摘 要

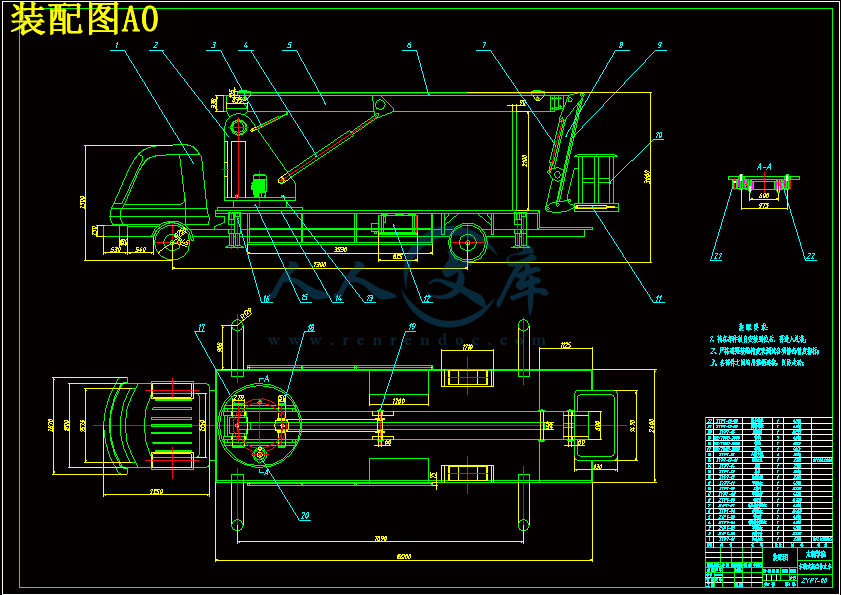

本课题首先对国内外高空作业车的发展进行了概括,提出了发展中的不足,简要介绍了高空作业车的组成,然后对目前国内生产技术不完善的混合臂和伸缩臂式高空作业车的关键结构进行了设计,同时对工作斗调平技术和液压系统等关键技术进行了研究分析。重点研究了伸缩臂的结构、运动特点,并对其进行了强度校核。根据高空作业车安全性要求高,工作幅度大,结构复杂等特点,提出了工作臂、副车架以及工作斗调平机构的研究设计方法。该课题以混合臂式高空作业车为研究对象,详细阐述了伸缩臂的结构设计、变形研究;副车架结构设计、工作稳定性分析;高空作业车的工作斗调平系统的研究分析;液压系统的设计计算。课题采用积分法对伸缩臂结构进行应力分析、变形分析。最后,对研究分析结果进行了试验和验证,将试验结果和理论分析结果进行了对比,通过对比分析进一步验证了本文提出的设计方法,对于同类型高空作业车研究计算,具有一定的参考价值。

关键词 :高空作业车;结构设计;调平系统研究;液压缸

Abstract

This paper arranged as follows. The first part is the summary of the development of aerial working platform at home and abroad, and put forward some shortages during the development. There is a brief introduction of the component parts of the aerial working platform. This paper introduces a new design proposal of the domestic production technology of mixing arm and telescopic arm aerial working platform. Meanwhile, the analysis can also be seen in the working bucket leveling, hydraulic systems and other key technology. This paper mainly focuses on the telescopic structure, movement characteristics, and its strength check. According to the special requirements of aerial vehicles because of the high security, large in range and the complicated structure, the special design was used in the working arm, subframe and bucket leveling institutions. The subject is based on the study of mixing arm of aerial working platform. The subject describes the structural design of the telescopic boom in detail, and analysis the design of subframe structure design and the job stability. The aerial working platform bucket leveling system analysis and hydraulic syetem design are also mentioned here.the subject adopts integration method on the telescopic structure stress analysis and deformation analysis. The results of research and analysis are also compared in this part. The new design method is created through comparative analysis. And it is an useful guideline for the same type of aerial working platform.

