摘 要

液压实验台是进行液压元件检测的关键设备,是集机、液、电为一体的现代化高技术设备。

本文针对实验室和生产的需求,提出了设计题目。并对该机的机械系统、液压系统、控制系统进行了全面设计。

液压系统设计中,首先分析液压实验台的工作过程,并在此基础上进行了液压系统原理图的设计,确定了液压系统的执行元件。计算了整个液压系统的流量,并根据流量和压力进行了液压阀的选型、油箱的设计和各个辅助元件的选择。计算了核个系统的的功率,据此选择了电动机的型号,最后绘制了液压泵站的装配图。

由于传统液压实验台采用继电器等元件作为控制系统的控制元件,存在可靠性、灵活性差等缺点。文中通过实例说明利用PLC对其进行改造

电气控制系统采用可编程控制器PLC作为整台机器的控制器,并对PLC的工作过程进行了介绍,对PLC及相关元件进行了选型,实现了整机的自动化。本设计己经应用于实际生产,取得了良好的效果。

关键词:液压实验台;可编程控制器;液压阀;液压系统;控制系统

Abstract

he hydraulic experimental stand is the critical equipment of testing hydraulic organ, which is a modernize technique equipment which centralizes the machinery, hydraulic and electric.

Aiming at the requirement of laboratory and producing ,the aulhor puts forward the topic and devises the hydraulic system and controlling system thoroughly.

In the process of the device of hydraulic system, firstly,process of hydraulic experimental stand working were analyzed. Based this, the principle plot of hydraulic system was devised;furthermore, the performing elements were decided. At the same time, the author Computed the flux of the whole system, And then, based on the flux and the pressure, the author accomplished the choices of valves, the design of gasoline tank and the choices of assistant components. And then,computed the power of the whole system and chose the model of electromotor. At last,the component plot of hydraulic station drawn.

The traditional hydraulic experimental stand using relays as control elements shows some disadvantages such as low reliability and flexibility.This paper discusses the improved design of hydraulic experimental stand based on PLC.

The controlling system adopts the PLC as the controller of the entire machine. It introduced the working process of' the PLC, chose the model of the PLC and related elements. At the same time, This design has already been applied to practice, and has gained a very good effect.

Key Words: hydraulic experimental stand,;PLC; hydraulic pressure valves; hydraulic system;controlling system

