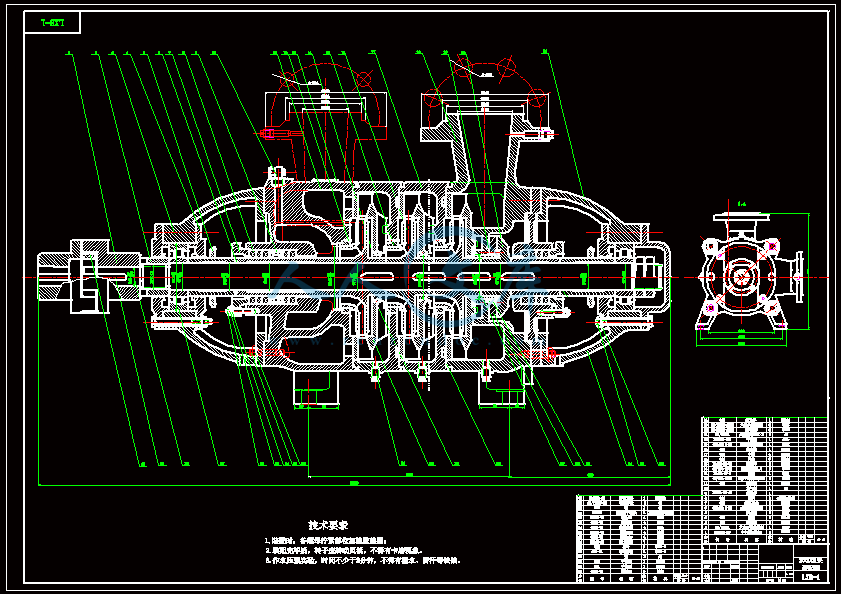

200D多段离心式清水泵结构设计【含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:

编号:60138622

类型:共享资源

大小:1.41MB

格式:ZIP

上传时间:2020-03-21

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、说明书

200

离心

清水泵

结构设计

CAD

图纸

说明书

- 资源描述:

-

- 内容简介:

-

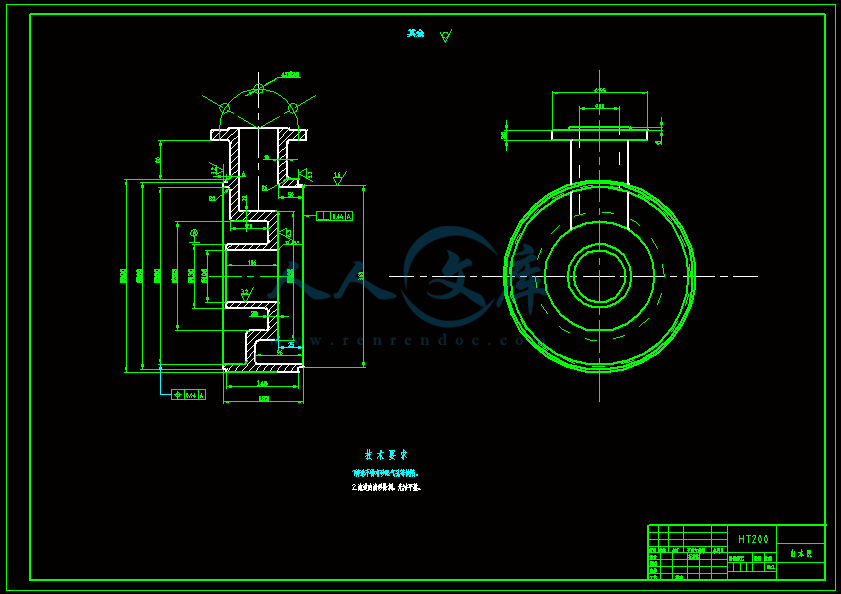

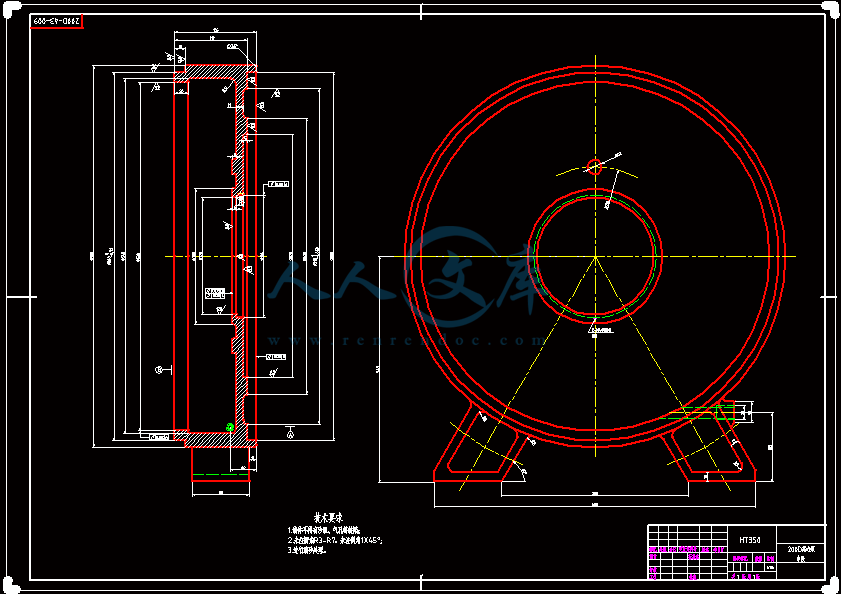

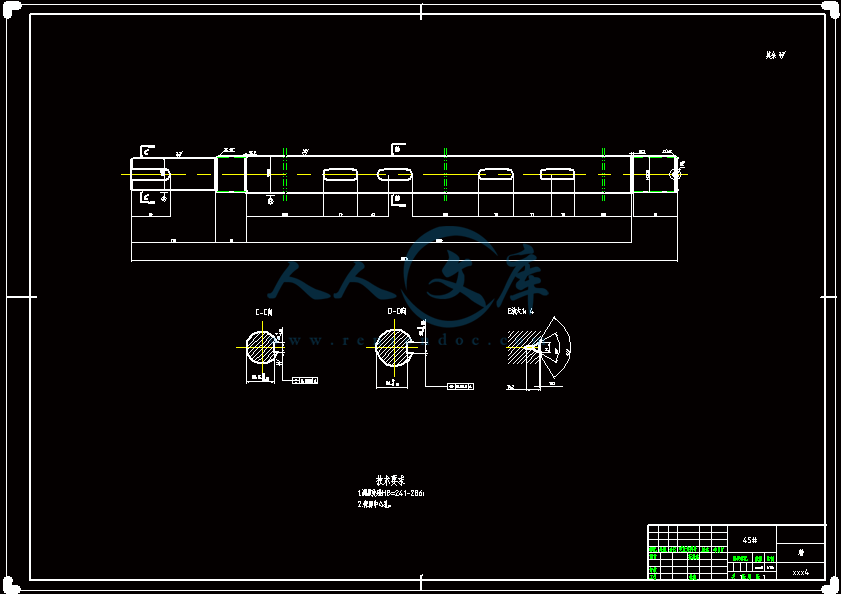

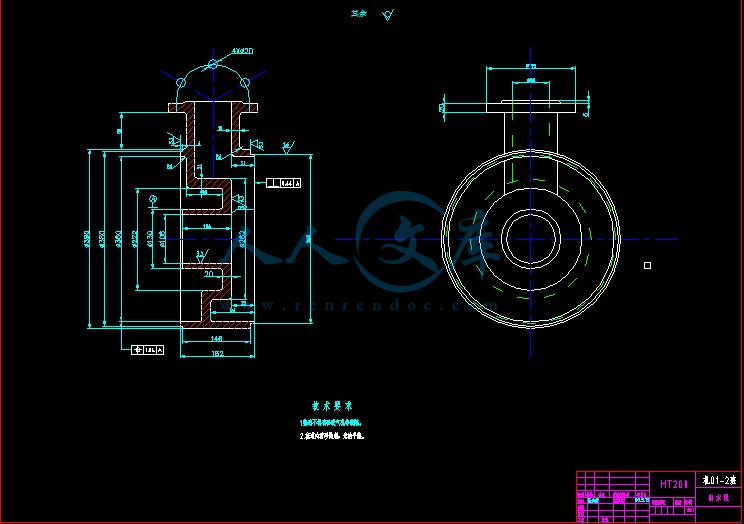

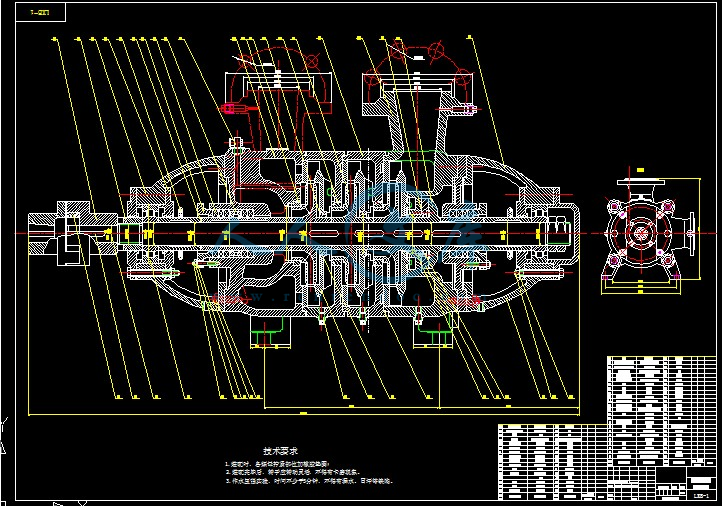

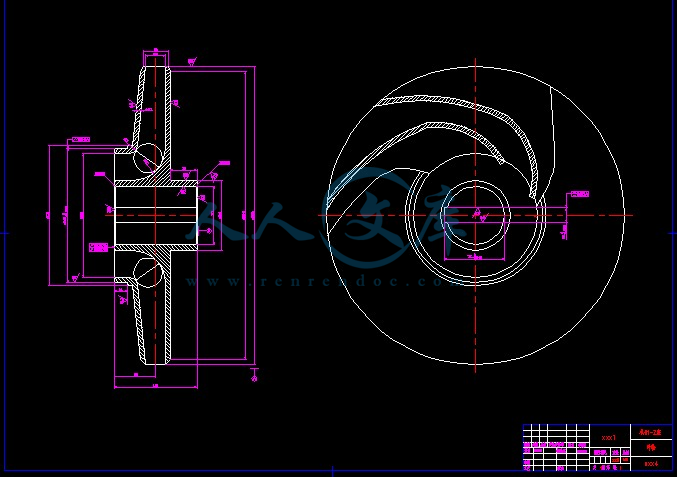

毕业设计(论文)任务书学生姓名: 毕业设计(论文)任务下达日期:毕业设计(论文)任务开始日期:毕业设计(论文)任务完成日期:1、一般部分题目:200D 多段离心式清水泵结构设计流量 Q=280m3/h ,扬程 H=260m 允许吸上真空度 hs=6m。效率 70%2、专题部分题目:离心泵故障分析3、工作量具体要求设计图纸(内容、幅面及其数量)图纸总量合计三张零号图左右。总装图、叶轮、出水室、轴中段说明书或论文(主要项目内容及字数要求)2 万字左右,内容包括摘要(中英文)、设计过程、参考文献等。指 导 教 师(签字) 日期教研室主任(签字) 日期系 主 任(签字) 日期1附录 2数控技术先进制造技术中的一个最基本的概念是数字控制(NC) 。在数控技术出现之前,所有的机床都是人工操纵和控制的。在与人工控制的机床有关的很多局限性中,操作者的技能大概是最突出的问题。采用人工控制时,产品的质量直接与操作者的技能有直接的关系。数字控制代表了从人工控制机床做出来的第一步。数字控制技术意味着采用预先录制的、存储的符号指令,控制机床和其他制造系统。一个数控技师的工作不是去操纵机床,而是编写能够发出机床操纵指令的程序。对于一台数控机床,其上必须有一个被称为阅读机的界面装置,用来接受和解译编程指令。发展数控技术是为了克服人类操作者的局限性,而且它确实完成了这项工作。数字控制的机器比人工操纵的机器的精度更高、生产零件的一致性更好、生产速度更快、而且长期的工艺装备成本更低。数控技术的发展导致制造工艺中其他几项新发明的产生。电火花加工技术激光切割电子束焊接 数字控制还使得机床比他们采用人工操纵的前辈们的用途更为广泛。一台数控机床可以自动产生很多种类的零件,每个零件都可以有不同和复杂的加工过程。数控可使生产厂家承担那些对于采用人工控制的机床和工艺来说,在经济上是不 划算的产品的生产任务。与许多先进技术一样,数控诞生于麻省理工学院的实验室中。数控这个概念是 20 世纪 50 年代初在美国空军的资助下提出来的。在其最初阶段,数控机床可以经济和有效地进行直线切割。然而,曲线轨迹成为机床加工的一个问题,在编程时应采用一系列的水平与竖直的台阶来生成曲线。构成台阶的每个线段越短,曲线就越光滑。台阶中的每个线段都必须经过计算。在这个问题促使下,与 1959 年诞生了自动编程工具(ATP)语言。这是个专门适用于数控的编程语言,使用类似于英语的语句来定义零件的几何形状,描述切削刀具的形状和规定必要的运动。ATP 语言的研究和发展是在数控技术进一步发展过程中 的一大进步。最初的数控系统与今天应用的数控系统是有很大差别的。在那时的机床中,只有硬线逻辑电路。指令程序写在2穿孔纸带上(后来它被塑料纸带所取代) ,采用带阅读机将写在纸带或磁带上的指令给机器翻译出来。所有这些共同构成了机床数字控制方面的巨大进步。然而,在数控发展的这个阶段还存在着许多问题。一个主要问题是穿孔纸带的易损坏性。在机械加工过程中,载有编程指令信息的纸带断裂和被撕坏是常见的事情。在机床上每加工一个零件,都需要将载有指令的纸带放入阅读机中重新运行一次。因此,这个问题变得很严重。如果需要制造 100 个某种零件,则应该将纸带分别通过阅读机 100 次。、易损坏的纸带显然不能承受严酷的车间环境和这种重复使用。这就导致了一种专门的塑料磁带的研制。在纸带上通过采用一系列的小孔来载有编程指令,而在塑料带上通过采用一系列的磁点来载有编程指令。塑料带强度比纸带强度要高很多,这就可以解决常见的撕坏和断裂问题。然而,它仍然存在着两个问题。其中最重要的一个问题就是,对输入带中的指令进行修改是非常困难的,或者是根本不可能的。即使对指令程序进行最微小的调整,也必须中断加工,制作一条新带。而且带通过阅读机的次数还必须与需要加工的零件个数相同。幸运的是,计算机技术的实际应用很快解决了数控技术中与穿孔纸带有关的问题。在形成直接数字控制(DNC)这个概念之后,可以不再采用纸带或塑料带作为编程指令的载体,这样就解决了与之有关的问题。在直接数字控制中,几台机床通过数据传输线路连接到一台主计算机上。操纵这些机床所需要的程序都存储在这台主计算机中。当需要时,通过数据传输线路提供给每台机床。直接数字控制是在穿孔纸带和塑料带基础上的一大进步。然而,它也有着与其他依赖于主计算机的技术一样的局限性。当主计算机出现故障时,由其控制的所有机床都将停止工作。这个问题促使了计算机数字控制技术的产生。微处理器的发展为可编程逻辑控制器和微型计算机的发展做好了准备。这两种技术为计算机数控的发展打下了良好的基础。采用 CNC 技术后,每台机床上都有一个可编程逻辑控制器或者微机对其进行数字控制。这可以使得程序被输入和存储在每台机器内部。它还可以在机床以外编制程序,并且将其下载到每台机床中。计算机数控解决了主计算机发生故障所带来的问题,但是它产生了另一个被称为数据管理的问题。同一个程序可能要分别装入十个相互之间没有通信联系的微机中。这个问题正在解决之中,它是通过采用局部区域网络将各个微机连接起来,以利于更好地进行数据管理。数控是可编程自动化技术的一种形式,通过数字、字母和其它符号来控制加工设备。数字。字母和符号用适当 格式编码为一个特定工件定义指令3程序。当工件改变时,指令程序就改变。这种改变程序的能力使数控适合于中,小批量生产,写一段新程序远比对加工设备做大的改动容易得多。 