Key words: Aerial working platform; Structure design; The research of leveling system; The hydraulic cylinder

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1本课题的研究内容和意义 1

1.1.1 课题研究背景 1

1.1.2 课题研究的意义 1

1.2 高空作业机械的国内外发展概况 1

1.2.1 高空作业机械的国外发展状况 1

1.2.2 高空作业机械的国内发展状况 2

1.3 高空作业车的组成 2

1.3.1 专用底盘 2

1.3.2 工作臂架 3

1.3.3 三维全旋机构 3

1.3.4 电气与液压系统 3

1.3.5 安全装置 3

1. 4 课题研究的内容 4

2伸缩臂结构分析 5

2.1 伸缩臂的结构 5

2.2 工况分析 6

2.3 伸缩臂强度计算分析 6

2.3.1 危险工况 1 计算 7

2.3.2 危险工况 2 计算 7

2.4 伸缩臂变形计算 8

2.4.1 力学模型的建立 8

2.4.2 弹性位移的计算 9

2.4.3 计算结果 12

2.5 伸缩臂强度校核 12

2.5.1 计算基本臂臂的截面尺寸 14

2.5.2对下臂进行正应力校核 15

2.6 本章小结 16

3 副车架结构及分析 17

3.1 副车架结构 17

3.2 支腿反力的计算 17

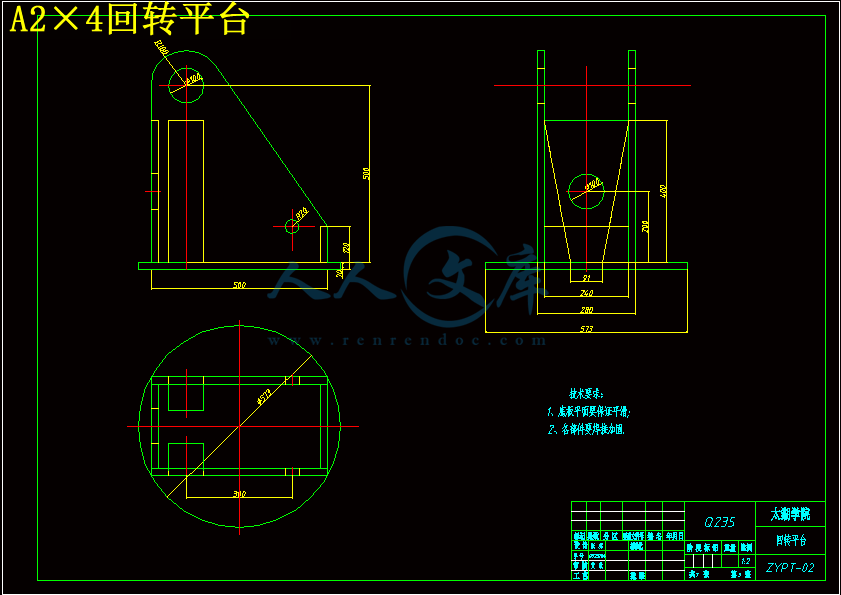

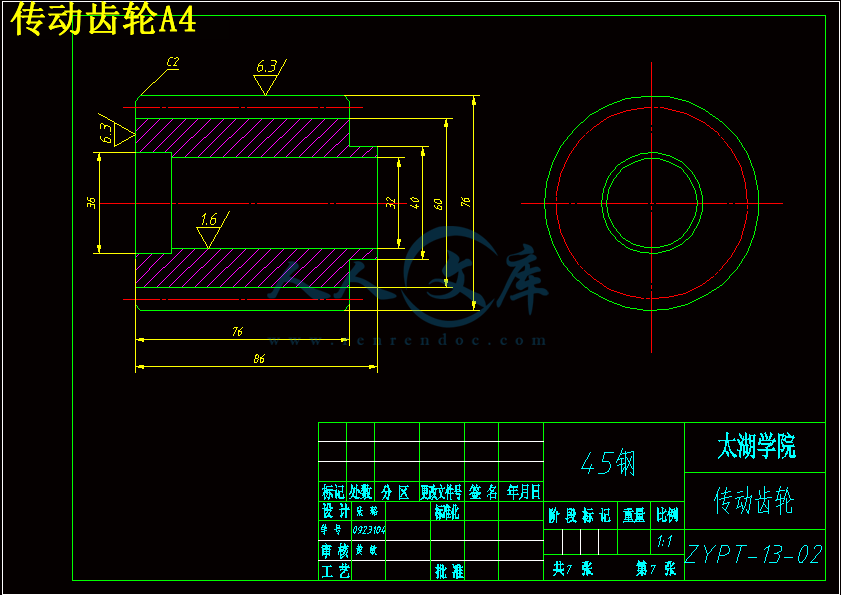

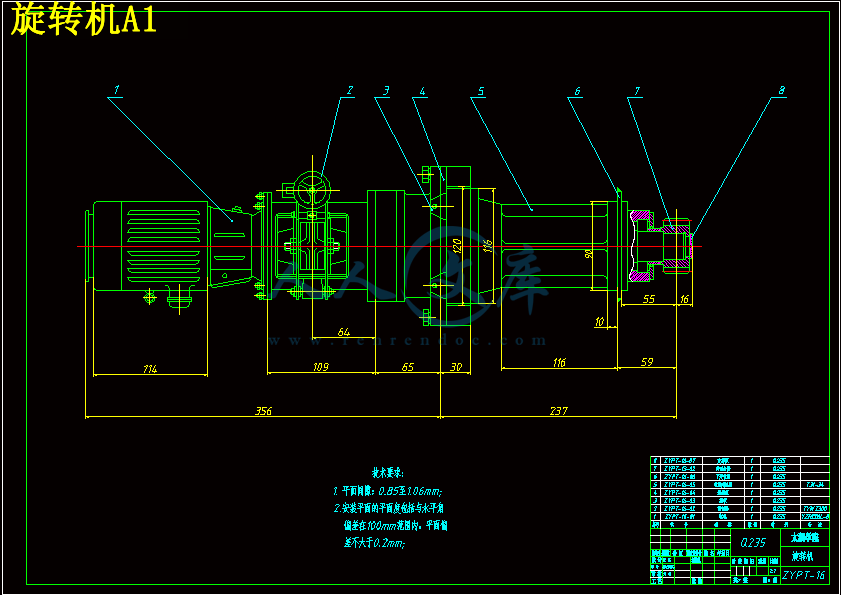

3.3 转台回转系统 21

3.4 本章小结 22

4 工作斗调平机构的研究 23

4.1 工作斗调平结构模型 23

4.2调平机构液压系统 25

4.3 本章小结 26

