摘 要

铲磨床是滚刀、成型铣刀等复杂刀具的精加工机床。由于传统铲磨床加工精度下降、生产效率低,工人劳动强度大,本设计对传统铲磨床的纵向进给机构进行数控化改造来改善其上述不足之处。

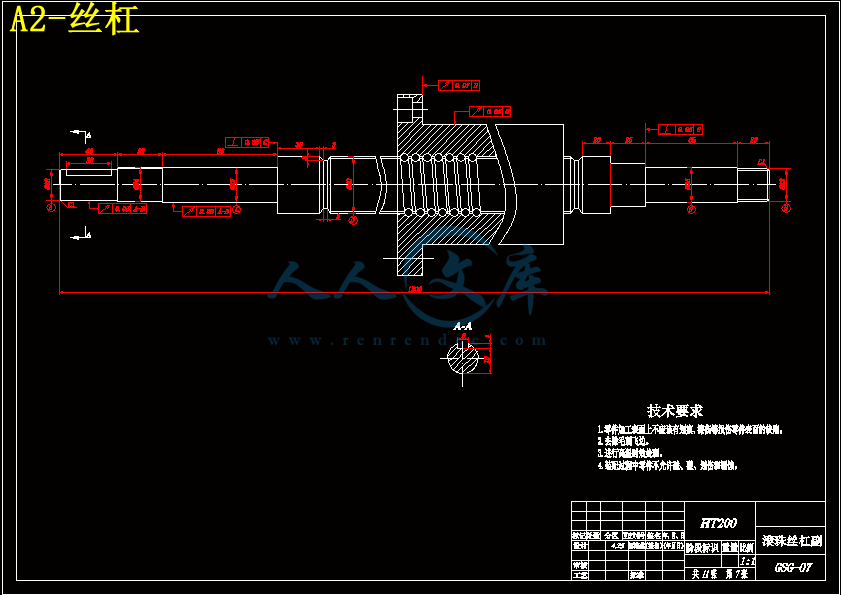

通过对目前工厂中传统的铲磨床进行研究,参考数控机床的相关文献,了解铲磨床纵向进给部分的工作原理,并深入分析铲磨床在加工的过程中各个零部件的受力情况,按寿命计算选择了丝杠的尺寸规格,并校核了额定动载荷、传动效率、刚度,最终选择了汉江机床厂生产的滚珠丝杠。通过对主轴受力的分析选择了用推力球轴承承受轴向力,用深沟球轴承承受径向力的形式。导轨的选取参考了汉江机床厂生产的滚动导轨,对导轨的寿命以及额定载荷进行了校核,均能满足要求。电机根据滚珠丝杠的导程计算出的最高转速,和传动过程中的最大转矩选取了富士公司的伺服电机并对转动惯量进行了校核。由于采用了闭环系统,在查阅了光栅尺的相关参数后,选择FAGOR公司的光栅尺能使在规定的行程内定位分辨率达到要求。

通过上述设计实现了铲磨床纵向进给系统的数控化改造,满足了加工精度的要求,具有加工稳定可靠,效率高等优点。

关键词: 数控铲磨床;纵向进给系统;精加工;闭环系统

Design of Longitudinal Feed System of CNC Relief

Grinding Machine

Abstract

CNC relief grinding machine is a complex tool finishing machine for hobbing cutter, formed mill cutter. Because traditional relief grinding machine’s accuracy and production efficiency is low, the workers labor intensity is too big .The purpose of the numerical control reformation for the longitudinal feed system of traditional relief grinding machine is to improve the performance.

After the traditional relief grinding machine had been researched in the factory at present, and reference related literature of CNC machine tools, The longitudinal feed part of relief grinding machine of working principle, and in-depth analysis of relief grinding machine in the process of machining force situation of every parts and components.

According to the life of screw,chosed the size of screw. And checked the dynamic load rating, transmission efficiency, stiffness. Ultimately chose the ball screw produced by Hanjiang Machine Tool Factory . Through the analysis of the force acting on the spindle. A thrust ball bearing under axial force had been chosed, and a deep groove ball bearings bear radial force. With reference to the rolling guide produced by Hanjiang Machine Tool Factory, and calculating the life of rail and rated load, All parameters of guide can satisfied the requirements. According to the highest speed of the motor which is calculated according to the lead of ball screw and maximum torque of transmission process, The servo motor Fuji Corp had been chosed. And the moment of inertia is checked. Due to the adoption of the closed-loop system, the related parameters of grating ruler lookup, The grating ruler produced by FAGOR company had been chosed, which can satisfied that Positioning resolution meet the requirements stipulated in the distance.

Through the design , Implementation of the NC transformation of relief grinding machine longitudinal feed system, It meet’s the requirement of processing precision , and the processing is stable and reliable, high efficiency.

Key words:CNC relief grinding machine; Longitudinal feed system; Finish machining;Closed loop system

目 录

1 绪论 1

1.1概述 1

1.2数控机床的优点 2

1.3数控机床的组成 3

2 总体方案设计 7

2.1机床的运动关系 7

2.2传动方案的设计 7

2.2.1丝杠的选型及支撑方式的设计 7

2.2.2检系统的选取 8

2.2.3导轨的选定 8

2.2.4丝杠和电机连接零件的选取 9

2.2.5轴承类型的选取 9

3 进给伺服系统机械部分计算与校核 10

3.1 滚珠丝杠螺母副的计算和选型 10

3.1.1额定动载荷 10

3.1.2传动效率校核 12

3.2轴承的计算和选型 12

3.2.1推力球轴承的选型 12

3.2.2深沟球轴承的选型 13

3.3丝杠的刚度和稳定性校核 14

3.3.1 丝杠的刚度校核 14

3.3.2稳定性校核 15

3.4导轨的计算和选型 15

3.4.1滚动直线导轨副行程长度的寿命 15

3.5 伺服电机的计算和选型 16

3.5.1电机转速的选取 17

3.5.2电机转矩的计算 17

3.5.3转动惯量的校核 18

3.6 编码器的选型 18

4 进给系统机械部分结构设计 19

4.1进给伺服系统装配图的设计 19

4.2安装过程中应注意的问题 19

5 总结 21

参考文献 22

致 谢 23

毕业设计(论文)知识产权声明 24

毕业设计(论文)独创性声明 25

1 绪论

1.1概述

我国目前机床总量为380万余台,而其中数控机床总数只有11.34万台,这说明我国机床数控化率不到3%。我们大多数制造业和企业的生产、加工设备大多数是传统机床,而且半数以上是役龄在10年以上的旧机床。用这种机床加工出来的产品普遍存在质量差、品种少、成本高等缺点,因此这些产品在国际、国内市场上缺乏竞争了,这直接影响了企业的生存和发展。所以必须提高机床的数控化率。

在过去的几十年,虽然金属切削的基本原理变化不大,但随着社会生产力的发展,要求制造业向自动化和精密化方向发展,而刀具材料和电子技术的进步,特别是微电子技术、电子计算机的技术进步,运用到控制系统中,既能帮助机床的自动化,又能提高加工精度。这些都要求对旧机床进行改造。另外,在经济方面,用机床的数控改造比更新设备节约50%的资金。再加上市场的原因,由于目前机床市场供给无法满足大量的机床设备的更新需要,因此更显示出机床数控改造的必要性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号