资源目录

压缩包内文档预览:

编号:6039708

类型:共享资源

大小:1.66MB

格式:ZIP

上传时间:2017-10-27

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

小型

气动

压力机

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

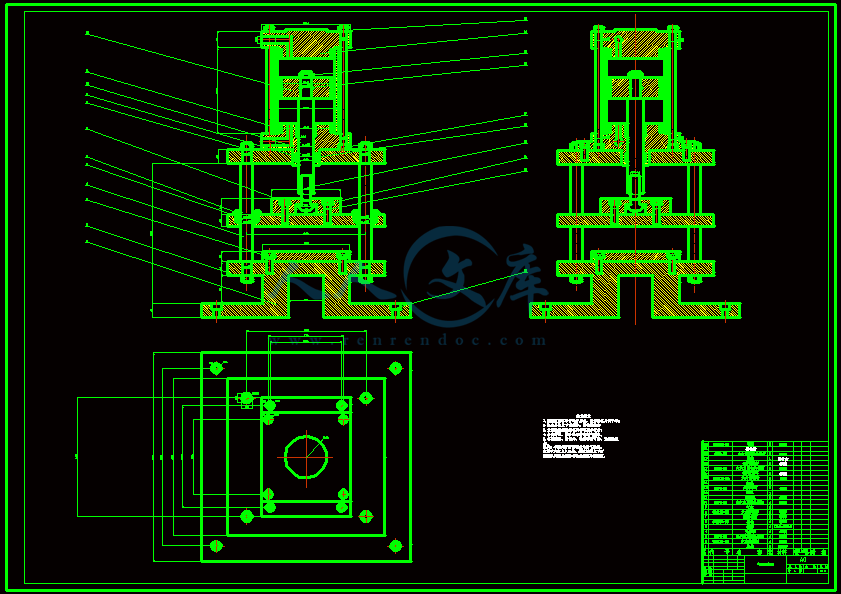

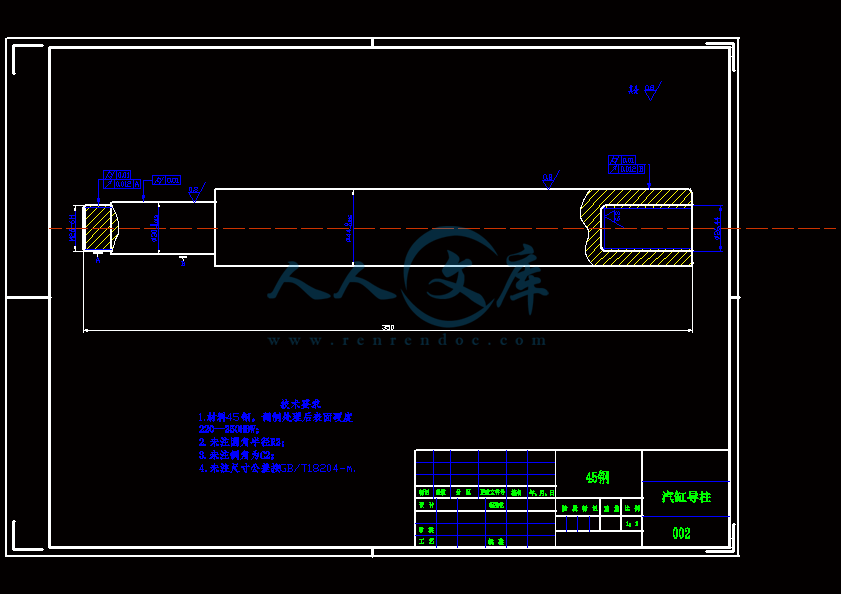

(本科毕业设计论文)毕业设计(论文)外文资料翻译附件:1.外文原文 2.外文资料翻译译文2014 年 6 月电动螺旋压力机的发展概况1 概述螺旋压力机是一种历史悠久的锻压设备,具有较人的能容量,结构简单、调整和维护简便、没有固定的下死点,能保证模锻件精度的稳定性。广泛应用于金属模锻、精压、冲压工艺以及耐火材料、陶瓷等非金属材料的压力加工。螺旋压力机的设备投资、模具和锻件成本比模锻锤和热模锻压力机便宜一半,加工余量小、锻件精度高。现代螺旋压力机相继采用了超载保护、力能显示、能量预选及先进的计算机控制系统和自动送料、模具更换等辅助装置。理论和实践都证明螺旋压力机工艺适应性广、生产率适中、劳动条件好,己成为现代锻压生产优选设备之一。国内外相关企业都十分重视螺旋压力机的开发与应用。青岛青锻锻压机械有限公司开发研制了 80MN 摩擦螺旋压力机,经查证为目前国内外最大规格的同类设备。由于摩擦压力机传动效率低、功率损耗较大和结构上的限制,规格发展受到了影响。随着科学水平的不断提高,螺旋压力机的结构形式及传动形式己经有了很大的改进。除了机械式摩擦传动以外,又采用了新的传动形式,如离合器式螺旋压力机、液压螺旋压力机和电动螺旋压力机等。这不仅提高了螺旋压力机的实用性、工作速度、生产率和可靠性,打击力和能量也得到了很大的发展。如电动螺旋压力机打击力己达到 320MN,能量达到 5000kJ 以上。电动螺旋压力机自上世纪 40 年代研制成功以来,在国内外得到了广泛响应。我国上世纪 80 年代由青岛青锻锻压机械有限公司与山东工业人学成功研制生产出了 J58- 160 型 1.6MN 电机直驱式电动螺旋压力机,但因当时电力条件和控制技术的限制而中断了进一步的研发工作,十分可惜。近年来,随着科技发展,变频技术和电子数控技术的不断提高,电动螺旋压力机的开发创新、生产制造己全面展开,华中科技人学、青岛青锻锻压机械有限公司等,都相继拥有了自己的技术和产品并迅速地推向市场。电动螺旋压力机己成为目前最具生命力的螺旋压力机产品。2 电动螺旋压力机的结构原理2.1 电机直驱式电动螺旋压力机电机直驱式电动螺旋压力机所用的电动机是特制的,其定子壳体坐在压力机机架的顶端,转子轴的上端由定子壳体支撑,下端紧固在压力机飞轮上。飞轮与螺杆采用键连接由推力轴承支撑在机架上,飞轮具有超载保护装置。制动器为抱闸形式,制动飞轮的外缘,通气松开,断气制动。电机的热量靠压力机顶部的风扇排走。压力机的机架结构采用预应力组合机架,由拉杆将上横梁、立柱和底座预紧为一体,使其具有足够的刚度。螺母装在滑块上,滑块采用四股导轨与机架立柱上的导轨配合。压力机可根据需要配置上下顶料装置。电机直驱式压力机传动链短,电机驱动飞轮旋转没有任何传动损失。工作时,风扇转动、制动器松开,同时主电机驱动压力机飞轮使螺杆定轴旋转,通过安装在滑块上的螺母将螺旋运动转换为直线运动,使滑块加速下行,主电机达到预先设置的打击能量所要求的转速时,利用飞轮储存的能量做功,使坯件成形。飞轮能量释放后,主电机反转,滑块上行,当滑块到达设定的位置时电机自身制动,制动器只是在主电机断电时抱住飞轮,制动力矩很小。2.2 经一级齿轮传动的电动螺旋压力机电动压力机的另一种形式是经一级齿轮传动,即电机轴上装有一个小齿轮驱动大齿轮正反旋转,大齿轮(即飞轮)与螺杆连接作定轴转动,带动装在滑块上的螺母使滑块做上卜直线运动实现打击。这种形式的压力机可由多台电机同时驱动大齿轮,因此可做到规格很大,目前世界最大吨位达 320MN,远远大于其他模锻设备的吨位,受到锻造业的青睐。目前,这种压力机采用的电机种类和控制尚不统一,应用比较多的是 ABB 变频器控制三相异步交流电动机,运用直接转矩控制。国内用电动机人致有三类:一类是变频器控制交流异步电动机,另一类是变频器控制交流伺服电动机,都是运用矢量控制技术,但两种变频器不一样。还有采用开关磁阻电动机的,但需匹配专用的控制器。上述变频器控制交流伺服电动机成本偏高,在大吨位压力机上极少使用。3 电动螺旋压力机的控制系统电动螺旋压力机的优点是能量大小可调。飞轮角速度 直接影响能量,因此,在打击过程中,控制能量的大小也就是控制角速度 的大小。青锻公司采用日本安川变频器控制特制交流异步电动机,运用矢量控制技术,电机采用编码器反馈,速度控制精度提高,从而控制能量更加精确。矢量控制技术可在极短时间内让电机达到额定转矩,适应电动螺旋压力机低速大扭矩的要求。可通过输入 0 10V 的电压信号或 4mA mA 的电流信号对应电动机速度,从20而控制能量大小 。(1)硬件设计控制系统以可编程序控制器 K7M- DR40U 为核心,辅以数字量输入/ 输出、模拟量输入/输出扩展模块,再加上外围的控制电路和控制对象。 CPU 模块通过通讯接口与触摸屏进行通讯,触摸屏负责数据的显示和必要的参数设定;开关量输入/输出模块主要负责一些开关信号的控制,模拟量输入/输出模块主要负责打击力的控制;模拟量模块产生打击力指令信号,打击力通过触摸屏显示出来,变频器采用矢量控制方式控制电机运转,电动机通过传动机构带动压力机滑块实现上下往复运动。控制系统运行时,通过安装在机身上的接近开关检测滑块的位置,并根据各接近开关信号发出一系列控制指令,满足各种操作要求。( 2)软件结构软件系统在 KGL -WC 环境下采用梯形图编写。根据螺旋压力机控制系统的要求,将主程序分化为多个子程序模块,各模块实现各个功能,以便识别和修改。控制程序对手动和运行分别进行控制。下行打击时,变频器正向运行触点闭合,电动机以设定好的加速时间使其达到设置的速度,此时滑块加速运行,达到打击工件所需的能量(根据不同工件调节安装在机身上接近开关的位置),切断变频器正向运行触点,滑块自由下滑打击工件,并在打击完毕后接受同程接近开关发出的信号;如果下行打击工件尚未达到所需能量,此时滑块己到达下死点,为保护设备及变频器必须断开运行信号。程序接受到滑块同程信号后,变频器反向运行触点闭合,电动机以设定好的速度加速反向运行,到达一定的位置断开变频器反向使能,刹车制动,一次打击完成。4 电动螺旋压力机的特点电机直接驱动形式的电动螺旋压力机,不存在电机与飞轮传动损失。