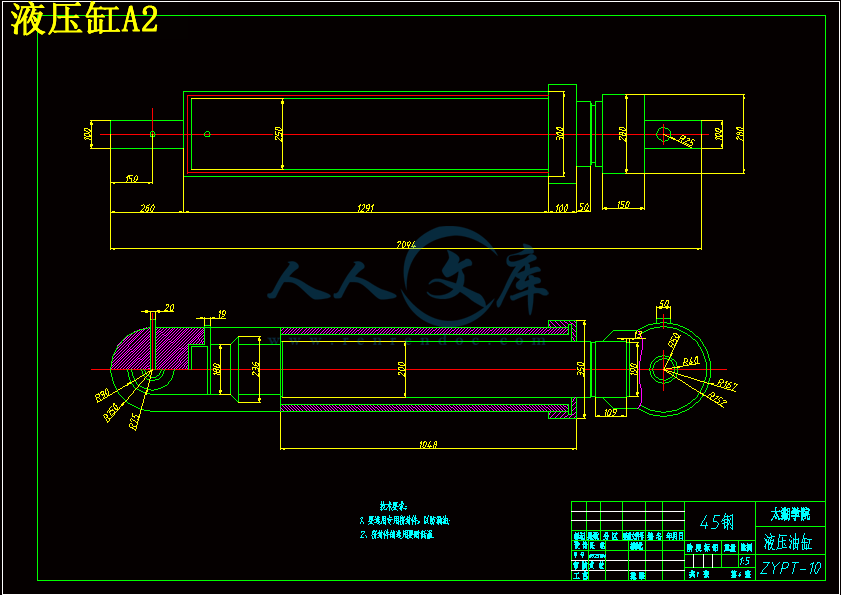

5液压油缸的设计计算 27

5.1 伸缩变幅油缸的结构 27

5.2 伸缩变幅油缸的设计计算 27

5.2.1 确定液压缸类型和安装方式 27

5.2.2 确定液压缸的主要性能参数和主要尺寸 27

5.3 本章小结 31

6 结论与展望 32

6.1 结论 32

6.2 展望 32

致 谢 33

参考文献 33

附 录 33

1 绪论

1.1本课题的研究内容和意义

1.1.1 课题研究背景

现如今我国经济的飞速发展以及政府对基础设施建设的力度逐渐增大,高空作业平台的需求量不断增加,市场前景非常广阔。然而由于我国对于高空作业平台的研究开发起步较晚,对其核心技术掌握的不足以及加工工艺的落后等方面的原因,使得我国高空作业产品的使用功能、安全性等方面得不到充分的质量保证。通过对目前高空作业产品市场的发展趋势和广泛的市场研究,发现国内产品具有类型单一、设计粗糙等缺陷,无法满足很多特殊施工环境的要求[l],因此我国高空作业设备大多依赖进口。虽然国外产品功能完善、性能比较优秀,但是由于价格太高,对很多建设公司或者施工方来说成本占用比例过大,使得利润空间降低。因此,研发生产属于我国自主品牌的高性能的高空作业平台有着极其重要的经济价值和战略意义。

高空作业平台是用来运送工作人员和工作装备到指定高度进行作业的一种大型工程机械设备,并广泛用于电力、路灯、市政、园林、通信、机场、造(修)船、交通、广告、摄影等高空作业领域。国家标准GB3608.93《高处作业分级》规定:VL在坠落高度基准面2m以上(含2m)有可能坠落的高处进行作业,都称为高处作业。"因此为保障工人在高处作业的安全性,出现了越来越多的高空作业设备,然而随着科技的发展和人们对使用要求的增加,传统的高空作业设备已经无法满足人们的需求,专用高空作业平台技术在最近几十年来得以快速发展。

1.1.2 课题研究的意义

