晶固体高分子在一个方向或两个方向上受到压延或拉伸时变形的能力。材料的这种性质为生产长径比很大的产品提供了可能,利用高分子的可延性,可通过压延或拉伸工艺生产薄膜、片材和纤维。但工业生产仍以拉伸法用的最多。线型高分子的可延性来自大分子的长链结构和柔性。可延性取决于材料产生塑性形变的能力和应变硬化作用。形变能力与固体高分子所处的温度有关,在 TgTm 温度区间高分子化合物的分子在一定拉力作用下能产生塑性流动,以满足拉伸过程材料截面积尺寸减小的要求。对半结晶高分子拉伸在稍低于 Tm 以下的温度进行,非晶体高分子则在接近 Tg 的温度进行。适当地升高温度,材料的可延性能进一步提高,拉伸比可以更大,甚至一些延伸性较差的高分子也能进行拉伸。通常把在室温至 Tg 附近的拉伸称为“冷拉伸”,在 Tg 以上的温度下的拉伸称为“热拉伸”。当拉伸过程高分子发生“应力硬化”后,它将限制聚合物分子的流动,从而阻止拉伸比的进一步提高。2)加工过程中的粘弹行为高分子在加工过程中通常是从固体变为液体,再从液体变成固体,所以加工过程中高分子在不同条件下会分别表现出固体和液体的性质,既表现出弹性和粘性。但由于大分子的长链结构和大分子运动的逐步性质,高分子的形变和流动不可能是纯弹性的或纯粘性,而是弹性和粘性的综合既粘弹性。当高分子在外力作用下发生普弹形变时,外力使大分子键长和键角或高分子晶体中处于平衡状态的粒子间发生形变和位移。推迟高弹形变是外力较长时间作用于高分子时,由处于无规则热运动的大分子链段形变和位移所贡献,形变值大,具有可逆性,它使高分子表现出特有的高弹性。粘性形变则是高分子在外力作用下沿力作用方向发生的大分子链之间的结缠和相对滑移,表现为宏观流动, 5形变值大,具有不可逆性。在通常的加工条件下,高分子形变主要由高弹形变和粘性形变组成。从形变性质来看包括可逆形变和不可逆形变两种成分,只是由于加工条件不同存在着两种成分的相对差异。当加工温度高于 Tf 以致高分子处于粘流态时,高分子的形变发展以粘性形变为主。此时,高分子粘度低流动性大,易于成型;加工温度低于 Tf 时,高分子转变成高弹态,随温度降低,高分子形变组成中的弹性成分增大,粘性成分减小,由于有效形变值减小,通常较少在这一范围成型制品。高分子在加工过程中的形变都在外力和温度共同作用下,大分子形变和进行重排的结果。由于大分子的长链结构和大分子运动的逐步性,高分子在外力作用时与应力相适应的任何形变都不可能在瞬间完成,通常将高分子于一定温度下,从受外力作用开始,大分子的形变经过一系列的中间状态过渡到与外力相适应的平衡状态的过程看成是一个松弛过程,过程所需的时间称为松弛时间。高分子对外力响应的这种滞后现象称为“滞后效应”或“弹性滞后”。在 TgTf温度范围对成型制品进行热处理,可以缩短大分子形变的松弛时间,加快结晶速度,使制品的形状能较快的稳定下来。3 聚氯乙稀的加工成型: 聚氯乙稀的缩写代号是 PVC。按照产量,聚氯乙稀在世界范围和我国皆是占据五大通用塑料的第二位。 1) 工艺特性 聚氯乙烯具有如下成型加工工艺特性:1、热稳定性差。为避免材料过热分解,应尽量避免一切不必要的受热现象,严格控制成型温度,避免物料在料筒内滞留时间过长(特别是生产启动和班次交接时),并应尽量减少塑化过程中的摩擦热。聚氯乙烯熔融粘度高,熔融加工工艺中应尽量避免使用分子量太高的品级,配料中应加入适当润滑剂以增加物料流动性,稳定剂应采用效率较高的有机锡类,如马来酸二丁基锡、二月桂酸二正辛基锡等。注塑成型不宜采用柱塞式注塑机。2、聚氯乙烯熔体粘度高,需要较高的成型压力,为避免熔体破裂,注塑、挤出时宜采用中、低速,避免高速。3、聚氯乙烯热分解时放出氯化氢,对设备有腐蚀作用,加工的金属设备应采取电镀的防护措施或采用耐腐钢材。4、聚氯乙烯熔体冷却速度快(比热容仅为 8361170kJ(kgK),且无相变热),成型周期短。 2) 加工工艺 6聚氯乙烯可以采用注塑、挤出、吹塑、压延、搪塑、发泡等成型工艺。对于增塑聚氯乙烯制品,成型加工前需先向聚氯乙烯粉料或颗粒料中加入增塑剂和其它助剂进行预混,并进行塑化。将塑化后的配料准备成适于加工的形状,例如采用注塑、挤出工艺时,则需要挤出造粒;用于压延工艺时,需要先预压成软板。注塑成型主要用于硬聚氯乙烯。硬聚氯乙烯注塑成型工艺条件列于表 41。聚氯乙烯可以挤出成型各种型材,也可以挤出吹塑薄膜。表 42 和表 43 分别是聚氯乙烯管材和聚氯乙烯薄膜的挤出成型工艺条件。 3) 聚氯乙稀的应用: 聚氯乙烯的应用主要集中在制备以下几方面的制品:(1)、薄膜和人造革,薄膜主要供农用。2)、耐油、耐腐、耐老化的不燃电线电缆包皮、绝缘层。(3)、种型材如管、棒、异型材、门窗框架;瓦楞板及建材、室内地板装饰材料、各种板材。(4)、家具、玩具、运动器材、医用管件、包装涂层等。 4) 聚氯乙稀的改性: 聚氯乙稀的缺点是软化点低,耐热性和耐寒性差,韧性也欠佳,特别是热稳定性差,此外熔体粘度也较高,加工较困难。为克服这些缺点,就产生了各种改性的聚氯乙烯。一、氯化聚氯乙烯:氯化聚氯乙烯又称为过氯乙烯,系由聚氯乙烯树脂经氯化后所得。(1).氯化方法:制取氯化聚氯乙烯主要采用悬浮氯化法。将聚氯乙烯树脂粉悬浮于浓度为 20左右的盐酸(或水)中,用氯仿或二氯乙烷为膨润剂,借以形成稳定的悬浮体。用过氧化物、引发剂引发或紫外光照射,在常压和 6065温度的条件下通人氯气进行氯化。氯化后的聚氯乙烯含氯量可达到 6667。(2)性能改善:氯化聚氯乙烯比之聚氯乙烯性能上有明显改善,主要表现在耐热性和耐寒性提高。未氯化的聚氯乙烯最高连续使用温度仅 6580C,氯化后的聚氯乙烯可提高到 100。未氯化的聚氯乙烯脆化温度仅一 20,氯化后的聚氯乙烯脆化温度可达到一 45。氯化聚氯乙烯的拉伸、弯曲强度比聚氯乙烯皆有所提高,耐腐蚀、耐老化性进一步提高,阻燃性也进一步提高,有限氧指数从原来的 47 提高到 60 左右。氯化聚氯乙烯密度大于聚氯乙烯,且含氯量愈大,密度愈大,当含氯量为 65时,密度为 152 gcm。二、共聚改性: 将氯乙烯与某些其它单体共聚,可以改善聚氯乙烯的某些性能。(1)氯乙烯与乙酸乙烯共聚。用过氧化物引发剂使二单体进行悬浮或溶液共聚,可以得到含乙酸乙烯 10一 25的共聚物。氯乙烯-L 酸乙烯共聚物分子链中,含有侧基氯原子和乙酰基,降低了分子链的有序性,故乙酸乙烯进人共聚物分子链实际上起到了内增塑作用,使共聚物熔体流动性增大;韧性 7和耐寒性也得到改善,但也因此使材料耐化学试剂、耐溶剂性降低,强度、硬度也不及聚氯乙烯。(2)氯乙烯与丙烯共聚: 氯乙烯与丙烯的共聚物可由过氧化物引发使二单体进行悬浮共聚而得,其中共聚物中丙烯含量不超过 10。这种共聚物比之聚氯乙烯的性能改善是流动性增大,不仅可进行注塑成型,还可中空吹塑形状复杂的容器。共聚物的热稳定性比聚氯乙烯提高,还具有良好的透明性和耐化学试剂性,可用以制备医药、食品的包装容器。(3)氯乙烯与丙烯腈共聚:采用本体法、溶液法、悬浮法、乳液法等共聚合,都可以制得氯乙烯与丙烯腈的共聚物,但乳液法最常用。乳液共聚时用过硫酸盐为引发剂。共聚物中丙烯腈含量在 2060的范围内。氯乙烯丙烯腈共聚物的软化点比聚氯乙烯有大幅度提高,可达到 140160,故耐热性也有较大程度提高。含有60丙烯腈的共聚物基本性能与聚丙烯腈相似,可以抽丝作为纤维,织物手感好,保温性优,难燃,耐酸碱,不怕虫蛀。(4)氯乙烯与丙烯酸酯共聚:氯乙烯可以与许多丙烯酸酯类单体共聚,共聚方法可以是乳液法或悬浮法。共聚物的软化点比聚氯乙烯高,流动性也比聚氯乙烯好,有利于成型加工;共聚物的冲击韧性、耐寒性也比聚氯乙烯有明显改善。这种共聚物是透明材料,可以制造座舱玻璃、仪表面板。(5)氯乙烯与偏二氯乙烯共聚:氯乙烯与偏二氯乙烯两单体可以在过氧化物、偶氮化合物或过硫酸盐的引发下进行共聚。共聚可采用乳液法或悬浮法,两种单体比例可以在很大范围内改变,所得到共聚物的性能和用途明显不同。作为塑料、涂料、胶粘剂使用的共聚物,偏二氯乙烯含量不超过 60,一般主要采用乳液共聚合。作为纤维使用的共聚物,偏二氯乙烯含量可达到 7590,主要采用悬浮共聚合。偏二氯乙烯与氯乙烯结构接近,二者的共聚物保持了聚氯乙烯的许多特点,由于主链由两种单体构成,使共聚物比之聚氯艺烯均聚物或聚偏二氯乙烯均聚物的流动性皆有明显改善,这是由于两单体的存在互相起着内增塑作用。偏二氯乙烯链节的存在使共聚物分子链间距增大,使共聚物流动性优于纯聚氯乙烯均聚物。纯聚偏二氯乙烯由于分子链的对称性,是高结晶度聚合物,熔融温度高,氯乙烯单体的存在又破坏了聚偏二氯乙烯分子链的对称性,使共聚物软化点降低,因此共聚物加工性比聚氯乙烯有所改善。氯乙烯偏二氯乙烯可采用注塑、挤出、吹塑方法加工。共聚物的强韧性和透明性优于聚氯乙烯,耐油性、耐化学试剂性、耐光性也较好,阻燃性亦优,但最大的特点是透气性、透湿性均很小,适宜于作为密封性包装材料。 