除此之外,无论哪种驱动形式的电动螺旋压力扫 L 都具有以下特点 : 结构简单、紧凑,传动链短,操作维修方便,检修工作量小,节约工时和维修费用,运行安全;打击能量可精确控制,可根据锻件成形工艺调整打击力和打击能量,锻件成形精度高,模具应力小,模具使用寿命长;采用先进的电动机驱动电气控制技术,压力机工作时,不会对电网产生冲击和影响其他设备的正常运行;滑块静止时,主电机不工作,电量消耗低,节约能源;无固定下死点,不必调整模具高度,不会产生闷车现象;可方便地调整行程高度,同程位置准确 ;与液压螺旋压力机相比,不需复杂的液压驱动设备,不存在液压油泄漏污染环境和出现液压故障问题;与摩擦螺旋压力机相比,无摩擦盘、横轴等中间传动装置和摩擦带易损件,零部件少,可靠性高,精度好。5 结束语电动螺旋压力机作为一种高效、节能、环保的新型锻压设备,已在高精度发动机、汽轮机的叶片,齿轮等重要零件的毛坏锻造和精密锻造中得到广泛应用。 现代螺旋压力机相继采用了超载保护、力能显示、能量预选及先进的计算机控制系统和自动送料、模具更换等辅助装置。理论和实践都证明螺旋压力机工艺适应性广、生产率适中、劳动条件好,已成为现代锻压生产优选设备之一。随着汽车、船舶、航空、航天等工业的发展,电动螺旋压力机的应用领域还会不断扩展。电动螺旋压力机虽已发展到了一个良好的阶段,但其理论系统尚未完善,控制技术也在不断探索,相信在业内开发机构和生产企业的不断创新努力下,电动螺旋压力机的发展前景一定会更加光明。近年来,随着科技发展,变频技术和电子数控技术的不断提高,电动螺旋压力机的开发创新、生产制造已全面展开,华中科技人学、青岛青锻锻压机械有限公司等,都相继拥有了白己的技术和产品并迅速地推向市场。电动螺旋压力机已成为目前最具生命力的螺旋压力机产品。 进一步提高螺旋压力机的自动化程度,使打击力、速度、位置等参数的控制更加准确、方便、将是螺旋压力机今后继续发展的方向。The development of the electric screw press 1 OverviewScrew press is a kind of forging equipment with a long history, has the persons capacity, simple structure, easy adjustment and maintenance, have no fixed bottom dead center, can guarantee the stability of precision die forgings. Widely used in metal forging, precision pressure, stamping process and refractories, ceramics and other non-metallic materials of pressure processing. The screw press equipment investment, the mold and the forging costs half cheaper than die forging hammer and hot die forging press, small machining allowance, high precision forgings. Modern screw press that have adopted the overload protection, force can display, primary energy, and advanced computer control system and the replacement of the automatic feeding, die and other auxiliary equipment. The theory and practice prove that screw press technology of wide adaptability, productivity is moderate, good working conditions, has become one of the preferred equipment for the production of modern forging. Relevant enterprises at home and abroad have attached great importance to the development and application of screw press.Qingdao green forging forging machinery co., LTD. 80 MN friction screw press is developed, the verification for the biggest specifications of similar equipment at home and abroad. Because of its high friction press transmission efficiency is low, the power loss and the limitation of the structure, specification development are affected. With the continuous improvement of scientific level, the structure of screw press and form has had the very big improvement. In addition to the mechanical friction drive, and adopted a new form of transmission, such as clutch screw press, hydraulic screw press, electric screw press and so on. This not only improves the practicability of screw press, the working speed, productivity, and reliability, it has received a lot of force and energy development. Such as electric screw press force of 320 mn, energy reaches more than 5000 kj. Successfully developed the electric screw press since the 1940 s, both