摘 要

随着工业生产的迅速发展,固体定量给料系统作为一项实用型的技术被广泛应用于冶金、化工、水泥、建材和食品等工业领域。在这样的环境下定量给料机的需求量日益增大。本系统采用电磁阀和流量计给料机作为定量给料设备,给料机采用控制流量来达到定量给料的目的。定量给料系统的PLC控制系统是机电一体化发展的必然结果。

本论文针对定量给料机的特点,并PLC控制技术,对定量给料系统进行的研究,其主要内容如下:

1、了解定量给料机控制系统的工作原理;

2、掌握PLC的硬件构成,工作原理,完成对PLC的选型;

3、设计定量给料机的控制系统;

4、用STEP7完成对控制系统的编程。

关键词:给料;定量;PLC;控制系统。

Abstract

With the rapid development of industrial production,the solid constant feeding system which is a practical technology has been widely used in metallurgy, chemicals, cement, building materials, food and as well as other industry circles. So, in this situation, the demand of constant feeder is increasingly augmented. This system adopts the electromagnetic valve and flowmeter feeder as the constant feeding device, the feeder achieves the goal of constant feeding by controlling the flow. The PLC control system of constant feeding system is the inevitable outcome of the development of mechatronics.

This article focuses on the characteristics of constant feeder, and PLC control technology, studies the constant feeding system. The main contents are as follows:

1、Understand the operating principle of the constant feeder control system ;

2、Master the PLC hardware structure, working principle, finish the selection of PLC type ;

3、Design the control system of constant feeder ;

4、Finish the programming of the control system with STEP7.

Key words: Feeding;Dosing ;Programmable Logic Controller;The control system.