控机床有两种基本形式:点控制和连续控制。点控制机床采用异步电动机,因此,主轴的定只能通过完成一个运动或一个电动机的转动来实现。这种机床主要用于直线切削或钻孔、镗孔等场合。图 20-1 表明了一个点位控制运动从 X、Y、Z 坐标 2,0,0(点 a)到 0,1,3(点 d)的典型顺序。在本倒中,三个伺服电动机同时式作,当到达各自轴的适当位置时,就分别停机。运动从坐标 2,0,0(点 a)开始,三个电动机一起动作,将主轴带到 1,1,1(点 b)符近,此时 y 轴电动机停转。主轴续运动到 0,1,2(点 c)此时轴 x 电动机停转。最后,主轴在轴电动机带动下运动到 0,1,3(点 d),完成运动.点控制的数控机床是最简单、最便宜的。 图 20-2 对点位控制运动和连续控制运动进行了比较。在连续控制时,三个电动机按一定的速度比倒连续运转,形成从 A 到 D 的一条直线。连续控制的数控机床通常由计算机控制。 数控系统由下列组件组成:数据输入装置,带控制单元的磁带阅读机,反馈装置和切削机床或其它形式的数控设备。 数据输入装置,也称“人机联系装置” ,可用人工或全自动主法向机床提供数据,人工方法作为输入数据唯一方法时,只限于少量输入,人工输入装置有键盘、拨号盘,按钮,开关或拨轮选择开关,这些都位于机床附近的一个控制台上。拨号盘通常到一个同步解析器或电位订的模拟装置上。在大多数情况下,按钮、开关、和其他类似的旋钮是数据输入元件。人工输入需要操作者控制每个操作,这是一个既慢又单调的过程, 除了简单加工场合或特殊情况,已很少使用。 几乎所有情况下,信息都是通过卡片、穿孔纸带或磁带自动提供给控制单元。在传统的数控系统中,八信道空孔纸带是最常用的数据输入形式,纸带上的编码指令由一系列称为程序块的空孔组成。每一个程序块代表一种加工功能、一种操作或两者的组合。纸带上的整个数控程序由这些连续数据单元连接而成,带有程序的长带子像电影胶片一样绕在盘子上,相对较短的带子上的程序可通过将纸带两端连接形成一个循环而连续不断地重复使用。带子一旦安装好,就可反复使用而无需进一步处理。此时,操作者只是简单地上、下工件。穿孔纸是在带有特制穿孔符件的打字机或直接连到计算机上的纸带穿孔装置上做成的。纸带制造很少不出错,错误可能由编程、卡片穿孔或编码、纸带穿孔时的物理损害等开成。通常,必须要试走几次来排除错误,4才能得到一个可用的工作纸带。 虽然纸带上的数据自动进给的,但实际编程却是手工完成的,在编码纸带做前,编程者经常要和一个计划人员或工艺工程师一起工作,选择合适的数控机床,决定加工材料,计算切削速度和进给速度,决定所需刀具类型,仔细阅读零件图上尺寸,定下合适的程序开始的零参考点,然后定出程序清单,其上记载有描述加工顺序的编码数控指令,机床按顺序加工工件到图样要求。 控制单元接受和储存编码数据,直到形成一个完整的信息程序块,然后解释数控指令,并引导机床得到所需运动。 为更好理解控制单元的作用,可将它与拨号电话进行比较,即每拨一个数字,就储存一个,当整个数字拨好后,电话就被激活,也就完成了呼叫。 装在控制单元里的纸带阅读机,通过其内的硅光二极管,检测到穿过移动纸带上的孔漏过的光线,将光束转变成电能,并通过放大来进一步加强,然后将信号送到控制单元里的寄存器,由它将动作信号传到机床驱动装置。 有些光电装置能以高达每秒 1000 个字节的速度阅读,这对保持机床连续动作是必须的,否则,在轮廓加工时,刀具可能在工件上产生划痕。阅读装置必须要能以比控制系统处理数据更快的速度来阅读数据程序块。 反馈装置是用在一些控设备上的安全装置,它可连续补偿控制位置与机床运动滑台的实际位置之间的误差。装有这种直接反馈检查装置的数控机床有一个闭环系统装置。位置控制通过传感器实现,在实际工作时,记录下滑台的位置,并将这些信息送回控制单元。接受到的信号与纸带输入的信号相比较,它们之间的任何偏差都可得到纠正。 在另一个称为开环的系统中,机床仅由响应控制器命令的步进电动机驱动定位,工作的精度几乎完全取决于丝杠的精度和机床结构的刚度。在这个系统中,没有信息反馈到控制单元的自矫正过程。出现误动作时,控制单元继续发出电脉冲。比如,一台数控铣床的工作突然过载,阻力矩超过电机转矩时,将没有响应信号送回到控制器。因为,步进电机对载荷变化不敏感,所以许多数控系统设计允许电机停转。然而,尽管有可能损坏机床结构或机械传动系统,也有使用带有特高转矩步进电机的其他系统,此时,电动机有足够能力应付系统中任何偶然事故。 最初的数控系统采用开环系统。在开、闭两种系统中,闭环更精确,一般说来更昂贵。起初,因为原先传统的步进电动机的功率限制,开环系统几乎全部用于轻场合,最近出的电液步进电动机已越来越多地用于较重的加工领域。5Numerical ControlOne of the most fundamental concepts in the area of advanced manufacturing technologies is numerical controlled (NC).Prior to the advent of NC; all machine tools were manually operated and controlled. Among the many limitation of operator skills. With manual control, the quality of the product is directly related to and limited to the skills of the operator. Numerical control represents the first major stop away from human control of machine tools.Numerical