at home and abroad has been widely response. In China in the 1980 s by Qingdao green forging forging machinery co., LTD and shandong industrial production out of the humanism developed J58-160 1.6 MN motor direct driving type electric screw press, but due to the limitation and control technology of power condition at that time and interrupt the further research and development work, great pity. In recent years, with the development of science and technology, frequency conversion technology and electronic numerical control technology unceasing enhancement, the development innovation, production of electric screw press manufacture already in full swing, Huazhong science and technology study, Qingdao green forging forging machinery co., LTD., etc., have had their own technologies and products and to market quickly. Current of electric screw press has become the most vitality of the screw press product. 2 The structure and principles of the electric screw press2.1 Motor direct driving type electric screw pressMotor direct drive motor used in the electric screw press is special, sitting in the stator shell press the top of the frame, with the top of the rotor shaft is supported by the stator shell, bottom fastening on the press flywheel. Flywheel and screw adopt the key connection is supported by thrust bearing on the rack, the flywheel has overload protection device. Form of brake for the brake, brake wheel rim, ventilation to loosen, barely able to brake. Motor heat with press at the top of the fan. Press the frame structure of prestressed composite frame, the rod will be preloaded beams, columns, and on the base as a whole, has the enough rigidity. Nut on the slider, the slider adopt four guide cooperate with the guide rail of the frame column. Press up and down according to need to configure the device.Motor direct driving type press short transmission chain, motor drive the flywheel rotating no transmission losses. Work, fan rotation, brake loosen, at the same time, the main motor driven press flywheel rotating screw fixed axis, by installing the nut on the slider will spiral movement into linear motion, make the slider to accelerate downward, main motor reaches preset strike energy when the required speed, use energy from the flywheel storage work, make the forming ware. Flywheel energy release, the main motor reversal, slider uplink, when the slider to set the position of the motor brake itself, embrace a flywheel brake only when the main motor power, braking torque is small. 