随着社会的进步和发展,人们对于产品的人性化要求越来越高,因此在产品结构设计的过程中应坚持人性化思想[2],以人机工程学原理为指导充分分析研究产品各方面因素,提出相应的设计方案。本课题在充分研究产品性能的基础上,对高空作业平台的功能模块进行了充分的结构分析,并根据其各方面的特殊性提出了相应的设计要求,指导其结构设计,因此课题研究的意义主要体现在以下几个方面:

(1)通过本课题的研究,掌握混合臂高空作业车金属结构件的设计理论和分析方法,了解高空作业车结构件的工作规律,从而达到减轻自重、优化结构、提高可靠性的目的,为研制系列伸缩臂、混合臂高空作业车奠定良好的基础。

(2)对车载式高空作业平台进行模块划分,将其分为工作平台、操作系统、运动系统和支持系统几个部分进行分别研究,对每一部分进行充分的结构分析,结合产品的相关标准和设计原则,对其结构设计进行指导。在课题的研究过程中结合产品的使用功能,通过计算机建模,在保证实现基本功能的基础上,总结相应的外观设计理论,以指导后续系列产品的结构设计,同时对于其它机械产品的外观设计研究具有一定的理论指导意义。

1.2 高空作业机械的国内外发展概况

1.2.1 高空作业机械的国外发展状况

高空作业车发展起步较早的欧美等发达国家和地区,从20世纪20年代就开始研制,发展历史久远,生产技术也很成熟,具有生产技术水平高、作业车的作业高度大、规格齐全、结构型式丰富、功能多样等优点。总体来看,技术和市场均已很成熟,产品能够进行高空作业、抢险、救援、消防等复杂工作,作业平台的最大载荷可达500kg,最大作业高度已经超过100m,这是我国目前无法设计达到的高度,同时具有各种安全保护措施,很好的保障了工人的安全。大型产品特点是科技含量高、研制与生产周期较长、投资大、市场容量有限,但市场竞争相对较少,产品的利润相对较高。如美国Genie公司、JLG公司和法国HAULOTTE公司在高空作业平台产品都形成了系列化,与此同时,产品更新换代的周期明显缩短。这大大提高了企业在国际市场中的竞争能力和企业的抗风险能力。

川公网安备: 51019002004831号

川公网安备: 51019002004831号