control means the control means the control of machine tools and other manufacturing systems through the use of prerecorded, written symbolic instructions. Rather than operational instructions to the machine tool. For a machine tool to be numerically controlled, it must be interfaced with a device error accepting and decoding the programmed instructions, known as a reader.Numerical control was developed to overcome the limitation of human operators, and it has done so Numerical control machines are more accurate the manually operated machines, they can produce parts more uniformly, they are faster, and the long-run tooling costs are lower. The development of NC led to the development of several other innovations in manufacturing technology:1. Electrical discharge machining 2. Laser cutting.3. Electrin beam welding.Numerical control has also made machine tools more versatile than their manually operated predecessors. An NC machine tool can automatically produce a wide variety of parts, each involving an assortment of widely varied and complex machining processes. Numerical control has allowed manufacturers to undertake the production of products that would not have been feasible from an economic perspective using manually controlled machine tools and processes. Like so many advanced technologies, NC was born in the laboratories of the Massachusetts Institute of Technology. The 6concept of NC was developed in the early 1950s with funding provided by the U.S. Air Force. In its earliest stages, NC machines were able to make straight cuts efficiently and effectively. However, curved paths were a problem because the machine tool had to be programmed to undertake a series of horizontal and vertical steps to produce a curve. The shorter is the straight lines making up the steps, the smoother is the curve. Each line segment in the steps had to be calculated.This problem led to the development in 1959 of the Automatically Programmed Tools (APT) language. This is a special programming language for NC that uses statements similar to English language to define the part geometry , describe the cutting tool configuration, and specify the necessary motions . The development of the APT language was a major step forward in the further development of NC technology. The original NC systems were vastly different from those used today. The machines had hardwired logic circuits. The instructional programs were written on punched paper, which was later to be replaced