8附录 BHigh polymer material processing technology1 High polymer material outline: The material is the science and the industrial technology development foundation. One new material appearance, can bring the huge change for the social civilization, brings the epoch-making breakthrough for the new technical development. The material has deserved becomes the contemporary science and technology one of three big props. The high polymer materials science already with the metal material, the inorganic nonmetallic material kept pace with, internationally is listed as the level discipline. The high polymer materials science is in a materials science important branch discipline. The modern materials science scope defines for studies the material nature, the structure and the composition, the synthesis and the processing, material performance these four essential factors as well as between them the reciprocity. The high polymer materials science basic task is: Research high polymer material synthesis, structure and composition and between material nature, performance reciprocity; Exploration processing craft and each kind of environmental factor to material performance influence; In order to improve the craft, enhances the high polymer material the quality, uses the high polymer material reasonably, develops the new material, the new craft and the new application domain provides the theory basis and the foundation data. The high polymer materials science is one young and the emerging discipline, its development request science and the project technology closest coordination, its progress needs trans-departmental, the multi-disciplinary 9best coordinations and participation together. At present each kind of synthesis high polymer application has spread the national economy various departments, specially the military and the most advanced technique to have each different performance polymer material urgent need, has urged the high polymer synthesis and the processing technology had a quicker development, the high polymer formation and the processing already becomes one kind of independent special project technology. Because the processing technology theory research, processing equipment design and aspects and so on processing process automatic control have all made the very big progress, the product quality and the production efficiency enhance greatly, the product adaptation scope expands, raw material and the product cost reduce, the polymer processing industry entered a high speed development time. In the processing process the high score sublist appears the shape, the structure, and aspect and so on nature changes. The shape transforms often is for satisfies the use the most minimum request to carry on; Material structural transformation including high polymer composition, composition way, material macroscopic and microscopic structure change and so on; The high polymer crystallization and the orientation also cause the material state of aggregation change, this kind of transformation mainly is in order to satisfy, generally through the formula design, the material mix which carries on to the end product intrinsic quality request, uses the different processing method and the formation condition realizes. In the processing process the material structure transformation some is material itself inherent, also perhaps the mean carries on; Some is not the normal processing method or the processing condition causes. In the majority situations, the high polymer processing usually includes two processes: First causes raw material to have the distortion or the flowing, and obtains the shape which needs, then tries the shape which maintains obtains. The high polymer processing and the formation usually has following form: High polymer melt processing, kind of rubber-like polymer processing, high polymer liquid processing, low-molecular polymer or prepolymer processing, high score pressure of the fetus on the mothers heart after fourth or fifth month of pregnancy buoy processing as well as high polymer machine-finishing. Besides in the machine-finishing majority processing technology, the