2.2 The primary gear drive electric screw pressAnother form of electric screw press is the level of gear drive, the motor shaft is equipped with a big gear and small gear drive rotation, big gear (i.e., the flywheel) connected to the screw fixed axis rotation, drive mounted on the slider nut on the slider do linear motion realization hit. This type of press can be made of more than one motor driven wheel at the same time, so can do the specification is very big, is the worlds largest tonnage of 320 mn, far more than other forging equipment tonnage, get the favour of the forging industry. At present, the press by the types of motor and control are not unified, the application is more ABB inverter control three phase asynchronous ac motor, using the direct torque control. Domestic motor to have three kinds: one kind is the inverter control of ac asynchronous motor, another kind is the inverter ac servo motor control, vector control technology is used, but is not the same as the two kind of frequency converter.And in the case of switched reluctance motor, but need to match a dedicated controller. The inverter control, ac servo motor higher cost in large tonnage presses rarely used.3 Electric screw press control systemThe advantage of electric screw press is energy size is adjustable. Flywheel angular velocity affect energy directly, therefore, in the process of blow, the size of the control energy, that is, control the size of the angular velocity. Green forging company USES Japan AnChuan inverter control the special ac asynchronous motor, using the vector control technology, the motor with encoder feedback, speed control precision, thus more accurate control energy. Vector control technology can achieve in a very short time to let motor rated torque, adapt to the requirement of low speed high torque electric screw press. By 010 v input voltage signal or 4 mama current signal corresponding to the motor speed, to control the size of the energy.(1) Hardware designControl system with programmable controller K7M - DR40U as the core, supplemented by digital quantity input/output, analog input/output module, combined with peripheral control circuit and the control object. CPU module to communicate through communication interface and touch screen, touch screen is responsible for data display and the necessary parameters set; Switch input/output module is mainly responsible for some of the switch signal control, analog input/output module is mainly responsible for the control of the force; Force command signal analog module, force through the touch screen display, inverter adopts vector control method of controlling the motor running, the motor through a transmission mechanism drives the press ram to realize reciprocating movement up and down. Control system is running, by means of the proximity switch installed in the fuselage detect the position of the slider, and according to the proximity switch signal is a series of control instruction, meet the requirements of various operations.