摘要:气流输送技术是一项综合技术,涉及流体力学、材料力学、自动化技术、制造技术等领域,属高新技术项目。气流输送的应用已有100多年的历史,早在1853年邮局就用来输送信件,1883 年港口用于装卸粮食,到20 世纪初开始用于工业生产。近年来,随着生产发展和生产过程日趋自动化,对节约能源和环境保护的要求越来越高,气流输送技术凭借自身的技术特点得到了迅速发展和应用。在不断地探索和创新过程中,气流输送的对象从早期的谷物,面粉和信件迅速扩展到水泥,砂料,化工原料,煤粉等物料。应用的范围遍及粮食,港口,化工,冶金,电力,铸造,食品,医药等领域。输送方式从原始到如今完善,合理,从稀相悬浮输送到浓相浓度的栓流输送,初步解决了气流输送能耗高,管道磨损及物料破碎等问题,提高了气流输送技术的可靠性和经济性。

本文通过对原始材料的分析,采用了吸送式气流输送。吸送式气流输送装置在气流输送技术中是一种较早发展起来的输送方式,目前在世界上使用十分广泛,这是因为它除了具有广泛适应条件外还有许多突出的优点:生产率高,结构简单紧凑,操作灵活方便易实现自动化等。

根据其原始材料,计算其输料管内径,确定输送风速及其风量,同时要计算系统中各项的压力损失。在这些都确定的情况下,根据上述分析计算结果选定适合的风机及其配备电动机,确定确实合理的管道布置方式,最后得出整套输送装置。

关键词: 吸送式气流输送 输料管内径 压力损失

目 录

1 绪论

1.1 气流输送简介与发展……………………………………………………… (01)

1.2 气力输送的类型和特点………………………………………………………(02)

1.3 气力输送系统的主要部件和设备……………………………………………(02)

1.4 选本课题的依据和意义………………………………………………………(03)

1.5负压气流输送的发展概况……………………………………………………(04)

1.6选本课题的依据和意义………………………………………………………(05)

2 吸送式气力输送

2.1 类型……………………………………………………………………………(06)

2.2 系统组成………………………………………………………………………(07)

2.3 技术特点………………………………………………………………………(07)

3 系统的设计计算

3.1 设计的原始材料………………………………………………………………(09)

3.2 设计程序………………………………………………………………………(09)

3.3 计算方法………………………………………………………………………(10)

4 主要部件

4.1 管道和管件……………………………………………………………………(22)

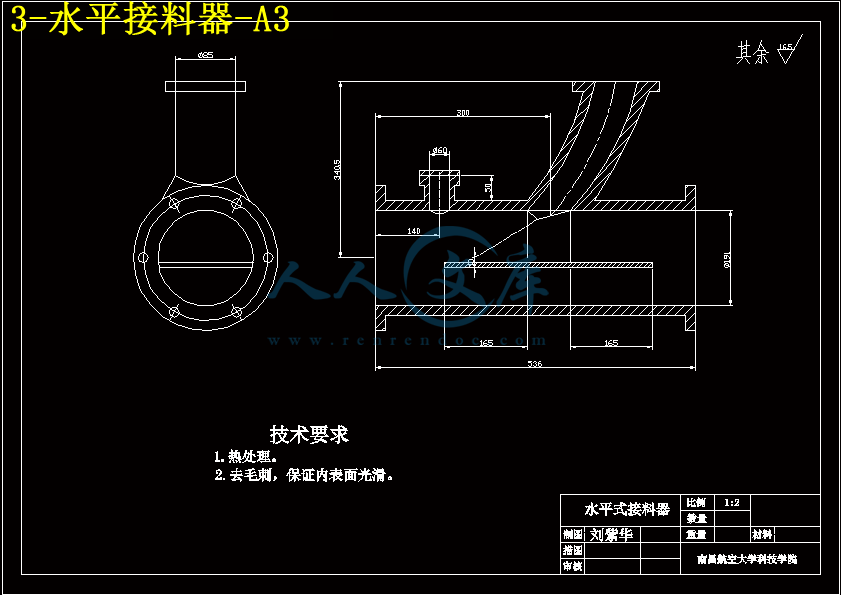

4.2 供料装置………………………………………………………………………(24)

