折叠臂式桥梁检测车的设计【6张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共31页)

编号:6044431

类型:共享资源

大小:2.66MB

格式:ZIP

上传时间:2017-10-30

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

折叠

桥梁

检测

设计

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

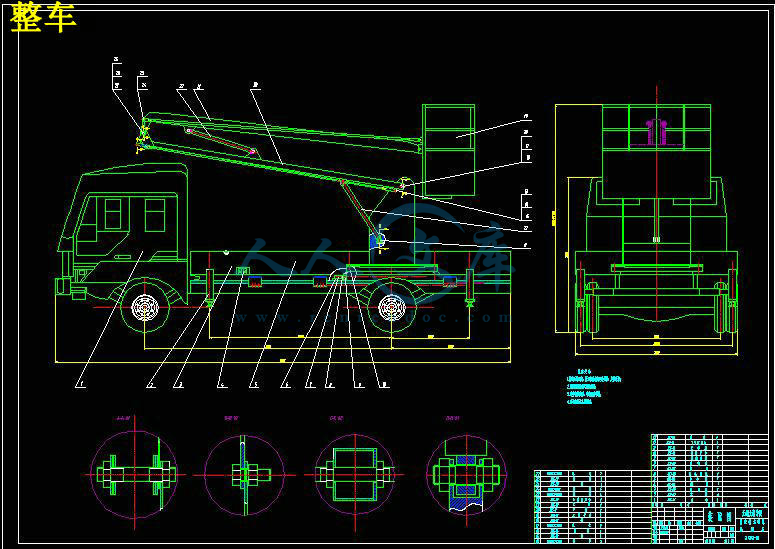

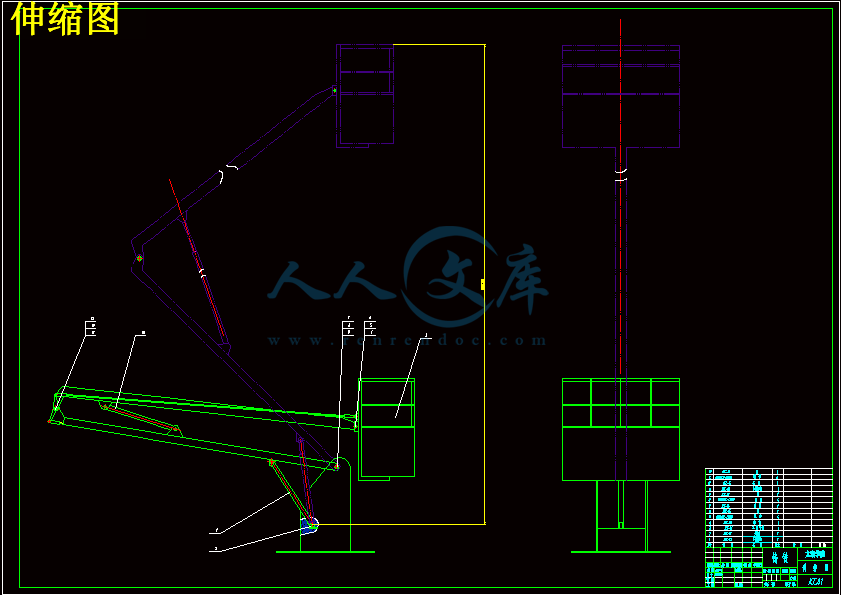

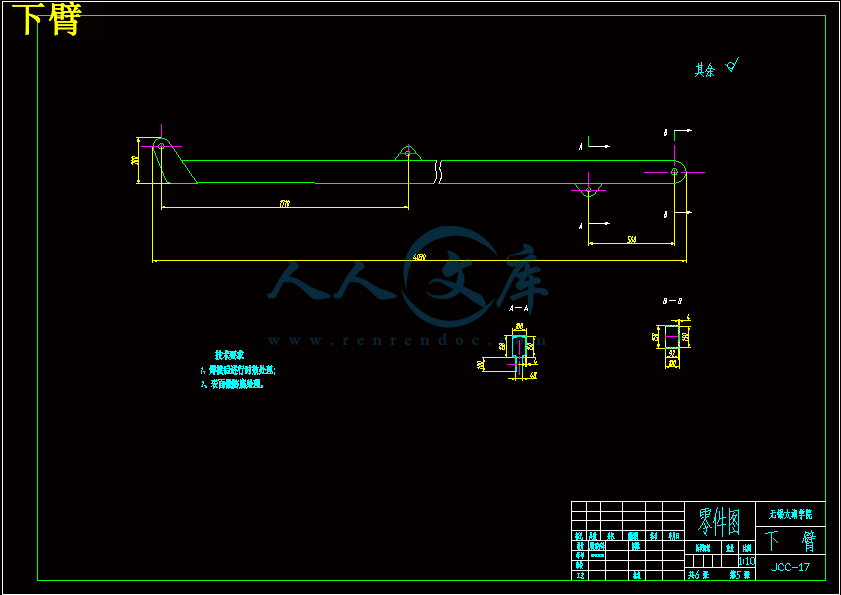

编 号无锡太湖学院毕 业 设 计 ( 论 文 )相 关 资 料题目: 折叠臂式桥梁检测车的设计 信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923110 学生姓名: 殷晓锋 指导教师: 黄敏 (职称:副教授 )(职称: )2013 年 5 月 25 日目 录一、毕业设计(论文)开题报告二、毕业设计(论文)外文资料翻译及原文三、学生“毕业论文(论文)计划、进度、检查及落实表”四、实习鉴定表无锡太湖学院毕 业 设 计 ( 论 文 )开 题 报 告题目: 折叠臂式桥梁检测车的设计 信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923110 学生姓名: 殷晓锋 指导教师: 黄 敏(职称:副教授)(职称: )2012 年 11 月 25 日 课题来源自拟题目科学依据(1)课题科学意义桥梁检测车是一种可以为桥梁检测人员在检测过程中提供作业平台,装备有桥梁检测仪器,用于流动检测和(或)维修作业的专用汽车。它可以随时移动位置,能安全、快速、高效地让检测人员进入作业位置进行流动检测或维修作业。工作时不影响交通,而且可以在不收回臂架的情况下慢速行驶。桥梁检测车技术含量很高,涉及到机械、液压、电子、雷达、通信等先进技术。具有效率高、安全性好、适应性强、功率消耗低等优点,适用于特大型公路桥、城市高架桥、铁路桥、公铁两用桥的预防性检查和维修作业,并为操作者在检测每一组成部分时提供安全保障,还可用于环境险恶不适合人工检测的场合。这种车辆一般是在二类货车底盘基础上加装专用工作装置而成的。(2)折叠臂式桥梁监测车的研究状况及其发展前景:折叠臂式桥梁检测车一般具有以下特点;采用机、电、液、讯一体化技术,控制系统采用电液比例及自动伺服调平技术,能精确控制每个细微动作;一般采用一级伸缩、二级回转、二级变幅机构,形成二维空间、6 个自由度的空间运动体系,工作臂可跨越一定宽度和高度的障碍物,以便顺利将工作斗或工作平台伸至桥下,安全、快捷地将工作人员和设备送到桥下幅度允许的任意位置;工作斗中加装先进的过载保护系统,可实时监控作业平台负荷,超载报警并自动限制操作,确保检测作业的安全性,若采用工作平台,则需具有自动液压水平调节功能,确保工作平稳;根据实际情况在底盘上加装支腿稳定器,并保证能使整车在桥下检修工作状态下行驶。桥梁检测作业车的发展适应了社会的需要,市场空间广阔,但由于技术含量较高,可靠性、安全性要求较高,而非一般企业所能生产。国内有条件的专用车生产厂应抓住有利时机和机遇,尽快提高我国桥梁检测车的技术水平,降低生产制造成本,提升市场竞争力。研究内容(1) 了解折叠臂式桥梁检测车的工作原理,国内外的研究发展现状;(2) 完成折叠臂式桥梁检测车的上体机的总体方案设计;(3) 完成零部件的选型计算、结构强度校核;(4) 熟练掌握有关计算机绘图软件,并绘制装配图和零件图纸,折合 A0 不少于 3张;(5) 完成设计说明书的撰写,并翻译外文资料 1 篇。拟采取的研究方法、技术路线、实验方案及可行性分析研究方法:通过参阅借来的参考资料,并对折叠臂式桥梁检测车进行实体观察,认真研究上体机结构,了解折叠臂式桥梁检测车工作原理,与指导老师交流来完成对折叠臂式桥梁检测车结构的毕业设计。技术路线:提出任务分析对机器的需求确定任务要求,完成设计任务书。方案设计阶段对检测车功能进行分析提出可能的解决方案,组合几种可能的方案进行评价决策,选定最优方案该阶段目标为提出原理性的设计方案原理图或机构运动见简图。技术设计阶段明确构形要求结构化选择材料决定尺寸,评价再决策,确定结构形状及尺寸,零件设计、部件设计、上体设计,该阶段完成上体结构、草图及部件装配草图,并绘制出零件图部件图总装图最后完成技术文件的编制其中包括编制设计计算说明书、使用说明书、标准明细表、其他技术文件等。技术可行性:作为机械专业的学生所常用的必备软件,CAD、UG 软件。研究计划及预期成果研究计划:2012 年 11 月 12 日-2012 年 1 月 20 日:按照任务书要求查阅论文相关参考资料,填写毕业设计开题报告书,并实训。2013 年 2 月 11 日-2013 年 2 月 23 日:找一篇相关外文期刊并翻译。构建框架,完成第一章绪论。2013 年 3 月 4 日-2013 年 3 月 8 日:完成总的结构方案设计。2013 年 3 月 11 日-2013 年 4 月 20 日:开始绘图,完成装配图以及部件图的绘制。2013 年 4 月 22 日-5 月 3 日:着手写说明书初稿,修改,完成初稿。2013 年 5 月 6 日-5 月 10 日:修改说明书并定稿,打印,整理资料准备答辩。特色或创新之处(1)主题明确,有针对性,稳定, 易操作, 通用性强。(2)使用简易,功能完善。已具备的条件和尚需解决的问题(1)技术条件:整体构架基本明确,有电脑,有 CAD 作图软件。(2)尚未解决的问题:技术还不够成熟。指导教师意见指导教师签名:年 月 日教研室(学科组、研究所)意见教研室主任签名:年 月 日系意见主管领导签名:年 月 日英文原文An innovative method for remote measurement of minimum vertical underclearance in routine bridge inspectionB. Riveiro a, D.V. Jauregui b, P. Arias c, J. Armesto c, R. Jiang da.Department of Materials Engineering, Applied Mechanics and Construction, School of Industrial Engineering, University of Vigo, C.P. 36208, Vigo, Spainb. Department of Civil Engineering, College of Engineering, New Mexico State University, Las Cruces, NM, USAc.Department of Natural Resources and Environmental Engineering, School of Mining Engineering, University of Vigo, C.P. 36310, Vigo, Spaind.Department of Engineering Technology and Surveying Engineering, College of Engineering, New Mexico State University, Las Cruces, NM, USAArticleinfoabstractArticle history:Accepted 18 April 2012Available online 17 May 2012This paper presents an innovative and low cost procedure for the complete and accurate measurement of minimum vertical underclearance in a safe environment for operators. This procedure draws on the principlesof terrestrial convergent photogrammetry which makes possible the reconstruction of the bridge