(2) Software architectureThe software system in KGL - WC environment using ladder diagram. According to requirements of the control system of screw press, the differentiation is the main program subroutine modules, each module implements the function, in order to identify and modify. Control programs and operation control, respectively. Downward blow when the inverter is running contact closure, motor to set speed up time to set up, the slider acceleration run, reach the amount of energy needed to crack down on workpiece installation (according to the different artifacts on the fuselage close to the position of switch), cut off contact inverter is running, the slider free falling against the workpiece, and in the fight against after the completion of acceptance with the signal from the proximity switch; If the downward blow artifact has yet to reach the needed energy, at this point the slider has reached the bottom dead center, to protect the equipment and frequency converter must be disconnected operation signal. Program receive the slider with signal process, the reverse operation contact closure, frequency converter motor to set the speed to accelerate the reverse operation, to disconnect the inverter can reverse the certain position, brake, completed a blow4 The characteristics of the electric screw pressMotor driven directly in the form of electric screw press, there is no motor and the flywheel transmission losses. In addition, in the form of either drive electric spiral pressure and L have the following features: (1) simple and compact structure, transmission chain is short, convenient operation and maintenance, and maintenance workload small, save time and maintenance cost, safe operation; (2) energy can accurate control, force can be adjusted according to forging forming process and the fight against energy, high precision forging forming, die stress is small, mould service life is long; (3) the use of advanced motor drive electric control technology, press work, will not impact and influence on power grid normal operation of other equipment; (4) the slider stops, the main motor does not work, low power consumption, save energy; (5) there is no fixed bottom dead center, dont need to adjust the mould height, wont produce stuffy car phenomenon; 6, stroke height can be adjusted conveniently, and the position accurately; Cruelly compared with hydraulic screw press, does not need complex hydraulic equipment, there is no leakage of hydraulic oil pollution of environment and hydraulic failure problem; Was compared with friction screw press, no friction plate, the horizontal axis and so on intermediate transmission device and friction belt wearing parts, spare parts, high reliability, good accuracy.5 ConclusionElectric screw press as a kind of high efficiency, energy saving, environmental protection new forging equipment, has been in high precision engine, turbine blades, gear and other important parts of MAO bad is widely used in forging and precision forging. Modern screw press that have adopted the overload protec

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号