flowing - hardening is these processing main routine. According to the processing method characteristic or the high polymer the characteristic which changes in the processing process, the available different way carries on the classification to these processing technology. Usual 10basis high polymer in processing process whether or not physics or chemical change, but divides into these processing technology 3 kinds: The first kind is the processing process mainly has the physical change; The second kind is the processing process only has the chemical change; The third kind is the processing process simultaneously has at the same time physics and the chemical change. These processing technology includes next four processes approximately: 1. mixes, fusing and homogenization; 2. transportations and extrusion; 3. stretches or blow molding; 4. cooling and solidification (including thermosetting high polymer crossing linking and rubber curing).But is not all product processing formation process all must complete including the above four steps. 2 High polymer material processing principle 1) high polymer material processing nature high polymer material workability: The high polymer has some unique processing nature, like good plasticity, extrudability, spinnability and mace ability. Was precisely these processing nature provides has been suitable for many and varied processing technology for the high polymer material the possibility, also was the high polymer can obtain the widespread application important reason. The high polymer usually may divide into the linear high polymer and the build high polymer, but the build high polymer also is obtains by the linear high polymer or certain low molecular material and the molecular weight low high polymer through the chemical reaction. The linear high polymer member has the long chain structure, in its aggregate their always each other penetration, overlaps and tangles in together .In high polymer, because long chain intramolecular and intermolecular formidable attraction function, causes the high score sublist to appear each mechanical properties. High polymer many nature and the behavior which displays in the processing process all mechanics condition which locates with the high polymer long chain structure and the tangle as well as the state of aggregation concern. Mechanical properties and molecular heat movement characteristic displays which according to the high polymer, may divide it into the glass condition, Gao Dantai and sticks the fluid state, usual name these conditions the states of aggregation. The high polymer molecular structure, the high polymer system composition, receives the stress and the ambient temperature and so on affects the primary factor which the state of aggregation transforms, when high polymer and 11composition certain, the state of aggregation transformation mainly concerns with the temperature. Different state of aggregation high polymer, because the principal valence healthy and the inferior price healthy affects the constitution the cohesive energy differently to display a series of unique nature together, these performance had decided to a great extent the high polymer material to processes technical the compatibility, and causes the high polymer to display the different behavior in the processing process. The high polymer all must experience the state of aggregation in the processing process to transform, understood these transformations the essence and the rule can choose the suitable processing method and the determination reasonable processing craft, in under the maintenance high polymer original performance condition, can by the least energy consumption, the high efficiency preparation good product. The glass condition high polymer carries on not suitably causes the big distortion processing, displays for the hard solid, but may through the vehicle, the mill, truncate, dig and so on to