目 录

摘 要 III

Abstract IV

目 录 V

1 绪 论 1

1.1 课题背景 1

1.2 定量给料机国内外发展情况 1

1.2.1 给料系统的分类 1

1.2.2 计算机控制系统 2

1.2.3 自动给料系统特点 3

1.3 课题意义 3

1.4 课题主要内容 3

2 定量给料机的总体方案 5

2.1 给料部分总体方案、基本原理 5

2.2 完成给料的运动分析 7

2.3 定量给料机的总体设计 7

2.4 本章小结 8

3 PLC控制系统的介绍和选择 9

3.1 PLC的概述 9

3.2 西门子PLC简介 10

3.2.1 西门子PLC简单介绍 10

3.2.2 西门子PLC的组成 10

3.3 PLC的工作原理 14

3.4 本章小结 14

4 控制系统的设计 15

4.1 控制系统元件的选择 15

4.2 绘制电气原理图 19

4.3 控制程序的设计 20

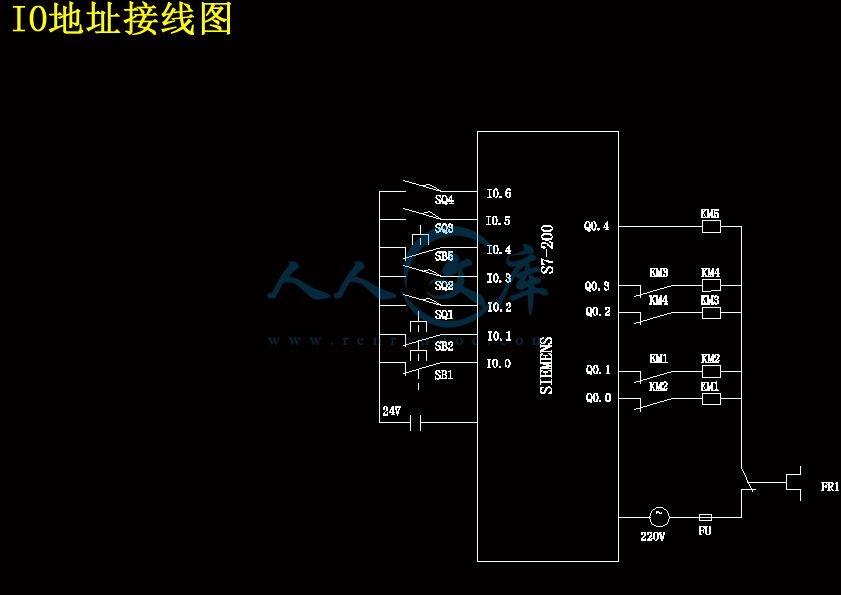

4.3.1 I/O分配表 20

4.3.2 接线图 21

4.4 本章小结 22

5 控制系统的编写 23

5.1 STEP7的介绍 23

5.2 系统程序流程图 23

5.3 梯形图的绘制 24

5.4 本章小结 30

6 总结 31

6.1 全文总结 31

6.2 需要提高、改善的方面 31

致 谢 32

参考文献 33

1 绪 论

1.1 课题背景

随着工业生产的迅速发展,导致了定量给料机的需求量日益增大。定量给料系统的单片机控制系统是机电一体化发展的必然结果。现今以应用工业计算机、PLC的自动配料技术已广泛应用于耐火、玻璃、水泥、医疗、建材、饲料、炼钢、筑路及包装生产等各种行业中。日用品中用的洗发液,洗衣粉/剂,灭虫剂等等均为配方产品。[1][2]以前在这类控制中大多是以继电器,接触器等电器设备来完成每一步的顺序控制,自动化程度低,而且许多地方都需要人来手动完成,不仅工作效率低控制精度也难以提高。特别是随着现代化生产的不断进步,更是对应用于过程生产中的各种自动化控制系统提出了更高的要求。配料工序是企业生产工艺过程中的一道非常重要的工序,配料工序对整个生产过程有非常大的影响,因此实现高精度自动配料对工业企业生产有极为重要的意义。另外对于一些现有的中小企业,特别是一些中小型的冶金企业由于建设之初的自动化水平低或者设备已经老化陈旧,造成对资源的浪费,环境的污染,同时也加大了工人的劳动强度。因此对一些落后的中小企业的自动化改造也是急需解决的问题。

当现代社会工业控制现场比较有代表性的定量给料系统的生产厂家有德国布莱本达公司和美国开创公司。这两家公司在中国有着成功的案例,由于垄断性和出于技术性的保密,要购买他们的产品投入需要很高,且不方便后期的维护。此定量给料系统是以提高系统的使用广泛性、低维护成本、投入低、可操作性相对较强的这些原则来进行设计和实现,到最后实现一个低成本,易于维护的定量给料系统。

1.2 定量给料机国内外发展情况

定量给料多种多样。从供给物料的连续性上看,可以分为间歇式和连续式两种给料系统;从供给物料的方式上看有体积式给料系统和质量(重量)式给料系统;从给料器的工作原理上分可以分为失重式给料和增重式给料;从供给物料的特性上看可以分为粉料、粒料(固态)、液体、混合体的给料[3]。

以下的篇幅对几种常用的给料系统做简单的介绍。

1.2.1 给料系统的分类

1. 间歇式给料系统

间歇式给料系统是一种不连续的给料系统。

在正常的情况下,机械不能生产连续化的产品。比较适合小批量的产品,也适合在小的场合使,比如说小型的企业、或者实验室。这种系统自动化程度不高,对机械的要求不高,操作比较复杂,必须有很大的工作量,要大量人力,由于这样操作易于受人为因素影响,所以不容易控制批次的质量,成品之间存在较大的差异性。这样的系统比较难以实现大批次的生产。生产初期投资较少,但是后续会出现很多问题。

2. 连续式给料系统

连续式给料系统运作方式是用连续式给料器给下面的机械设备供给物料的。它所必需采用的设备是连续式给料器,如固态物料流量计,自动给料器等。这种给料机常见的的工艺是使用几台连续式给料器,按照一定的已经设定好的量,让各种物料下游设备。

这种机械方面较复杂,有较高的自动化,精度比较高,操作比较方面,对人力的需求量比较小,质量稳定,适用于大批量生产和各方面的要求都较高的地方,大的规模生产具有配方的食品,对精度要求比较高的实验设备等。这样的加料方法不太受人为影响,生产出来的质量比较稳定。

3. 体积式给料系统

体积式给料系统的运作原理是对下面的机械按照单位时间内的流量而给料的的系统。

料体在特定转速/流速等下给料系统通过测试这些来计算出产量,然后算出体积式给料器的给料量与转速/流速的函数曲线。参照这条曲线函数,可以得出所需的给料量所对应的给料器的转速/流速等,让料体定量给到下面的设备产品机械。

这样的系统设备相对不复杂,有比较简单的操作,需要较少的设备,投资量不大,适合连续运行。但是此系统要求物料的堆积密度相对稳定,对机器的调试很不方便,精度比较低,约 5-10%,不能满足高要求产品生产的要求。

川公网安备: 51019002004831号

川公网安备: 51019002004831号