by magnetic plastic tape. A tape reader was used to interpret the instructions written on the tape for the machine. Together, all of this represented a giant step forward in the control of machine tools. However, there were a number of problems with NC at this point in its development.A major problem was the fragility of the punched paper tape medium. It was common for the paper tape containing the programmed instructions to break or tear during a machining process. This problem was exacerbated by the fact that each successive time a part was produced on a machine tool, the paper tape carrying the programmed instructions had to be rerun through the reader , If it was necessary to produce 100 copies of a given part , it was also necessary to run the paper tape through the reader 100 separate times. Fragile paper tapes simply could not withstand the rigors of a shop floor environment and this kind of repeated use.This led to the development of a special magnetic plastic 7tape. Whereas the paper tape carried the programmed instructions as a series of holes punched in the tape, the plastic tape carried the instructions as a series of magnetic dots. The plastic tape was much stronger than the paper tape, which solved the problem of frequent tearing and breakage. However, it still left two other problems.The most important of these was that it was difficult or impossible to change the instructions entered on the tape. To make even the most minor adjustments in a program of instructions, it was necessary to interrupt machining operations and make a new tape, It was also still necessary to run the tape through the reader as may times as there were parts to be produced, Fortunately, computer technology became a reality and soon solved the problems of NC associated with punched paper and plastic tape.Te development of a concept known as direct numerical control (DNC) solved the paper and plastic tape problems associated with numerical control by simply eliminating tape as the medium for carrying the programmed instructions. In direct numerical control, machine tools are tide, via a data transmission link, to a host computer. Programs for operating the machine tools are stored in the host computer and fed to the machine tool as needed via the data transmission linkage. Direct numerical control represented a major step forward over punched tape and plastic tape. However, it is subject to the same limitations as all technologies that depend on a host