carry on the processing. Below vitrification temperature Tg some temperature, the material stress easy to have the break to destroy, this temperature is called the embrittled temperature, it is the material use lower limit temperature. Above the Tg high ball condition, the high polymer module reduces very much, deformability remarkable enlarge. Approaches Tf in the Tg-Tf temperature area, because the high polymer coherency is very big, may carry on certain materials the vacuum forming, the pressure formation, the rolling and the curving formation and so on. Cools the product temperature to Tg below the temperature is rapidly this kind of processing process key. Tg is the choice reasonable application material important parameter, simultaneously also is the majority high polymer processing lowest temperature. Above Tf, the high-molecular compound transforms for sticks the fluid state, usually is called this kind of liquid condition high polymer the melt. The material not the high temperature range performance stands out the rubber mobile behavior above Tf. This transforms the region usually to use for to carry on the rolling formation, certain squeezes out the formation and the blow molding formation and so on. Causes the molecular heat movement big intensification compared to a Tf higher temperature, the material module to fall the minimum value, by now the high polymer melt deformation characteristic was not the big external force can cause the macroscopic flowing, by now in the deformation mainly was the irreversible coherent distortion, the cooling high polymer can permanent maintain the deformation, this temperature range often uses for to carry on the melting spinning, the injection, 12squeezes out, processings and so on blow molding and fitting. The excessively high temperature will cause the high polymer the viscosity to reduce greatly, not suitable will increase the fluidity easily to cause phenomena and so on flash, shape distortion, broken filament break. The temperature also can cause the high-molecular compound decomposition as high as decomposition temperature Td nearby, so that reduces the product physics mechanical property or causes the outward appearance not to be good. The high polymer often receives the extrusion function when the processing process, the extrudability is refers to the high-molecular compound through the extrusion function distortion obtains the shape and maintenance shape ability. In the extrusion process, the high polymer melt mainly receives the shear action, therefore the extrudability mainly is decided by the melt shear viscosity and the stretch viscosity. The majority high-molecular compound melt viscosity increases along with the shearing force or the shear rate reduces. If the extrusion process material viscosity is very low, although the material has the good fluidity, but maintenance shape ability is bad; On the contrary, melt shear viscosity very Gao Shi can create the flowing and the formation difficulty. The material extrusion nature also concerns with the processing equipment structure. The extrusion process high polymer melt mobile speed increases along with the pressure increases, through the flowing speed survey may decide when processing needs pressure and equipment geometry size. The material extrusion nature and the high polymer rheological property, the fusing index and the changing speed concern closely. The high polymer may the compression molding be refers to the material under the temperature and the pressure function the deformation and in the mold molded formation ability. Has may the compression molding material be possible through the injection, the mould pressing and squeezes out and so on the formation methods to make each kind of shape the compression molding product. But the compression molding mainly is decided by the material rheological property, the thermal property and other physics mechanical properties