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 概况和发展趋势 1

1.1.1 锡柴汽车厂简介 1

1.1.2 国内外自卸车的概况和发展趋势 1

1.1.3 液压检测技术的概况和发展趋势 2

1.2 课题的提出与意义 3

1.3 课题的主要内容 4

2 总体方案的确定 5

2.1 设计依据 5

2.2 确定液压系统方案 6

2.3 确定控制系统方案 6

2.4 确定外观及机械附件的设计方案 6

2.5 总体配置设计 6

3 液压系统的设计及其校核 7

3.1 液压系统的组成 7

3.1.1 能源装置 7

3.1.2 执行元件 7

3.1.3 调节控制元件 7

3.1.4 辅助元件 7

3.2 液压系统的主要优缺点 7

3.2.1 液压传动的优点 7

3.2.2 液压传动的缺点 8

3.3 液压系统方案设计 8

3.3.1 液压系统原理图设计 8

3.3.2 液压系统参数设计和液压件的选择 12

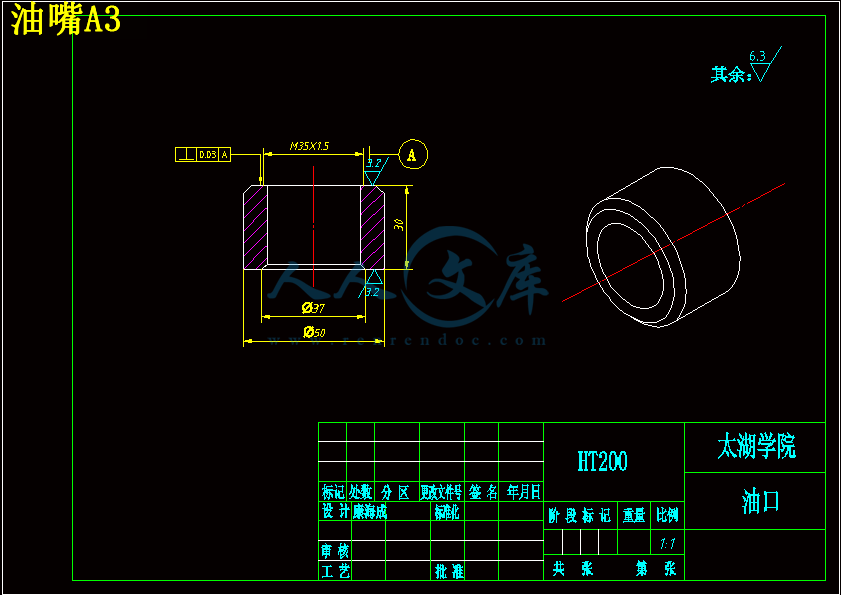

3.3.3 液压辅助元件的设计与选择 25

3.3.4 液压元件的安装和键校核 29

4 机械附件设计 32

4.1 自卸钢架的设计 32

4.1.1 方案的拟定 32

4.1.2 方案的确定及部件分析 34

4.2 油箱的设计 35

4.3 实验台操作面板及控制电柜的外形设计 37

4.3.1 设计依据与问题的提出 37

4.3.2 设计方案的确定 37

5 控制系统的设计 39

5.1 PLC与继电器控制系统的比较 39

5.2 PLC与微型计算机的比较 39

5.3 PLC可靠性高的原因 40

5.4 PLC的安装与抗干扰措施 40

5.5 PLC系统的调试和运行 41

5.5.1 通电前的检查 41

5.5.2 调试运行主要过程 41

5.6 PLC系统的维护 42

5.7 PLC控制系统的设计 42

5.7.1 设计内容 42

5.7.2 控制流程的拟订 43

5.7.3 PLC控制电路元气件的选用 43

5.7.4 PLC的编制 44

6 UG有限元分析方法 46

6.1 有限元分析方法简介 46

6.2 进行有限元分析的目的和意义 46

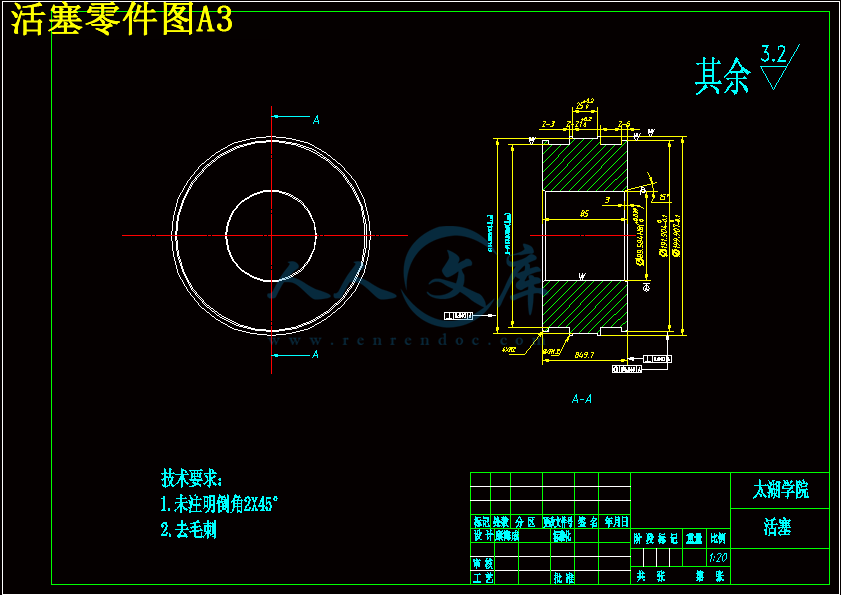

6.3 活塞杆的受力变形情况进行分析 47

6.3.1 分析步骤 47

6.3.2 分析载荷 47

6.3.3 分析结果 47

6.4 自卸钢架端板受力变形的分析 48

6.4.1 分析步骤 48

6.4.2 分析载荷 48

6.4.3 分析结果 48

7 活塞杆的最优化设计 49

7.1 优化设计简介 49

7.2 活塞杆的可靠性优化设计方法 49

7.2.1 活塞杆的工况分析 49

7.2.2 选择设计变量、建立目标函数 49

8 液压综合实验台测试实例 51

8.1 自卸油缸试验 51

8.1.1 空载的往复运行 52

8.1.2 全行程长度 52

8.1.3 满载的往复运行(最大推力(慢速)对顶) 52

8.1.4 内泄漏及外泄漏 53

8.2 单向阀(DF-F20A1)试验 53

8.2.1 内泄漏 53

8.2.2 耐压试验 53

8.2.3 正向压力损失 54

8.2.4 开启压力 54

9 液压原理改进设计 55

9.1 液压系统现状 55

9.2 液压系统的改造 55

9.3 液压系统改造原理图的绘制 55

10 结论与展望 57

10.1 结论 57

10.2 展望 57

参考文献 58

致谢 59

1 绪论

1.1 概况和发展趋势

1.1.1 锡柴汽车厂简介

一汽解放汽车有限公司无锡锡柴汽车厂是一汽解放汽车有限公司无锡柴油机 厂下设生产各类改装车的专业化分厂,是一汽集团在华东地区设立的改装汽车生产基地。工厂具有年产10000辆改装汽车和5000辆底盘的生产能力,拥有国家公安部和国家技术监督总局核准的汽车安全环保性能检测线。产品的销售、服务纳入一汽营销大网络统一运作,已经发展培育了46家锡柴改装车专营销售网点。

川公网安备: 51019002004831号

川公网安备: 51019002004831号