computer. When the host computer goes down, the machine tools also experience downtime. This problem led to the development of computer numerical control.The development of the microprocessor allowed for the development of programmable logic controllers (PLCs) and microcomputers. These two technologies allowed for the development of computer numerical control (CNC). With CNC, each machine tool has a PLC or a microcomputer that serves the same purpose. This allows programs to be input and stored at each individual machine tool. It also allows programs to be developed off-line and downloaded at the individual machine tool. CNC solved the problems 8associated with downtime of the host computer, but it introduced another problem known as data management .The same program might be loaded in ten different microcomputers with no communication among them. This problem is in the process of being solved by local area networks that connect microcomputers for better data management. Numerical control (n/c) is a form of programmable automation in which the processing equipment is controlled by means of numbers, letters, and other symbols. The numbers, letters, and symbols are coded in an appropriate format to define a program of instructions for a particular workpants or job .When the job changes, the program of instructions is changed .The capability to change the program is what makes N/C suitable for low-and medium-volume production. It is much easier to write programs than to make major alterations of the processing equipment. There are two basic types of numerically controlled machine tools: point-to-point and continuous-path (also called contouring). Point-to-point machines use unsynchronized motors, with the result that the position of the machining head can be assured only upon completion of a moment, or while only one motor is running. Machines of this type are principally used for straight-line cuts or for drilling or boring.fig.20-1 illustrates a typical sequence of a point-to-point movement from xyz coordinates 2,0,0(point A)to 0,1,3(point D).In this example, all three servomotors would begin operating and then each would shut off as it reached the proper station for this axis. the action would start at coordinate 2,0,o(point A).The three motors operating together would carry the machining head to the vicinity of 1,1,1(point B),where the y motor would stop. The head would then continue to 0, 1, and 2(point C), where the x motor would stop. Finally, the