!【包含文件如下】【冲压模具设计类】CAD图纸+word设计说明书.doc【需要咨询购买全套设计请企鹅97666224】.bat

3D.zip

swzp

上凸模固定板.dwg

上垫板.dwg

上模座.dwg

下凸模固定板.dwg

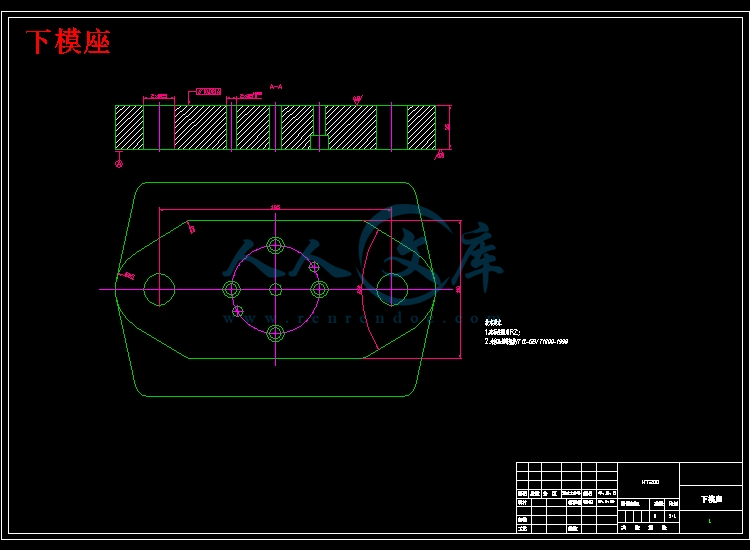

下模座.dwg

任务书.doc

全部图纸.dwg

冲压件工艺规程.docx

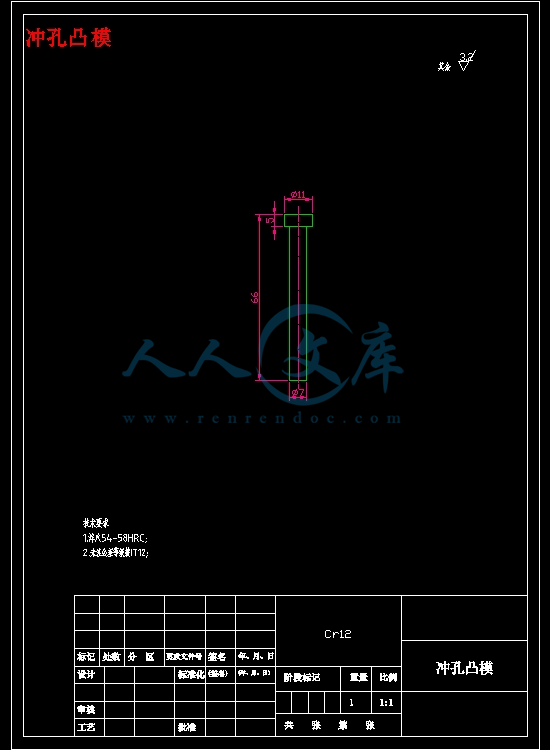

冲孔凸模.dwg

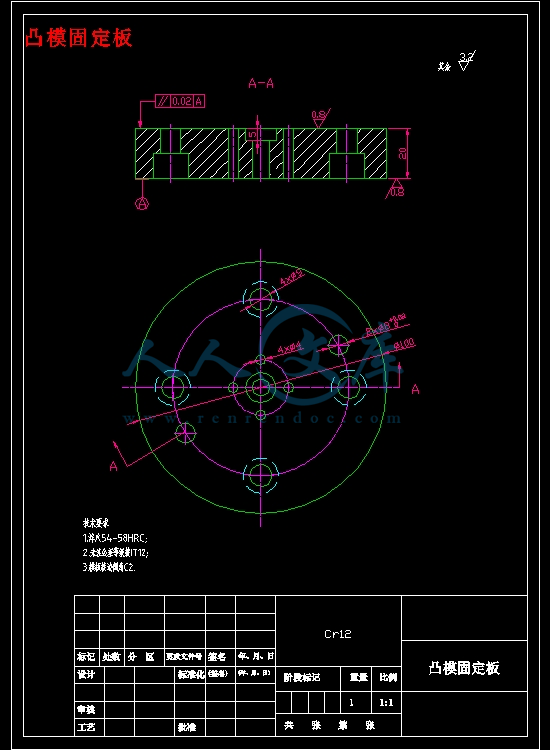

凸模固定板.dwg

凹模.dwg

卸料板.dwg

压边圈.dwg

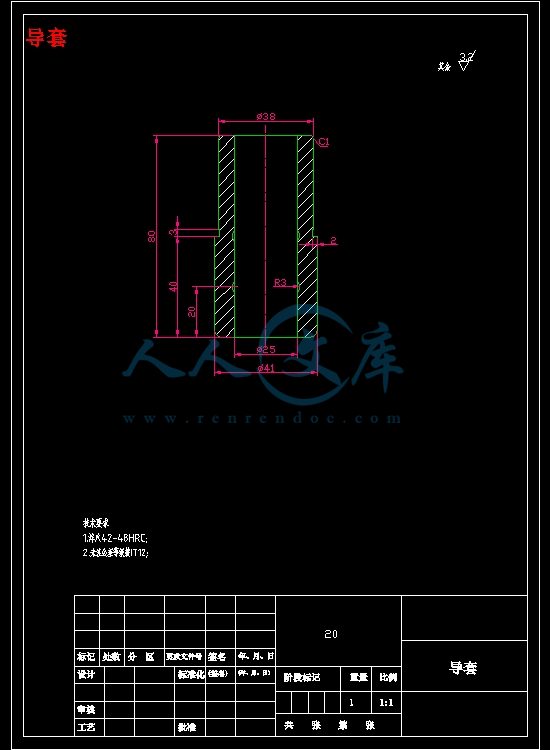

导套.dwg

导柱.dwg

打杆.dwg

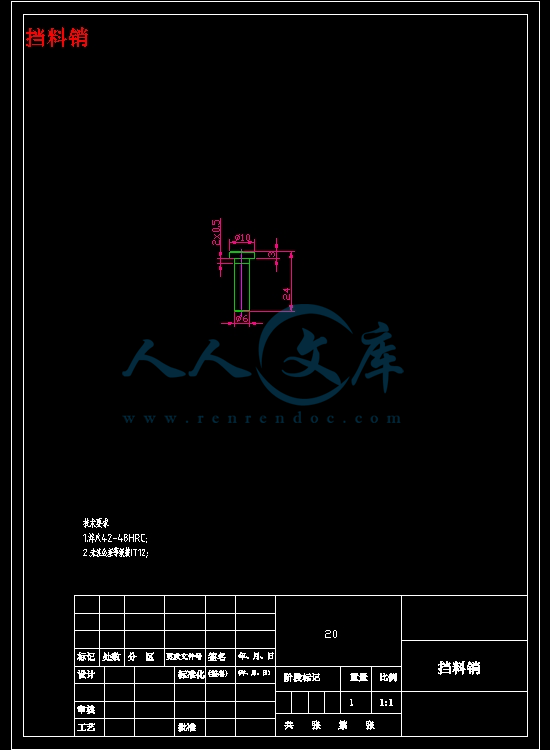

挡料销.dwg

推块.dwg

推板.dwg

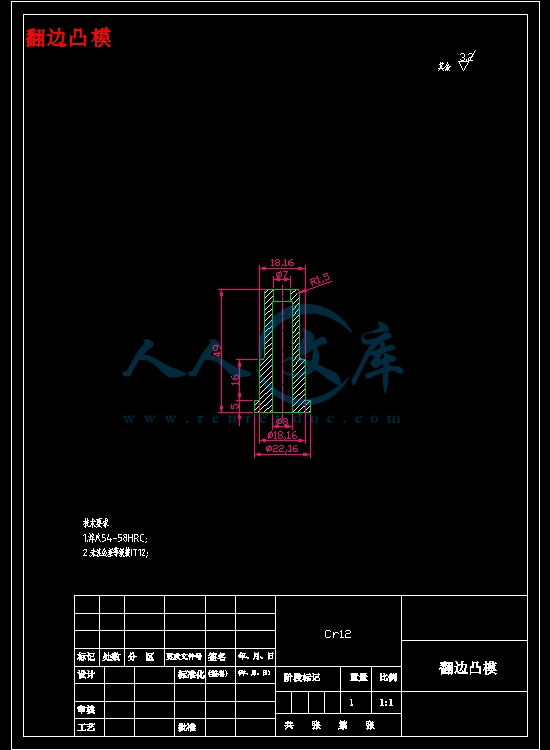

翻边凸模.dwg

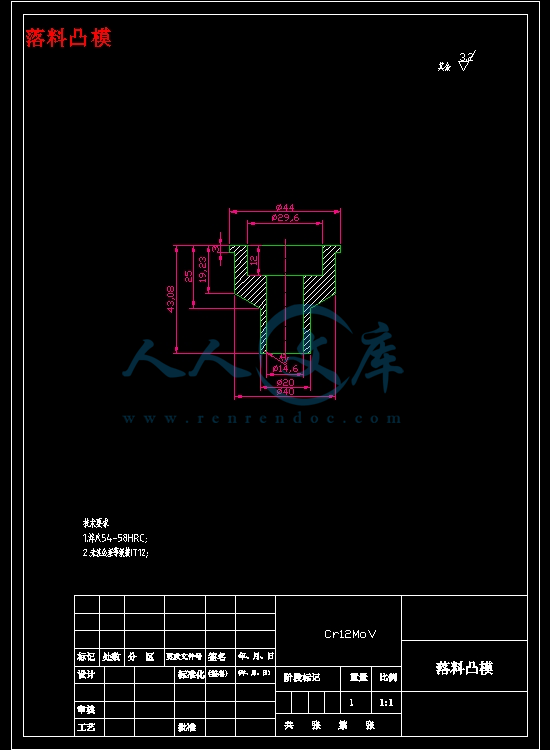

落料凸模.dwg

装配图.dwg

说明书.doc

摘 要

近年来,冲压成形工艺有很多新的进展,特别是精密冲裁、精密成形、精密剪切、复合材料成形、超塑性成形、软模成形以及电磁成形等新工艺日新月异,冲压件的精度日趋精确,生产率也有极大提高,正在把冲压加工提高到高品质的、新的发展水平。前几年的精密冲压主要市是指对平板零件进行精密冲裁,而现在,除了精密冲裁外还可兼有精密弯曲、压延、压印等,可以进行复杂零件的立体精密成形。导师选择了气缸护垫圈课题,为了能深入了解和学习模具设计知识,通过毕业设计的工艺分析优化、模具结构设计优化、CAD、UG软件操作应用等过程,进步巩固、拓展专业知识、掌握多工位级进模的特点及典型结构,提高了理论联系实际解决实际问题的能力,对将来走向工作岗位,更好的适应工作具有指导意义。毕业设计的主要内容为汽缸垫护圈复合冲压模设计,首先要分心冲裁件的工艺内容,选择合理的冲压方案,计算相关冲压工艺参数,设计模具的总体结构,零件等,最后利用2D和3D制图软件绘制出模具主要非标准件和标准间零件图、模具总装图,并撰写相关工艺计算说明书。

关键词 复合模具;汽缸垫护圈 :工艺计算:冲压方案

ABSTRACT