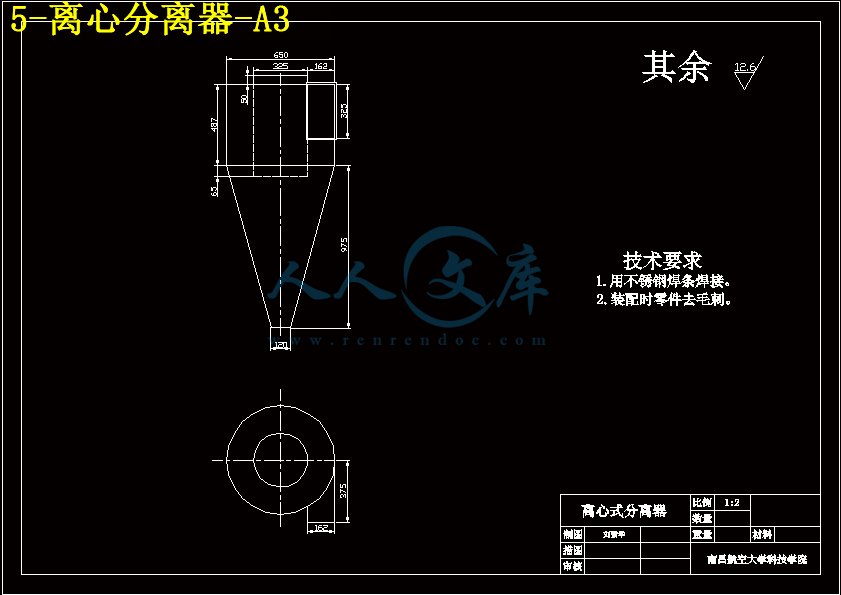

4.3 物料分离器……………………………………………………………………(24)

4.4 除尘器…………………………………………………………………………(27)

4.5 卸料器…………………………………………………………………………(28)

结 论…………………………………………………………………………………(32)

参考文献……………………………………………………………………………(33)

致 谢…………………………………………………………………………………(34)

气流输送系统

1 绪 论

1.1 气流输送的概况

气流输送(又称气力输送),即利用气流的能量,在密闭管道内沿气流方向输送颗粒状物料,是流态化技术的一种具体应用。气流输送装置的结构简单,操作方便,可作水平的、垂直的或倾斜方向的输送,在输送过程中还可同时进行物料的加热、冷却、输送和气流分级等物理操作或某些化学操作。与机械输送相比,此法能量消耗较大,颗粒易受破损,设备也易受磨蚀。含水量多、有粘附性或在高速运动时易产生静电的物料,不宜于进行气流输送。当人们从自然风力吹石卷尘和日常生活中见的吮吸现象得到启示后,就设想到利用气流在管道中运送物料。基于这个想法,早在1810年英国Medhurst就提出了利用管道将邮件作气流输送的方案。因此,气流输送技术乃始于成件物品的筒式输送。数十年后气流输送才开始用来卸送谷物,棉花等散状物料,出现了第一台浮船式气流卸船设备以及固定式的吸粮机设备。这些气流卸船设备问世之后曾经在欧洲各国,特别是在当时的粮食输入大国,如英国,荷兰,德国等获得了应用和普及。

气流输送具有防尘效果好;便于实现机械化、自动化,可减轻劳动强度,节省人力;在输送过程中,可以同时进行多种工艺操作,如混合、粉碎、分选、输送、冷却;防止物料受潮、污染或混入杂物等优点,因而在铸造、冶金、化工、建材、粮食加工等部门都得到应用。近年来,气流输送技术在以往低压气流输送和高压输送技术的基础上进一步开拓应用。例如,将粉料喷吹送入高温熔化的液态金属中;利用港口吸卸谷物的吸粮机原理将气流输送技术用语高温熔渣的吸出清理;对以往难以输送物料的输送技术;磨损性大的物料的输送技术以及塑料成形体中物件的输送技术等。

我国从1985年就在港口对气流输送技术进行研究实验并应用于卸船,其他各行业也开发了多种形式气流输送装备在生产上获得了应用。如建立了风送系统的面粉厂,气流输送烟丝,铸造车间型砂气流输送技术也逐渐发展起来。

除此之外,我国其他行业中气流输送的发展也很快,铸造车间中的型砂,新砂,旧砂,煤粉和粘土粉等造型材料均已实现了气流输送,特别是近年来新一代低风速高混合比气流输送装置的开发和成功应用使我国的气流输送技术水品有很大的提高。 我国早已成立中国机械工程学会物料搬运专业分会,并设立了管道物料输送技术专业委员会。在各行业和地方还成立了粮食、铸造行业的气流输送等专业学组,这一切均将促进气流输送技术在我国的应用和进一步发展。

1.2 气流输送的分类

根据颗粒在输送管道中的密集程度,气流输送分为:①稀相输送。固体含量低于100kg/m3或固气比(固体输送量与相应气体用量的质量流率比)为0.1~25的输送过程,操作气速较高(约18~30m/s)。②密相输送。固体含量高于100kg/m3或固气比大于25的输送过程。操作气速较低,用较高的气压压送。间歇充气罐式密相输送。是将颗粒分批加入压力罐,然后通气吹松,待罐内达一定压力后,打开放料阀,将颗粒物料吹入输送管中输送。脉冲式输送是将一股压缩空气通入下罐,将物料吹松;另一股频率为20~40min-1脉冲压缩空气流吹入输料管入口,在管道内形成交替排列的小段料柱和小段气柱,借空气压力推动前进。密相输送的输送能力大,可压送较长距离,物料破损和设备磨损较小,能耗也较省。

川公网安备: 51019002004831号

川公网安备: 51019002004831号