head would complete its movement to 0,1,3(point D) under the action of motor Z. Machine tools with point-to-point system controls are the simplest and least expensive. A comparison of continuous-path motion to point-to-point motion is illustrated in Fig.20-2.In this example, the motors 9would run continuously at proportional speeds. A straight line would be generated from A to D .Machine tools equipped with continuous-path capabilities are normally operated by computers. The N/C system consists of the following components: data input, the tape reader with the control unit, feedback devices, and the metal-cutting machine tool or other type of N/C equipment. Data input, also called man-to-control link, may be provided to the machine tool manually or entirely by automatic means. Manual methods when used as the sole source of input data are restricted to a relatively small number of inputs. Examples of manually overstated devices are keyboard dials, pushbuttons, switches, or thumbwheel selectors. These are located on a comps; e mere tie , caromed. Dials are analog devices usually connected to a synchronic-type resolved or potentiometer. In most cases, pushbuttons, switches, and other similar controls for each operation. It is a slow and tedious process and is seldom justified except in elementary machining applications or in special cases. In practically all cases, information is automatically supplied to the control unit and the machine tool by cards, punched tapes, or by magnetic tape. Eight-channel punched paper tape is the most commonly used form of data input for conventional N/C systems .The coded instructions on the tape consist of sections of punched holes called blocks .Each block represents a machine function, a machining operation, or a combination of the two .The entire N/C program on a tape is made up of an accumulation of these successive data blocks. Programs resulting in long tapes are wound on reels like motion-picture film. Programs on relatively short tapes may be continuously repeated by joining the two ends of the tape to form a loop .Once installed, the tape is used again and again without further handling. In this case, the operator simply loads and unloads the parts. Punched tapes are prepared on typewriters with special tape-punching attachments or in tape punching units connected directly to a computer system. Tape production is rarely error-free, Errors may 10be initially caused by the part programmer, in card punching or