components and surrounding features in 3D space. Using themeasured 3D coordinates, an algorithm was developed in the Matlab software to calculate the vertical underclearance. Furthermore, a procedure based on 3D curve fitting was developed to estimate the mathematical expression of the beam curve. The resulting methodology is suitable and advantageous for implementation in routine bridge inspection because it provides a more extensive and accurate measurement of vertical underclearance under much safer conditions. In addition, the estimate of the beam equation can be used not only for clearance measurement but also for periodic monitoring of the beam shape over time.Keywords:Bridge inspection ;Close range photogrammetry ;Vertical underclearance.1 IntroductionIt is true that extensive knowledge of the functional and conservation states of a structure is needed in order to properly schedule its maintenance and ultimately, ensure its preservation. Periodic monitoring of geometry usually plays a key role in the detection of structural anomalies, and in some cases such as stone arch bridges, can aid in preventing collapse due to problems with equilibrium and stability 1. In the case of modern bridges (mainly composed of concrete or steel), although the diagnosis of their condition state is assessed based primarily on the physical condition of the structural elements, the external shape and geometry also plays a very important role in the overall evaluation. The presence of deterioration, defects, and damages (e.g., impact damage caused by truck collisions, concrete spalls or delaminations, fatigue or shear cracks, section loss) and evidence of irregular movement are the most important parameters considered during a routine bridge inspection, and move advanced tools for their detection and quantification need to be investigated.Bridge inspection is a key factor in the maintenance and preservation of the civil infrastructure of a country. Many parameters have to be periodically evaluated in order to determine the physical condition of the structure 45. In the bridge management protocol of transportation agencies, there usually exists an initial phase focused on routine inspection, where, by means of quick and simple documentation, the first diagnosis of the current state of the structure is obtained 68. When some evidence of distress about the physical condition or stability of the structure is found in this initial step such as excessive beam sag or support settlement, a special inspection plan should be initiated to perform an in-depth evaluation of the bridge. Currently, there are several basic techniques available to measure irregular bridge movement such as plumb bobs, laser levels, theodolites, and total stations.Horizontal and vertical clearances are important geometric parameters that must be measured to a high level of accuracy during a routine bridge inspection. The acquisition of these dimensions is traditionally accomplished by means of basic contact tools such as tape measures and range poles that lack metric accuracy, and which also require the operators to perform the clearance measurements under dangerous traffic conditions. Fig. 1 illustrates the use of a range pole to measure the minimum vertical underclearance which is the distance from the roadway or railroad track beneath the bridge to the underside of the superstructure . As shown in the figure, measurements are usually taken at discrete points on the bottom surface of the beam to save time and also due to safety concerns. Furthermore, it is difficult to keep the range pole perfectly vertical to obtain an accurate