and so on, also concerns in the thermosetting high polymer situation with the high polymer chemical reactivity. Excessively high temperature, although the melt fluidity is big, easy to take shape, but can cause the decomposition, the product shrinkage is big; The temperature excessively low melt viscosity is big, the mobile difficulty, the formability is bad; Because of the elastic development, obvious causes the product shape stability to be bad. The suitable increase pressure, usually can improve the high polymer the fluidity, but the high pressure has caused the flash and increases 13the product planted agent; When hypotonia creates the lack materials. Not only the compression molding condition the influence high polymer may the compression molding, also to in the product mechanics performance, the outward appearance, the contraction as well as the product crystallization and the orientation and so on all has the widespread influence. Thermal properties influence high polymer processing and cooling process, thus influence melt fluidity and hardened speed, therefore also can affect the high polymer product the nature. The mold structure size also affects the polymer the compression molding, not the good mold structure even can cause the formation defeat. The spinnability is refers to the high polymer material to form the continual solid state textile fiber through the processing ability It mainly is decided with the material changing nature, the melt viscosity, the melt intensity as well as the melt thermo stability and chemically stable and so on. The spinning material, first requests the melt after to spurt the screw stock wool pore to flow out can form the stable rivulet. The rivulet stability usually with from spurts the screw stock by the melt to flow out the speed, several crowds which the melt viscosity and the surface tension are composed concerns. Because the spinning process the stretch and the cooling function all causes the spinning melt viscosity to increase, also is advantageous in increases the spinning rivulet the stability .But increases along with the spinning speed, the melt rivulet receives the tensile stress increase, the stretch elongation increases, if the melt intensity low will appear the rivulet break. Therefore has the spin ability high polymer also to have to have the high melt intensity. The unstable stretch speed easy to create the spinning rivulet break. When the material condensation can small also easy to appear the coherence break. To certain high polymer, the melt intensity increases along with the melt viscosity increases As the spinning material also must under the spinning condition, the high polymer have the good heat and the chemical stability, because the high polymer must pause the long time under the high temperature and must undergo in the equipment and the wool pore flows the time shear action. The mace ability expressed ability which when a direction or two directions amorphous either the hypocrystalline solid high polymer receives rolling or stretch distorts. Material this nature has provided the possibility for the production length to diameter ratio very big product, the use high polymer mace ability, may through the rolling or the stretch craft production thin film, the sheet material and the textile fiber. But the industrial production still stretched the law to use most much. The linear high polymer mace ability comes from the macro-molecule long 14chain structure and the flexibility. The mace ability is decided in the material has the plastic deformation ability and the strain hardening function. Deformability and the solid high polymer locates temperature related, can produce the plastic flow in the Tg-Tm temperature sector high-molecular compound member under certain pulling force function, satisfies stretch process material cross-sectional area minification the request.Fifty-fifty crystallizes the high polymer