compilation, or as a result of physical damage to the tape during handling, etc. Several trial runs are often necessary to remove all errors and produce an acceptable working tape. While the data on the tape is fed automatically, the actual programming steps are done manually. Before the coded tape may be prepared, the programmer, often working with a planner or a process engineer, must select the appropriate N/C machine tool, determine the kind of material to be machined, calculate the speeds and feeds, and decide upon the type of tooling needed. The dimensions on the part print are closely examined to determine a suitable zero reference point from which to start the program. Aerogram manuscript is then written which gives coded numerical instructions describing the sequence of operations that the machine tool is required to follow to cut the part to the drawing specifications. The control unit receives and stores all coded data until a complete block of information has been accumulated. It then interprets the coded instruction and directs the machine tool through the required motions. The function of the control unit may be better understood by comparing it to the action of a dial telephone, where, as each digit is dialed, it is stored. When the entire number has been dialed, the equipment becomes activated and the call is completed. Silicon photo diodes, located in the tape reader head on the control unit, detect light as it passes through the holes in the moving tape. The light beams are converted to electrical energy, which is amplified to further strengthen the signal .The signals are then sent to registers in the control unit, where actuation signals are relayed to the machine tool drives. Some photoelectric devices are capable of reading at rates up to 1000 characters per second. High reading rates are necessary to maintain continuous machine-tool motion; other-wise dwell marks may be generated by the cutter on the part during contouring operations .the reading device must be capable of reading data 11blocks at a rate faster than the control system can process the data. A feedback device is a safeguard used on some N/C installations to constantly compensate for errors between the command position and the actual location of the moving slides of the marching tool. An N/C machine equipped with this kind of a direct feedback checking device has what is known as a closed-loop system. P

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号