measurement particularly for higher clearances. Consequently, it is possible that the minimum vertical underclearance is not measured accurately at the correct location. There are 116 items of bridge data used by the FHWA to monitor and manage the National Bridge Inventory (NBI) in the United States as given in the Structure Inventory and Appraisal (SI&P) sheet. The data are divided between inventory items that pertain to the permanent conditions of the bridge and appraisal items that pertain to the condition of the bridge component in comparison to current standards . In the SI&P sheet, geometric data are considered inventory items under which the minimum vertical underclearance is item 54. This particular item is coded with 5 digits; the first digit represents the reference feature (highway or railroad beneath structure) and the remaining four digits represent the minimum vertical underclearance (in feet and inches). Underclearance information is used by personnel involved with the permitting of oversize/overweight vehicles and is used in evaluating the sufficiency of a bridge to remain in service (i.e., sufficiency rating). Four separate factors are determined (using 19 of the 116 items reported in the SI&A sheet) to arrive at the sufficiency rating:(1) structural adequacy and safety; (2) serviceability and functional obsolescence; (3) essentiality for public use; and (4) special reductions. Horizontal and vertical underclearances and the deck condition affect the second factor while the superstructure and substructure conditions affect the first factor. The sufficiency rating ranges from 0 to 100% with the latter percentage representing an entirely sufficient bridge. Bridges qualify for replacement when the rating falls below 50% and rehabilitation when the rating falls below 80% . In spite of the simplicity and rapidity in using traditional instruments, the quality of metric results is poor. Surveying techniques offer better quality results in terms of accuracy, but these methods have important limitations for regular use in relation to handling of equipment and the amount of data collected. Terrestrial photogrammetry and laser scanning are two geomatic techniques which have significantly evolved, being more and more used in diverse fields including architecture 9,10; civil engineering 1114; industry15,16;and archaeology 17,18. Many investigations show the potential of these new technologies in the field of bridge engineering 19. From the captured precise 3D geometry of bridges, for example, an improved assessment of the structure can be made 20. Laser scanning is gaining popularity due to its simplicity in usage and speed of acquisition 21. A few studies of damage detection in concrete bridges using terrestrial laser scanner data can be found in 2224. Similar to traditional surveying equipment, laser scanning presents important limitations for routine inspection work including cost of equipment, necessity for trained operators, and amount of data stored during the bridge survey. Consequently, low cost technologies capable of collecting meaningful and accurate metric data without the need for overly complicated equipment operation and extensive data processing are needed. Close range photogrammetry has several strengths that make it a suitable method for measuring bridge features during a routine inspection such as it utilizes low cost equipment, it is relatively easy to use, and it provides high metric precision. An extensive review of the application of this technique in bridge engineering can be found in 19. Gonzalez-Aguilera and Gmez-Lahoz 25 present a novel photogrammetric