to stretch is being lower than the Tm following temperature to carry on slightly, the amorphous body high polymer carries on in the close Tg temperature. The temperature elevation, the material mace ability can further enhance suitably, stretches may be bigger than, even some extensible bad high polymer also can carry on the stretch. Usually is called in the room temperature to the Tg nearby stretch “the cold stretch”, is called “the hot stretch” under the Tg above temperature stretch. After the stretch process high polymer occurrence “the stress hardens”, it will limit the polymer member the flowing, thus impediment stretch ratio further enhancement. 2) in the processing process sticks the ball behavior: The high polymer usually is becomes the liquid in the processing process from the solid, again turns the solid from the liquid, therefore in the processing process the high polymer can display solid and the liquid nature separately under the dissimilar condition, also displays the elasticity and the coherency .But as a result of the macro-molecule long chain structure and the macro-molecule movement the nature, the high polymer deformation and the flowing not impossible is gradually pure elastic or the pure viscosity, but is the elasticity and the coherent synthesis already viscoelasticity. When the high polymer has the Pu ball deformation when the exogenic process, the external force causes the big molecular linkage long and the bond angle or in the high polymer crystal is at the state of equilibrium between the granule to have the deformation and the displacement. Postpones the high ball deformation is when the external force long time does uses in the high polymer, by is in the non-regular heat movement the macro-molecule segment deformation and the displacement contributes, the deformation value is big, has the invertibility, it causes the high score sublist to appear the unique high elasticity. The coherent shape abnormality is the high polymer between the macro-molecule chain knot which occurs along the force direction entangles under the exogenic process with the relative slip, the performance is the macroscopic flowing, the deformation value is big, has the irreversibility. 15Under the usual processing condition, the high polymer deformation mainly is composed by the high ball deformation and the coherent deformation .From the deformation nature looked including the reversible deformation and the irreversible deformation two ingredients, only is because the processing condition has two ingredients differently the relative differences. When the processing temperature is higher than when Tf the high polymer is in sticks the fluid state, high polymer deformation development by coherent deformation primarily. This time, the high polymer viscosity low fluidity is big, easy to take shape; When the processing temperature is lower than Tf, the high polymer transforms Cheng condition, along with temperature drop, in the high polymer deformation composition elastic ingredient increases, the coherent ingredient reduces, because the effective deformation value reduces, usually is short in this scope formation product. The high polymer in processing process deformation all under the external force and the temperature together function, the macro-molecule deformation and carries on the rearrangement the result. As a result of macro-molecule long chain structure and macro-molecule movement gradually, high polymer when exogenic process adapts any deformation with the stress all not not impossibly in instantaneous to complete, usually the high polymer under certain temperature, from receives the exogenic process to start, the macro-molecule deformation passes through a series of compound states to transit to the state of equilibrium process which adapts with the external force regards as is a flaccid process, the time which the process needs is called the flaccid time. The