In recent years, stamping forming process has a lot of new developments, especially in precision stamping, precision forming, precision cutting, composite forming, superplastic forming, flexible die forming and electromagnetic forming new technology changes with each passing day, precision stamping parts of the increasingly precise, productivity greatly, is the stamping processing to improve quality, a new level of development. A few years ago the precision stamping mainly, is refers to the fine blanking of flat parts, and now, in addition to the precision blanking outside also can be both precision bending, rolling, embossing, etc., can be part of the complex three-dimensional precision forming. Teacher chooses the cylinder pad ring subject, in order to in-depth understanding and study of die design knowledge, through the process of graduation design analysis optimization, optimization of mould structure design, CAD, UG software application process and progress to consolidate and expand their professional knowledge, master of multi position progressive die characteristics and typical structure, improve the theory connecting with practice to solve practical problems ability, the developing trend of future jobs, better to work is of guiding significance. Graduation design of the main content for cylinder head gasket retainer compound stamping die design, first of all to be distracted by blanking technology content, choose the reasonable stamping scheme, calculation of stamping process parameters, the overall structure of the mold design, parts and so on. Finally, the 2D and 3D drawing software to draw the mold mainly non standard parts and standard between the parts drawing, mold assembly diagram and write process related calculation manual.

Keywords composite die; gasket retainer: process calculation: stamping scheme

目 录

第1章 绪言 1

1.1冷冲压模具的发展及概述 1

第2章 冲压件工艺分析 3

2.1材料力学性能分析 3

2.2 工件结构形状分析 4

2.3 尺寸精度 4

第3章 冲压工艺方案确定 5

3.1 冲裁工艺方案的确定 5

3.2 冲裁工艺方法的选择 5

第4章 模具总体结构 5

4.1 定位方式的选择 5

4.2 出件方式的确定 5

4.5模架结构和导向装置的选择 5

第5章 工艺参数计算 6

5.1 坯料尺寸计算 6

5.2 排样方式的选择 6

5.2 冲压力的计算 9

第6章 刃口尺寸的计算 13

6.1 冲裁间隙的确定 13

6.2 刃口尺寸的计算及依据与法则 14

第7章 主要零部件设计 18

7.1 凹模设计 18

7.2 凸模的设计 20

7.3 卸料装置的设计 21

7.4 凸模固定板的设计 21

7.5 导向零件及模架的选用的设计 22

7.6 模柄的选用 22

第8章 冲压设备的校核与选定 26

8.1 冲压设备的校核 26

8.2压力机的选择 26

结 论 28

参考文献 29

致 谢 30

川公网安备: 51019002004831号

川公网安备: 51019002004831号