system based on a single image for obtaining the overall geometry of bridges by means of dimensional analysis. Other studies related to bridge monitoring based on photogrammetric methods included those performed by Chang and Ji 26 and Hang et al. 27. Before new technologies are included in the protocols for metric documentation, they must first be validated. In this context, methodologies of surveying need to be adapted to overcome the existing difficulties in routine bridge inspection. This paper presents an innovative and low cost procedure for the complete and accurate measurement of minimum vertical underclearance in a safe environment for operators. This procedure draws on the principles of terrestrial convergent photogrammetry which makes possible the reconstruction of the bridge components and surrounding features in 3D space.Using the measured 3D coordinates, an algorithm was developed in the Matlab software to calculate the vertical underclearance. Furthermore, a procedure based on 3D curve fitting was developed to estimate the mathematical expression of the beam curve. The resulting methodology is suitable and advantageous for implementation inroutine bridge inspection because it provides a more extensive and accurate measurement of vertical underclearance under much safer conditions. In addition, the estimate of the beam equation can be used not only for clearance measurement but also for periodic monitoringof the beam shape over time.2 Theoretical backgrounds2.1 Photogrammetric processClose range photogrammetry is a non-destructive geomatic technique which allows the 3D shape of objects to be reconstructed from photographic images. The conversion from 2D information of images to 3D models is achieved by means of the photogrammetric process. Two main steps contribute to this process: inner orientation and external orientation. The inner orientation reconstructs the internal geometry of the imaging system, which defines the perspective system, by means of the camera calibration process. The metric parameters obtained from the camera calibration include the 3D position of the perspective centre in the image space (focal length and principal point on the sensor), sensor dimensions, and lens distortions. The lens distortions are sources of errors during the image recording and must be compensated for to obtain the most accurate reconstruction of the 3D model. The symmetric radial distortion significantly influences the photogrammetric reconstruction as shown in 28,29. There are two common formulations for radial distortion: balanced and unbalanced models. Although these models can be mathematically equivalent, the balanced model results in smaller apparent distortions so is commonly used by camera and lens manufacturers 3032. The external orientation locates the relative position of each camera used in the 3D reconstruction process at the time images were taken. Hence, if the position of one camera is known, the relative external orientation is done using the positions (X, Y, Z) and orientations (, , ) of the other cameras. For a given point in an object space, the coplanarity condition requires that the points position in two overlapped images and the cameras perspective centre are situated in the same plane. As shown by Krauss in 33, the relative orientation of images is achieved when the image coordinates of Fig. 1.Fig. 1. Measurement of minimum vertical underclearance during a routine bridge inspectionMeasurement of minimum vertical underclearance during a routine bridge .Inspection five points are known. The external orientation is completed when the model is scaled and placed in the absolute coordinate system.When the relative camera position is solved, the camera perspective centre Oi, a point in the image (xi, yi), and the position of this point over the surface of the object (X, Y, Z) are located in the same straight linebased on the collinearity equation. It is then possible to obtain the 3D position of a point on the object surface from measurements in the image. The mathematical principles of this process are further explained in 34 and 35. 