high polymer is called “the after effect” to the external force response this kind of hysteresis or “the elastic hysteresis” . Carries on the heat treatment in the Tg-Tf temperature range to the formation product, may reduce the macro-molecule deformation the flaccid time, speeds up the crystallization velocity, enables the product the shape quick to stabilize down.3 gathers the chlorine second grade thin processing formation Gathers the chlorine second grade thin abbreviation code number is PVC. According to the output, gathers the chlorine second grade thinly all occupies five big general plastic second in the worldwide scale and our country.1).craft characteristic: 16The polyvinyl-chloride has following formation processing craft characteristic: 1st, the thermostability is bad. In order to avoid the material superheat decomposition, should as far as possible avoid all nonessential being heated phenomenon, controls the formation temperature strictly, avoids the material the dead time excessively is long when the material tube is specially produces start and school grade order connection), and should as far as possible reduce in the plastified process the friction heat. The polyvinyl-chloride fusing viscosity is high, in the fusing processing craft should avoid using the molecular weight too high grade as far as possible, in the ingredient should join the suitable lubricant to increase the material fluidity, the stabilizer should use the efficiency high organic tin class, like maleic acid two butyl tin, in February lauric acid two octyl tin and so on. The injection molding formation uses the plunger injection molding machine not suitably.2nd, the polyvinyl-chloride melt viscosity is high, needs the high formation pressure, for avoids the melt bursting, the injection molding, squeezes out uses, the low speed appropriate to the occasion, avoids high speed.3rd, when polyvinyl-chloride thermal decomposition emits the Hydrogen chloride, has the corrosive action to the equipment, the processing hardware should adopt the galvanization the protective measure or uses the anticorrosive steel products.4th, the polyvinyl-chloride melt cooling rate quick (compared to the heat capacity only is 836-1170kJ/(kg K), also does not have heat of transformation), the formation cycle is short.2) processes the craftpolyvinyl-chloride to be possible to use the injection molding, to squeeze out, the blow molding, the rolling, keeps out models, becomes spongy and so on the formation crafts.Regarding the plastify polyvinyl-chloride product, before the formation processing must first foresees accurately to the polyvinyl-chloride powder material or the pellet joins the plasticizer and other helps the medicinal preparation to carry on mixes in advance, and carries on the plasticizing. Will plastify the shape which after the ingredient will prepare to be suitable for to process, for example will use when the injection molding, will squeeze out the craft, then needs to squeeze out makes the grain; When uses in the rolling craft, needs first precompression Cheng Ruanban. The injection molding formation mainly uses in the hard polyvinyl-chloride. The hard polyvinyl-chloride injection molding formation technological conditions are listed in Table 4-1.The polyvinyl-chloride may squeeze out takes shape each kind of molding, also may 17squeeze out the blow molding thin film. Table 4-2 and Table 4-3 respectively is the polyvinyl-chloride tubing and the polyvinyl-chloride thin film squeezes out the formation technological conditions. 3) gathers the chlorine second grade thin application: The polyvinyl-chloride application mainly concentrates is preparing following several aspects the product: (1)th, the thin film and the imitation leather, the thin film mainly uses for the agriculture.(2), oil resistant, anticorrosive, bears the aging not to burn the electric wire cable sheath, the insulating layer.(3)th, kind of molding like tube, stick, different molding, windows and doors frame; In corrugated board and building materials, room floor decoration material, each kind of plate.(4)th, furniture, toy, movement equipment, medical fitting, packing coating and so on. 4) gathers the chlorine second grade thin modification: Gathers the chlorine second grade thin shortcoming is the softening point is low, the thermal stability and the resistance to cold are bad, toughness also unsatisfactory, the thermostability is specially bad, in addition the melt viscosity is also high, the processing is difficult. In order to overcome these shortcomings, has produced each kind of modified polyvinyl-chloride.First, chlorination polyvinyl-chloride: The chlorination polyvinyl-chloride has been called the chloroethylene, is by the polyvinyl chloride after the chlorination obtained.(1). chlorination method: The system takes the chlorination polyvinyl-chloride mainly to use the aerosol chlorination process. The polyvinyl chloride powder aerosol in the density is 20% about hydrochloric acid (or water), for swollens the Run medicinal preparation with the chloroform or the dichloroethane, in order to forms the stable aerosol body. With the peroxide, the initiator initiation or the ultraviolet ray illumination, and 6065 under the temperature condition the learned person chlorine carries on the chlorination in the atmospheric pressure. After the chlorination polyvinyl-chloride chlorinity may achieve 66%67%.(2). performance improvement: The chlorination polyvinyl-chloride has the distinct improvement compared to it polyvinyl-chloride performance in, mainly displays in thermally stable and the cold resistant enhancement. The chlorination polyvinyl-chloride has not been highest long-term usage temperature only 6580C, after the chlorination polyvinyl-chloride may enhance 100.The 18chlorination polyvinyl-chloride embrittlement temperature only 120 , after the chlorination polyvinyl-chloride embrittlement temperature has not been possible to achieve 145 .The chlorination polyvinyl-chloride stretch, the curving strength ratio polyvinyl-chloride all have the enhancement, anti-corrosive, bears the old chemical property further to enhance, the flame retardance also further enhances, the limited oxygen index from original 47 enhances to 60 about. The chlorination polyvinyl-chloride density is bigger than the polyvinyl-chloride, also the chlorinity is bigger, the density is bigger, when the chlorinity is 65%, the density is 1.52 g/cm. Second, copolymerization modification: The chloroethylene with certain other monomer copolymerization, may improve the polyvinyl-chloride certain performance.(1). chloroethylene and ethanoic acid ethylene copolymerization. Causes two monomers with the peroxide initiator to carry on aerosol or the solution copolymerization, may obtain including the ethanoic acid ethylene 135% copolymer.In the chloroethylene - L sour ethylene copolymer member chain, includes the side group chlorine atom and the acetazolamide, reduced the molecular chain ordered nature, therefore the ethanoic acid ethylene entered the human copolymer member chain in fact to get up in the plasticization, caused the copolymer melt fluidity to increase; Toughness and the resistance to cold also are improved, but therefore also causes the material to bear the chemical reagent, to bear the solvent to reduce, the intensity, degree of hardness also are inferior to the polyvinyl-chloride. (2).chloroethylene and propylene copolymerization: The chloroethylene and the propylene copolymer may cause two monomers by the peroxide initiation to carry on the aerosol copolymerization, in which copolymer the propylene content does not surpass 10%.This kind of copolymer is the fluidity increases compared to it polyvinyl-chloride performance improvement, not only may carry on the injecti

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号