2.2 3D fitting algorithmThe shape of object surfaces can be usually modelled by means of parametric surfaces. When a set of data points defining the object surface is available, a function of two independent variables (x and y) can be determined to best fit a parametric surface to the data. For 3D curve fitting, a dependent variable f can be modelled from two independent variables x and y, where data are a set of n3D points (xi, yi, fi), for i=1: n, nN. In this case, object points with three spatial coordinates (xi, yi, zi) are obtained from the photogrammetric process. Xi and Yi components of space points are initially aligned according to transversal and longitudinal bridges directions, respectively. Zi corresponds to the vertical component (clearance direction).This 3D information provides the two independent variables (x and y) as well as a third component zi for the minimization of the following expression.3 Methodology3.1 InstrumentationTo be feasible, an important aspect to consider in the effort to enhance routine bridge inspection work is maintaining the simplicity of equipments used for basic inspection tasks while providing better documentation. For this reason, the measurement procedure developed in this study was based on simple field setups and the usage of digital cameras which do not require advanced knowledge of digital image recording by operators. A digital, semi-metric camera (Canon EOS 10D) equipped with a CCD sensor, RGM matrix resolution of 6.29 million pixels and a Canon EF 20 mm f/2,8 lens was used for image acquisition. External information with real dimensions of a reference body is required in order to get the 3D model scaled. In this sense, duringthe execution of this project a reference distance was obtained by means of measuring coordinates of two control points. To validate the photogrammetric results, separate measurements using topographic equipment were made. A total station (Leica model TCR 1203+) was used to measure a set of points defining the lower profile of the beam and control points. The technical features of the instrument include long-range coverage (up to 400 m); 2 mm+2 ppm accuracy; 10 cc angular accuracy (1 cc typical average measurement in angles deviation);and 6/2 mm sensitivity of levels.3.2 Camera calibrationThe cameras are calibrated under fixed imaging parameters in the laboratory prior to the field work. Consequently, operators only have to acquire a few photographs during the actual bridge survey (field calibration requires significantly more photographs). The camera calibration process is performed in the “Calibration module” of the Photomodeler Pro software using a scaled planar grid of points which is captured by means of several images from different points of view. The calibration images are marked and imported into the photogrammetric platform where the geometric parameters of the camera are almost automatically obtained. The parameters representing the inner orientation of the camera used in this study are presented in Table 1, as well as the components of the mathematical polynomials t

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号